A tool profiling device

A profiling device and cutting tool technology, applied in the direction of manufacturing tools, copying process control systems, metal processing equipment, etc., can solve the problems of the influence of workpiece shape processing, increasing the size of the profiling, and the limited total length of the profiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

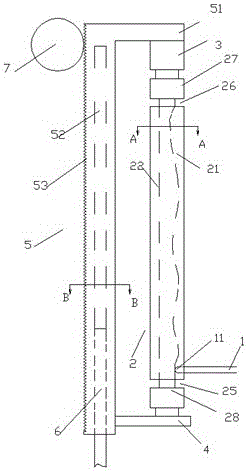

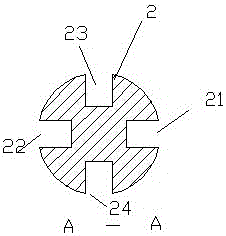

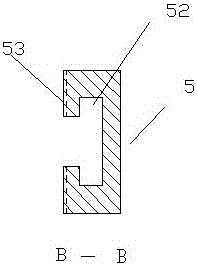

[0017] Combine below Figure 1-3 , the present invention will be described in detail.

[0018] The cutter profiling device comprises a cutter 1 and a profiling column 2, wherein the profiling column 2 is generally cylindrical, and the two ends of the cylinder are respectively an upper plug 27 and a lower plug 28, the upper plug 27 and the lower plug 28 respectively. Between the lower plugs 28 is an intermediate former part, which is evenly distributed with four longitudinal former grooves (21, 22, 23, 24) in the circumferential direction, and the former grooves and the cutter 1 At least one of the four longitudinal cam grooves is a return groove 22, the profile of the return groove 22 is planar, and the rest of the four longitudinal cam grooves The groove is a curved surface groove, which is used to control the feed rate of the cutter 1, and the number of the curved surface grooves is multiple, and the curved surface shapes of the curved surface grooves are different;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com