Patents

Literature

37results about How to "Realize two-dimensional movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

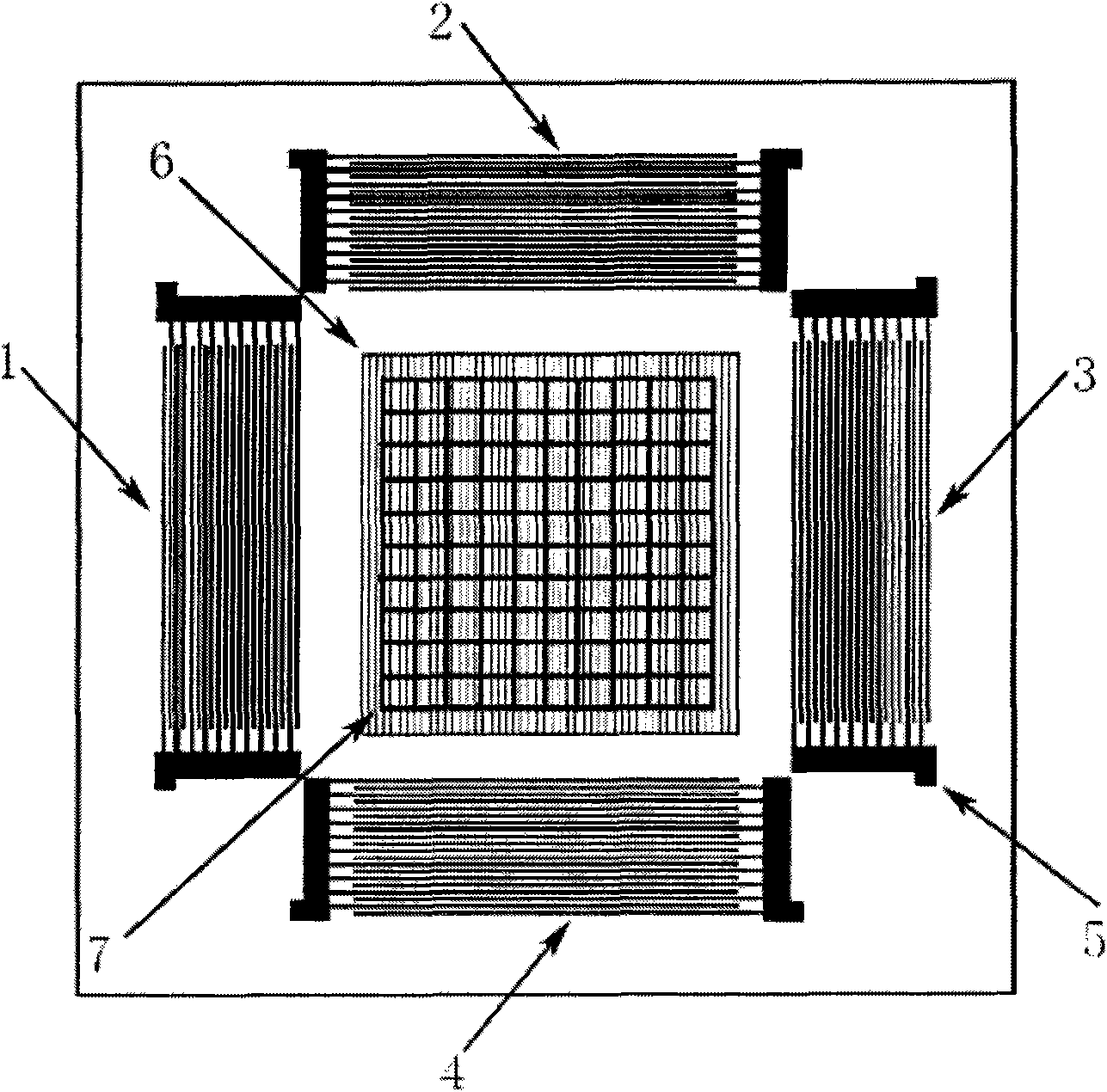

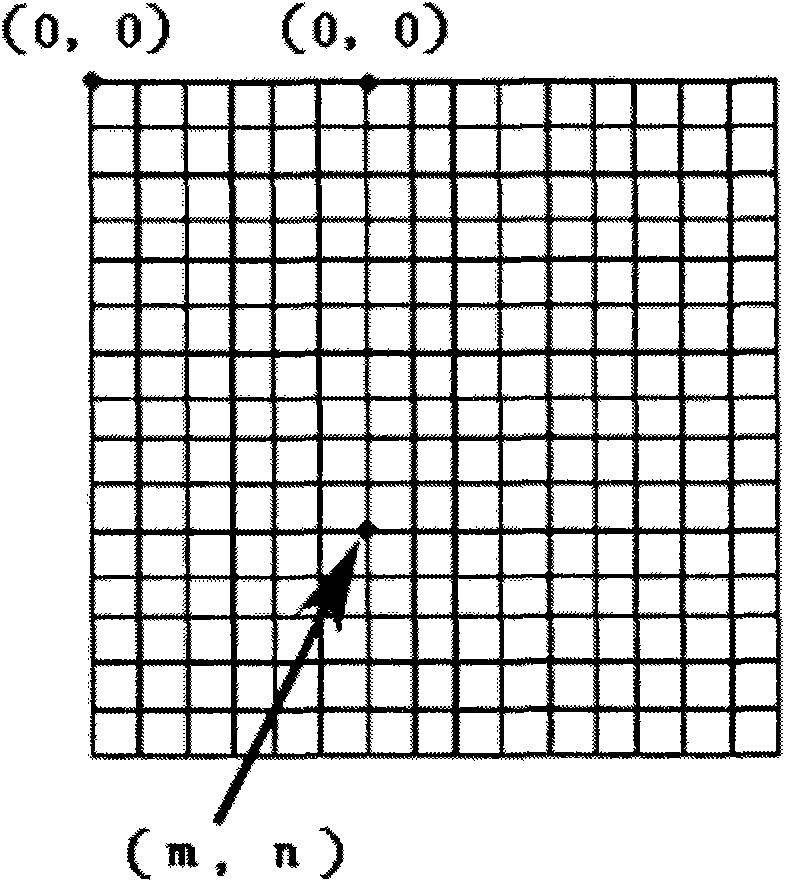

Two-dimensional digital microfluid analysis test platform based on acoustic surface wave

InactiveCN101556276AOvercoming complexityOvercoming the possibility of entering the dead zoneBiological testingTest platformLithium niobate

The invention belongs to the microfluid manipulation field and relates to a two-dimensional digital microfluid analysis test platform based on acoustic surface wave. The invention comprises four groups of metal comb-like interdigital electrodes with the same sizes and in symmetrical distribution, a graphical hydrophobic coating, a two-dimensional hydrophilic guide rail and a lithium niobate substrate. The invention is characterized in that the bottom is the lithium niobate substrate; the middle of the upper layer is the graphical hydrophobic coating; above the graphical hydrophobic coating are the evenly distributed two-dimensional hydrophilic guide rails; the intersection of the two-dimensional hydrophilic guide rails are a node and the four groups of metal comb-like interdigital electrodes are symmetrically distributed at four sides. The invention not only can resolve the problems of the complicated process of digital microfluid manufacturing and the possibility to enter a dead zone, but also can retain the advantages of less fluid demand of the existing digital microfluid and rapid analysis. The invention can be widely used in chemical and biological detection fields.

Owner:SHANGHAI JIAO TONG UNIV

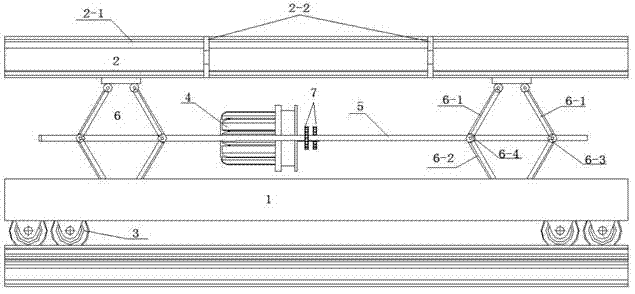

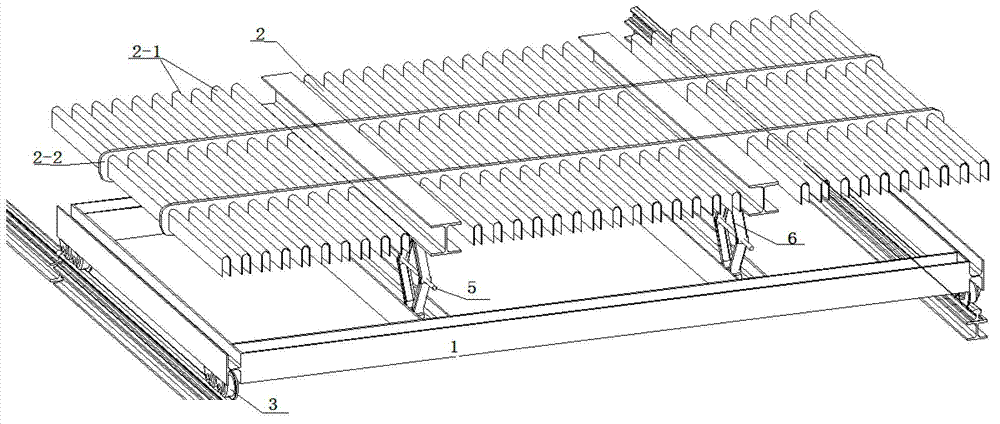

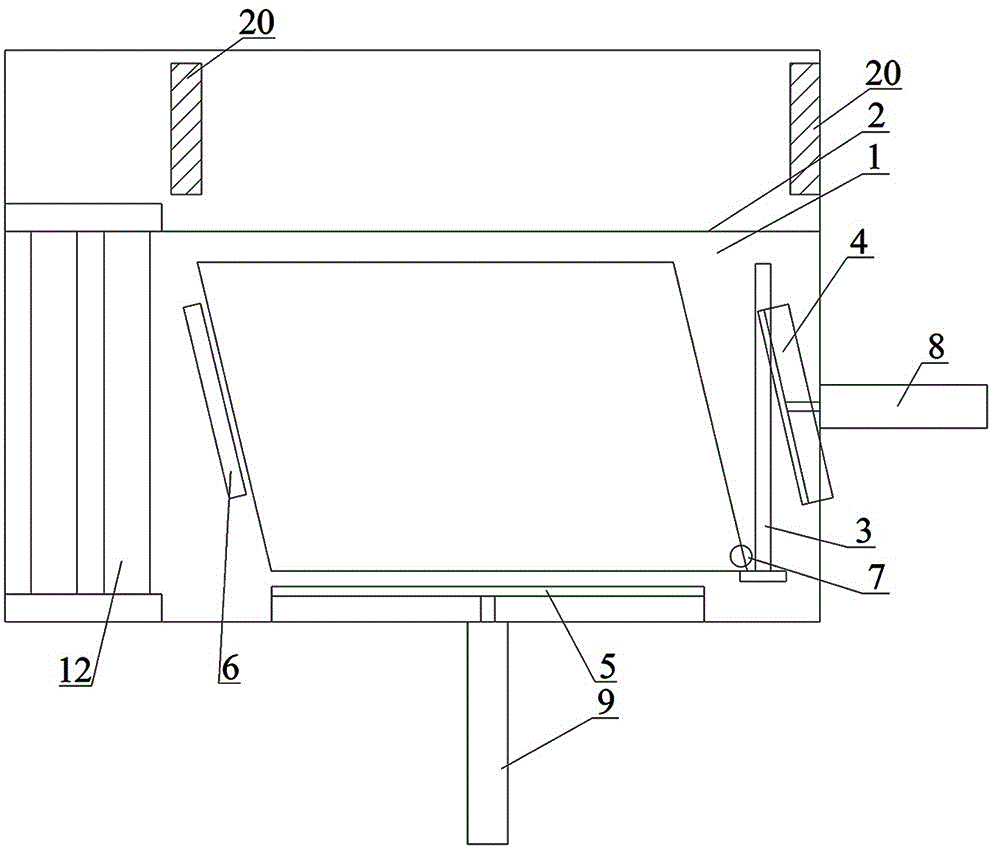

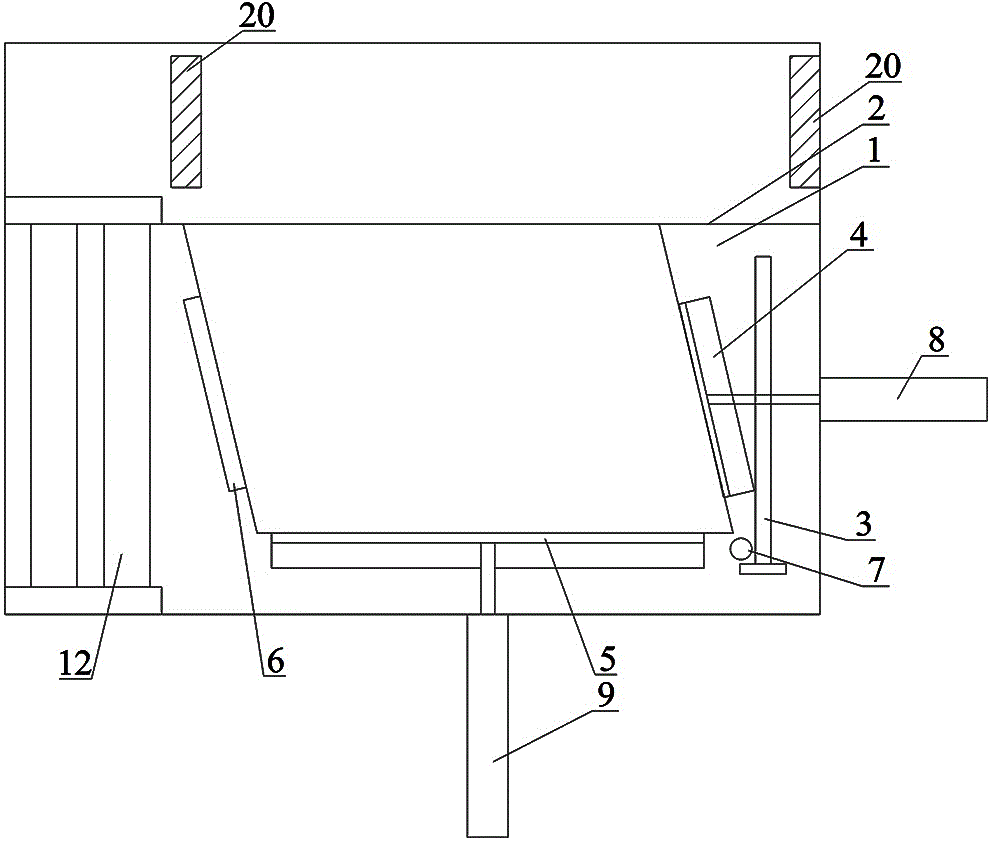

Two-dimensional moving vehicle-mounted platform and operating method and application thereof

InactiveCN102926568AImprove synchronicitySimple mechanical structureParkingsSynchronismThrough transmission

The invention relates to a two-dimensional moving vehicle-mounted platform, which comprises a translation chassis and a translation grid platform, wherein the translation chassis is connected with the translation grid platform through a first lifting device, so that the translation grid platform moves along the z direction; and a pulley which slides along the y direction is arranged at the bottom of the translation chassis. The invention relates to an operating method and application of the two-dimensional moving vehicle-mounted platform. The vehicle-mounted platform slides in the y direction through the pulley and moves in the z direction through the first lifting device, two-dimensional movement of the vehicle is realized, and the vehicle is accurately moved in a small space. The first lifting device adopts the chain screw transmission principle that the opening angle of a crank moving bracket is changed through transmission, so that lifting control of the translation grid platform is realized, the whole transmission mechanism is simple, easy to maintain and extremely high in synchronism, and the technical defects in a hydraulic lifting device are overcome.

Owner:SHANDONG UNIV

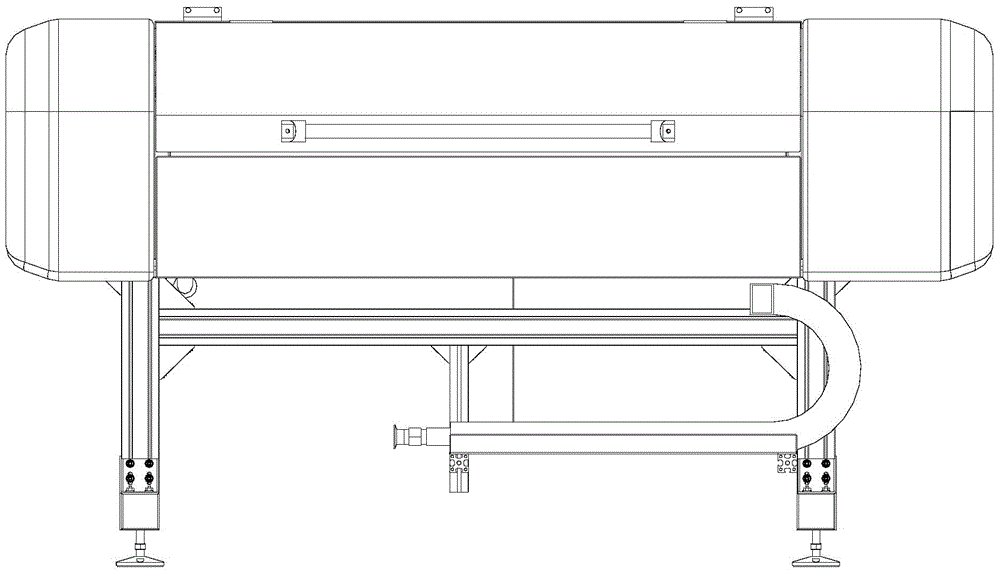

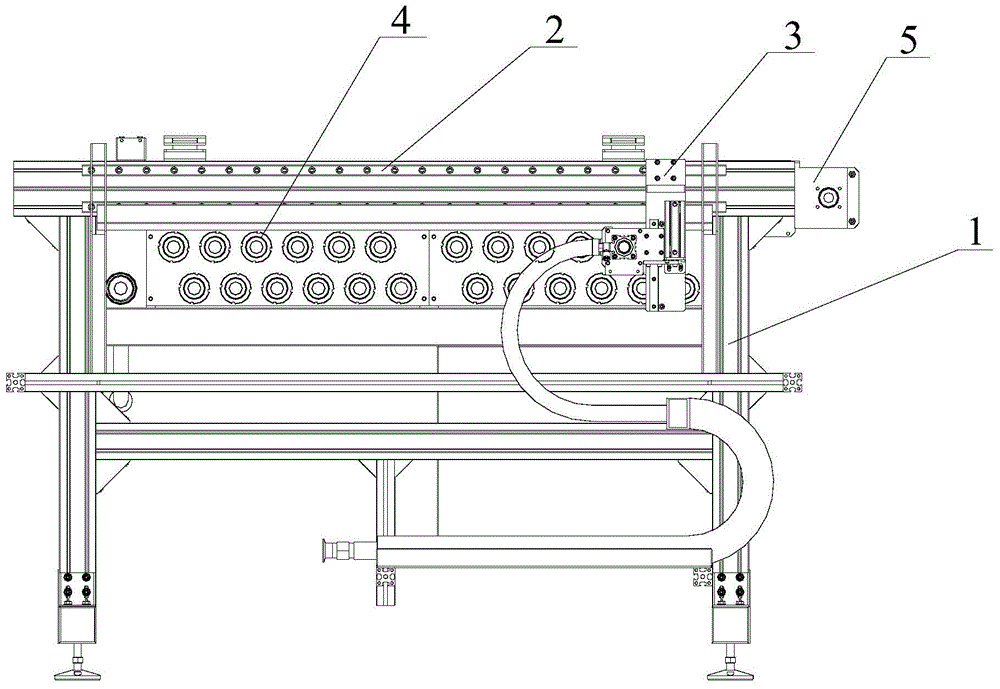

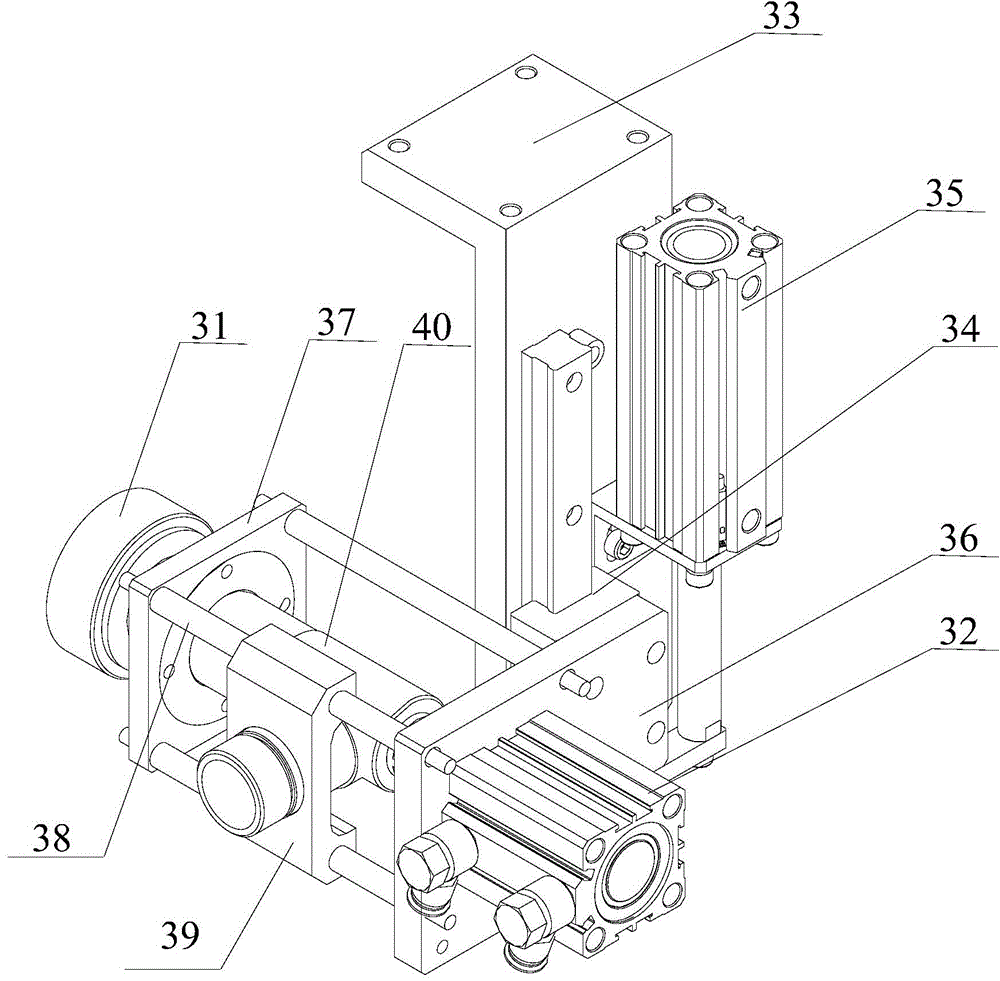

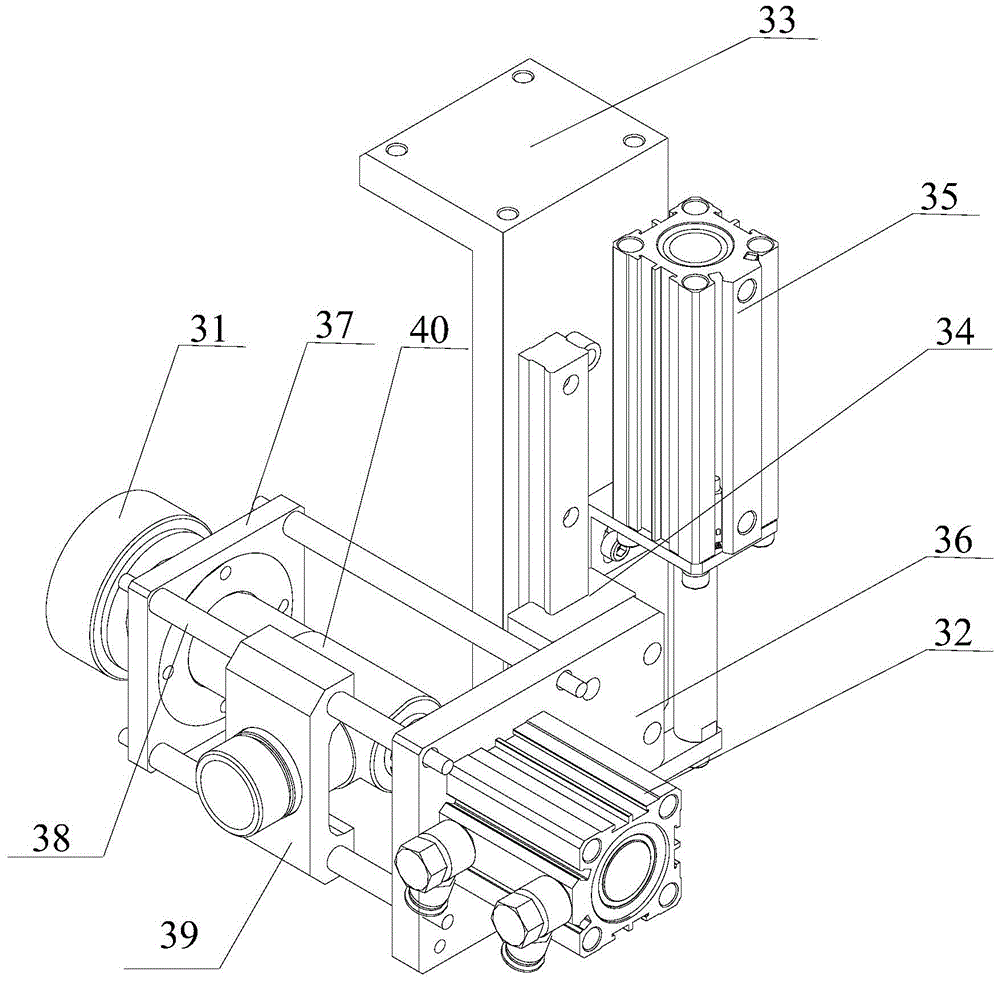

One-to-many automatic docking system

ActiveCN104445035AIncrease the number ofIngenious designLiquid transferring devicesButt jointEngineering

The invention discloses a one-to-many automatic butt joint system which comprises a support, a horizontal guide rail pair arranged on the support, a butt joint mechanism and a plurality of pipeline connectors. The horizontal guide rail pair comprises a horizontal guide rail and a horizontal sliding block in sliding fit with the horizontal guide rail, the butt joint mechanism is arranged on the horizontal sliding block, and the pipeline connectors are arranged on the support and matched with the butt joint mechanism. According to the one-to-many automatic butt joint system, one-to-many automatic butt joint can be achieved, the structure is simple and reliable, switching is free, and movement locating is accurate. In a preferable technical scheme, the butt joint mechanism comprises a vertical guide rail pair, the two-dimensional movement of the connectors is achieved under the action of the horizontal guide rail pair and the vertical guide rail pair, the pipeline connectors can be arranged in multiple rows, the number of the pipeline connectors can be greatly increased, the system can be accurately located right ahead the pipeline connectors needing to be connected, butt joint is completed under the action of a butt joint air cylinder, and the system is especially suitable for the field of printing and dyeing, and has the wide application prospect.

