Combined ball shock insulation support

A seismic isolation bearing and combined technology, applied in the field of seismic isolation and shock absorption of building structures, can solve the problems of no tensile strength, large ball friction, and easy crushing, etc., and achieve strong tensile capacity, increased reset capacity, and reduced The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

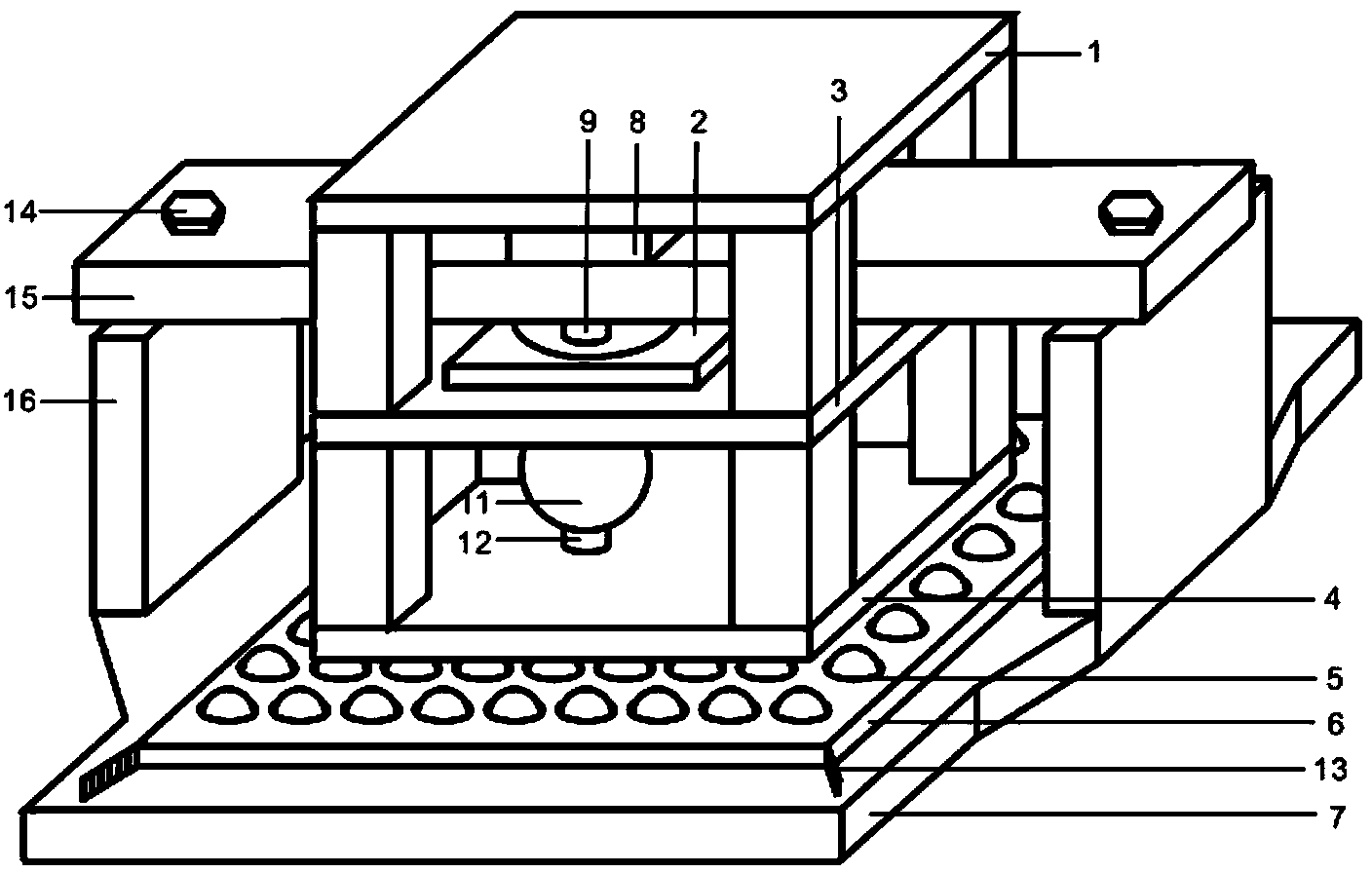

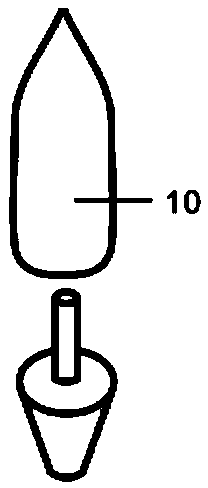

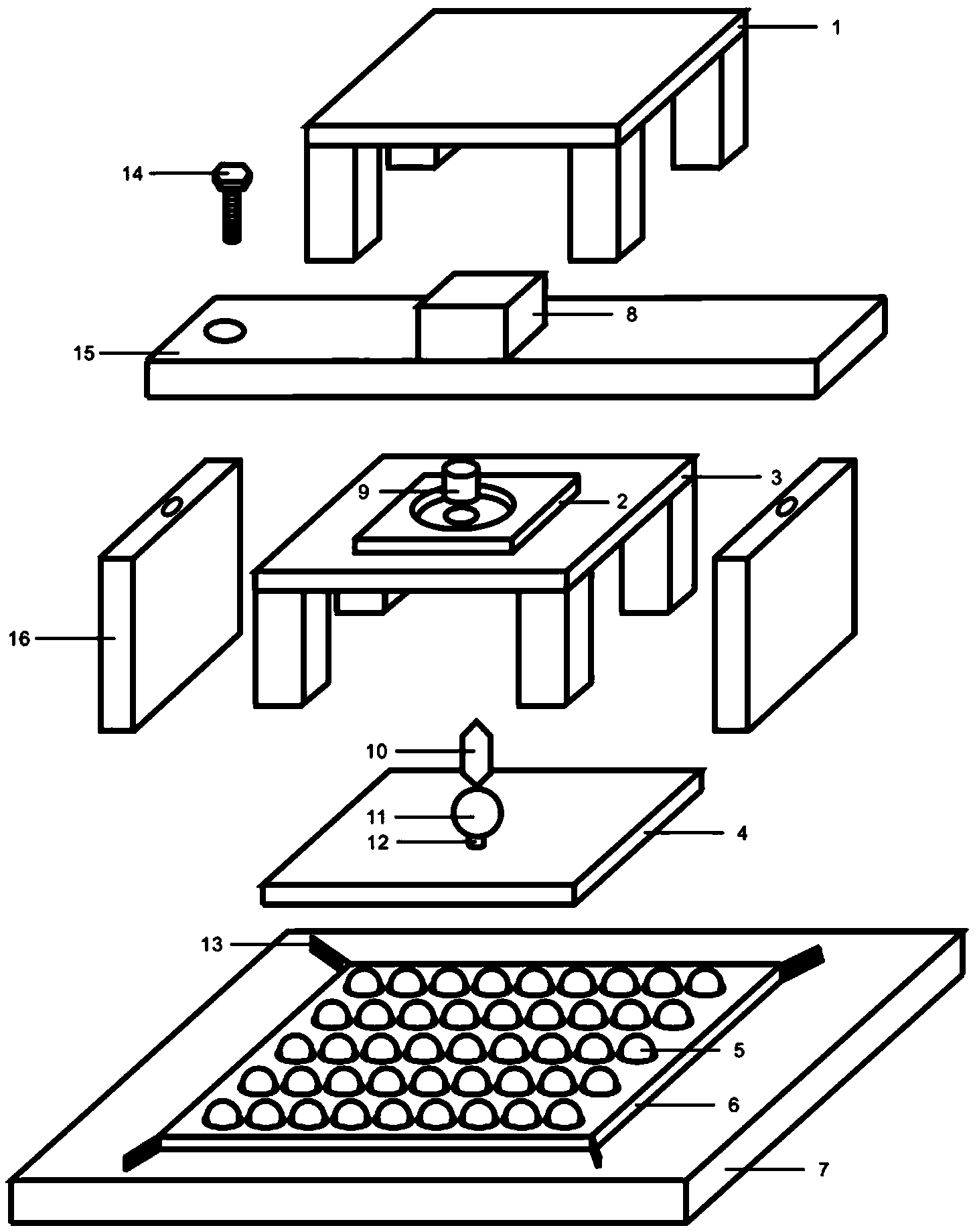

[0017] A combined ball shock-isolation bearing of the present invention comprises an upper connecting plate 1, a limiting plate 2, a positioning plate 3, a ball cover plate 4, a ball 5, a ball distance limiting plate 6, a base plate 7, a reset rubber 8, a limiting plate Position positioning post 9, reset positioning pin 10, positioning ball 11, positioning ball bearing 12, positioning spring 13, moving lever 15, moving lever bearing 16; upper connecting plate 1, positioning plate 3, ball cover plate 4 are equal in size The upper connecting plate 1, the positioning plate 3, and the ball cover plate 4 are arranged sequentially from top to bottom. The two adjacent plates are connected by steel columns at the four corners, and the limiting plate 2 is fixed on the positioning plate. 3, a limit hole is opened on the limit plate 2, the moving lever 15 passes between the limit plate 2 and the upper connecting plate 1 and slides with the limit plate 2, and one end of the reset rubber 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com