Constant-current water distribution equipment and method

A technology of water distribution and equipment, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as heavy workload, short stable water injection cycle, and change in water injection volume, so as to improve the qualified rate and have broad application prospects , to achieve the effect of constant flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

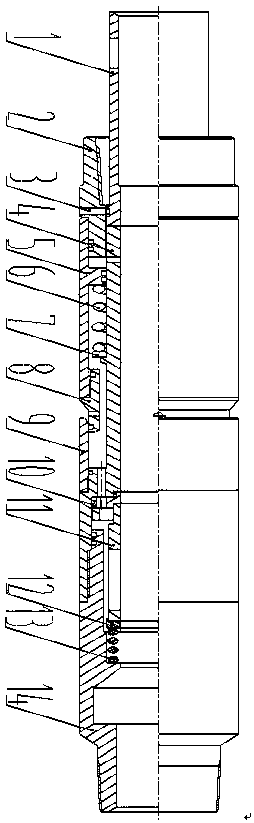

[0027] according to figure 1 , a constant flow water distribution equipment, including an inner center pipe 4, a swimming valve 5, a water outlet valve 8, a constant flow fixed valve 9, a throttle valve plate 10, a rotary joint 11, and the swimming valve 5 is set in the inner center pipe 4 Externally, the inner wall of the floating valve is provided with an inner ring platform, and the inner wall of the inner ring platform is connected with the outer wall of the inner central pipe in a sealed and sliding manner. The upper ring cavity is formed above the inner ring platform, and the lower ring cavity is formed below the inner ring platform. The central pipe is provided with a radial pressure transmission hole connected to the upper ring cavity, and a thrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com