Owner:杭州开源科派思智能科技有限公司

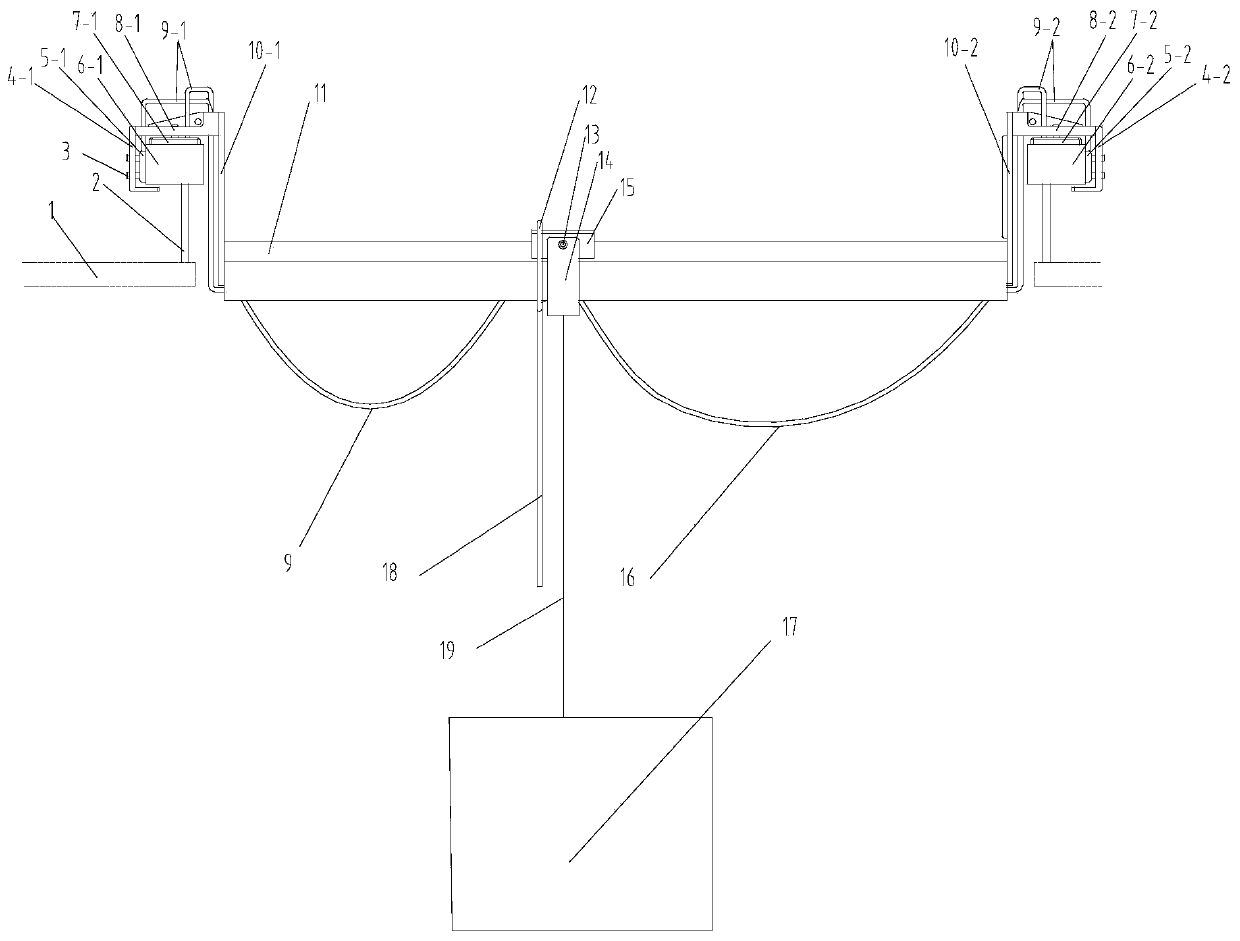

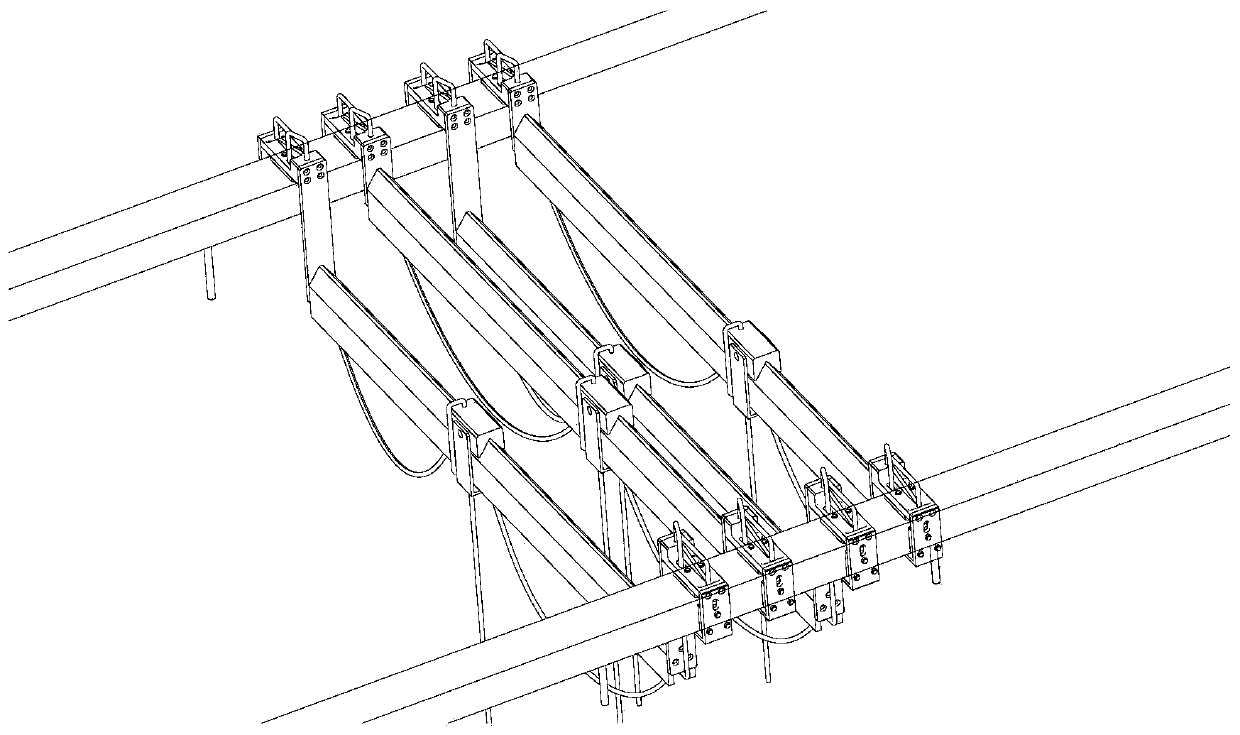

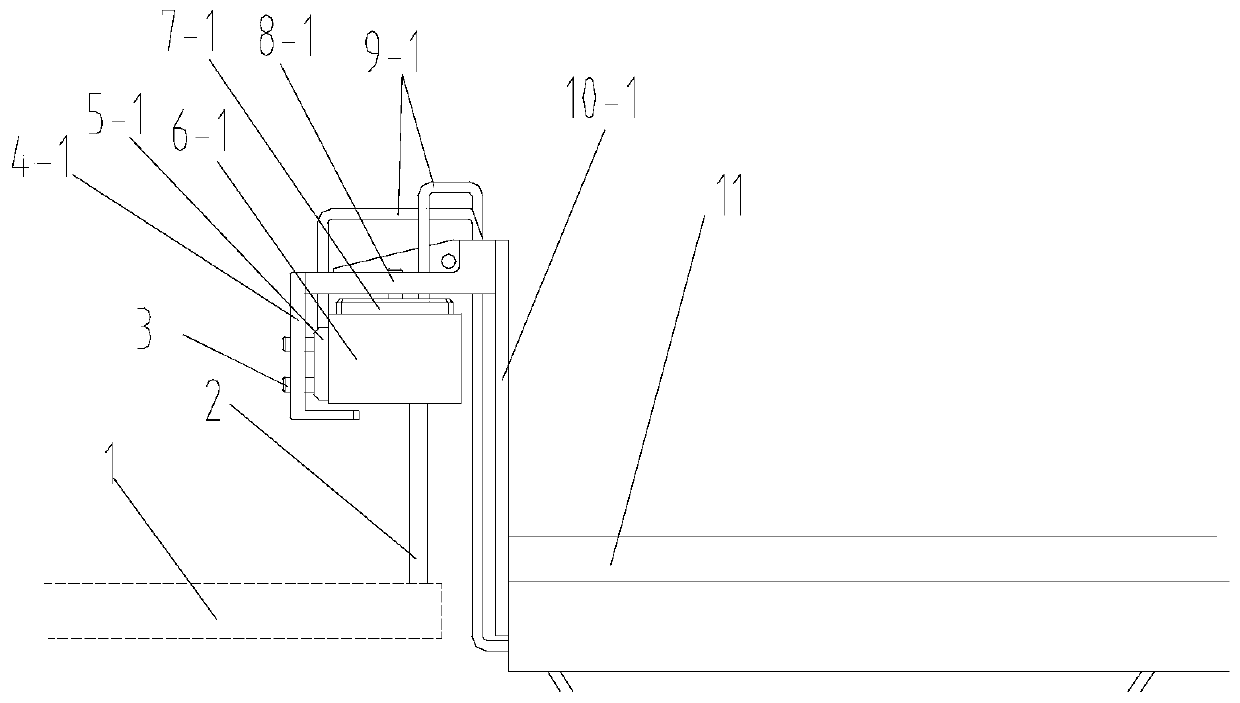

Air floatation hanging type gravity unloading device for space deployable mechanism

InactiveCN110901966ALow damping motionAvoid trial failureCosmonautic condition simulationsClassical mechanicsStructural engineering

The invention relates to an air floatation hanging type gravity unloading device for a space deployable mechanism. A first longitudinal guide rail and a second longitudinal guide rail are located on the same horizontal plane and are parallel to each other; the first lateral air floating block is mounted on the outer side surface of the first longitudinal guide rail, and the first upper air floating block is mounted on the upper side surface of the first longitudinal guide rail; the first lateral air floating block and the first upper side air floating block are fixedly connected with one end of the transverse guide rail through a bracket; the second lateral air floating block and the second upper air floating block are fixedly connected with the other end of the transverse guide rail through a bracket; the lateral air floating block, the upper air floating block and the transverse air floating block are suspended by compressed air; the lateral air floating block and the upper air floating block move on the longitudinal guide rail, the transverse air floating block moves on the transverse guide rail, the target mechanism is connected with the transverse air floating block, and the two-dimensional movement of the target mechanism in a plane is simulated through the longitudinal movement of the lateral air floating block and the upper air floating block and the transverse movementof the transverse air floating block.

Owner:BEIJING SATELLITE MFG FACTORY

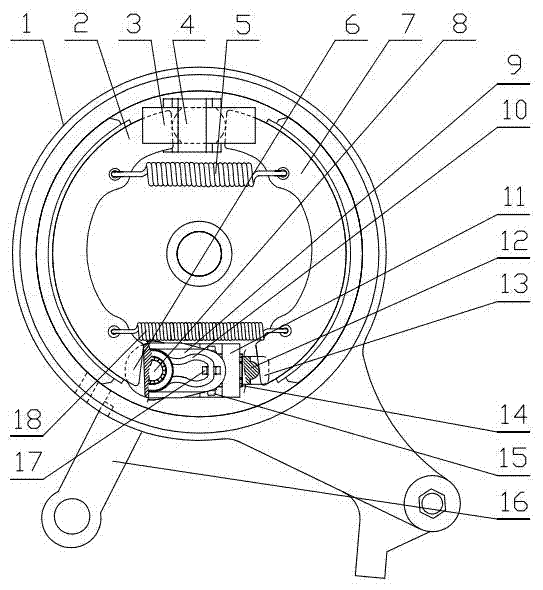

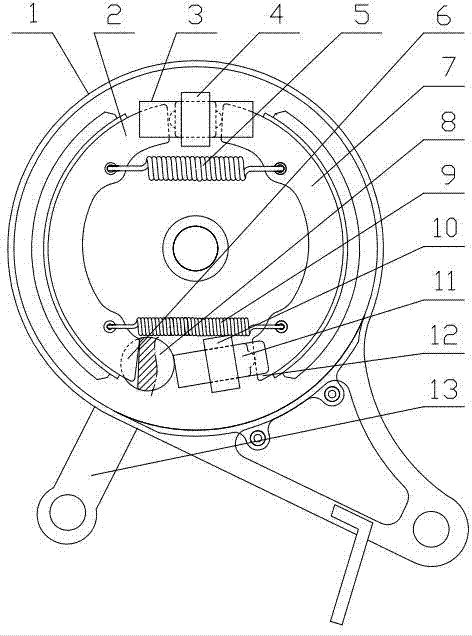

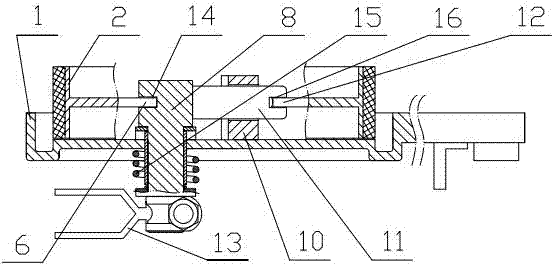

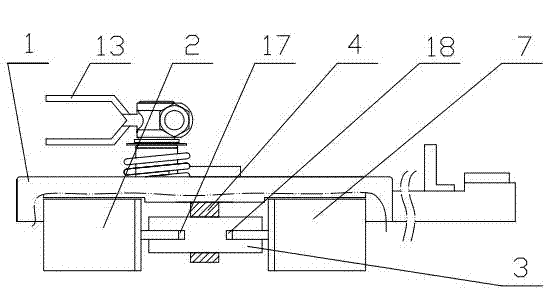

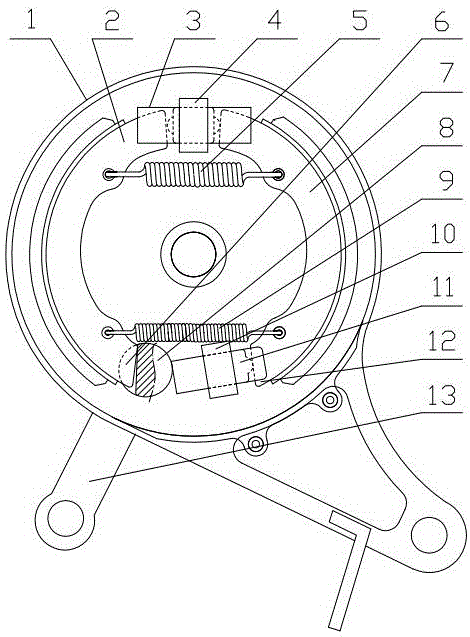

Hub type brake

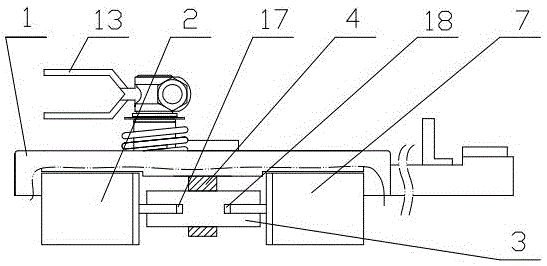

InactiveCN103486158AFacilitate safe brakingRealize the braking functionBrake actuating mechanismsMechanically actuated drum brakesEngineeringTorsion spring

The invention discloses a hub type brake. The hub type brake comprises a casing, a rocker arm, a torsion spring, a left friction sheet, a right friction sheet, a rocker arm shaft and a sliding shaft, wherein the left friction sheet and the right friction sheet are movably arranged on the casing. The rocker arm penetrates into a through hole which is formed in the casing and matched with the rocker arm shaft, a spline ratchet wheel pocking device is arranged at the upper end of the rocker arm shaft, the lower end of the rocker arm shaft is connected with the rocker arm, the rocker arm is connected with the casing through the torsion spring, the left end of a spline nut butts against the rocker arm shaft, a sliding groove matched with the front end of the left friction sheet is formed in the rocker arm shaft, a convex block is arranged on the rocker arm, a limiting block is arranged on the edge of the casing, the limiting block is used for blocking the convex block arranged on the rocker arm, a sliding shaft hole matched with the sliding shaft is formed in a rear fixing base, a left sliding groove matched with the rear end of the left friction sheet is formed in the left end of the sliding shaft, a right sliding groove matched with the rear end of the right friction sheet is formed in the right end of the sliding shaft, and the bottom face of the left sliding groove and the bottom face of the right sliding groove are respectively an arc face.

Owner:盐城市诚良高尔夫电动车配件有限公司

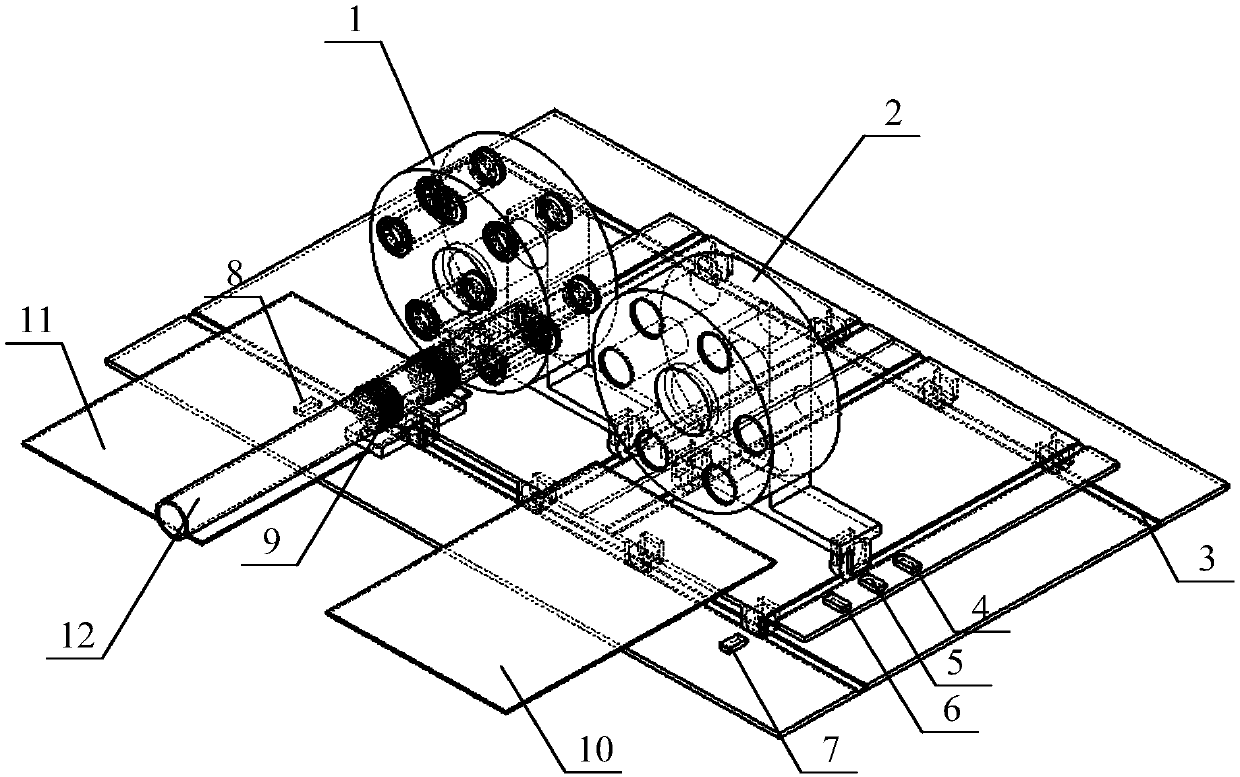

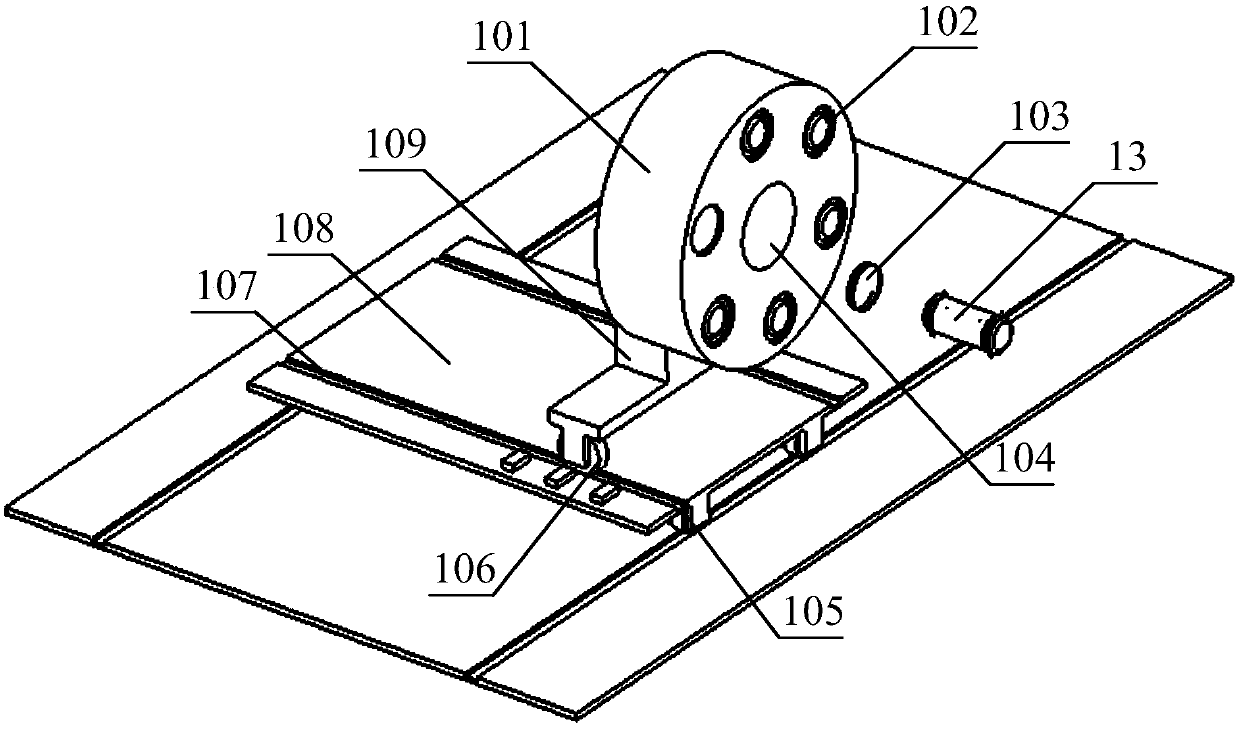

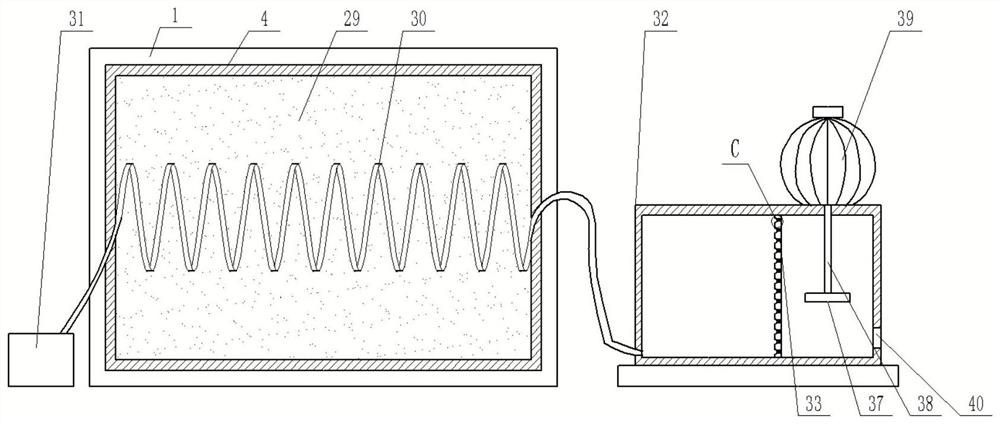

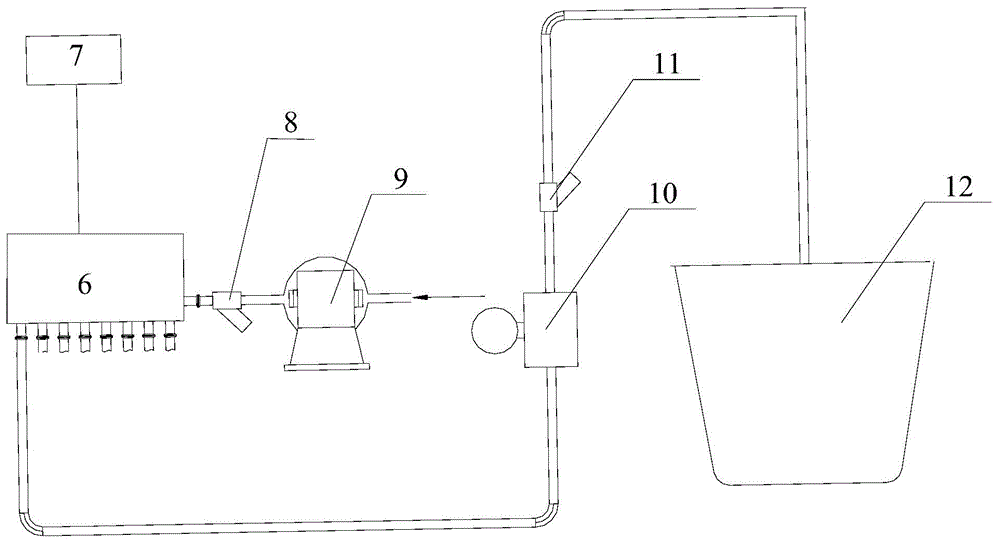

Rotary continuous receiving and sending system and method for cold chain logistics pipeline system

