One-to-many automatic docking system

An automatic docking and one-to-one technology, which is applied in special distribution devices, packaging, distribution devices, etc., can solve problems such as the inability to realize one-to-many automatic docking, unclean pipeline cleaning, and hidden quality hazards, etc., to achieve ingenious mechanism design, structural Simple and reliable, volume-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

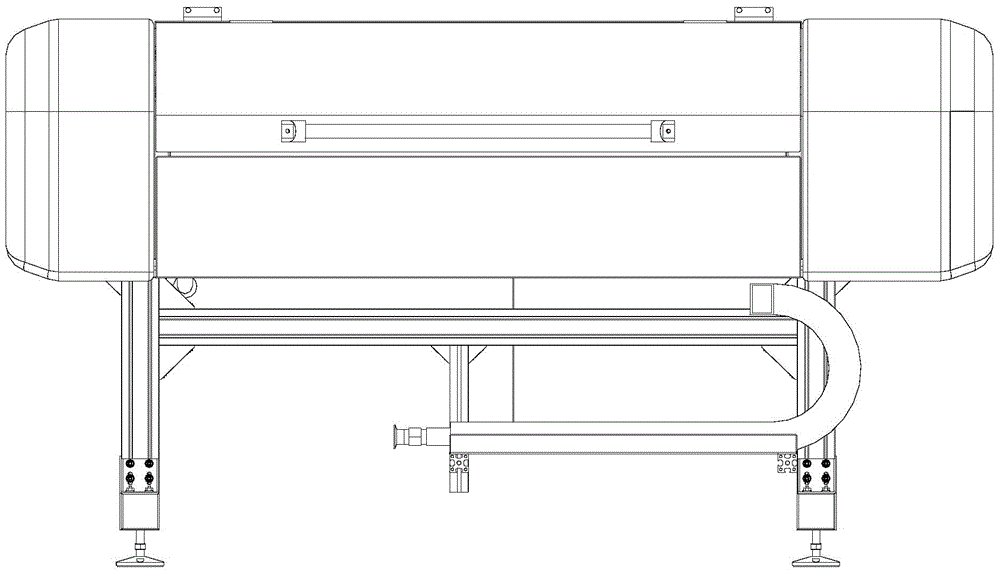

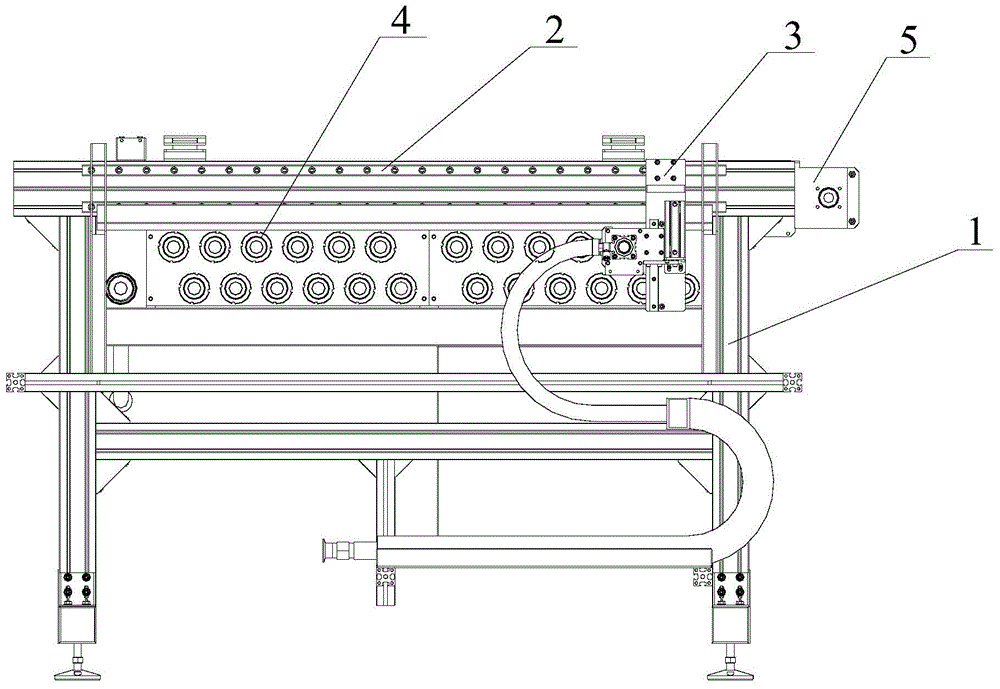

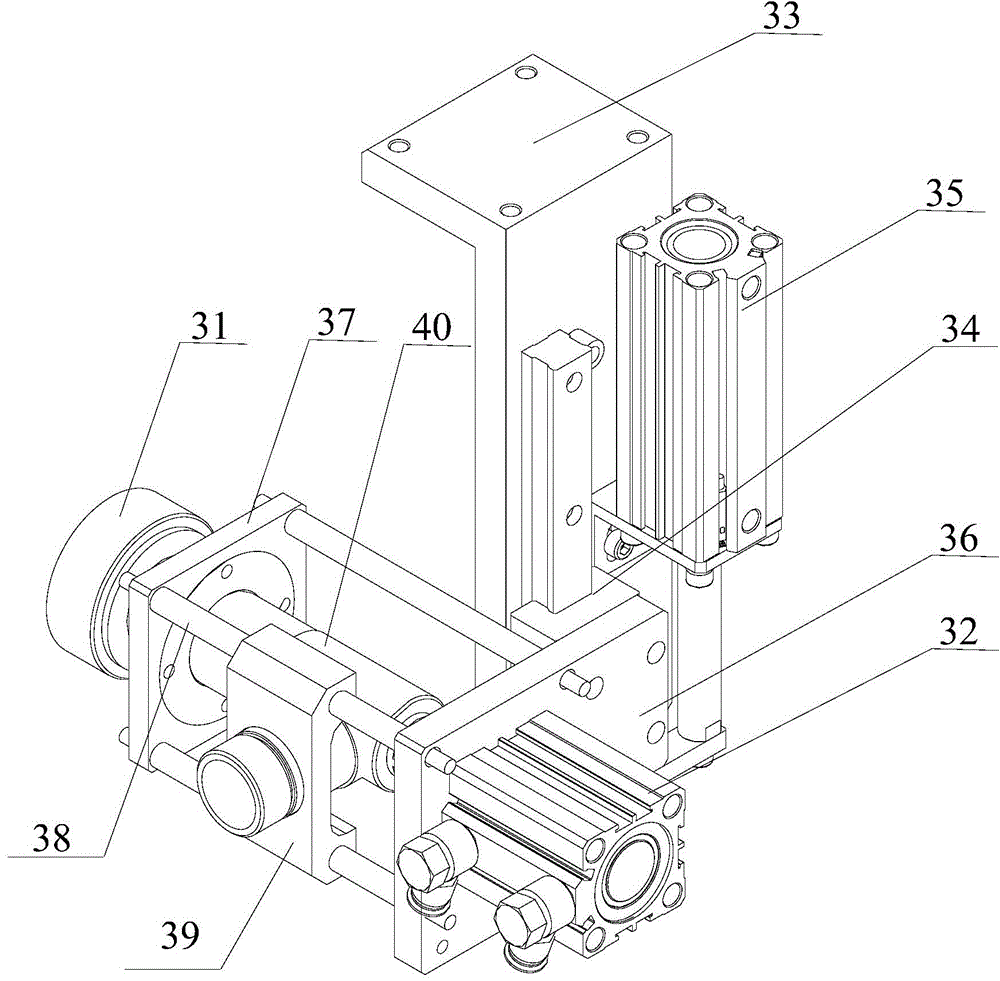

[0025] like figure 1 , figure 2 As shown, it is a one-to-many automatic docking system of the present invention, including: a bracket 1; a horizontal guide rail pair 2 on the mounting bracket 1, and the horizontal guide rail pair 2 includes a horizontal guide rail and a horizontal slider slidingly matched with the horizontal guide rail, and the horizontal slider can be Sliding along the horizontal guide rail; a docking mechanism 3 installed on the horizontal slider; and a plurality of pipeline joints 4 installed on the bracket 1 and matched with the docking mechanism 3 . Wherein, the horizontal guide rail pair 2 is placed horizontally. Multiple pipeline joints 4 are in the same direction, the movement direction of the horizontal guide rail pair 2 is perpendicular to the inlet direction of the pipeline joint 4, multiple pipeline joints 4 are arranged below the horizontal guide rail pair 2, and multiple pipeline joints 4 are arranged along the horizontal guide rail The direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com