Terminal structure

A technology of terminal structure and microstructure, which is applied in the direction of fixed connection, circuit, connection, etc., and can solve problems such as poor contact, high cost, and small scraping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

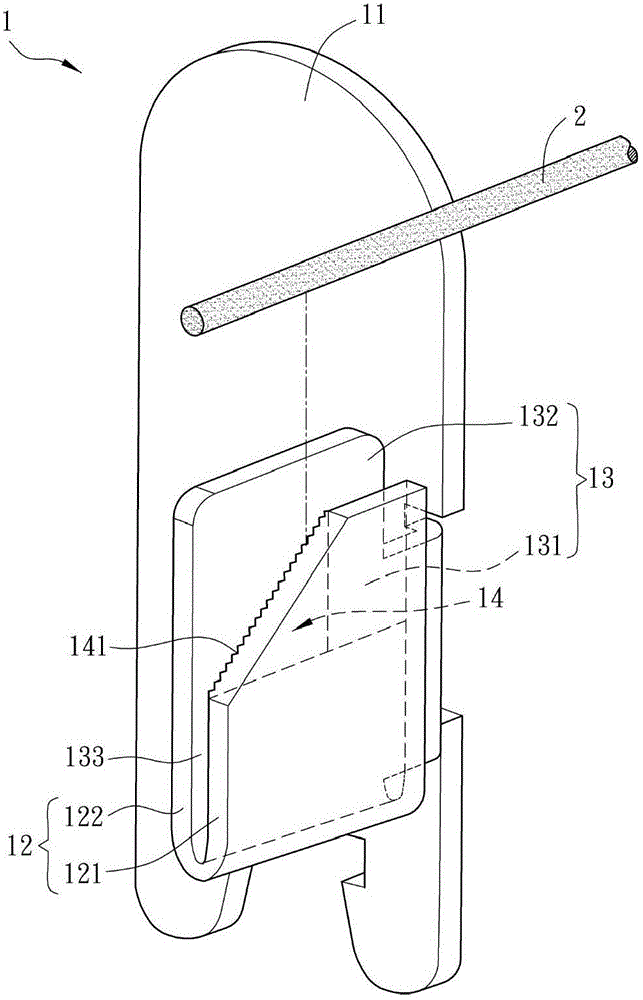

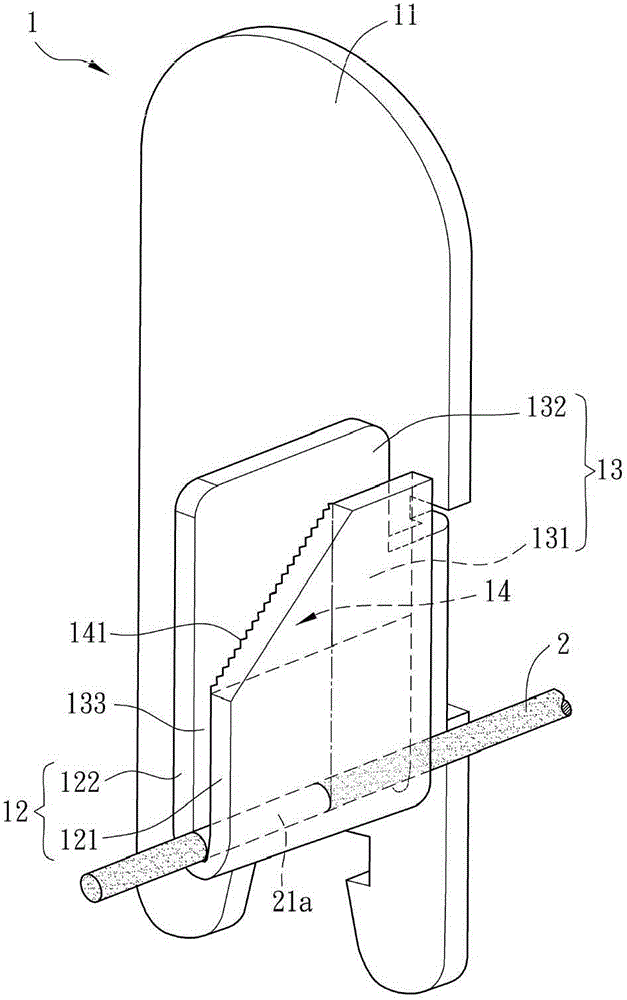

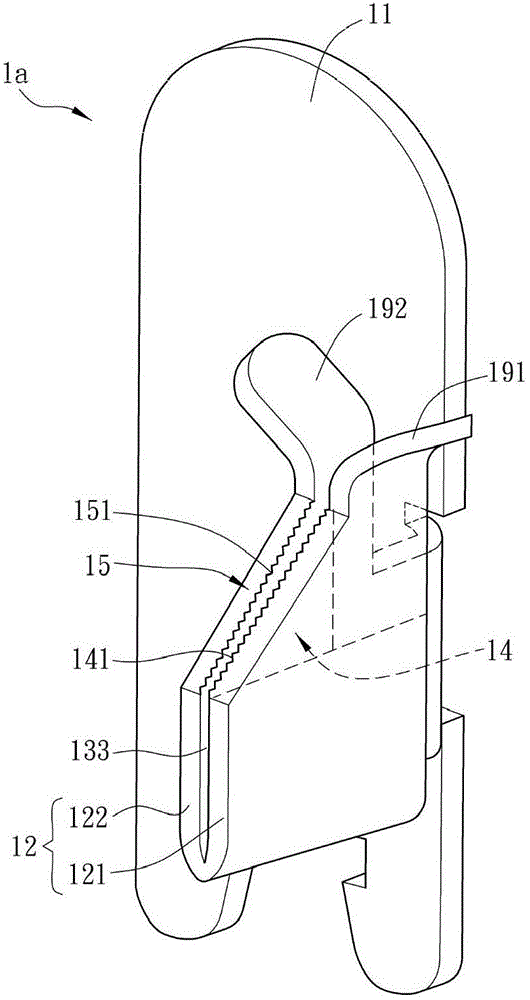

[0042] A terminal structure according to a preferred embodiment of the present invention will be described below with reference to the related drawings, wherein the same elements will be described with the same reference symbols. It should be noted that the accompanying drawings are only schematic representations, and do not represent actual dimensions and proportions. In practice, the dimensions and proportions can be designed in different ways according to needs.

[0043] Please refer to figure 1 As shown, it is a schematic diagram of a terminal structure 1 according to a preferred embodiment of the present invention. In practice, the terminal structure 1 can be used with a circuit board (not shown) and one or more wires 2 , wherein the wires 2 can be polyester enamelled wire (PEW), the surface of which is coated with a layer of Insulating paint to protect the conductive material inside from damage. The terminal structure 1 can be used to electrically connect the circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com