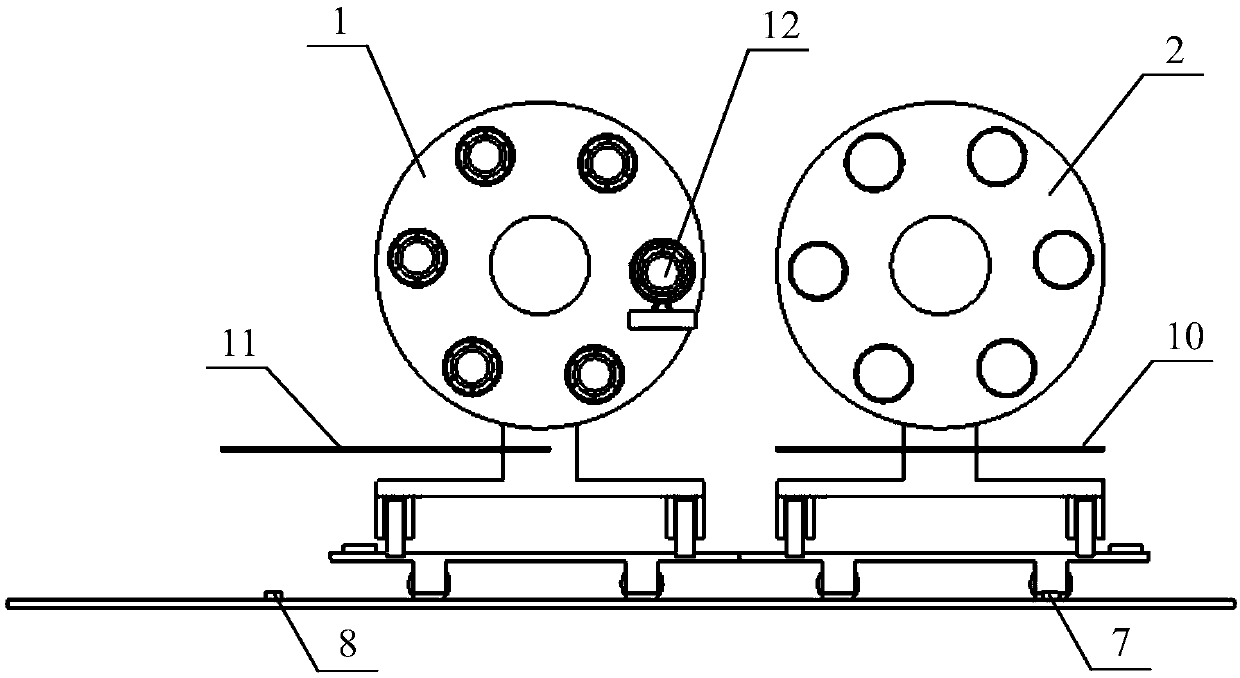

ActiveCN109552887AImplement pipeliningFast and efficient deliveryNon-mechanical conveyorsCold chainLogistics management

The invention discloses a rotary continuous receiving and sending system for a cold chain logistics pipeline system, characterized by comprising: a first rotary receiving and sending device (1), a second rotary receiving and sending device (2), a lateral movement device, and longitudinal movement devices; the first rotary receiving and sending device (1) and the second rotary receiving and sendingdevice (2) are each configured with a plurality of receiving and sending places (102) for housing cold chain collectors (13); the first rotary receiving and sending device (1) and the second rotary receiving and sending device (2) are fixedly connected in a lateral direction of a cold chain transmission conduit (12), and laterally and synchronously driven by the lateral movement device; longitudinal movements of the first rotary receiving and sending device (1) and the second rotary receiving and sending device (2) in a longitudinal direction of the cold chain transmission conduit (12) are independent of each other, and the first rotary receiving and sending device (1) and the second rotary receiving and sending device (2) are respectively driven by the first longitudinal movement deviceand the second longitudinal movement device to do longitudinal movements without interference. The invention adopts two sets of rotary receiving and sending devices to alternate operations, which is fast and efficient.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Working station for square pipe cutting

PendingCN110328455ARealize the cutting operationRealize the punching operationLaser beam welding apparatusEngineeringDrive motor

The invention relates to a working station for square pipe cutting. The working station for square pipe cutting comprises a cutting assembly and a laser cutting workpiece clamping assembly, wherein the cutting assembly comprises an installation table, an installation table drive mechanism, a connection arm arranged on the surface of the installation table, a connection arm drive mechanism, and a laser cutting device arranged on the end part of the connection arm, and the laser cutting workpiece clamping assembly comprises two movable tables, a movable table drive mechanism and a plurality of workpiece clamping devices; each workpiece clamping device comprises a base, a supporting plate arranged above the base, a supporting plate lifting device arranged on the surface of the base and provided with an output shaft which is connected with the supporting plate, and clamping plates arranged at the left side and the right side of the surface of the supporting plate; and an opening is formedin one side of each movable table, an overturning disc is arranged on the inner side surface of each movable table, a location groove adaptive to a square pipe is formed in the inner side surface of each overturning disc; and an overturning disc drive motor driving the corresponding overturning disc to rotate is further arranged on each movable table. The working station for square pipe cutting islow in environment pollution, and high in automation degree and working efficiency.

Owner:江苏国电新能源装备有限公司

Air floatation hanging type gravity unloading device for space deployable mechanism

PendingCN112498755AReduce the distance between lifting pointsReduce thicknessCosmonautic condition simulationsClassical mechanicsStructural engineering

Owner:北京太和科技有限公司 +1

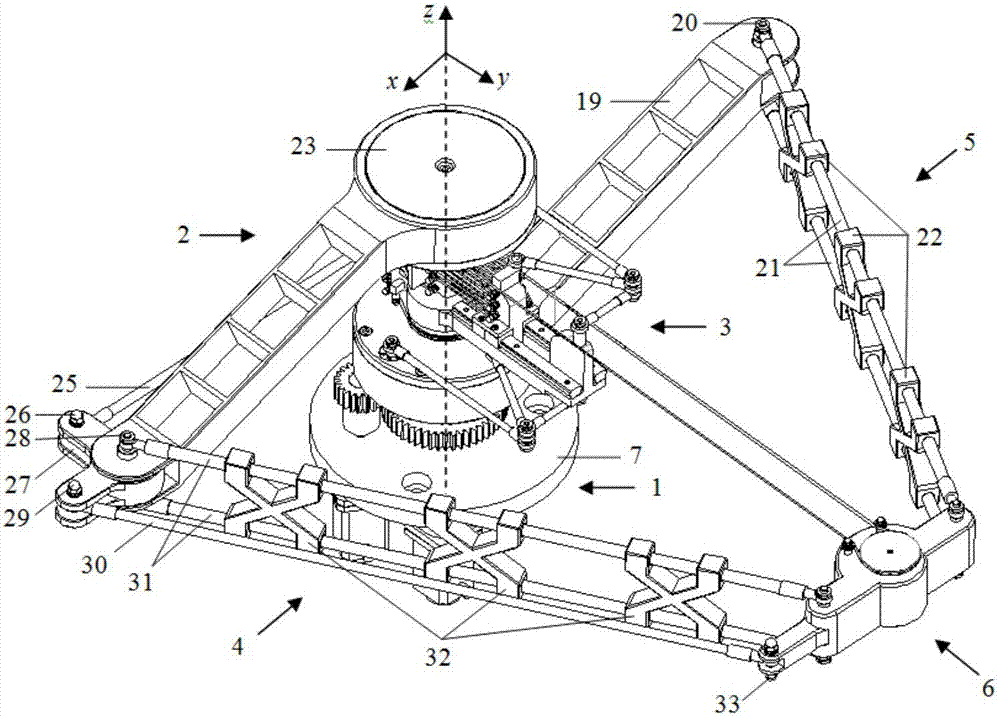

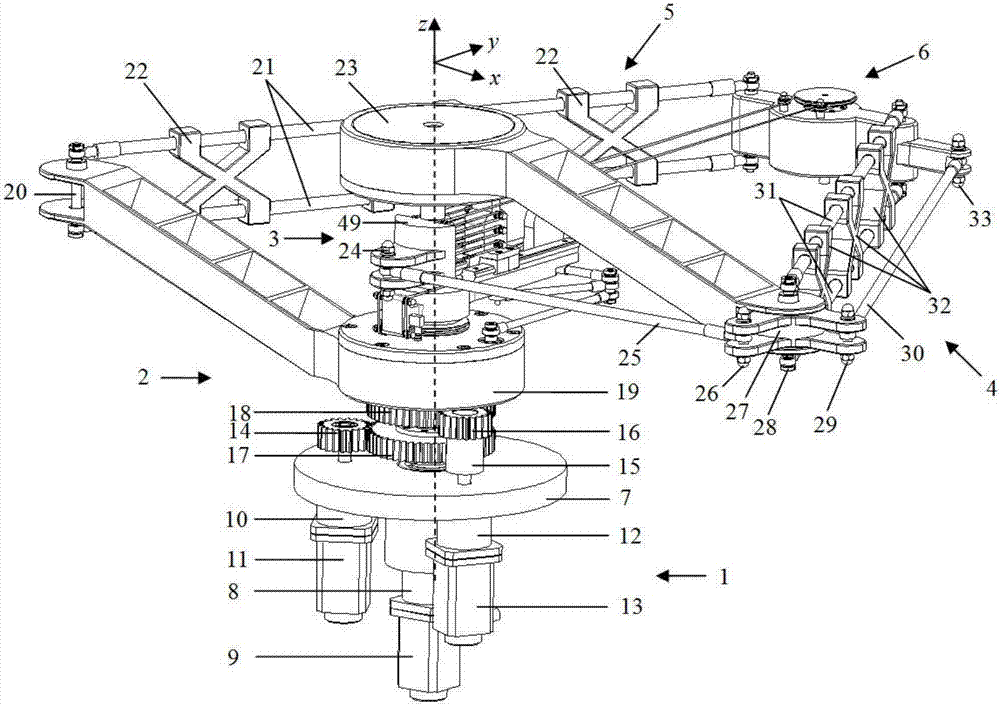

Photovoltaic power generation device with two-dimensional photovoltaic heliostat mechanism

ActiveCN112769381AReduce damage ratePlay a protective effectPhotovoltaic supportsPhotovoltaic energy generationHeliostatEngineering

The invention discloses a photovoltaic power generation device with a two-dimensional photovoltaic heliostat mechanism, which comprises a solar cell panel, wherein a rotating disc is arranged at the bottom of the solar cell panel, two symmetrically-arranged electric telescopic rods are fixed to the top surface of the rotating disc, a shaft rod mechanism is arranged at the inner rod position of each electric telescopic rod in a penetrating mode, the solar cell panel is fixed between the two shaft rod mechanisms, and a heat exchange box is fixed to the back face of the solar cell panel. According to the invention, the photovoltaic power generation device is provided with the two-dimensional photovoltaic heliostat mechanism, so that the photoelectric efficiency is improved, the working motor is well protected, the service life is long, and the energy utilization rate is greatly improved.

Owner:HENAN UNIV OF URBAN CONSTR

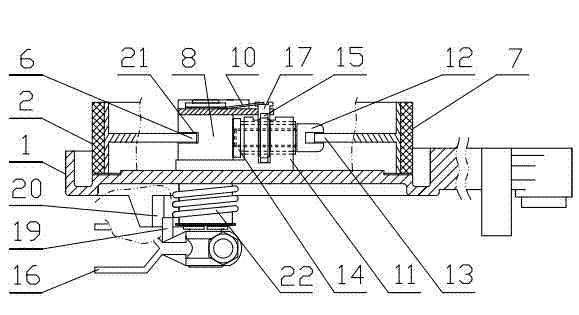

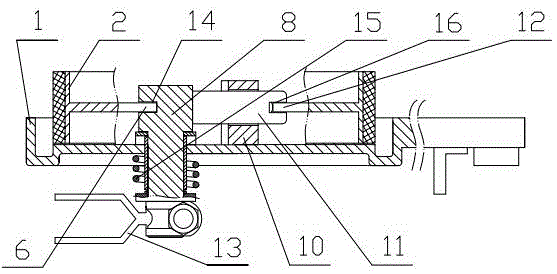

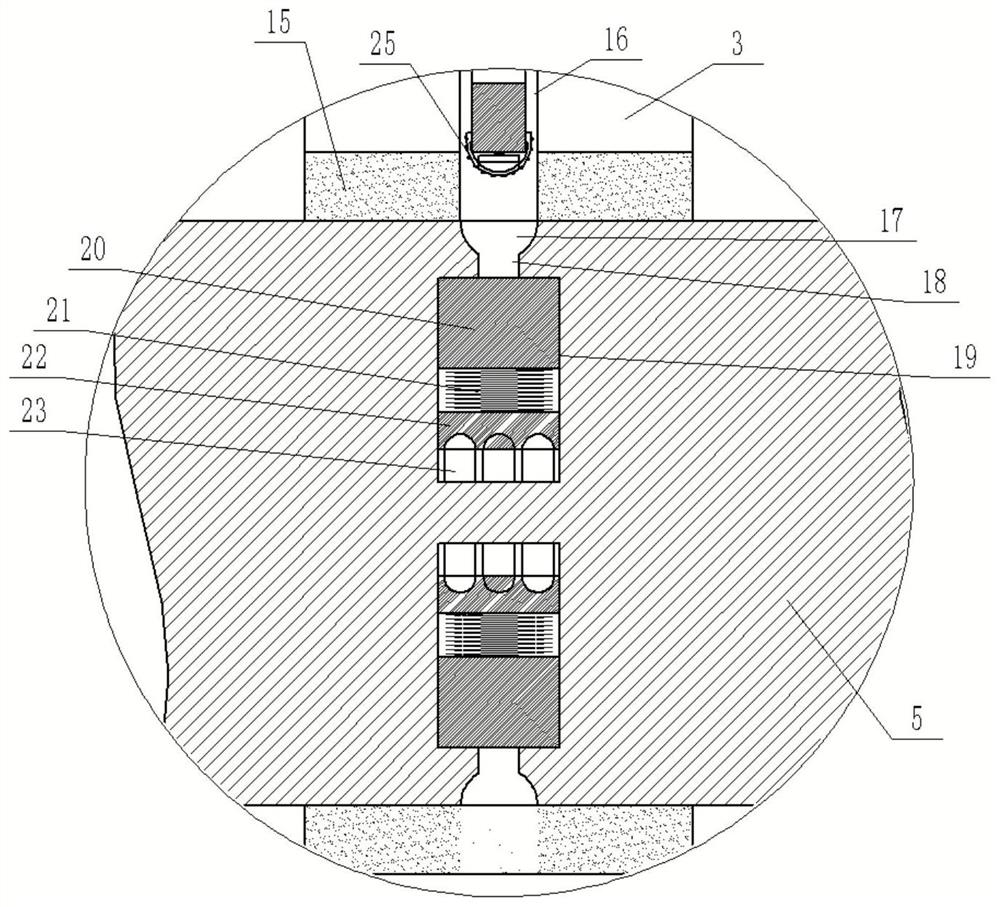

Tool profiling control system

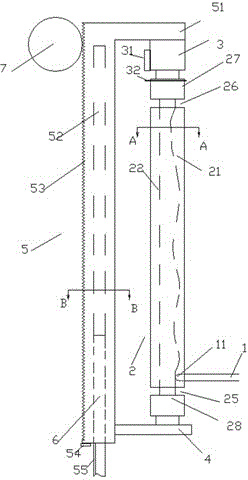

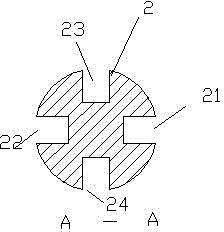

InactiveCN104084845AStable mold changeMachining shape influenceCopying process control systemsControl systemEngineering

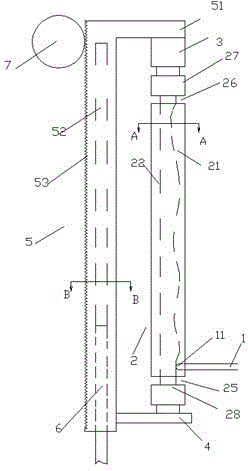

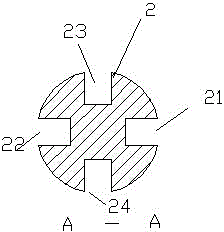

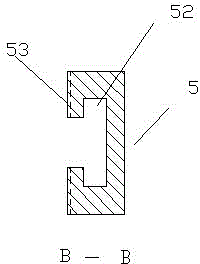

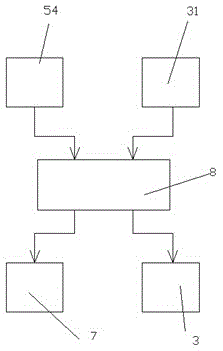

Disclosed is a tool profiling control system. The tool profiling control system comprises a tool profiling device and a control processor (8). The tool profiling device comprises a tool (1) and a profiling column (2), wherein the profiling column (2) is integrally in a cylindrical shape, and both ends of the cylindrical shaped are provided with an upper plug (27) and a lower plug (28); a middle profiling unit is formed between the upper plug (27) and the lower plug (28) and circumferentially and uniformly provided with four longitudinal profiling grooves (21, 22, 23 and 24) which are connected with the connecting end (11) of the tool (1); at least one of the four longitudinal profiling grooves is a return groove (22), the profiling contour of the return groove (22) is of a flat type, the other profiling grooves are curved grooves and are used for performing feeding control on the tool (1), and meanwhile, the curved grooves are different in curved surface shape.

Owner:AIRUI KETE TIANJIN PRECISION METAL TOOL CO LTD

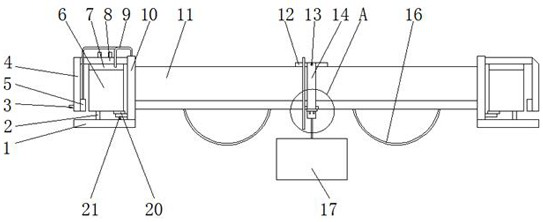

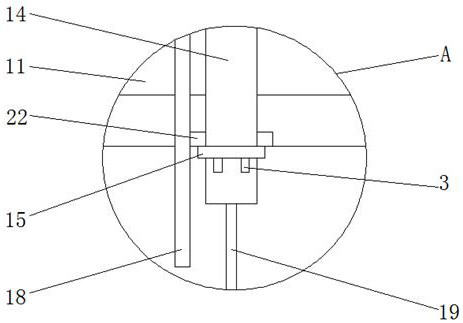

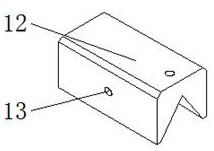

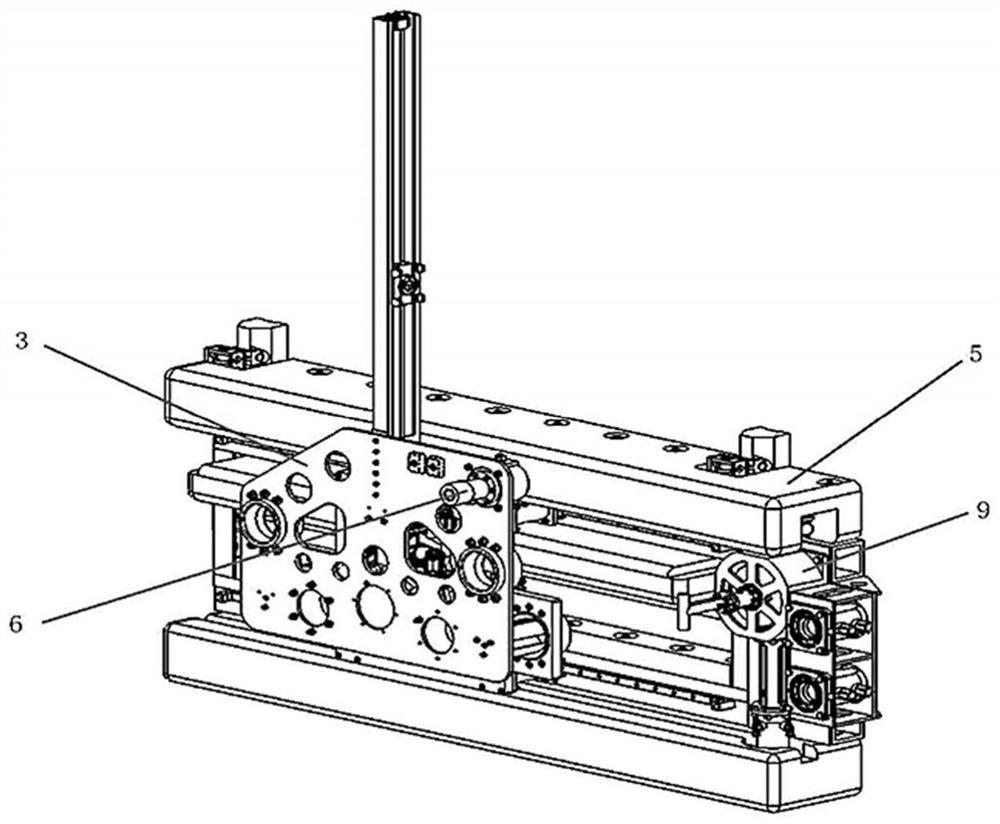

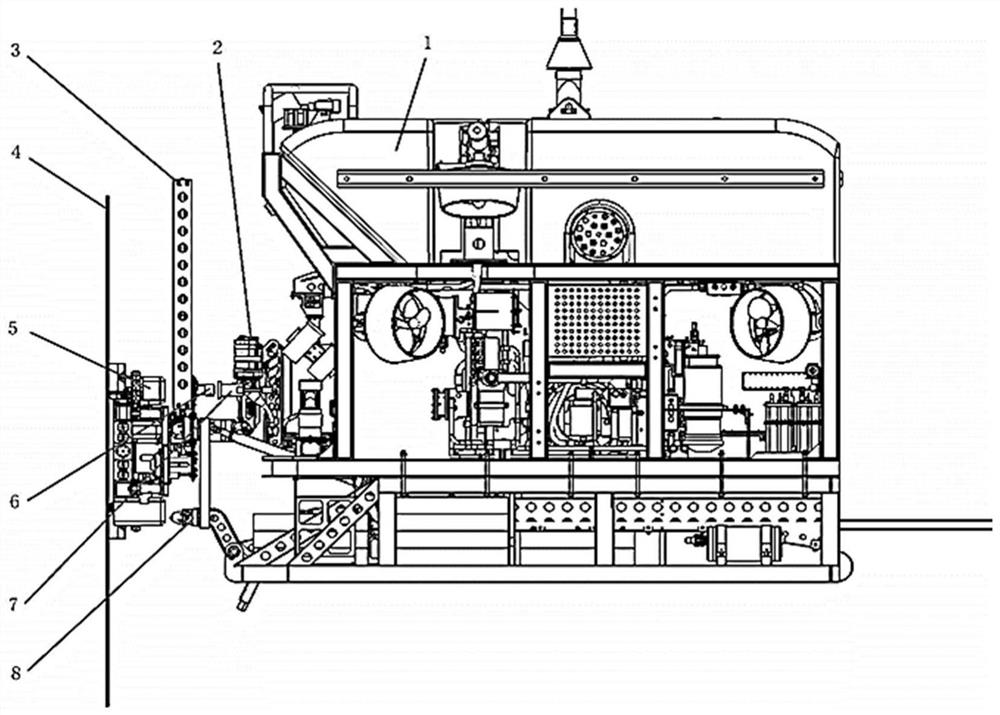

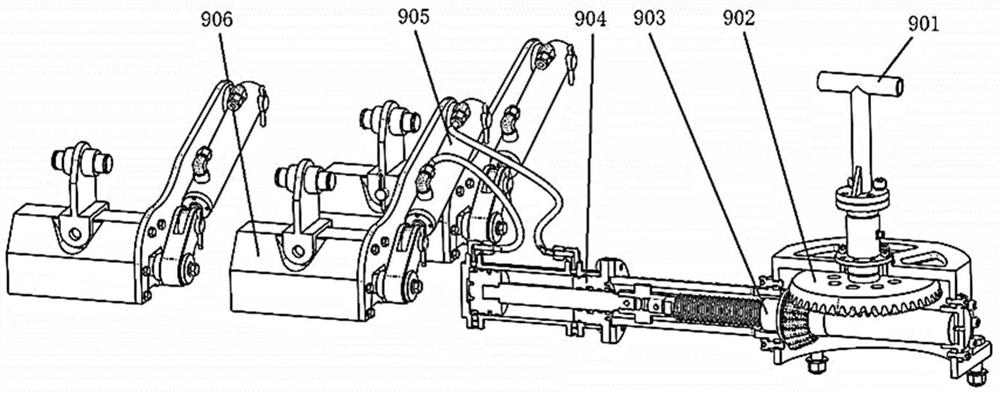

Mobile guide rail suitable for underwater working tool, underwater robot and working method

ActiveCN112591051BRealize two-dimensional movementRealize linear movementManipulatorUnderwater equipmentLinear motionControl engineering

The invention provides a moving guide rail suitable for underwater working tools, including: a Y-axis module, an X-axis module, an electric wet plug socket and a magnet opening and closing device, wherein the Y-axis module and the X-axis module are vertically arranged; The wet plug socket is set on the Y-axis module; when the X-axis module and the Y-axis module are used in combination, the underwater moving guide rail suitable for underwater working tools can realize two-dimensional movement in the plane; when the X-axis module is used independently , can be equipped with other underwater working tools to achieve linear motion; the magnet opening and closing device is set on the X-axis module. The invention solves the problem that the underwater working tools must be assembled on the water surface before being launched into the water by adopting the underwater docking and loading method; the mobile guide rail system is powered by an electric wet plug connector, and a communication channel is established at the same time.

