Angle measuring device

An angle measuring device, a mass body technology, applied to the measuring device, the components that damp the movement of the measuring device, the use of optical devices, etc., can solve the problems of reduced motor efficiency, motor heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

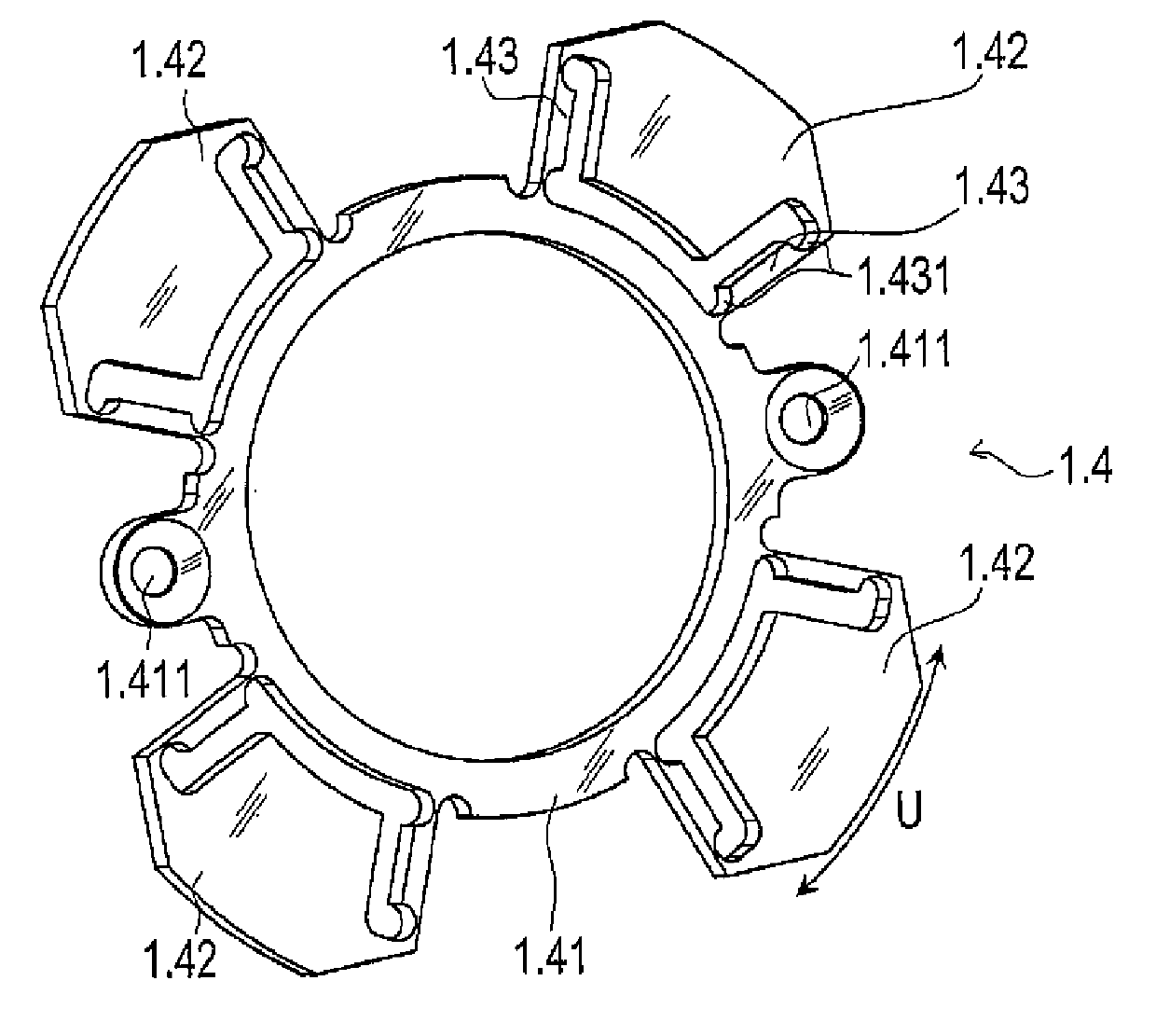

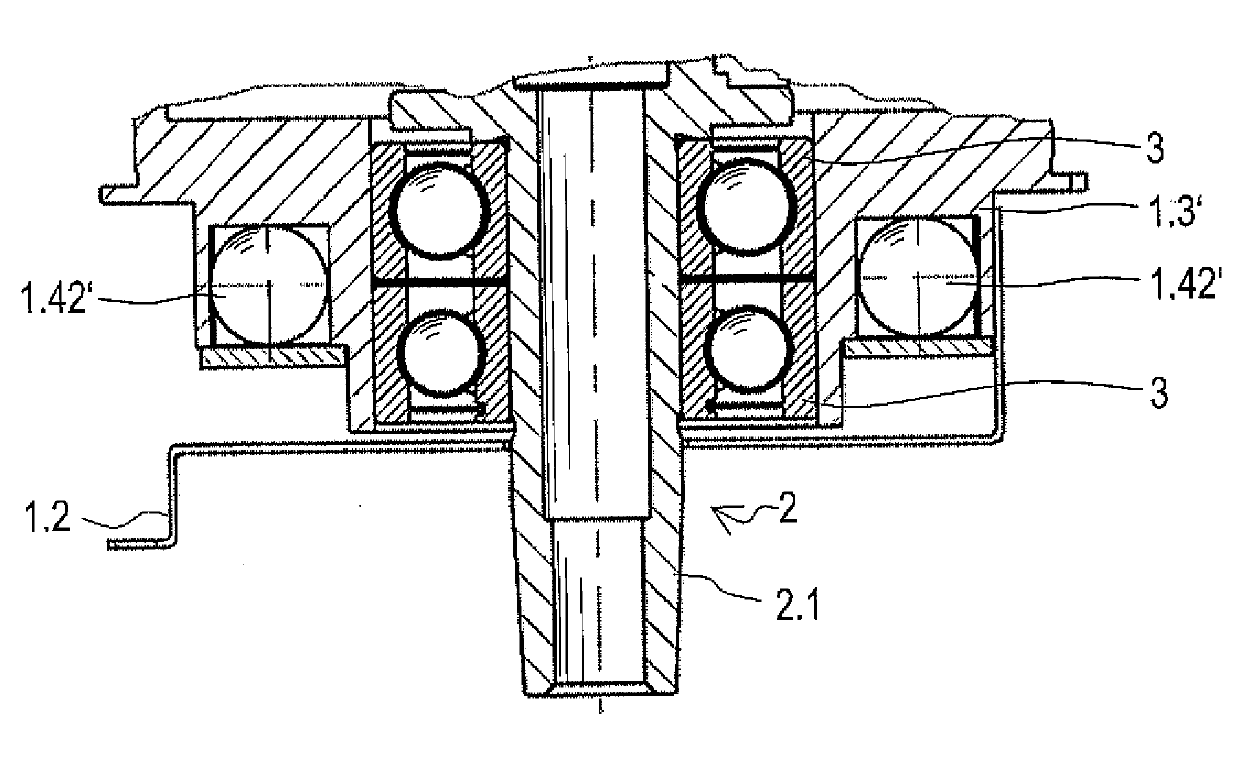

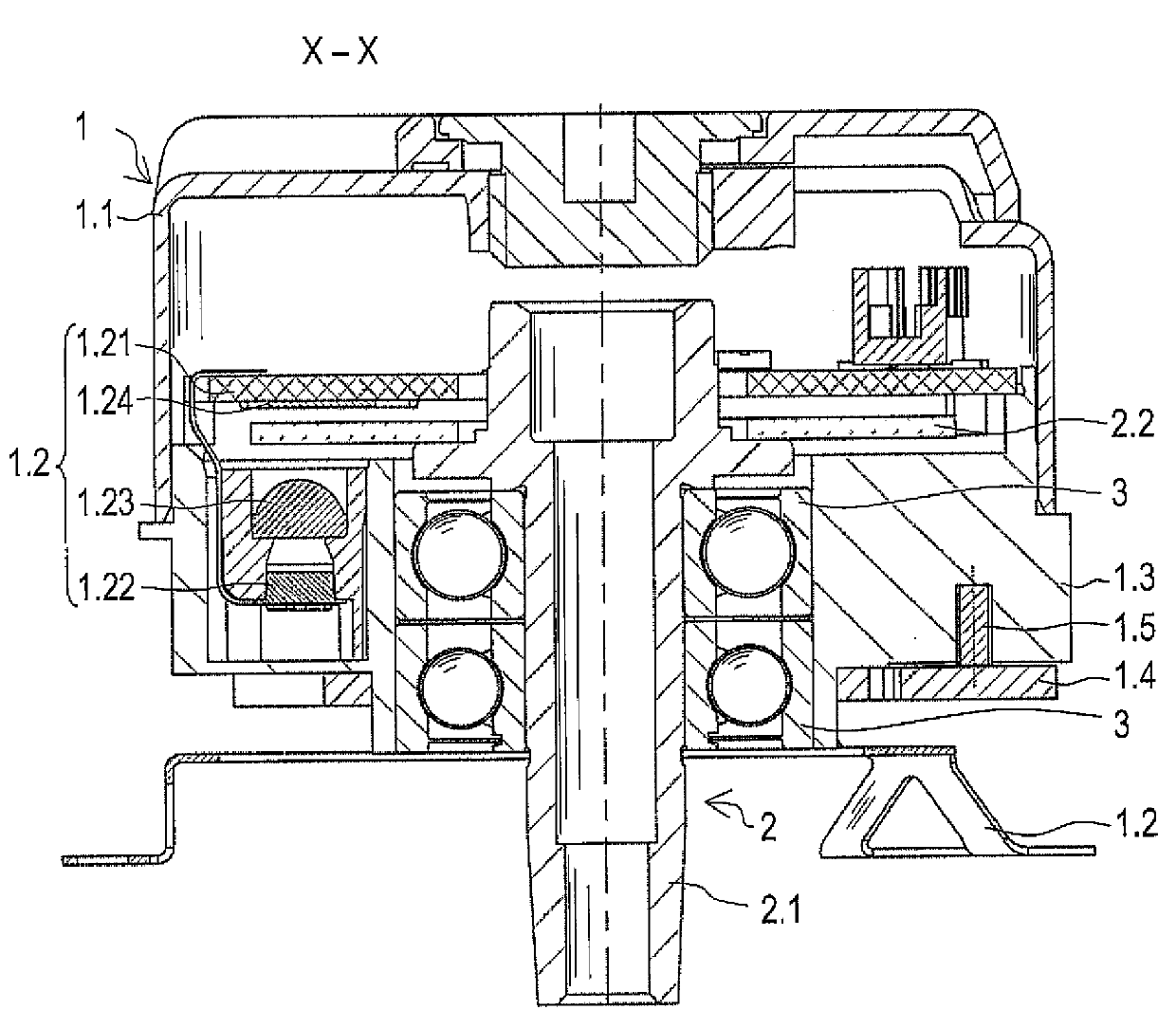

[0029] exist figure 1 The angle measuring device shown in includes a stator 1 and a rotor 2 . The rotor 2 has a shaft 2 . 1 for rotationally fixed coupling to a structural element to be measured, for example to a motor shaft. The connection between the shaft 2.1 of the angle measuring device and the motor shaft is realized, for example, by means of a connecting means in the form of a fastening screw protruding through the shaft 2.1, wherein for this purpose the end of the shaft 2.1 The head is conically designed. The relative angular position or rotational movement between the stator 1 and the rotor 2 can thus be determined by means of the angle measuring device. Such an angle measuring device is also often referred to as a rotation generator.

[0030] The shaft 2.1 is mounted rotatably via a bearing, here two roller bearings 3, inside a body 1.3, which is assigned to the stator 1. A code disk 2.2 arranged inside the angle measuring device is fastened to the shaft 2.1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com