Casing Subsidy Layered Water Injection String

A technology of layered water injection and casing subsidy, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problem of affecting oil field water injection and oil production, casing subsidized wells cannot perform layered water injection, and ordinary layered water injection Tool can not be used and other problems, to achieve the effect of improving the development effect, improving the qualified rate of layers, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are described below in conjunction with accompanying drawings:

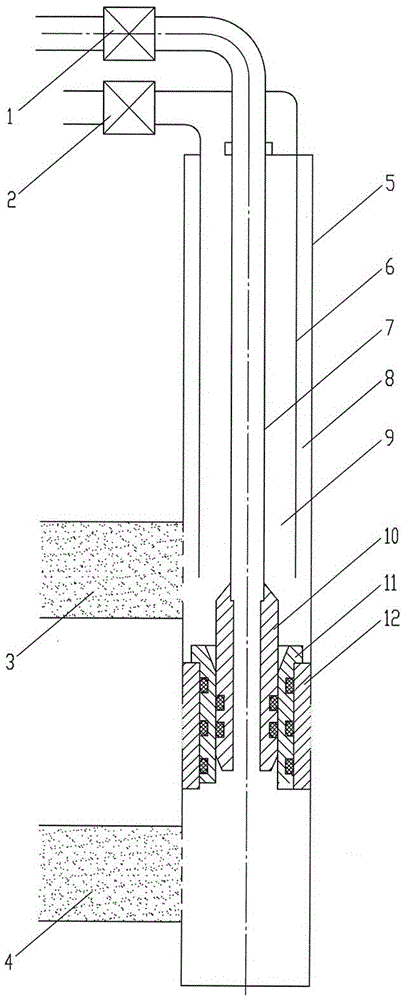

[0010] Depend on figure 1 It can be seen that the embodiment of the present invention includes a lower flow regulator 1, an upper flow regulator 2, a casing 5, an outer water injection pipe 6, an inner water injection pipe 7, an insertion sealing pipe 10, a sealing cylinder 11, a subsidy pipe 12, and an upper The water injection layer 3 and the lower water injection layer 4 are in communication with the casing 5, and there is a damaged section on the casing 5, which is located between the upper water injection layer 3 and the lower water injection layer 4, and the subsidy pipe 12 is inserted in the damaged section, and the sealing tube 11 is first installed in the subsidy pipe 12 and then lowered into the casing 5 along with the subsidy pipe 12. A sealing device is installed between the sealing cylinder 11 and the subsidy pipe 12. Down into the outer water injection pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com