Owner:SHANGHAI JIAO TONG UNIV +1

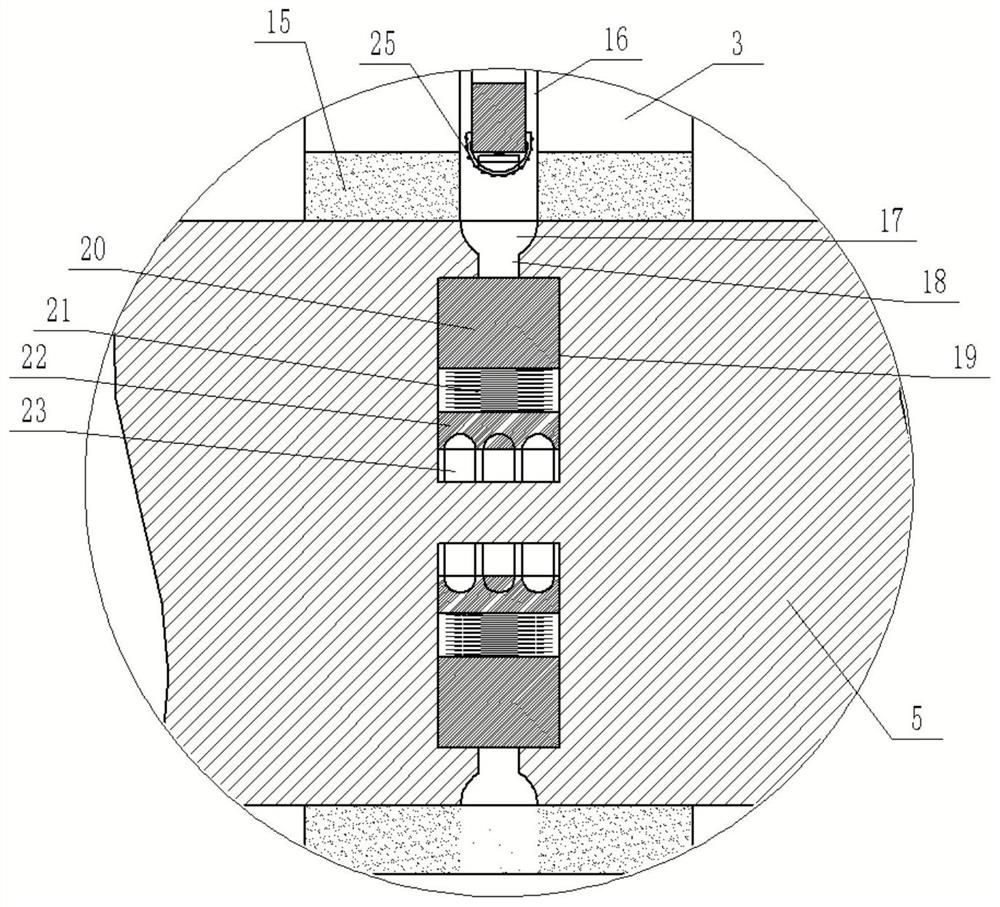

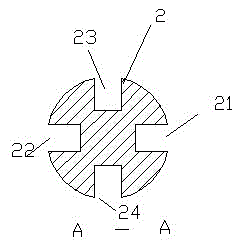

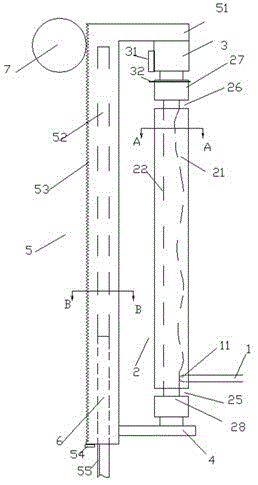

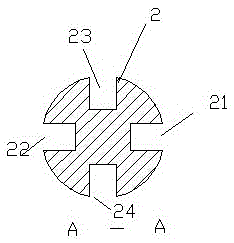

Cutter profiling device

InactiveCN104015102AStable mold changeMachining shape influenceCopying process control systemsEngineeringRisk stroke

The invention discloses a cutter profiling device. The cutter profiling device comprises a cutter (1) and a profiling column (2), wherein the profiling column (2) is cylindrical in the whole; two ends of the cylindrical part are respectively provided with an upper end cap (27) and a lower end cap (28); a middle profiling part is arranged between the upper end cap (27) and the lower end cap (28); four longitudinal profiling grooves (21, 22, 23 and 24) are uniformly distributed on the middle profiling part peripherally; the profiling grooves and a joint end part (11) of the cutter (2) are joined; at least one of the four longitudinal profiling grooves is a return stroke groove (22); the profiling outline of the return stroke groove is plane type; the rest profiling grooves in the four longitudinal profiling grooves are curved surface grooves for controlling feeding quantity of the cutter (1); moreover, the plurality of curved surface grooves have different curved surface shapes.

