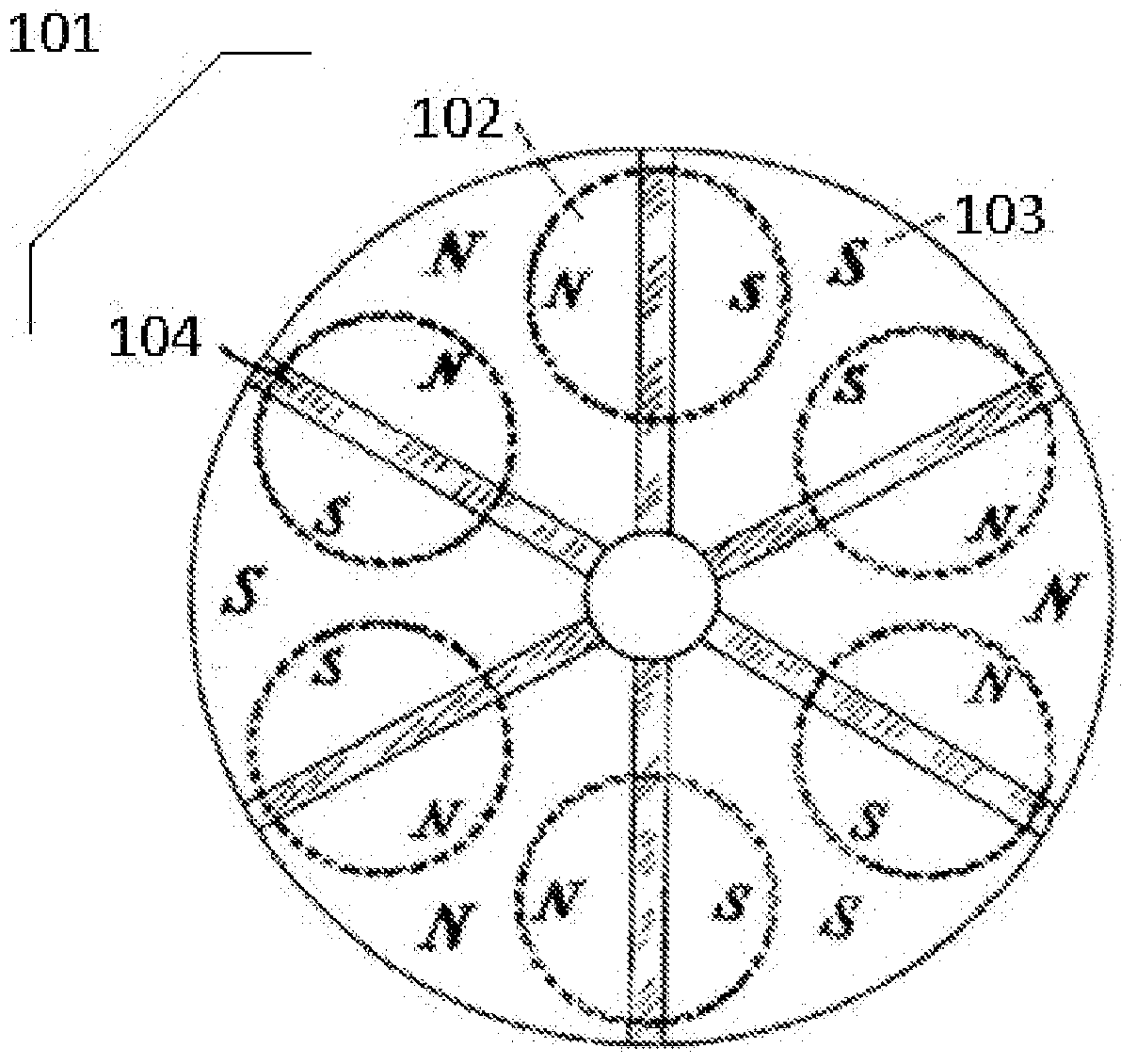

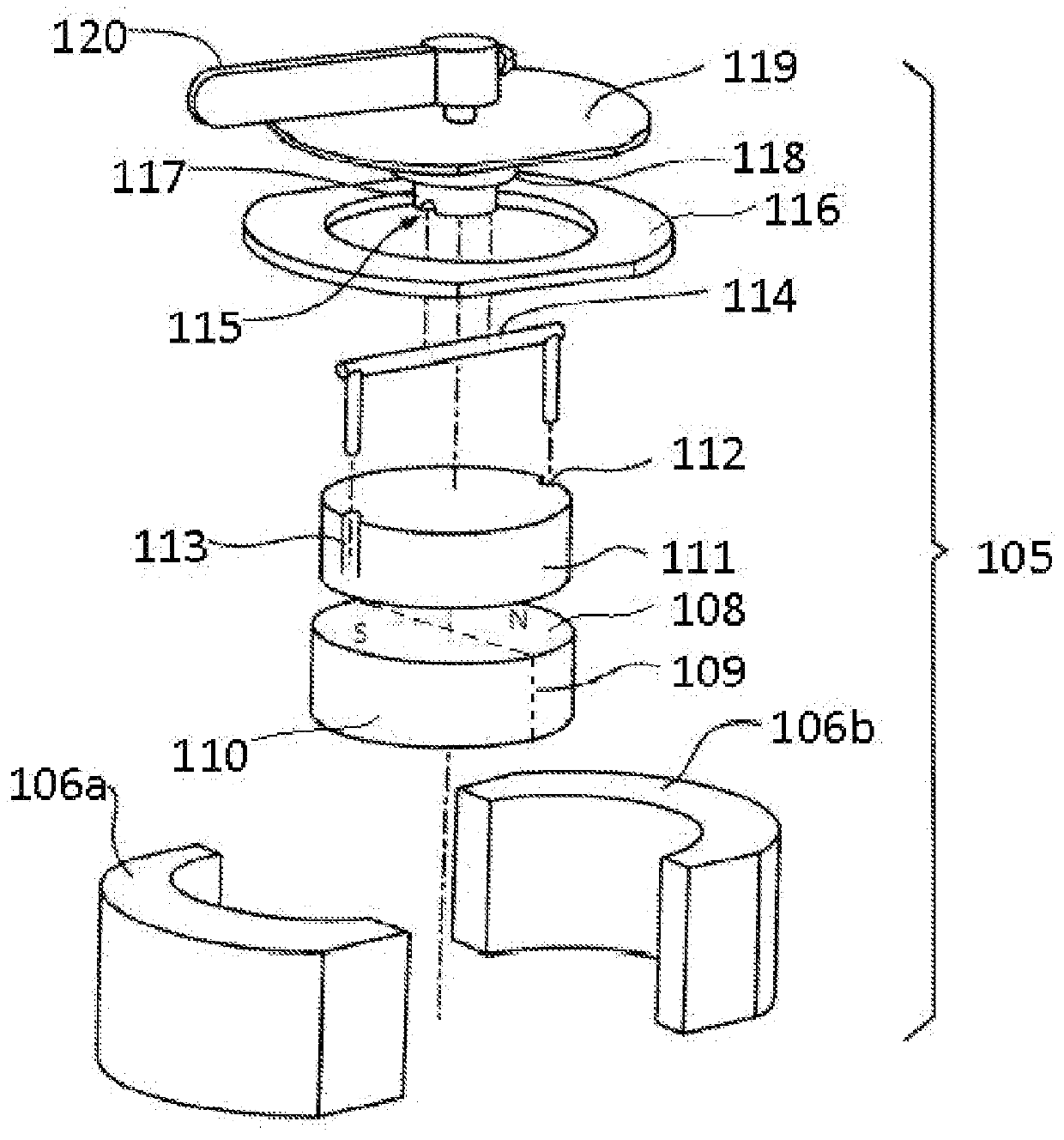

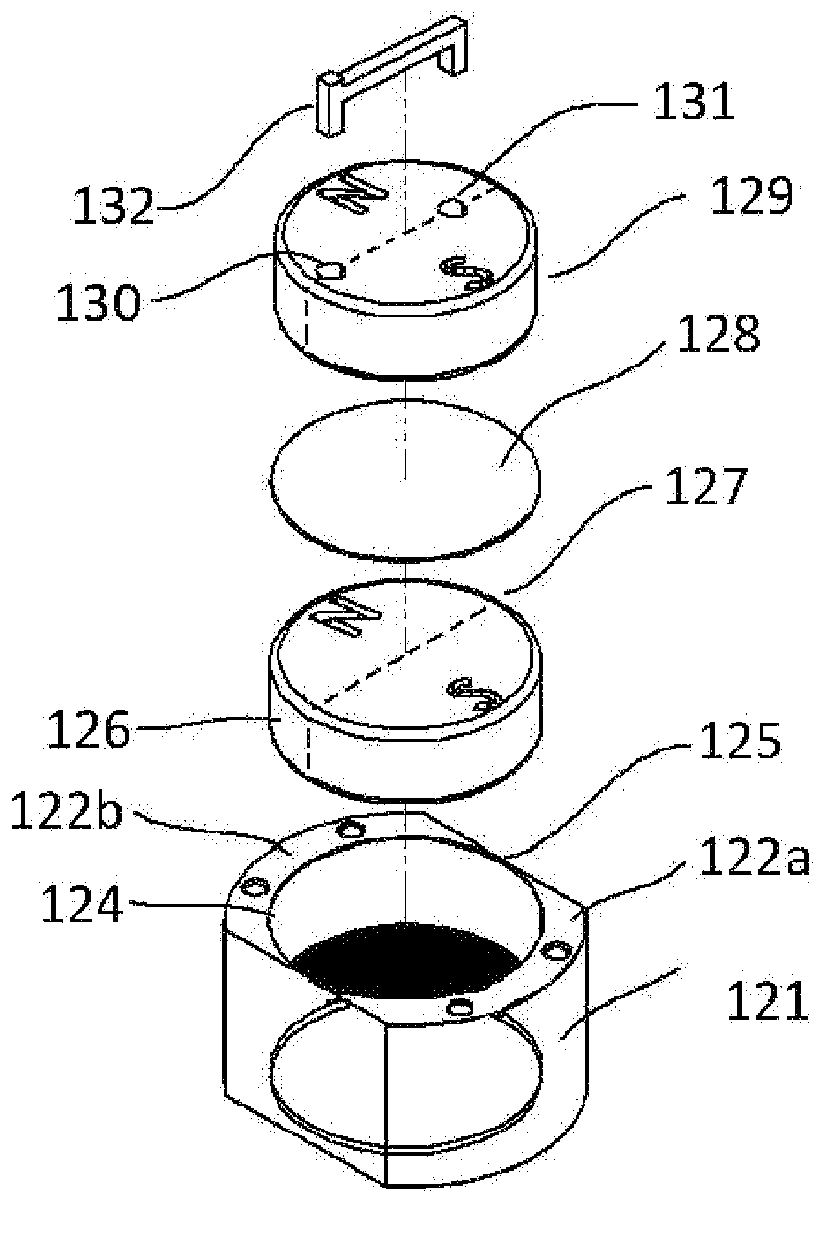

Rotary switchable multi-core element permanent magnet-based apparatus

A technology of magnetic core elements and permanent magnets, applied in the field of permanent magnet-based devices with multiple rotary switchable magnetic core elements, can solve the problems of difficult startup, expensive switchable magnetic design, difficult to manufacture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The RSM has various preferred embodiments described herein. However, invariably, the steps to implement different embodiments of the present invention are the same. Steps to accomplish the various embodiments of the invention include: design and operational considerations; selecting the size and shape of the permanent magnets; determining friction reducing members; matching pole tubes; designing the core elements;

[0079] Design and Operational Considerations

[0080] The highly flexible structure of the present invention enables rapid configuration of the device that best suits the application or end product design. By combining the desired grip strength, holding position, and offset load (moment) with characteristics typical of the desired goals, it can help to select the appropriate components needed in the RSM to achieve these goals. Target specifications such as material, thickness, composition, finish, stiffness, size and weight need to be determined in advan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com