Owner:深圳市乔本金刚石刀具有限公司

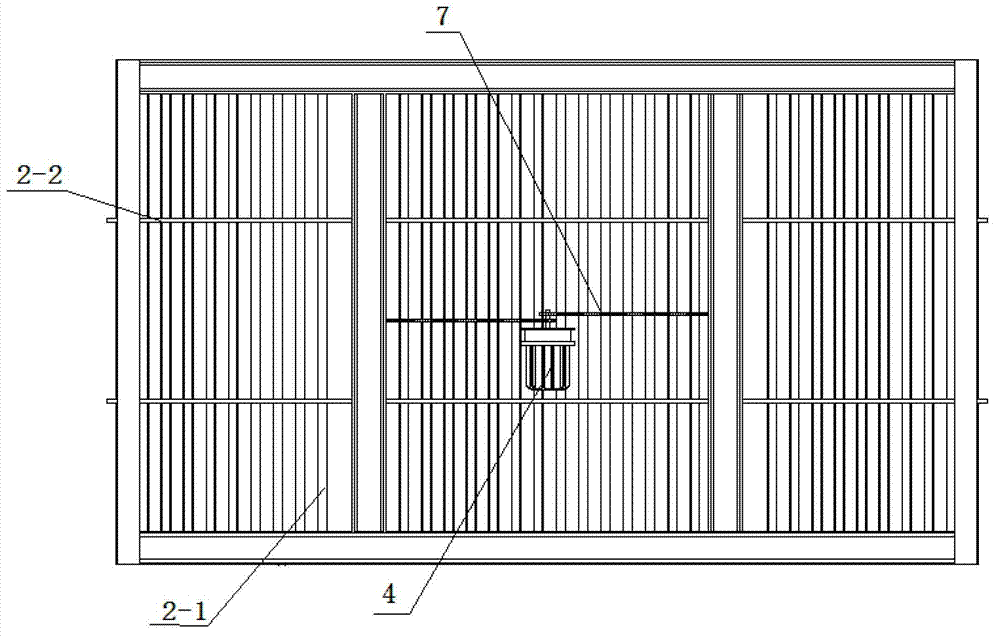

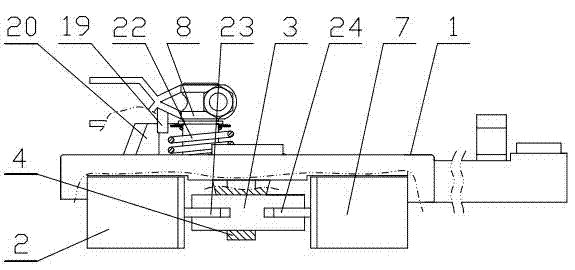

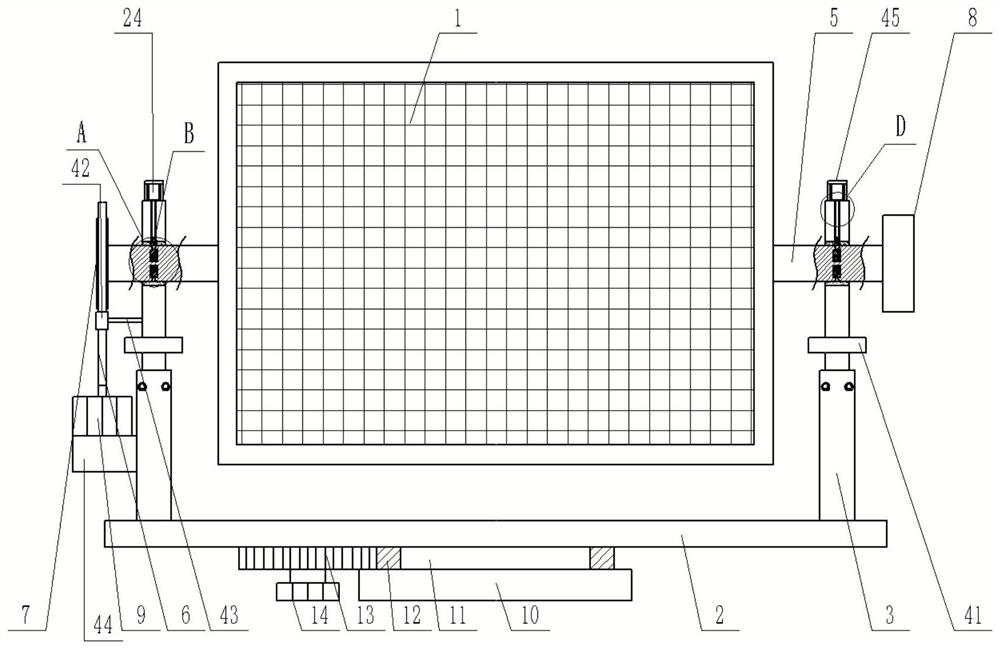

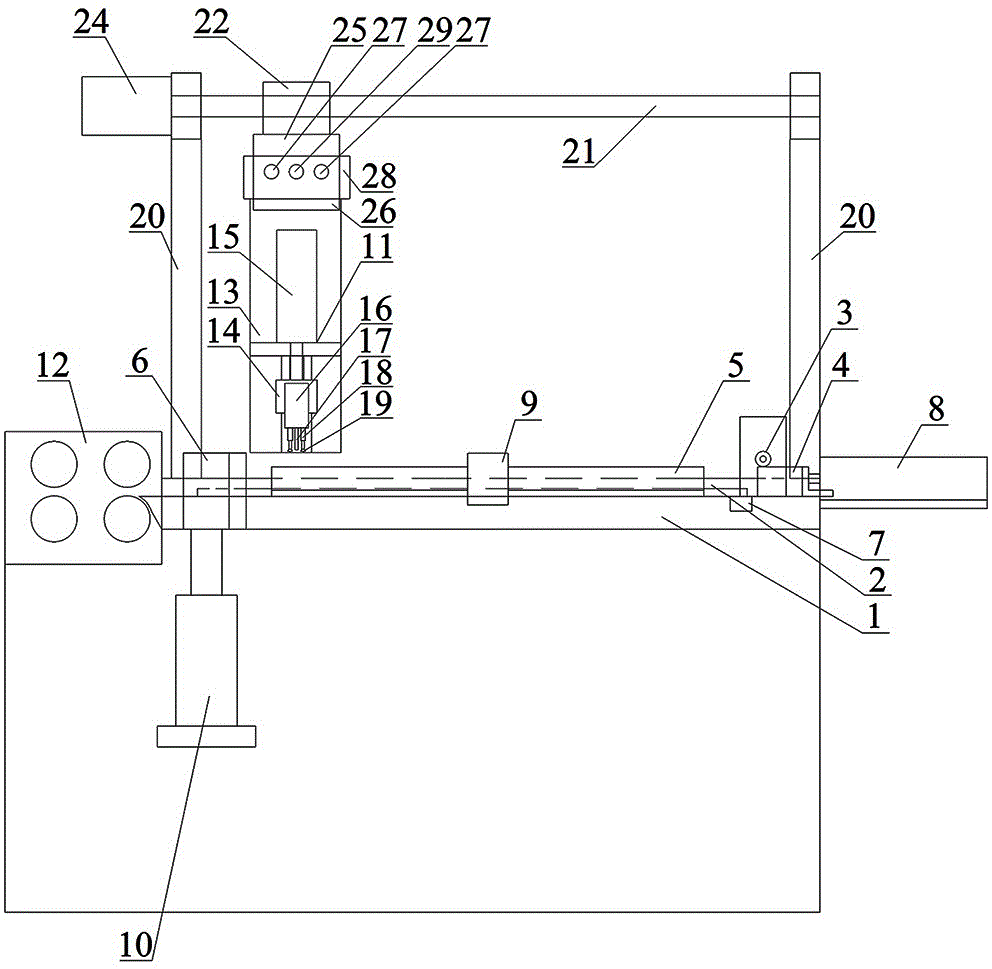

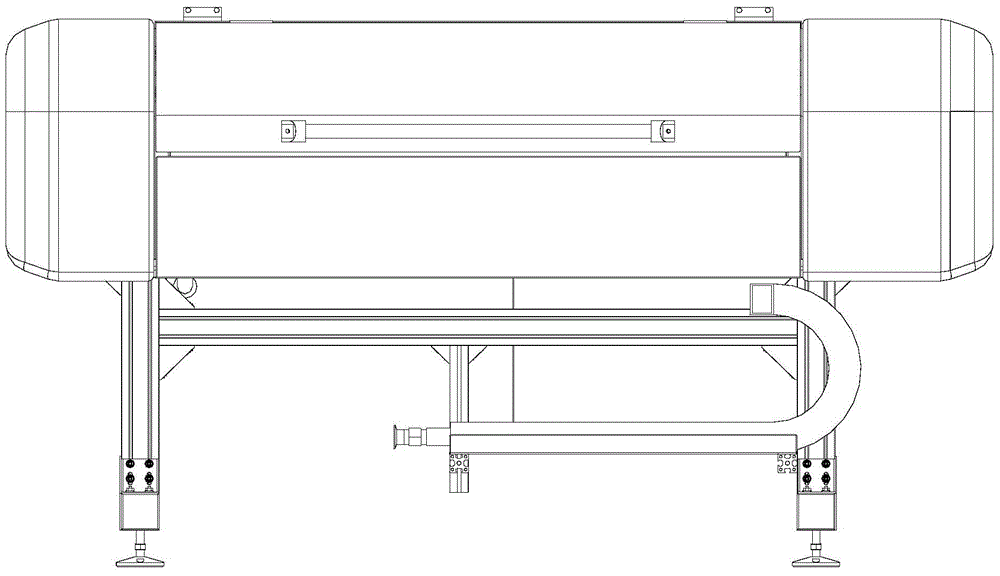

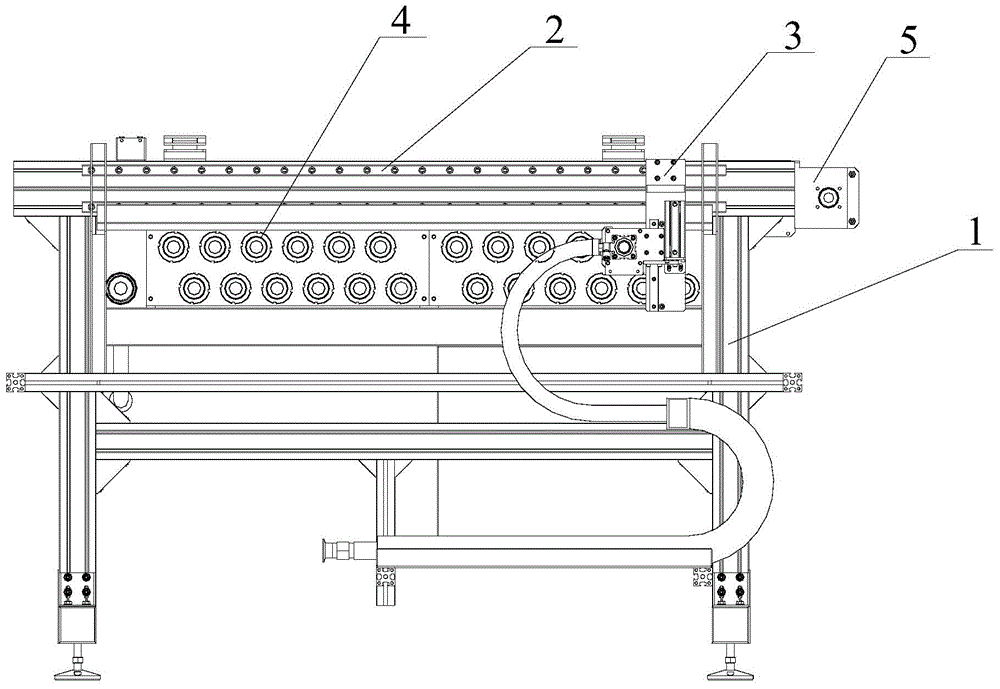

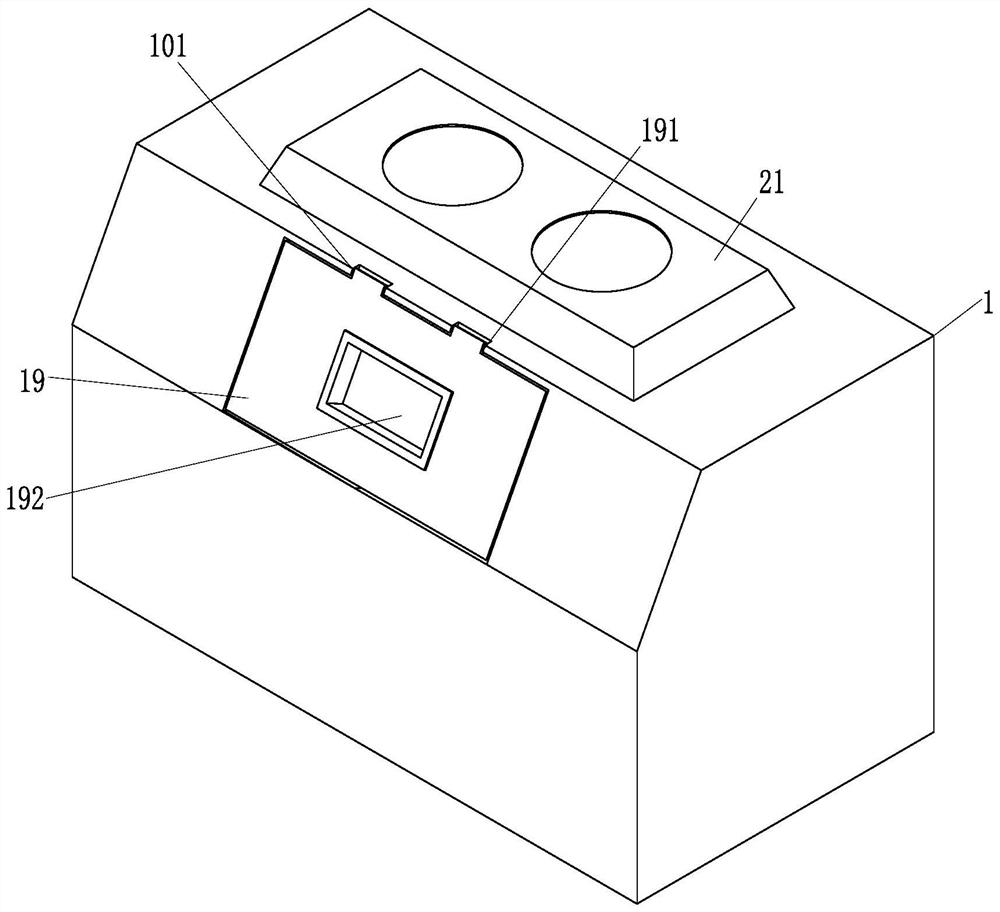

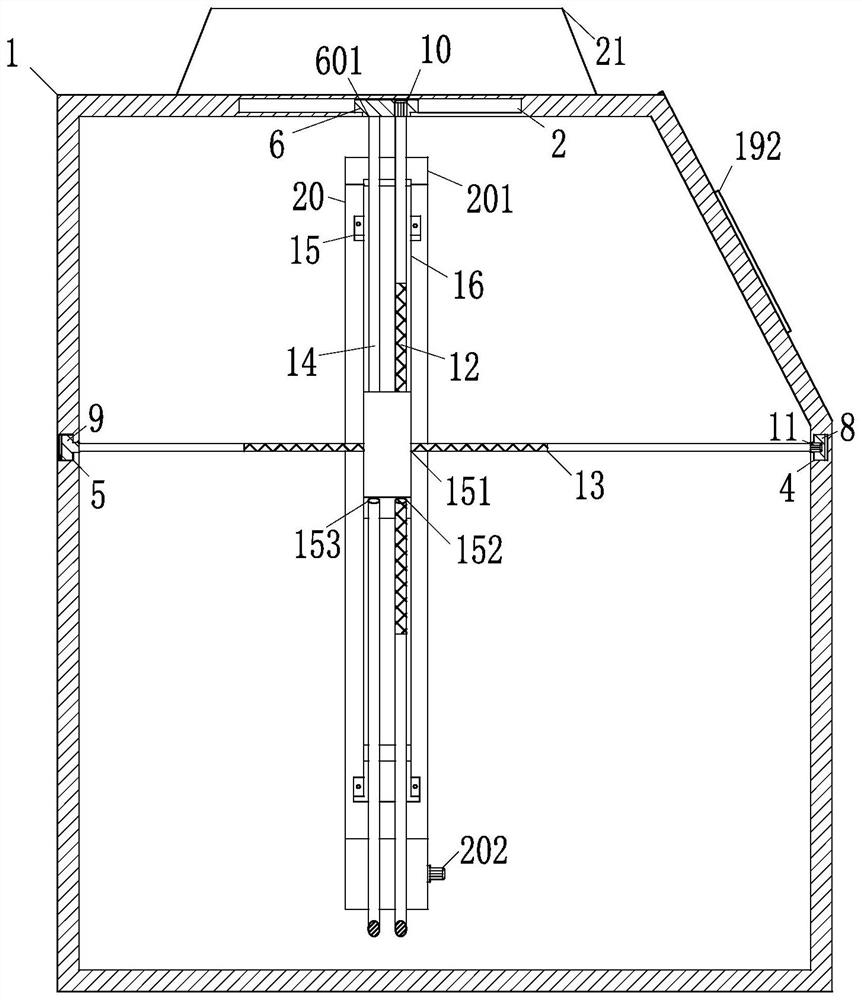

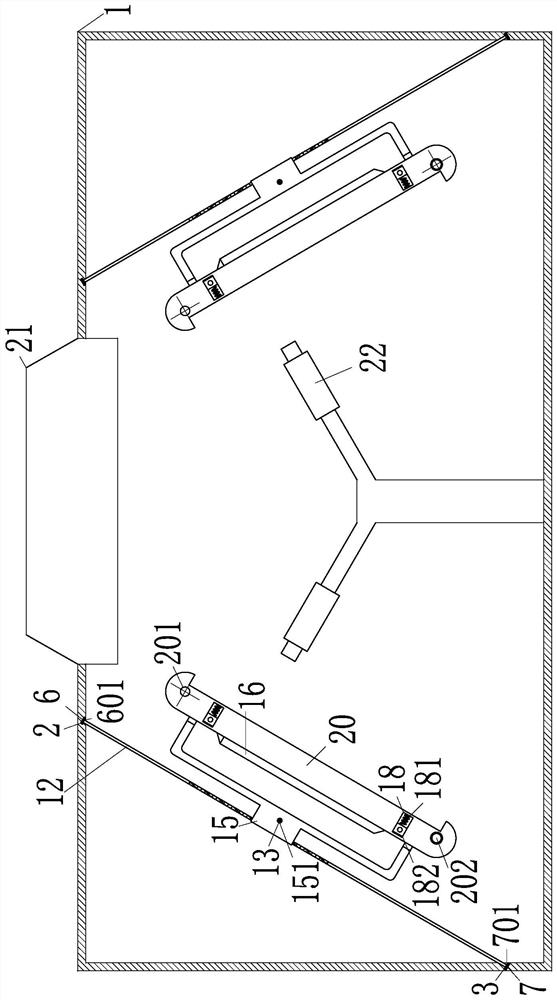

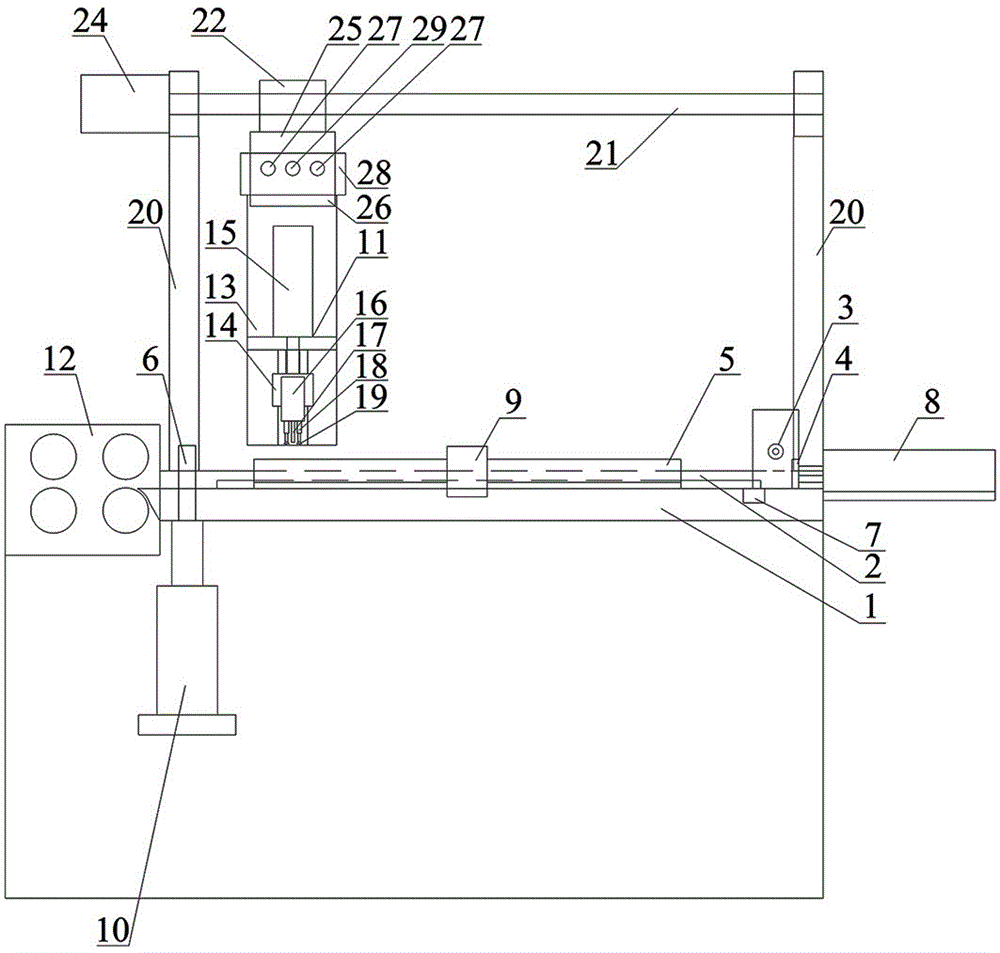

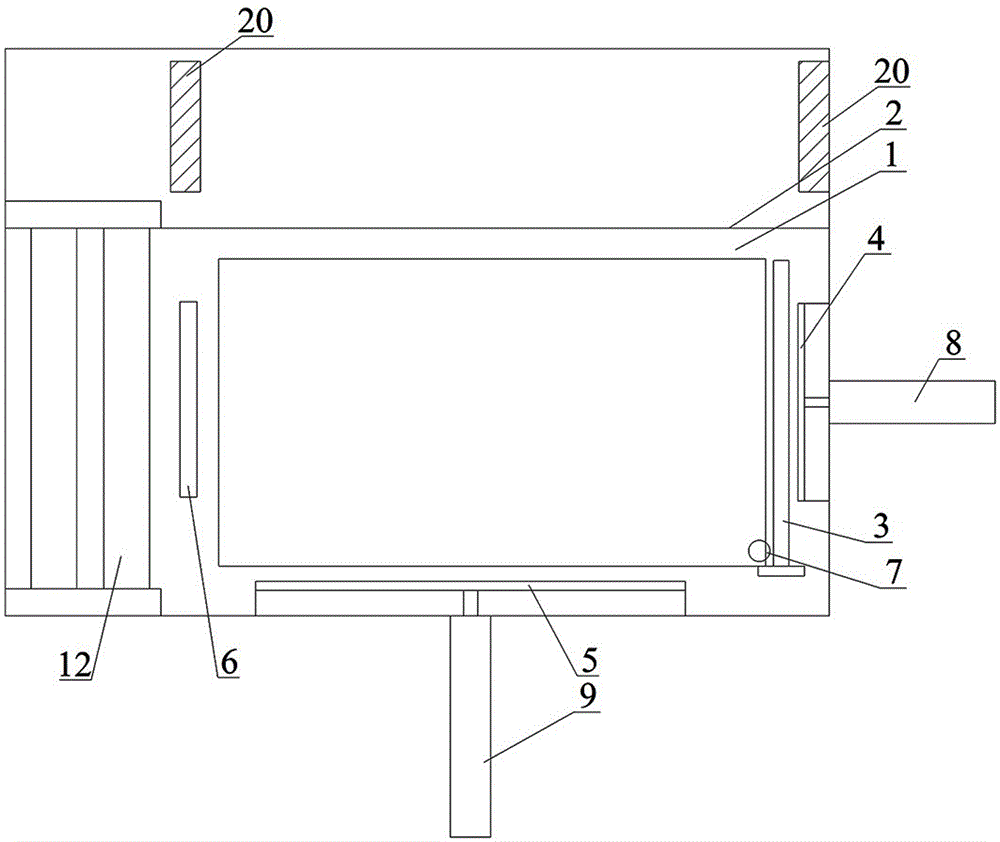

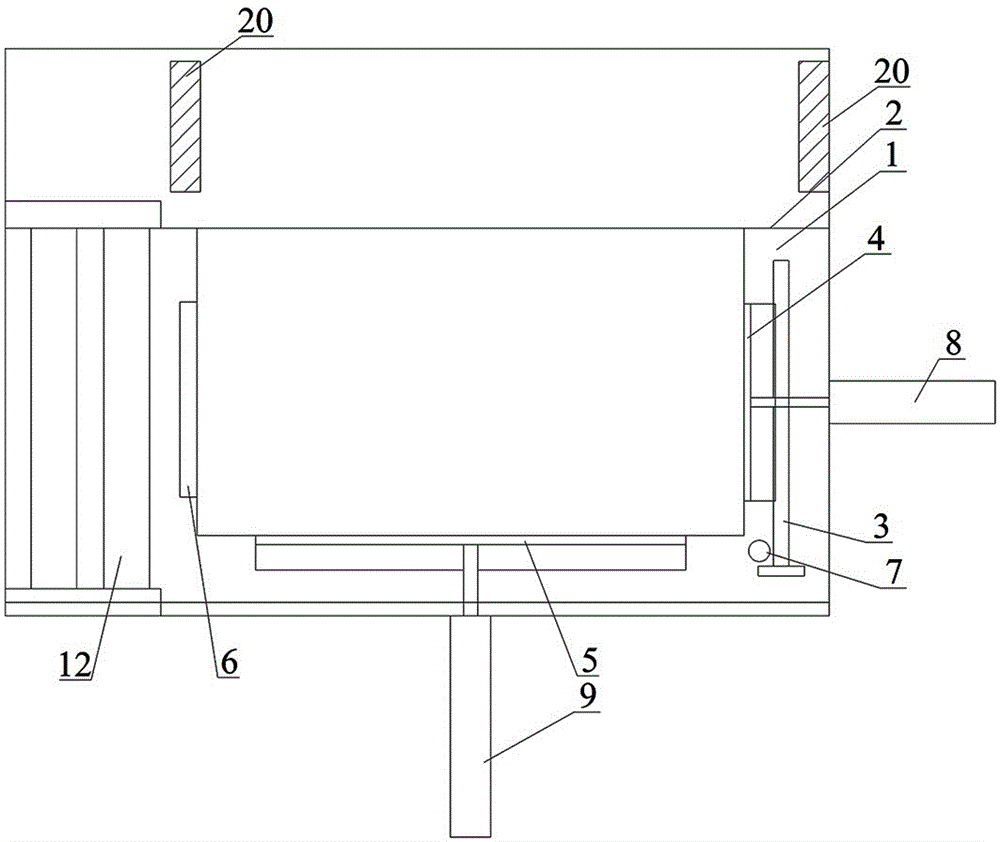

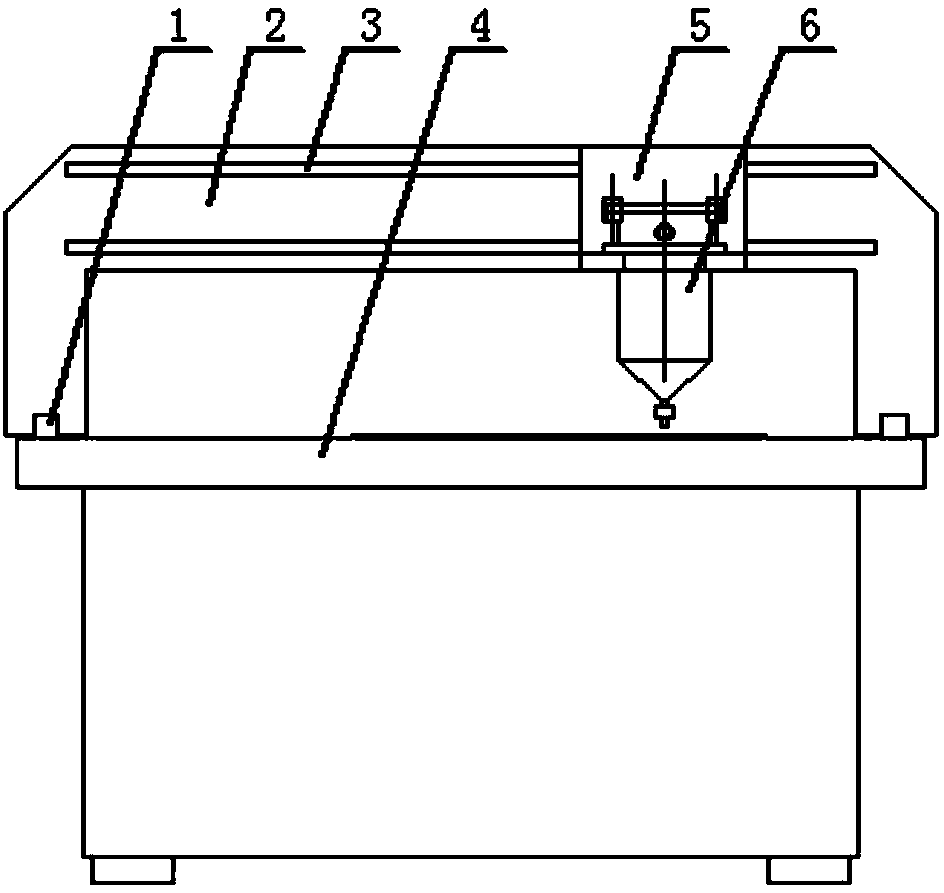

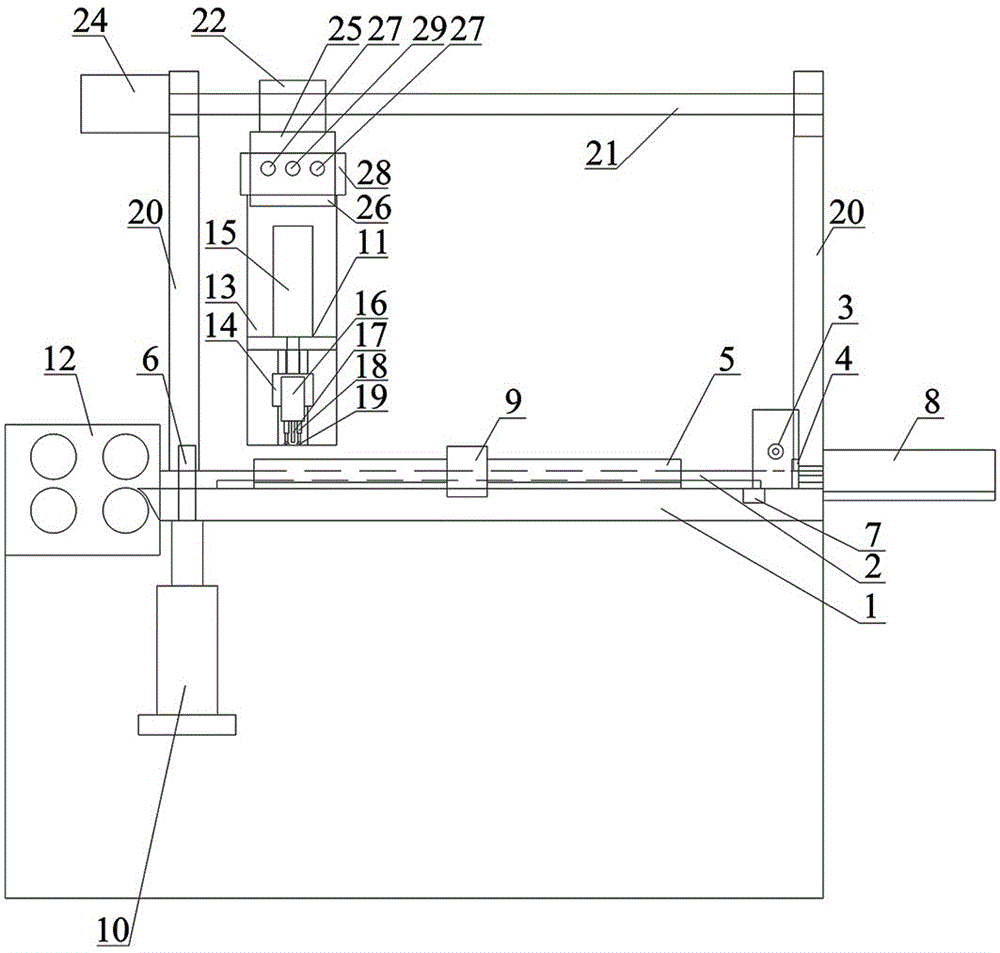

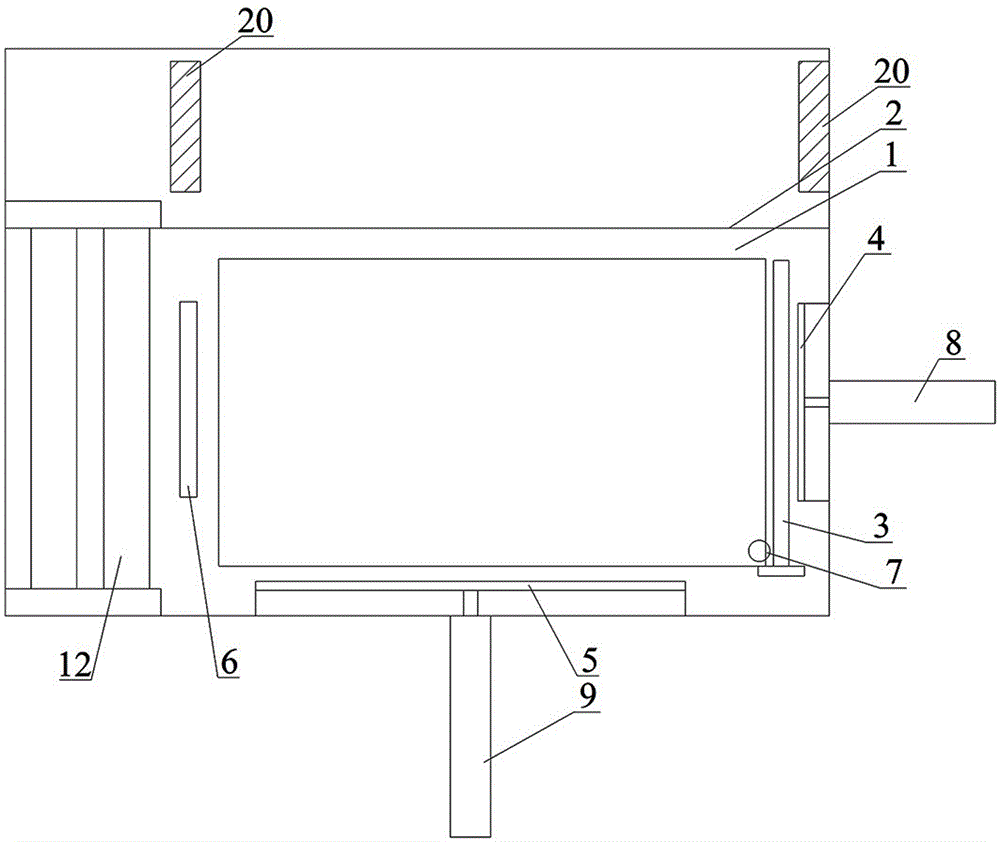

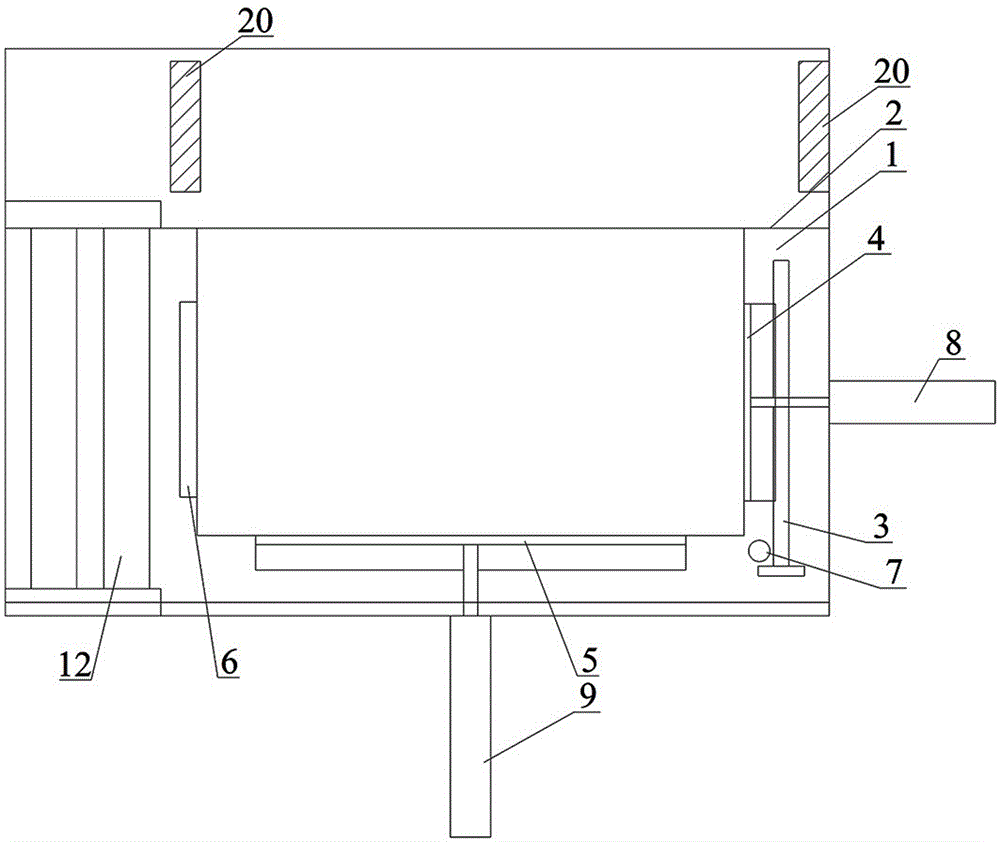

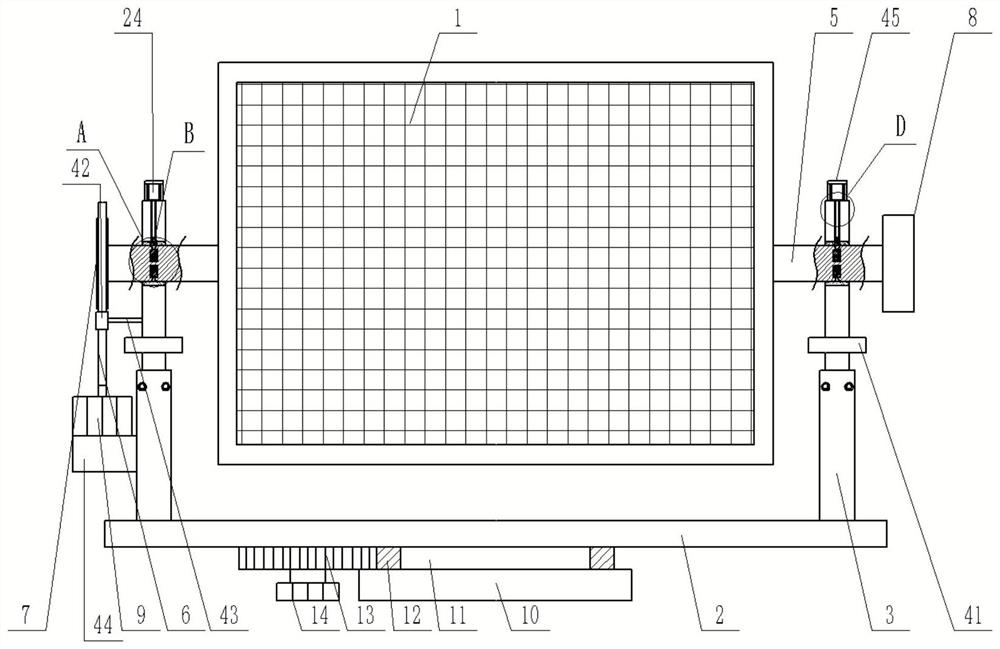

A fully automatic two-dimensional drilling device for beveled plate and its processing method

InactiveCN104626285BHigh degree of automationHigh positioning accuracyStationary drilling machinesProgrammable logic controllerEngineering

The invention discloses a full-automatic two-dimensional beveled plate drilling device. The device comprises a worktable (1), a drilling machine (11) and a PLC (programmable logic controller), wherein a rear side stop surface (2), a left ejector plate (4), a backward ejector plate (5) and a left-side limiting plate (6), which are used for positioning beveled plates, are formed on the worktable (1); cylinders which drive the left ejector plate (4), the backward ejector plate (5) and the left-side limiting plate (6) to move are connected with the PLC; and the drilling machine (11) which can move along the left-right direction and the front-rear direction is arranged on the upper part of the worktable (1). The device disclosed by the invention has the beneficial effects that the degree of automation is high, the positioning accuracy is high, and the machining efficiency and yield are improved; and moreover, any part of a whole beveled plate can be drilled by virtue of two-dimensional motion of the drilling machine, and the device can be applied to machining of the beveled plates with different drilling positions and is wide in application range.

Owner:BILLION GOLD FURNITURE

A three-degree-of-freedom coaxial output mechanism with wire transmission

InactiveCN105690374BSmall moment of inertiaAxisymmetricProgramme-controlled manipulatorGear driveThree degrees of freedom

Owner:TIANJIN UNIV

A one-to-many automatic docking system

ActiveCN104445035BIncrease the number ofIngenious designLiquid transferring devicesButt jointEngineering

Owner:杭州开源科派思智能科技有限公司

Laser film carving machine for thin-film solar cell panel

PendingCN114273787ARealize vertical transformationRealize two-dimensional movementLaser beam welding apparatusElectrical batteryThin membrane

The invention belongs to the technical field of thin-film solar cells, and particularly relates to a laser film carving machine for a thin-film solar cell panel, which is characterized in that a winding roller wound with the thin-film solar cell panel can be mounted in a processing groove through structural modification of a traditional horizontal laser film carving machine, and is matched with a laser at the bottom of a box body in the processing groove; the horizontal type laser film carving machine is simple in structure and convenient to operate, electrical machining of a battery panel is completed, vertical transformation of the horizontal type laser film carving machine is achieved, compared with a traditional horizontal type structure, the occupied area of the device is reduced, in addition, two-dimensional movement can be achieved in a moving system composed of a motor, a bidirectional lead screw, a polished rod, a sliding groove and a sliding block through the two machining grooves which are symmetrically arranged in a splayed shape, and the machining efficiency is improved. And therefore, the processing of the battery panel on the two winding rollers can be completed simultaneously, and the production efficiency is improved.

Owner:蒋伟

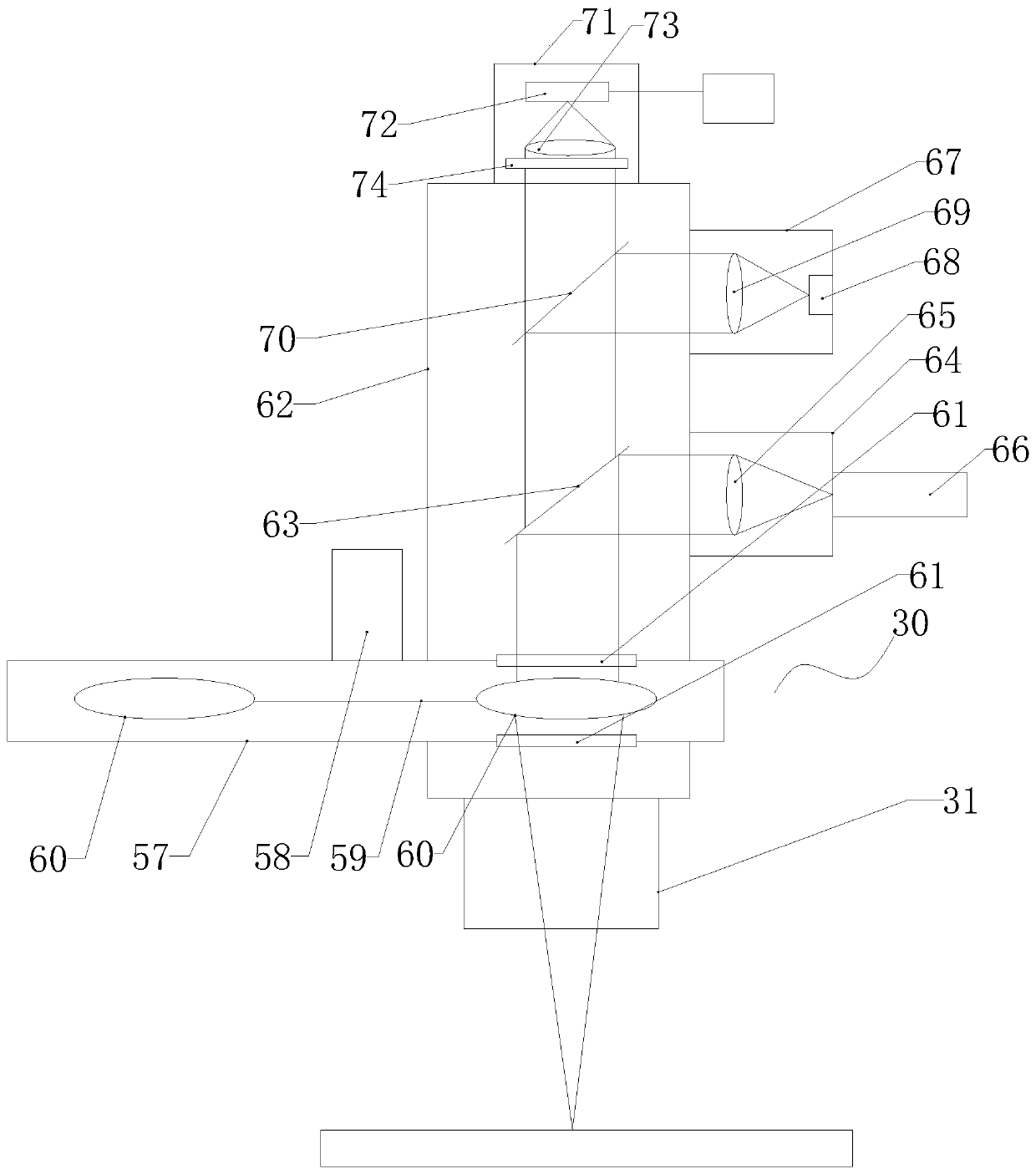

A New Optical Arm Amplified Two-Dimensional Linear Measuring Head

ActiveCN105180814BCompensation for positioning deviationEasy to measureUsing optical meansPhotovoltaic detectorsBatch processing

The invention discloses a novel light arm amplifying two-dimensional linear probe. The probe comprises two laser sources for transmitting two laser beams and a probe base for reflecting the laser beams. The probe base comprises at least two reflecting surfaces, a measurement rod, and a measurement ball. The probe also comprises two photoelectric detectors for receiving the two reflected laser beams, a translation part for driving the probe base or the photoelectric detectors and the probe base to move linearly to change the positions of reflection points of the two laser beams on the reflecting surfaces, a reset part for resetting the probe base to an initial position, and a processing system for calculating and obtaining the displacement change value of the measurement ball. The probe can obtain the displacement values in two different linear directions through the two photoelectric detectors to compensate for the measurement deviation of a to-be-measured workpiece during positioning and to obtain more accurate measurement coordinates, so that the measurement precision is improved, the structure is simplified, the production cost is lowered, and batch processing and production are facilitated.

Owner:成都中科卓尔智能科技集团有限公司

Non-contact image detection device

InactiveCN106018428AAvoid influenceRealize motion controlTelevision system detailsMaterial analysis by optical meansComputer hardwareCamera control

The invention discloses a non-contact image detection device. The device comprises an image acquisition device and a worktable. The worktable comprises a carrier belt conveying rail, a camera control rail is arranged above the carrier belt conveying rail in parallel, and the two ends of the camera control rail are fixed to lifting control devices. The image acquisition device comprises a CCD camera, a camera control device, a signal processing device and a main controller which are sequentially connected, the main controller is connected with a display device, and the CCD camera is arranged on the camera control rail and provided with an electrostatic protection device which can avoid influences of static electricity on the CCD camera.

Owner:成都格虹电子科技有限责任公司

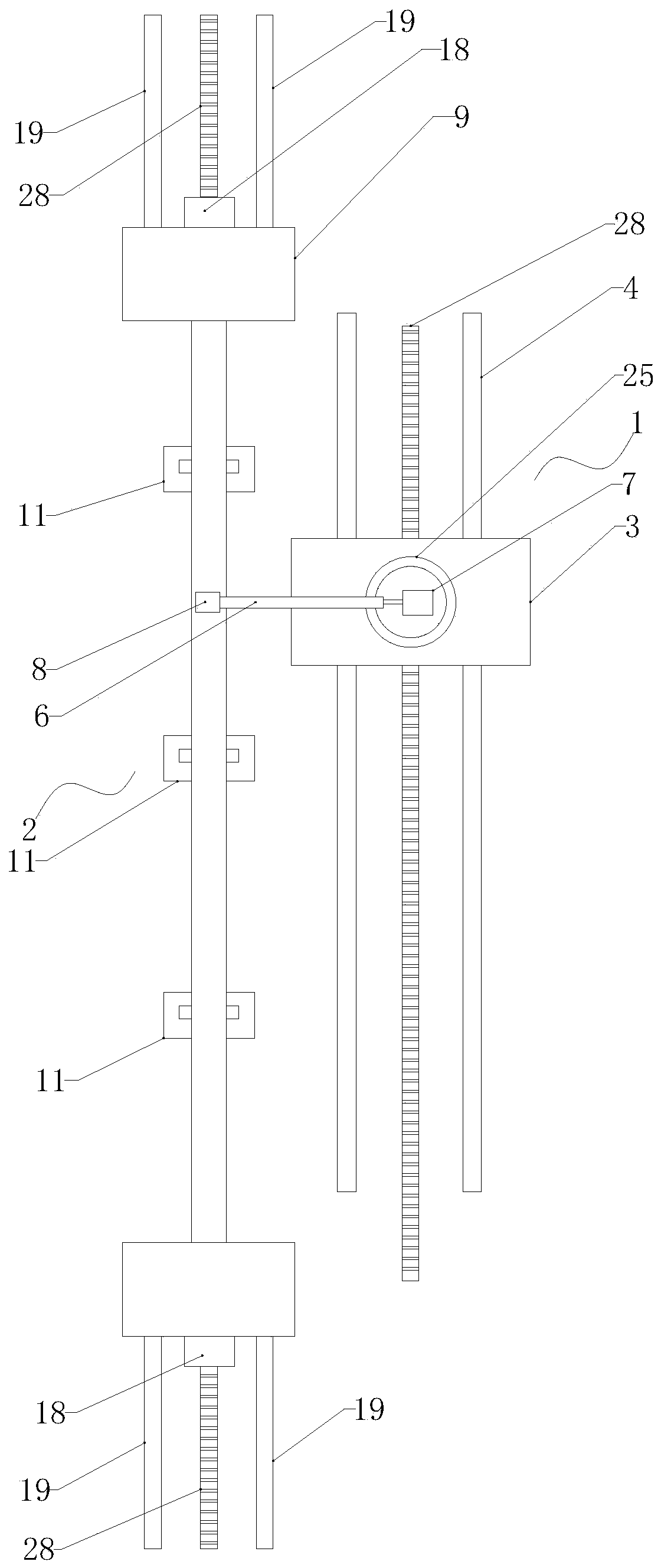

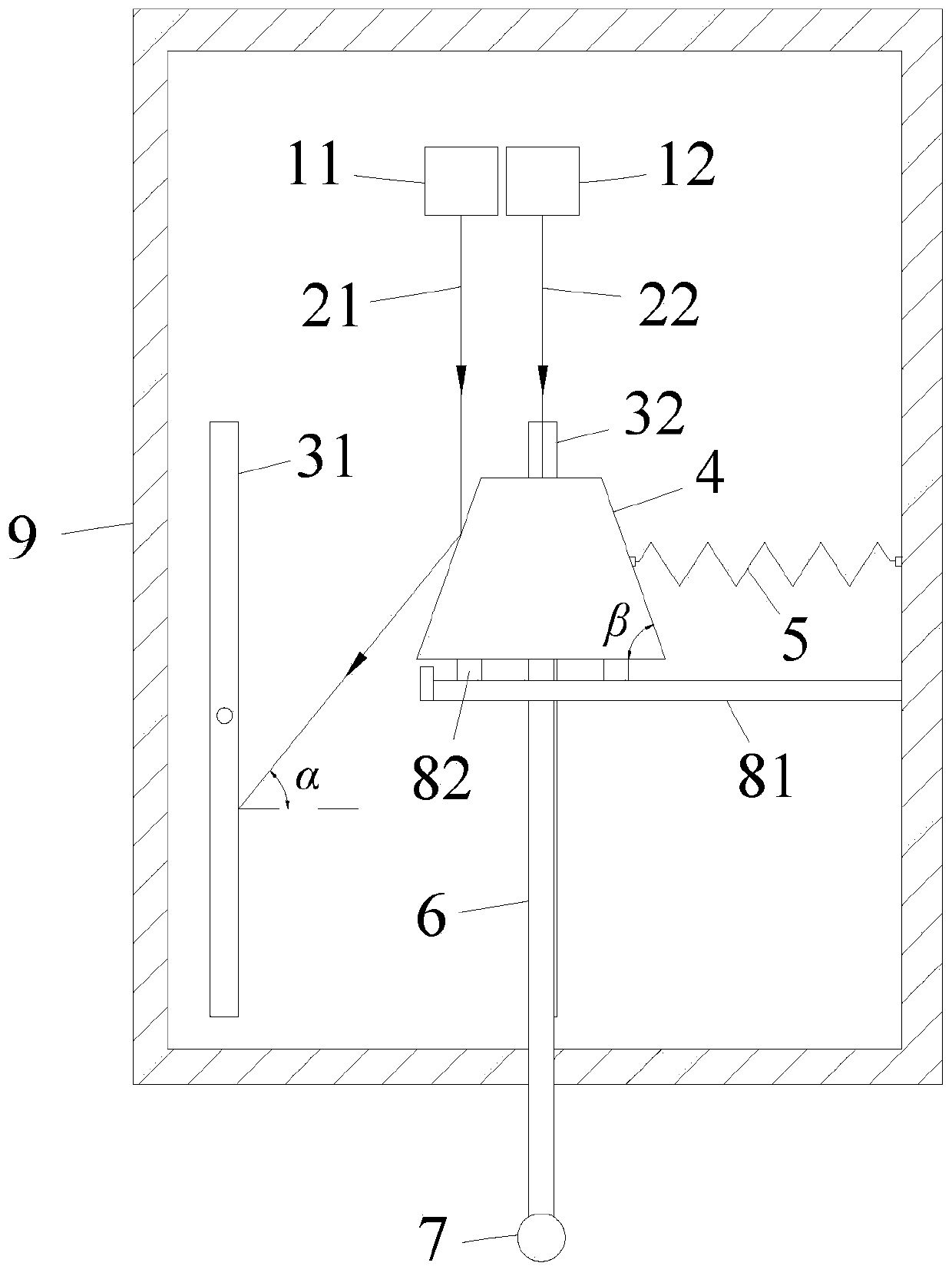

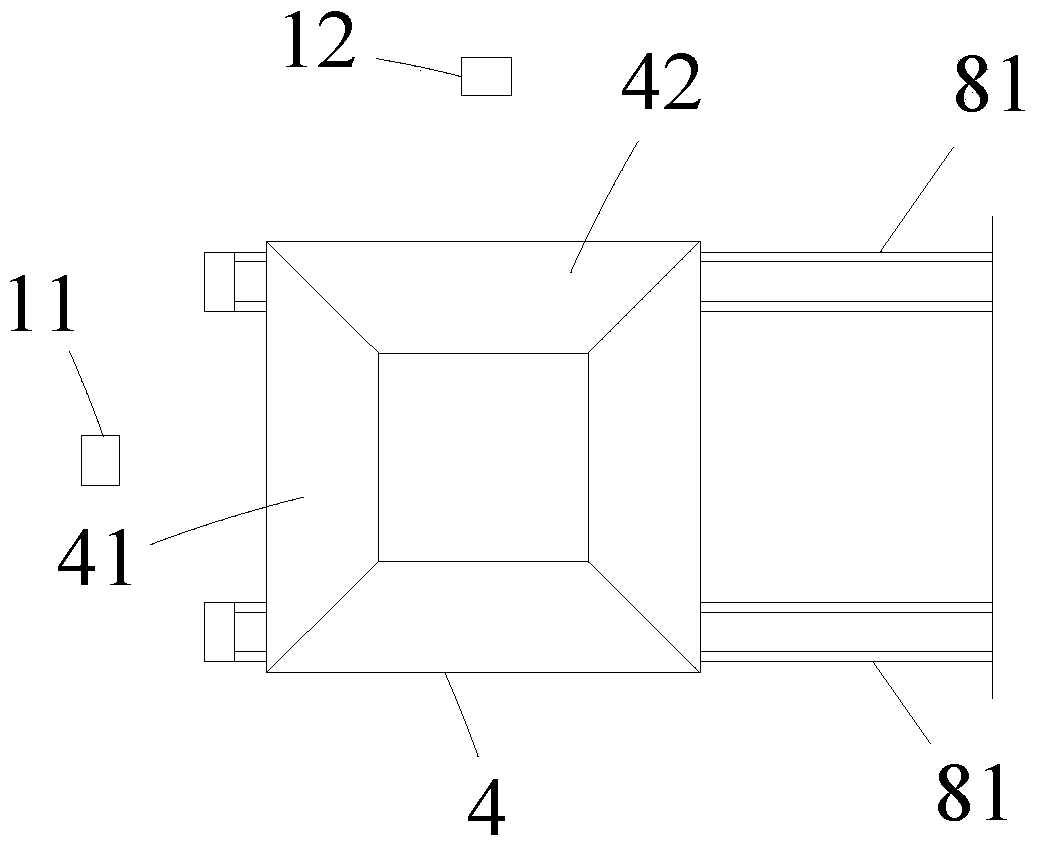

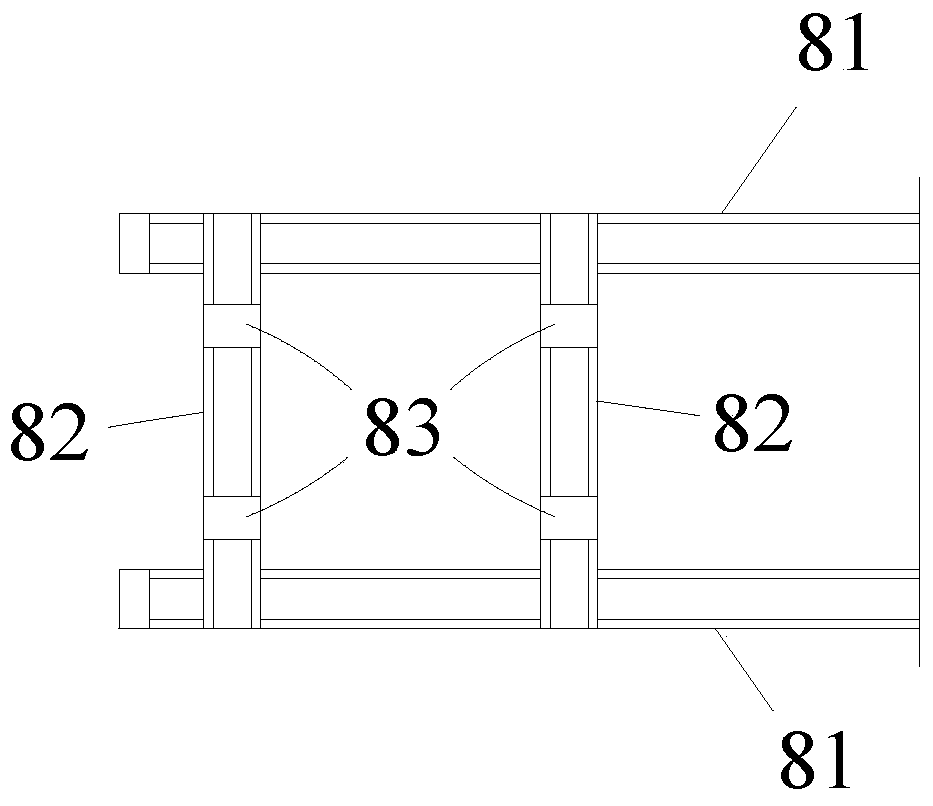

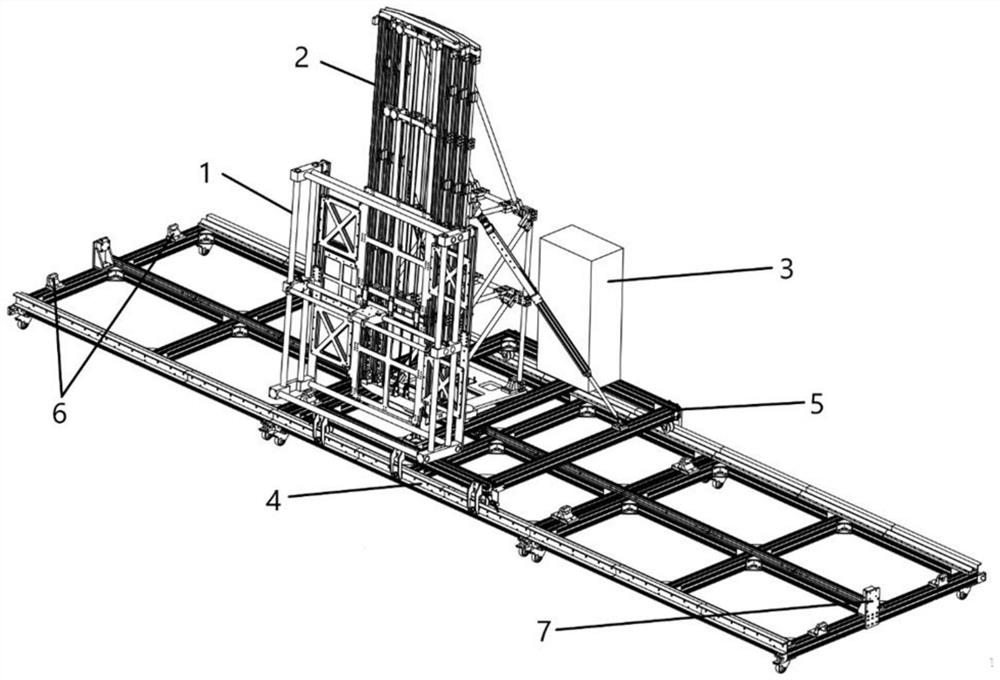

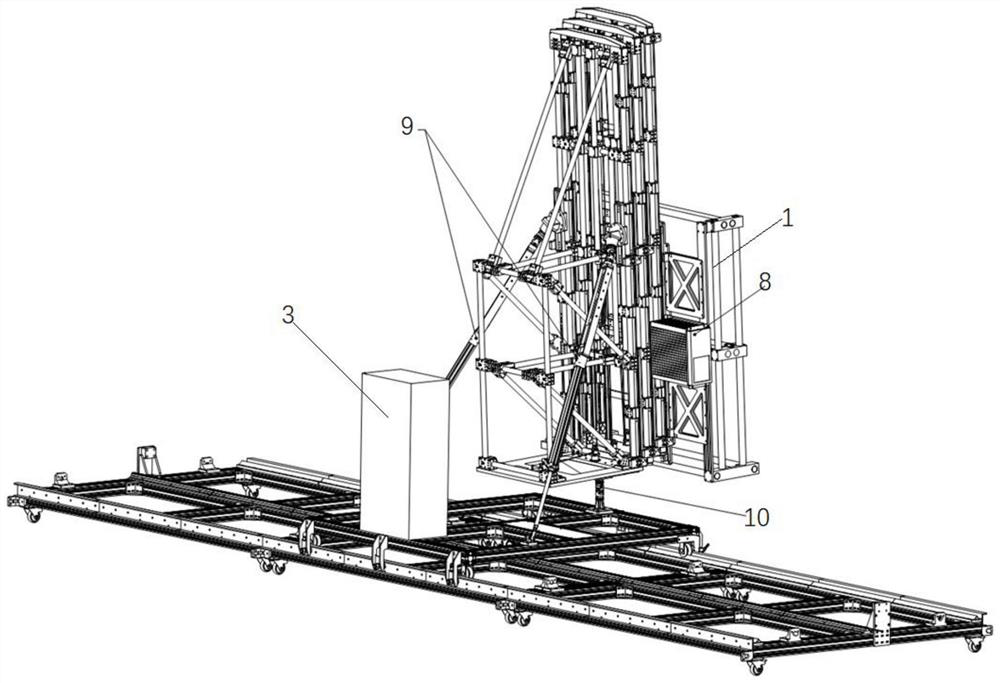

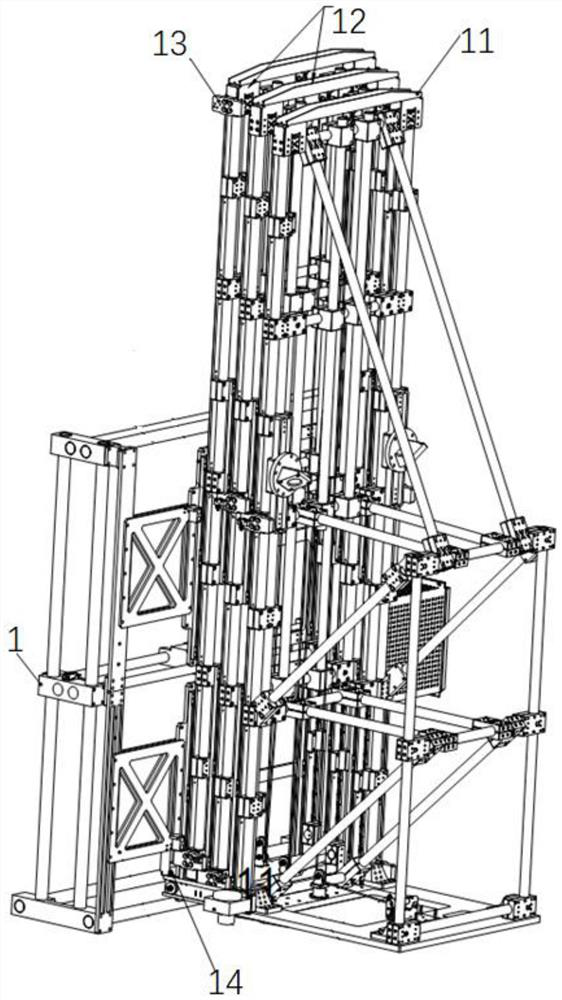

High-precision large-area electromagnetic field two-dimensional space field distribution scanning device and method

PendingCN113092874ARealize two-dimensional movementAdjust the horizontal angleElectromagentic field characteristicsMeasuring instrumentMechanical engineering

The invention discloses a high-precision large-area electromagnetic field two-dimensional space field distribution scanning device and method. The scanning device comprises a ground rail, a walking frame, a lifting frame, a control box, a scanning frame and an instrument frame, wherein the walking frame is movably matched on the ground rail; the lifting frame and the control box are mounted on the walking frame; theinstrument frame is arranged on the scanning frame; the lifting frame comprises a base part and a lifting part, the base part is supported on the walking frame in an angle-adjustable mode through an inclined supporting rod and a universal seat, the lifting part is arranged on the base part in a lifting mode, the scanning frame is arranged at the transmission tail end of the lifting part, the scanning frame is used for installing a receiving probe to conduct high-precision scanning, the instrument frame is used for erecting a measuring instrument to collect, display and process test data, and the control box is used for controlling the whole scanning device to scan according to a preset or instructed scanning track. Large-area and high-precision scanning of two-dimensional space field distribution of the electromagnetic field is realized, automation is realized, and measurement is convenient.

Owner:CHINA SHIP DEV & DESIGN CENT

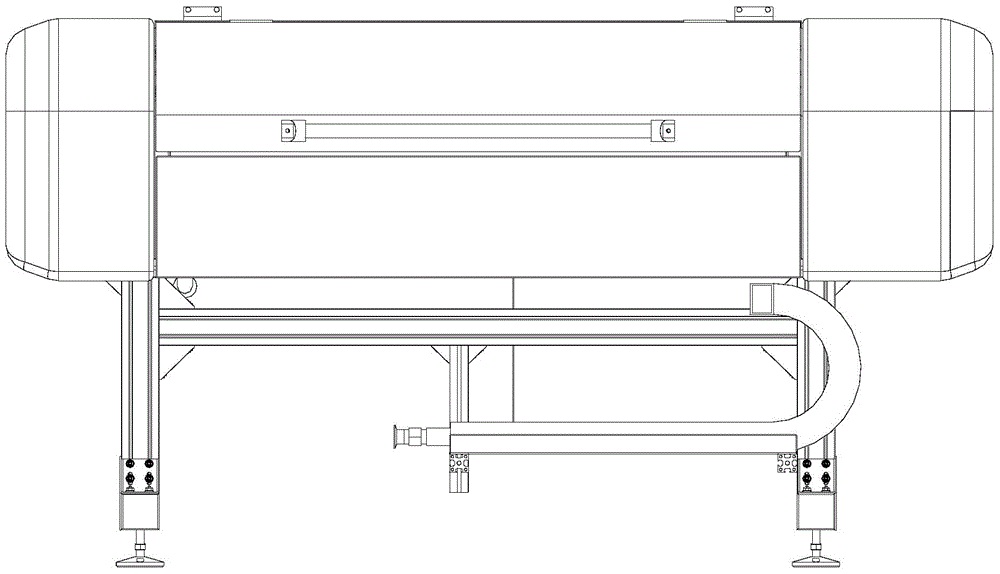

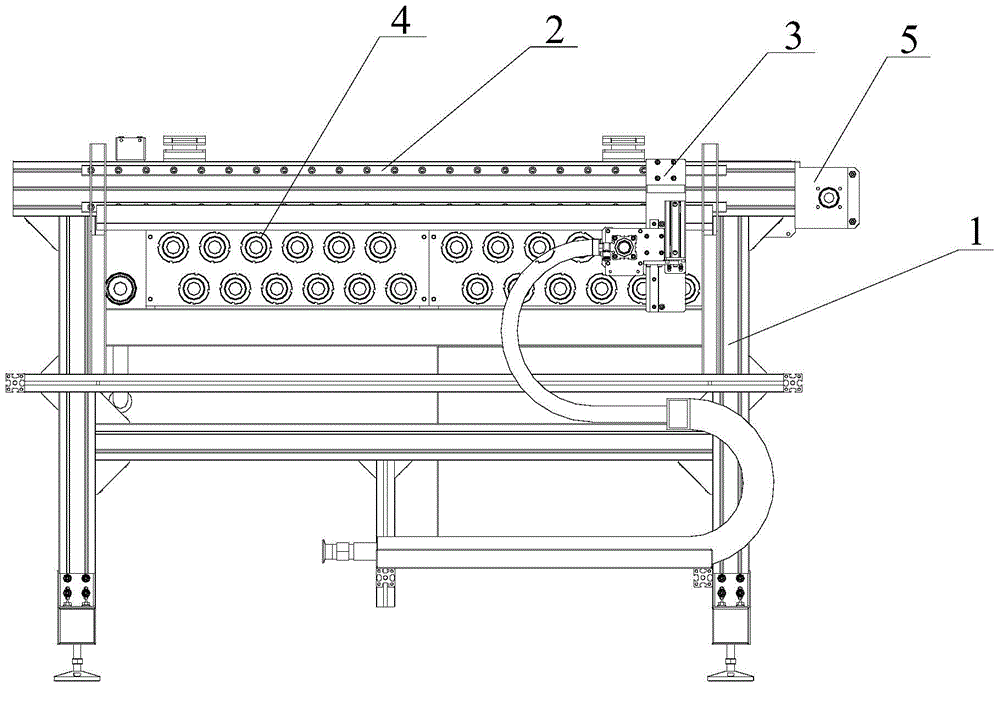

Fluid distribution system

ActiveCN104528626ARealize two-dimensional movementIncrease the number ofLiquid transferring devicesDistribution systemEngineering

The invention discloses a fluid distribution system. The fluid distribution system comprises a feeding device, a one-to-many automatic abutting joint device and an output device, wherein the one-to-many automatic abutting joint device is connected with the feeding device and the output device is connected with the one-to-many automatic abutting joint device; the one-to-many automatic abutting joint device comprises a support, a horizontal guide rail pair, an abutting joint mechanism and a plurality of pipeline joints; the horizontal guide rail pair is arranged on the support and comprises a horizontal guide rail and a horizontal sliding block which is matched with the horizontal guide rail in a sliding mode; the abutting joint mechanism is arranged on the horizontal sliding block; the plurality of pipeline joints are arranged on the support and matched with the abutting joint mechanism. According to the fluid distribution system, the one-to-many automatic abutting joint can be implemented, the structure is simple and reliable, the switching is free, and the movement positioning is accurate. In the optimal technical scheme, the abutting joint mechanism comprises a vertical guide rail pair, the two-dimensional motion of an abutting joint is implemented under the action of the horizontal guide rail pair and the vertical guide rail pair, and the number of the pipeline joints can be greatly increased due to the fact that a plurality rows of pipeline joints can be set, the fluid distribution system is particularly suitable for the dyeing and printing field, and the application prospect is broad.

Owner:杭州开源科派思智能科技有限公司

Drum brake of electric bicycle

InactiveCN103498881AFacilitate safe brakingRealize the braking functionDrum brakesCycle brakesEngineeringTorsion spring

The invention discloses a drum brake of an electric bicycle. The brake comprises an outer shell, a left friction piece, a right friction piece, a rocker arm shaft and a rocker arm, wherein the left friction piece and the right friction piece are movably arranged on the outer shell, a rear fixing base is arranged at the rear end of the outer shell, the rocker arm is connected with the outer shell through a torsion spring, a left sliding groove is formed in the left of the rocker arm shaft, and the front end of the left friction piece is located in the left sliding groove of the rocker arm shaft. The brake further comprises a rear sliding shaft and a front sliding shaft, a front fixing base is arranged at the front end of the shell body, a left sliding groove and a right sliding groove are formed in the left end of the rear sliding shaft and the right end of the rear sliding shaft respectively, the rear sliding shaft is located in a rear sliding shaft hole formed in the rear fixing base, the rear end of the left friction piece and the rear end of the right friction piece are located in a left sliding groove and a right sliding groove of the front sliding shaft, the front sliding shaft is located in a front sliding shaft hole formed in the front fixing base, the right sliding groove is formed in the right end of the front sliding shaft, the left end of the front sliding shaft abuts against the rocker arm shaft, the front end of the right friction piece is located in the right sliding groove of the front sliding shaft, the bottom face of the left sliding groove of the rear sliding shaft and the bottom face of the right sliding groove of the rear sliding shaft are both arc-shaped faces, and the bottom face of the right sliding groove of the front sliding shaft is an arc-shaped face.

Owner:盐城市诚良高尔夫电动车配件有限公司

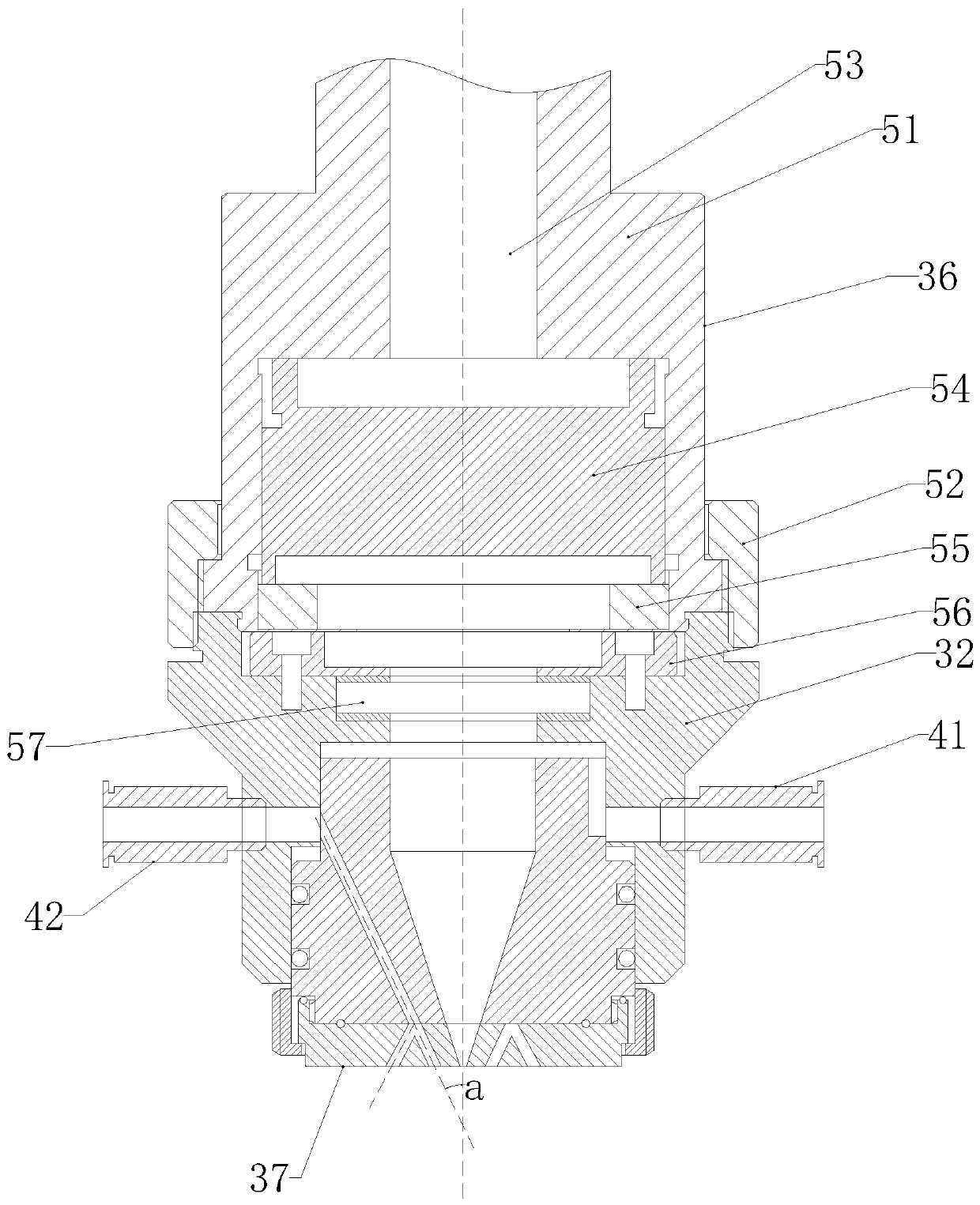

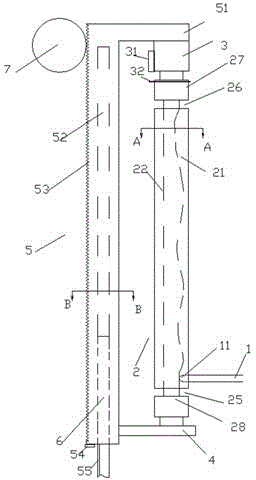

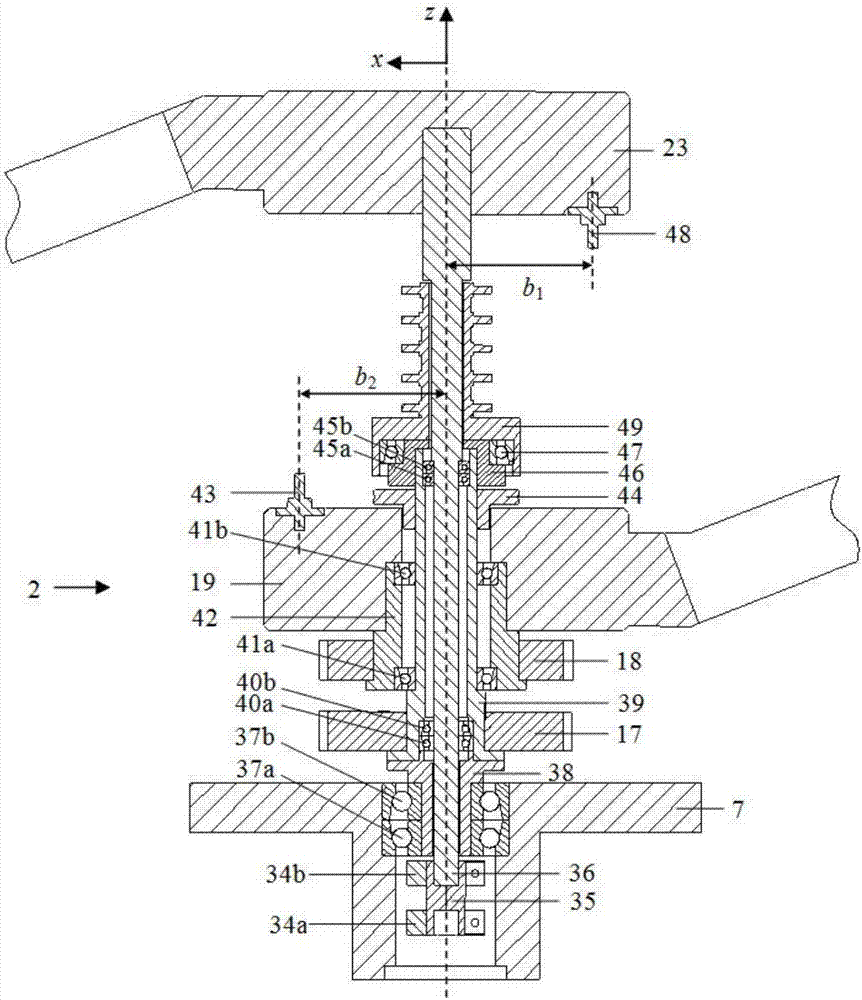

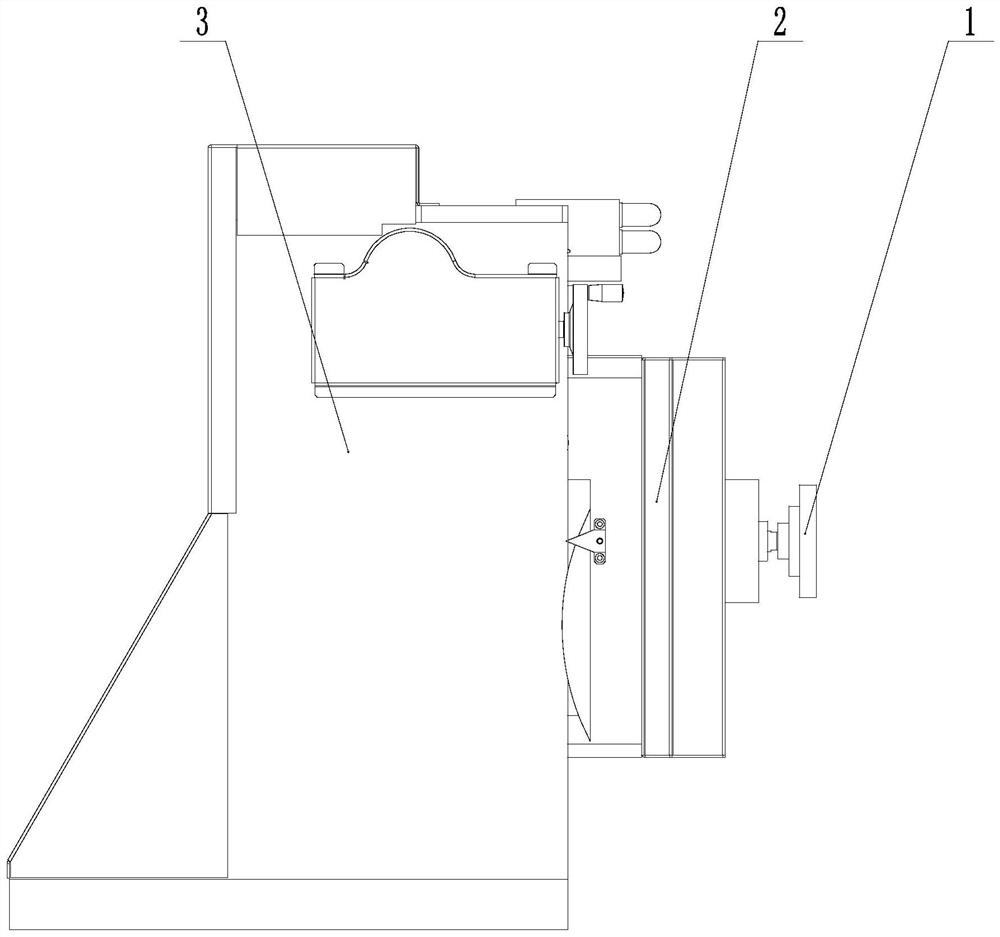

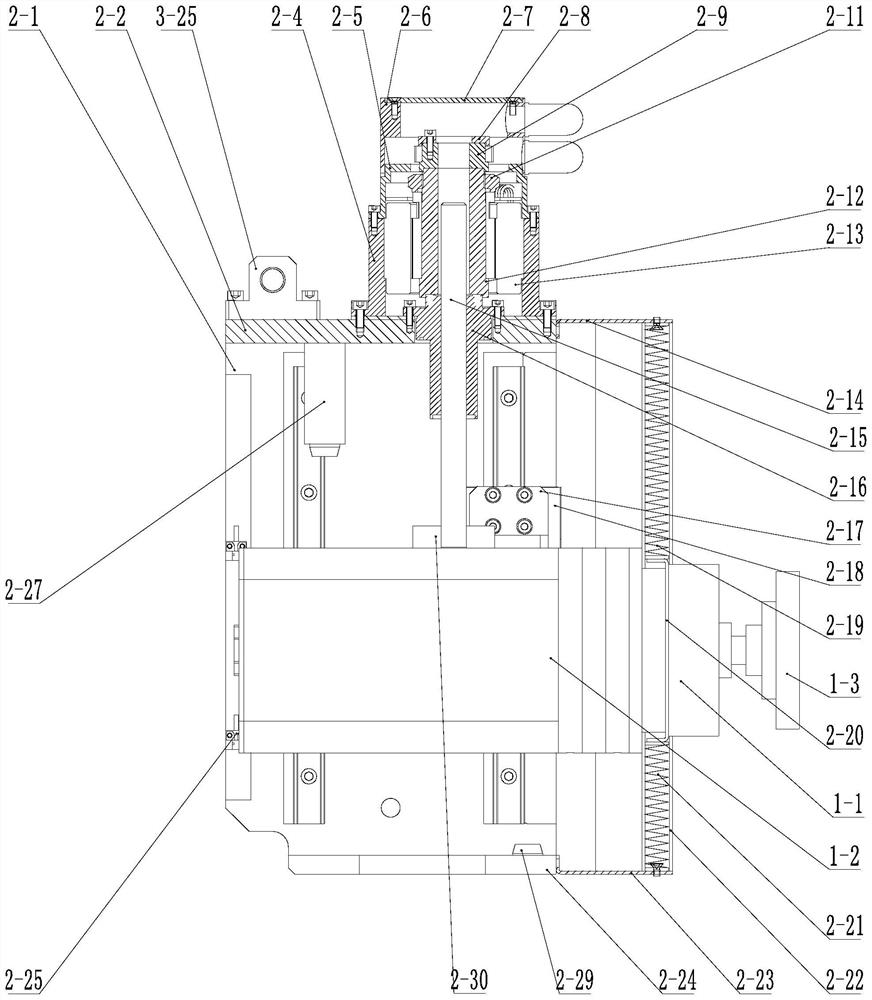

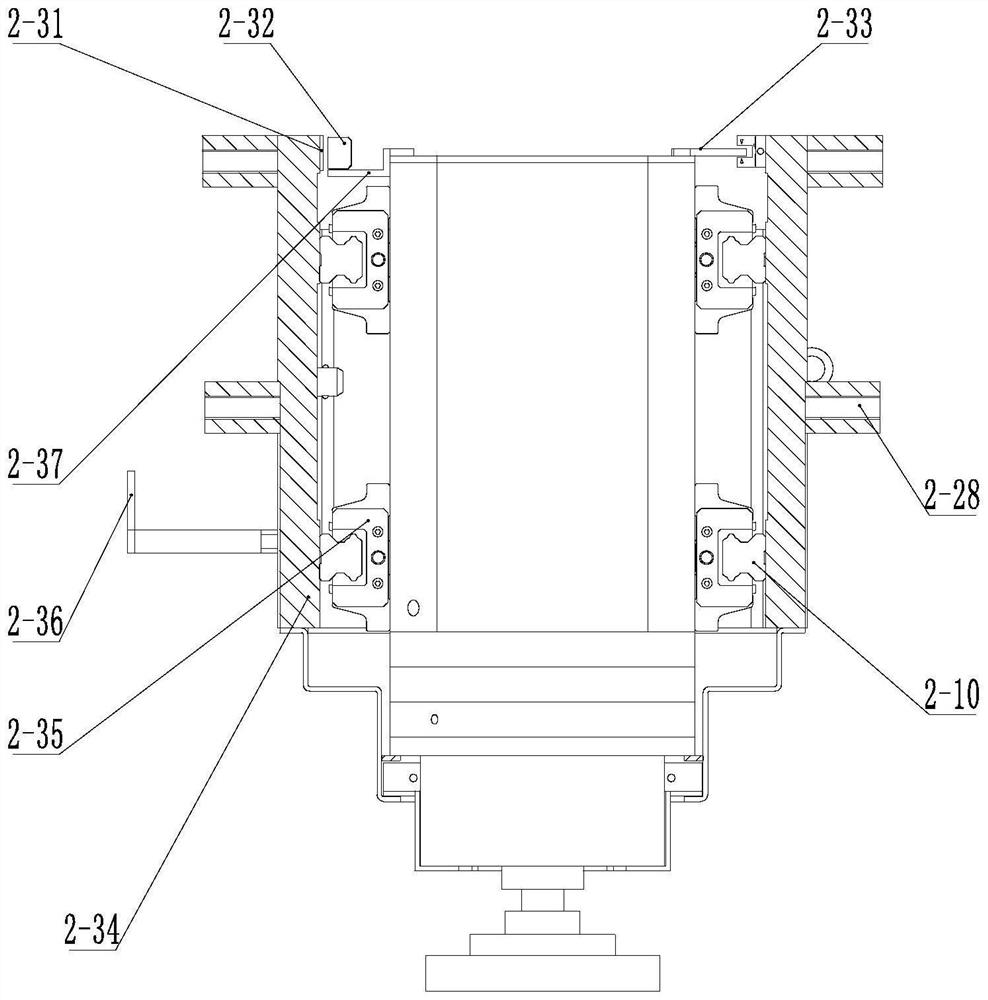

Spindle pitching lifting device of diamond cutter sharpening machine tool

ActiveCN114310502AGrinding direction changeTo meet manufacturing needsGrinding carriagesGrinding drivesElectric machineryStructural engineering

The invention relates to a diamond cutter sharpening machine tool spindle pitching lifting device which comprises a high-speed spindle component, a lifting frame mechanism, a linear guide rail guide mechanism, a lifting limiting mechanism and a motor driving mechanism which are arranged in the spindle lifting component, and a pitching frame mechanism, an arc guide rail guide mechanism and a hand wheel mechanism which are arranged in the spindle pitching component. The main shaft lifting component drives the high-speed main shaft component to linearly lift and move, and the main shaft pitching component drives the main shaft lifting component and the high-speed main shaft component to pitch and swing, so that the lifting and pitching functions of the high-speed main shaft component are realized. Through the combined action of the main shaft lifting component and the main shaft pitching component and the cooperation with the reciprocating movement of the whole equipment, the lifting and pitching of the main shaft and the two-dimensional movement between the main shaft and the cutter can be realized, and then the change of the grinding direction of the cutter in the machining process is realized, so that the manufacturing requirement of the high-precision diamond cutter is met.

Owner:姜堰经济开发区科创中心

An electric bicycle drum brake

InactiveCN103498881BFacilitate safe brakingRealize the braking functionDrum brakesCycle brakesEngineeringTorsion spring

The invention discloses a drum brake of an electric bicycle. The brake comprises an outer shell, a left friction piece, a right friction piece, a rocker arm shaft and a rocker arm, wherein the left friction piece and the right friction piece are movably arranged on the outer shell, a rear fixing base is arranged at the rear end of the outer shell, the rocker arm is connected with the outer shell through a torsion spring, a left sliding groove is formed in the left of the rocker arm shaft, and the front end of the left friction piece is located in the left sliding groove of the rocker arm shaft. The brake further comprises a rear sliding shaft and a front sliding shaft, a front fixing base is arranged at the front end of the shell body, a left sliding groove and a right sliding groove are formed in the left end of the rear sliding shaft and the right end of the rear sliding shaft respectively, the rear sliding shaft is located in a rear sliding shaft hole formed in the rear fixing base, the rear end of the left friction piece and the rear end of the right friction piece are located in a left sliding groove and a right sliding groove of the front sliding shaft, the front sliding shaft is located in a front sliding shaft hole formed in the front fixing base, the right sliding groove is formed in the right end of the front sliding shaft, the left end of the front sliding shaft abuts against the rocker arm shaft, the front end of the right friction piece is located in the right sliding groove of the front sliding shaft, the bottom face of the left sliding groove of the rear sliding shaft and the bottom face of the right sliding groove of the rear sliding shaft are both arc-shaped faces, and the bottom face of the right sliding groove of the front sliding shaft is an arc-shaped face.

Owner:盐城市诚良高尔夫电动车配件有限公司

A fully automatic plate two-dimensional drilling device and its processing method

ActiveCN104647479BHigh degree of automationHigh positioning accuracyDrilling machinesEngineeringFully automatic

The invention discloses a fully automatic two-dimensional plate drilling device which comprises a workbench (1), a drilling machine (11) and a PLC, wherein a rear position stopping face (2), a leftward ejecting plate (4), a backward ejecting plate (5) and a left limiting plate (6) which are used for positioning wood plates are arranged on the workbench (1), air cylinders for driving the leftward ejecting plate (4), the backward ejecting plate (5) and the left limiting plate (6) to act are all connected with the PLC, and the upper part of the workbench (1) is also provided with the drilling machine (11) which can move along the left-right direction and the front-rear direction. The drilling device disclosed by the invention has the beneficial effects that the degree of automation is high, the positioning accuracy is high, and the machining efficiency and the rate of finished products are improved; and due to the two-dimensional motion of the drilling machine, the any position of a whole wood plate can be drilled, and the device can be applied to the processing of plates with different drilling positions, and therefore, the drilling device is wide in application scope.

Owner:广东郑太机械设备有限公司

Tool processing method

InactiveCN104084844AStable mold changeMachining shape influenceCopying process control systemsEngineeringMachine tool

The invention provides a tool processing method. The method is characterized in that a profiling machine tool consisting of a cutter (1) and a cutter profiling device is arranged; the cutter profiling device comprises a profiling column (2) that is generally in a shape of a cylinder; an upper plug (27) and a lower plug (28) are respectively arranged at two ends of the cylinder; a medium profiling part is arranged between the upper plug (27) and the lower plug (27); four longitudinal profiling grooves are uniformly distributed in the medium profiling part along the circumferential direction; the profiling grooves are jointed with a jointing end part (11) of the cutter; at least one of the four longitudinal profiling grooves is a return groove (22); the profiling line of the return groove (22) is a plane; the rest longitudinal profiling grooves are curved grooves and used to control the feed rate of the cutter (1).

Owner:东莞市莱锐精密五金科技有限公司

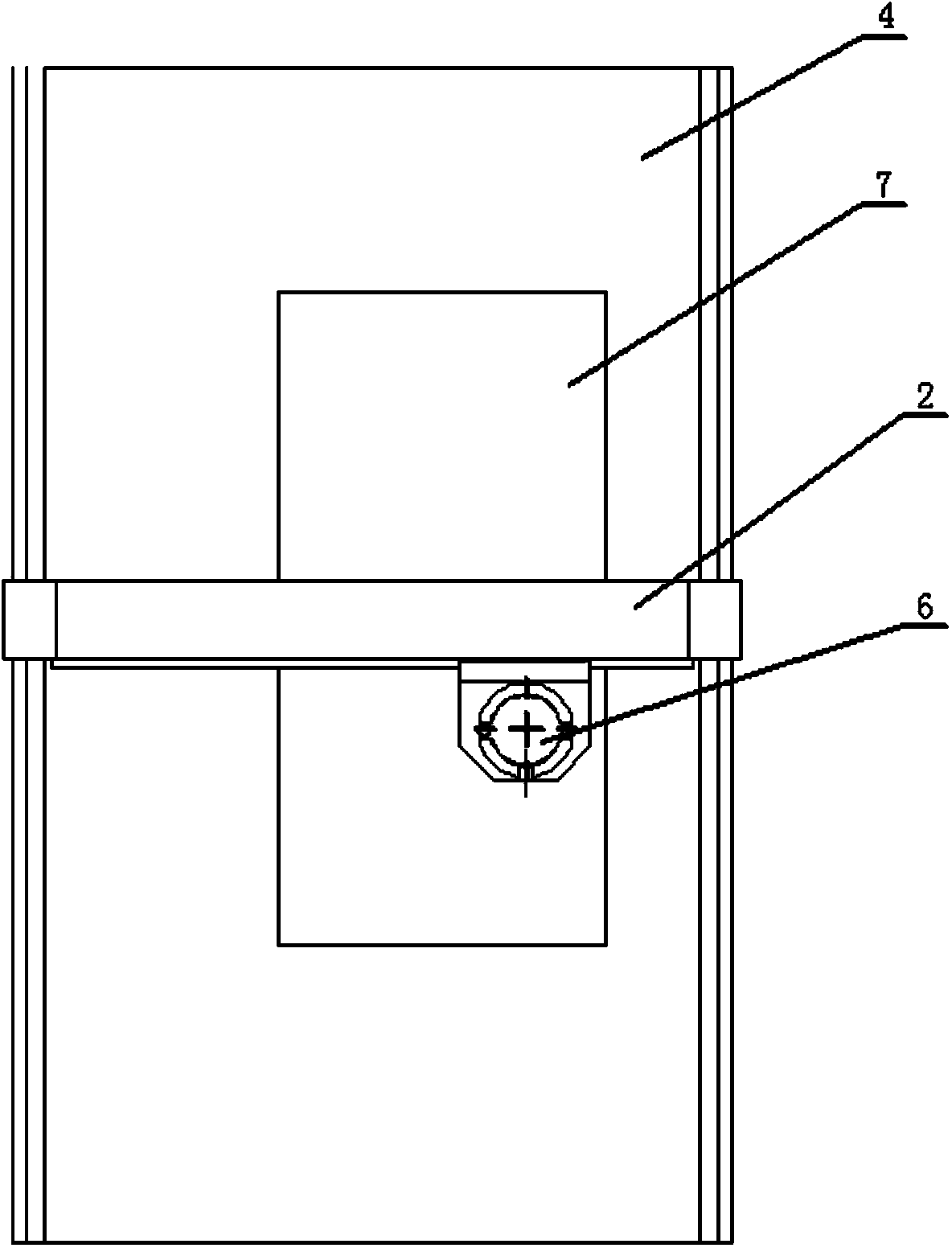

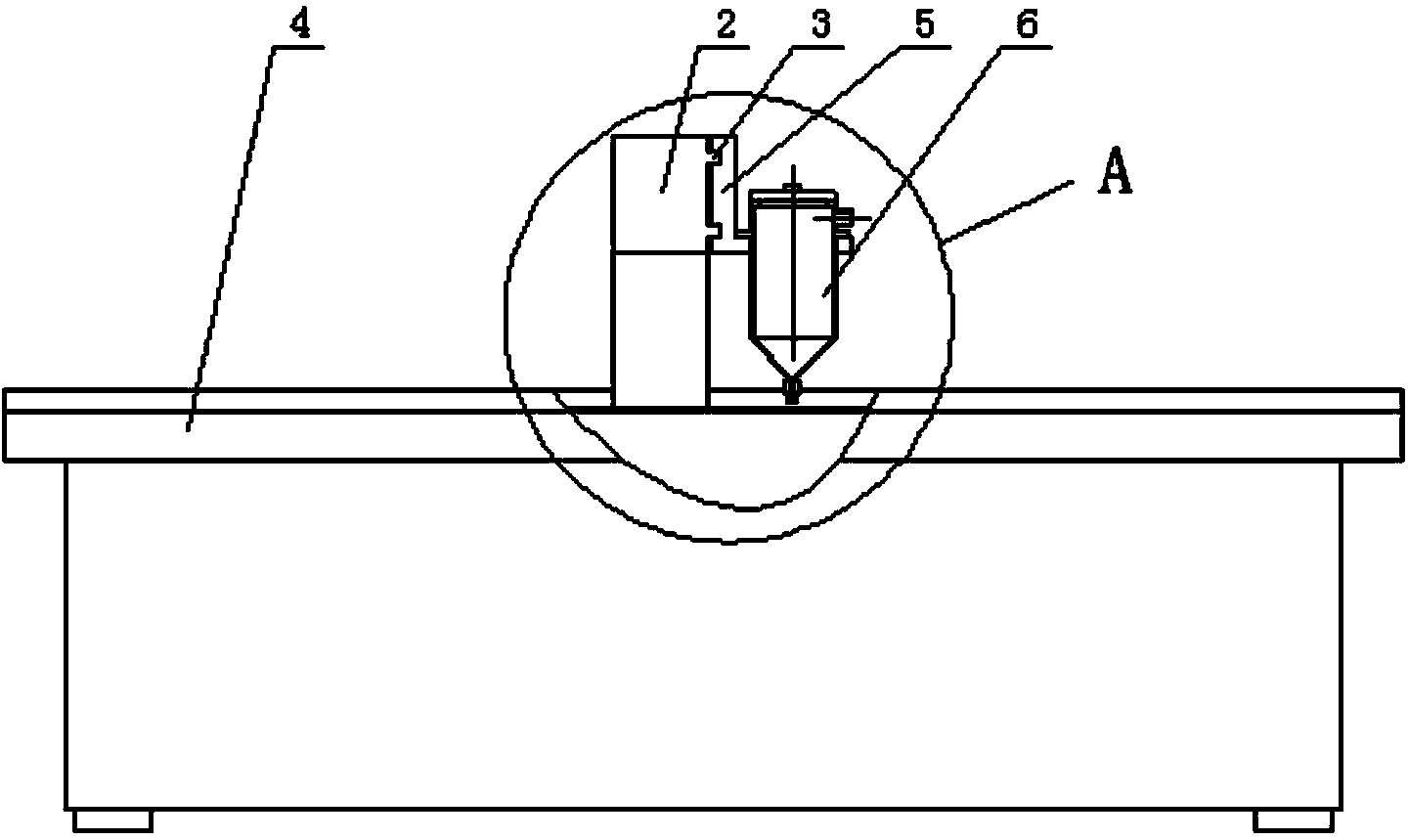

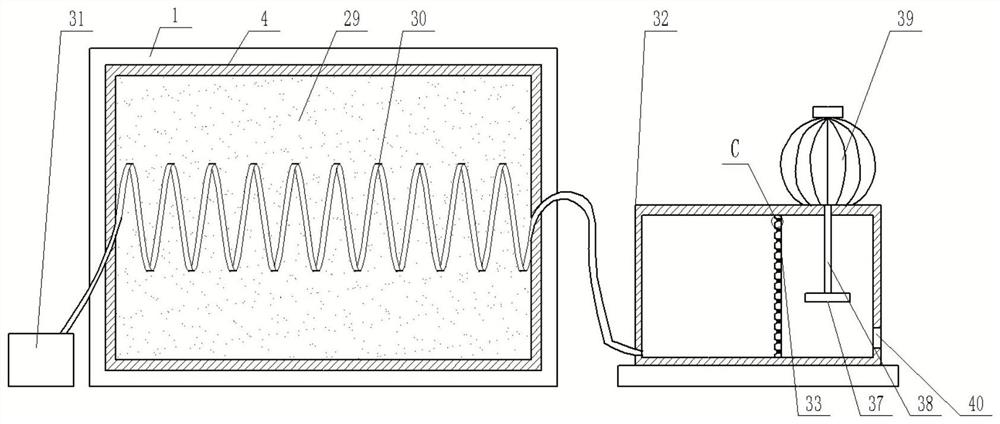

Powder coating machine special for vacuum glass

InactiveCN103553313ARealize two-dimensional movementExtended edge bandingGlass reforming apparatusEngineeringTraveling block

The invention relates to a powder coating machine special for vacuum glass. The powder coating machine consists of a worktable, a portal guide rail, a transverse pulley and a powder barrel, wherein two guide rails are symmetrically arranged on two longitudinal sides of the worktable; the portal guide rail is guided and operated on the guide rails in a sliding mode; a transverse sliding rail is arranged on the portal guide rail; the transverse pulley is guided and operated on the transverse sliding rail in a sliding mode the powder barrel is vertically and fixedly arranged on the transverse pulley; a barrel cover is sealed on the powder barrel; a compressed air inlet is formed in the upper part of the powder barrel; the lower end of the powder barrel is conical, and a powder outlet is formed in the lower end of the powder barrel. The powder coating machine longitudinally operates on the portal guide rail on the two sides of the worktable and transversely operates on the sliding rail, so that two-dimensional motion of the powder coating machine on the worktable is realized. By adopting the powder coating machine, edge sealing on a straight line is realized, arc-shaped edge sealing and edge sealing of irregular vacuum glass can also be realized, and the functions of glass powder edge sealing and opening sealing are greatly expanded.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

A two-dimensional drilling device for plate and its processing method

ActiveCN104647480BAvoid the effects of processingHigh degree of automationStationary drilling machinesEngineeringDrilling machines

The invention discloses a two-dimensional sheet material drilling device. The two-dimensional sheet material drilling device comprises a worktable (1) and a drilling machine (11), wherein a rear side stopping surface (2) for positioning a wood plate, a leftward material ejection plate (4), a backward material ejection plate (5) and a left side limiting plate (6) are arranged on the worktable (1); the leftward material ejection plate (4), the backward material ejection plate (5) and the left side limiting plate (6) are driven by an air cylinder; and the drilling machine (11) which can move along a left-right direction and a front-back direction is further arranged at the upper part of the worktable (1). The two-dimensional sheet material drilling device has the beneficial effects that the positioning precision is high, and the machining efficiency and yield are improved; and the two-dimensional movement of the drilling machine can be used for drilling any position of the whole wood plate, so that the two-dimensional sheet material drilling device can be suitable for machining sheet materials in different drilling positions and has a wide applicable range.

Owner:CHINA FORGING MACHINERY

Photovoltaic power generation device with two-dimensional photovoltaic heliostat

ActiveCN112769381BReduce damage ratePlay a protective effectPhotovoltaic supportsPhotovoltaic energy generationEngineeringMechanical engineering

The invention discloses a photovoltaic power generation device with a two-dimensional photovoltaic heliostat, which includes a solar cell panel, a turntable is arranged at the bottom of the solar cell panel, and two symmetrically arranged electric telescopic rods are fixed on the top surface of the turntable. , the inner rod of the electric telescopic rod is pierced with a shaft mechanism, the solar cell panel is fixed between the two shaft mechanisms, and a heat exchange box is fixed on the back of the solar cell panel. The invention has a two-dimensional photovoltaic sun-fixing mechanism, which improves the photoelectric efficiency, and at the same time plays a good role in protecting the working motor, has a long service life, and greatly improves the energy utilization rate.

Owner:河南中原金太阳技术有限公司

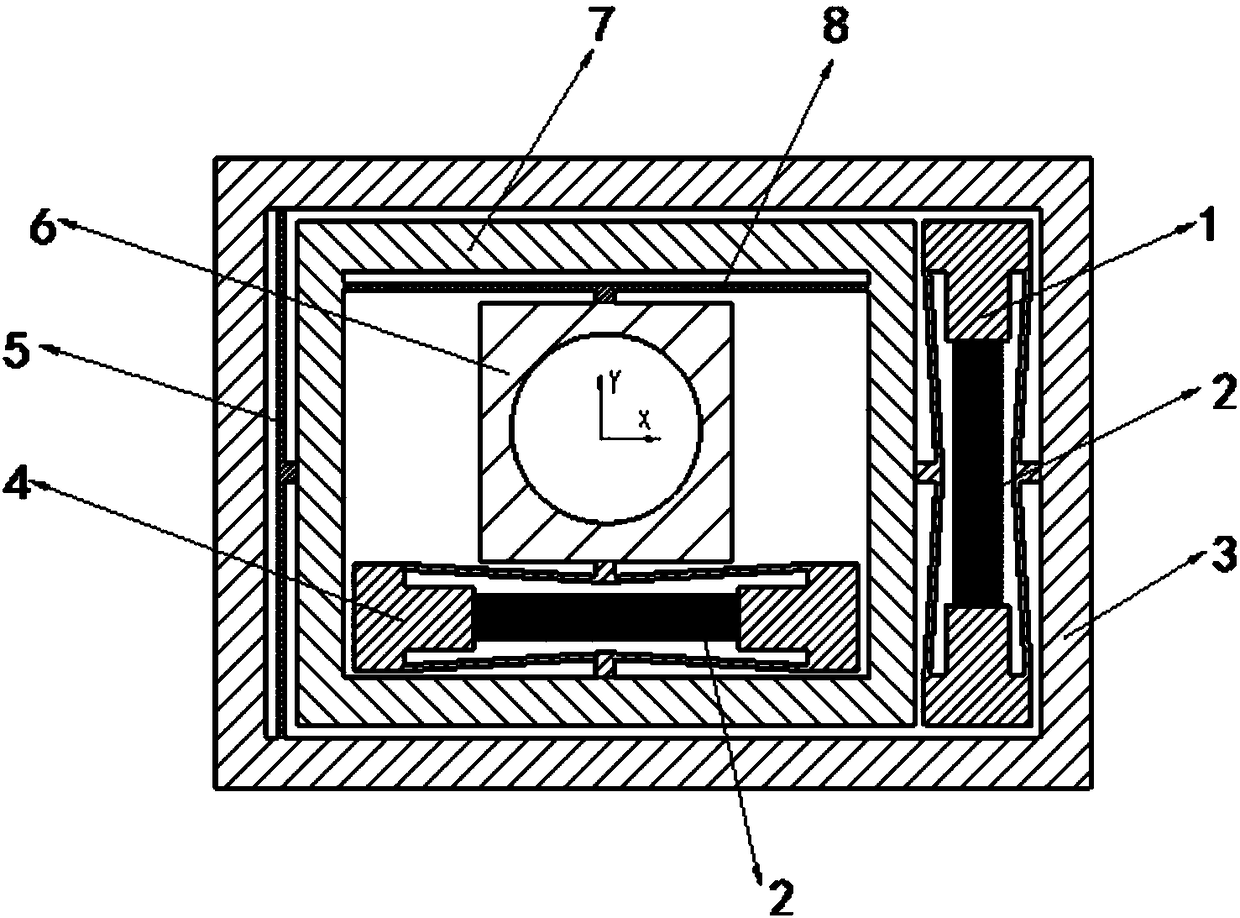

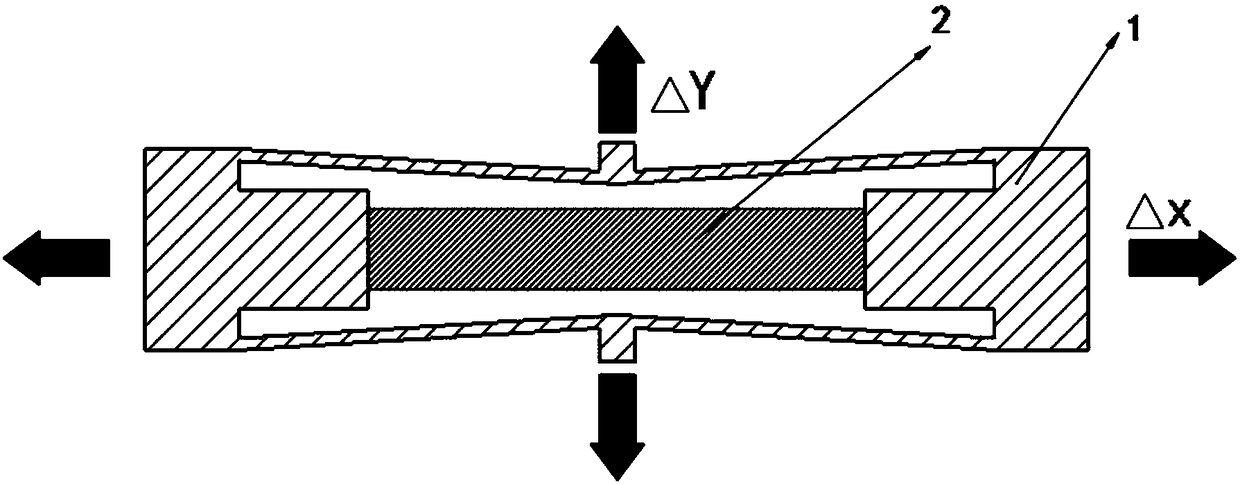

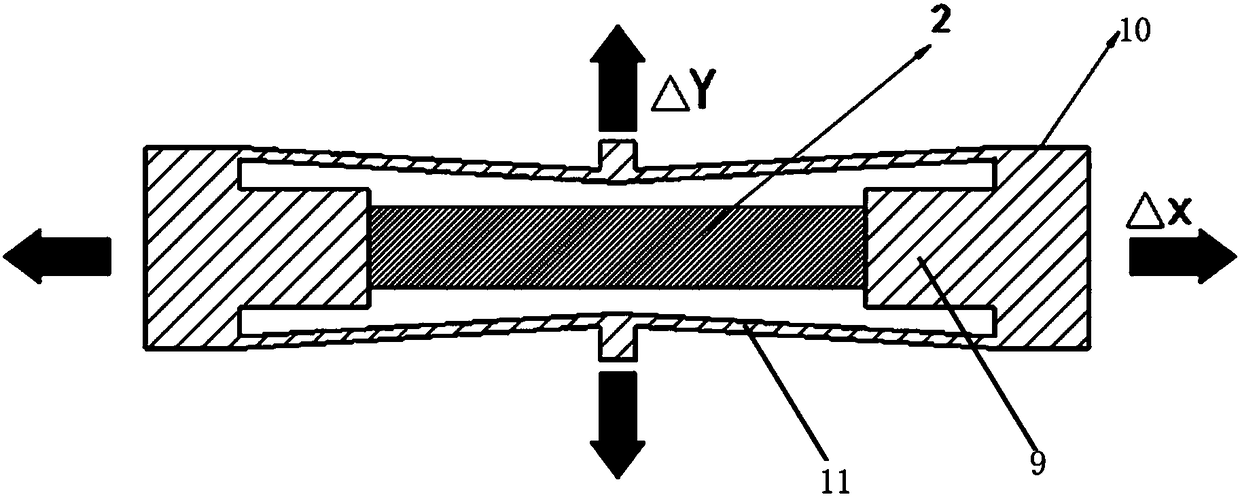

Piezoelectric driven micro-positioning platform based on hourglass displacement amplifier mechanism

InactiveCN108199610ASolve the problem of small output displacementHigh positioning accuracyPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

The invention provides a piezoelectric driven micro-positioning platform based on an hourglass displacement amplifier mechanism. The platform comprises an outer-layer support (3), the hourglass displacement amplifier mechanism, a piezoelectric ceramic actuator (2), symmetrical long arm hinges, a workbench (6) and an inner-layer substrate (7). The hourglass displacement amplifier mechanism comprises an x-direction hourglass displacement amplifier mechanism (1) and a Y-direction hourglass displacement amplifier mechanism (4). The symmetrical long arm hinges comprise x-direction symmetrical longarm hinges (5) and Y-direction symmetrical long arm hinges (8). The piezoelectric driven micro-positioning platform based on the hourglass displacement amplifier mechanism can realize large-stroke motion of the workbench. Certainly, implementation of any product or method of the invention does not necessarily require all the advantages described above to be achieved simultaneously.

Owner:SHENYANG POLYTECHNIC UNIV

A tool profiling control system

InactiveCN104084845BStable mold changeMachining shape influenceCopying process control systemsControl systemEngineering

Disclosed is a tool profiling control system. The tool profiling control system comprises a tool profiling device and a control processor (8). The tool profiling device comprises a tool (1) and a profiling column (2), wherein the profiling column (2) is integrally in a cylindrical shape, and both ends of the cylindrical shaped are provided with an upper plug (27) and a lower plug (28); a middle profiling unit is formed between the upper plug (27) and the lower plug (28) and circumferentially and uniformly provided with four longitudinal profiling grooves (21, 22, 23 and 24) which are connected with the connecting end (11) of the tool (1); at least one of the four longitudinal profiling grooves is a return groove (22), the profiling contour of the return groove (22) is of a flat type, the other profiling grooves are curved grooves and are used for performing feeding control on the tool (1), and meanwhile, the curved grooves are different in curved surface shape.

Owner:AIRUI KETE TIANJIN PRECISION METAL TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com