Patents

Literature

64 results about "Linear probe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear Probe. A linear probe contains one or more acoustic linear array transducer elements arranged in a line to send pulses of sound into a material. The linear array gives a large probe surface (footprint) and near field.

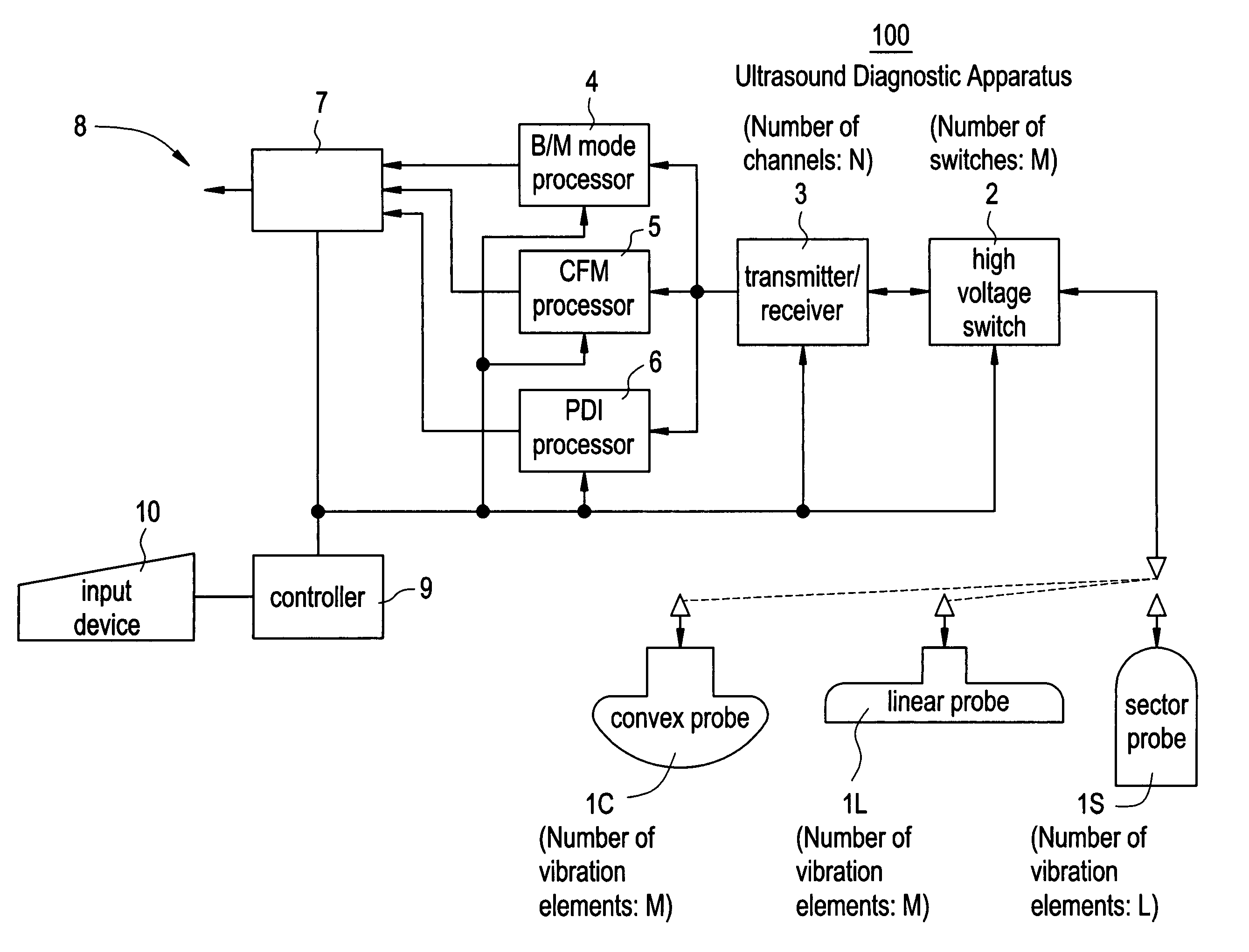

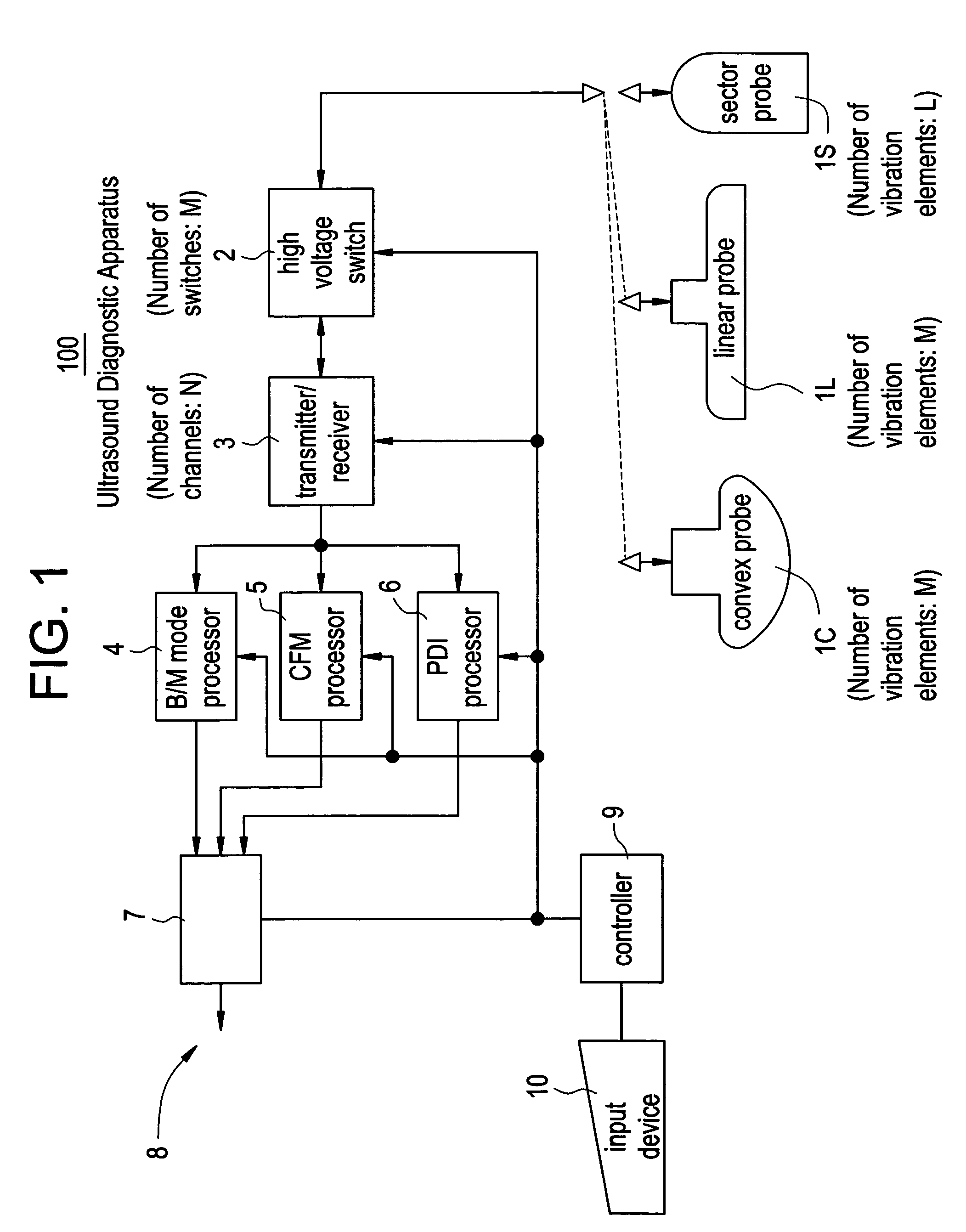

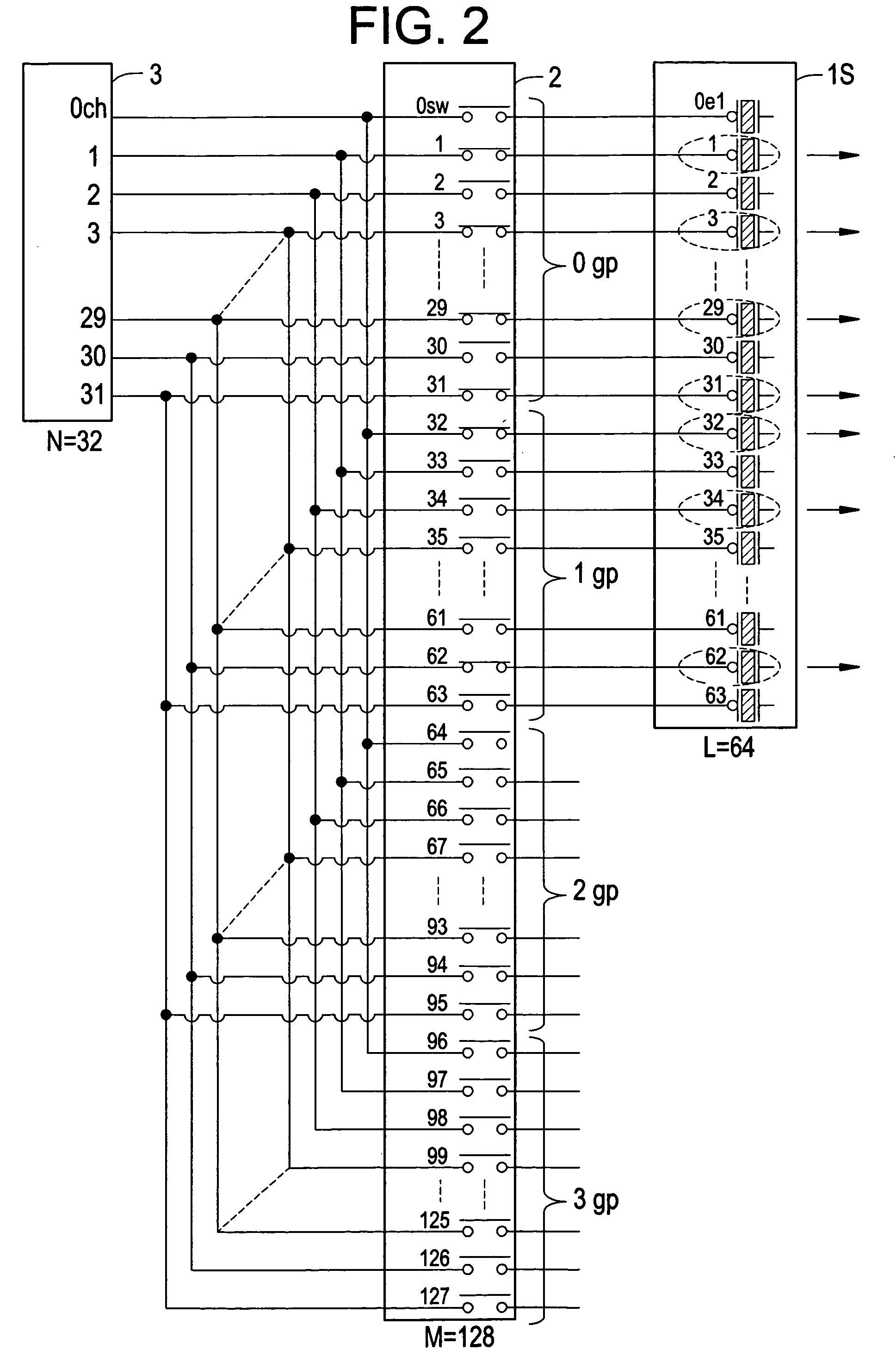

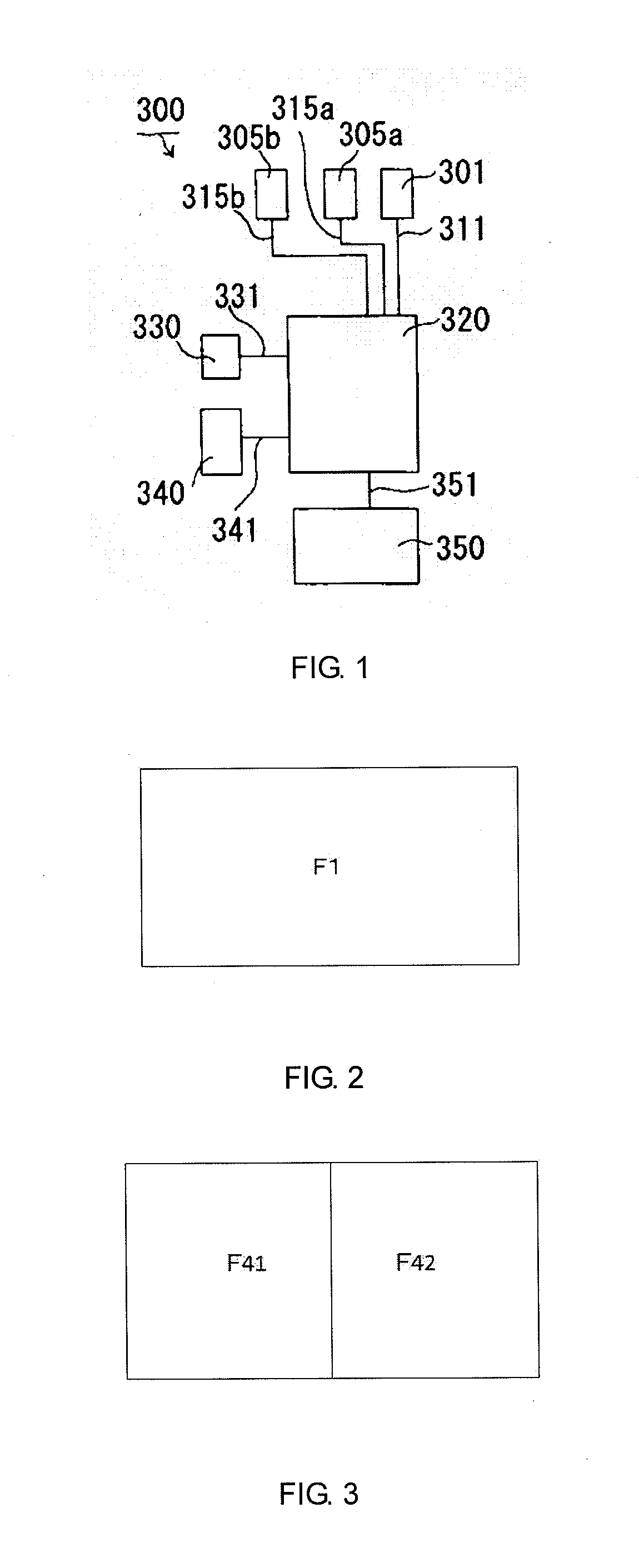

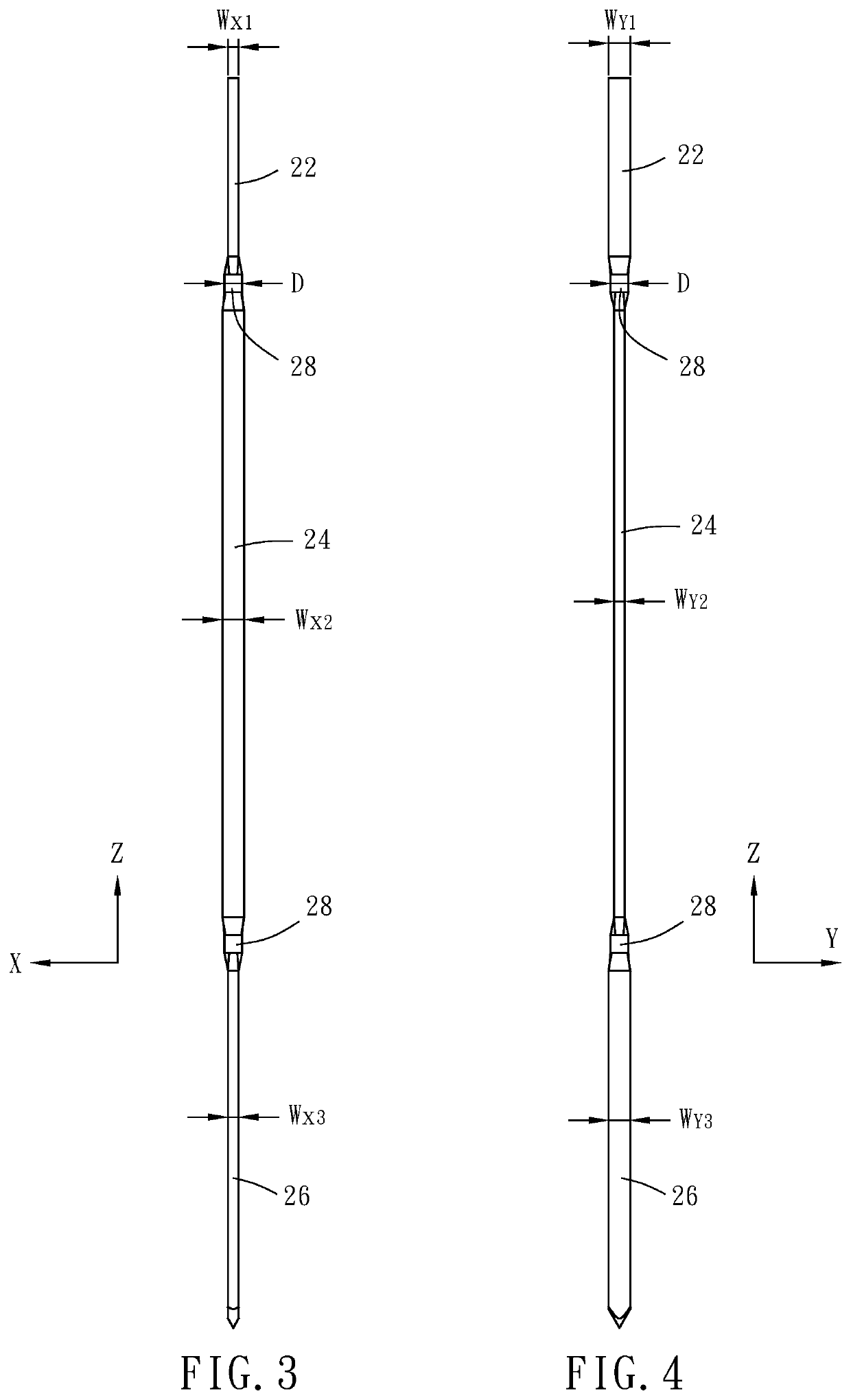

Method of sector probe driving and ultrasound diagnostic apparatus

InactiveUS7775112B2Reduce problemsEnsure proper implementationAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSonificationDiagnostic ultrasound

The transmitter / receiver for a convex probe and linear probe are used to drive a sector probe. Usually, when an ultrasound diagnostic apparatus using a convex probe and linear probe uses a sector probe, it selects vibration elements of N in number, which is equal to the number of channels of the sector probe, out of vibration elements of L in number (N is smaller than L), so that the selected elements are distributed at a virtually constant pitch in the alignment of vibration elements, and turns on only high voltage switches which are connected with the selected vibration elements to implement the sector scanning with the transmitter / receiver. It becomes possible to implement the sector scanning by using the transmitter / receiver having channels less than the number of vibration elements of the sector probe.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

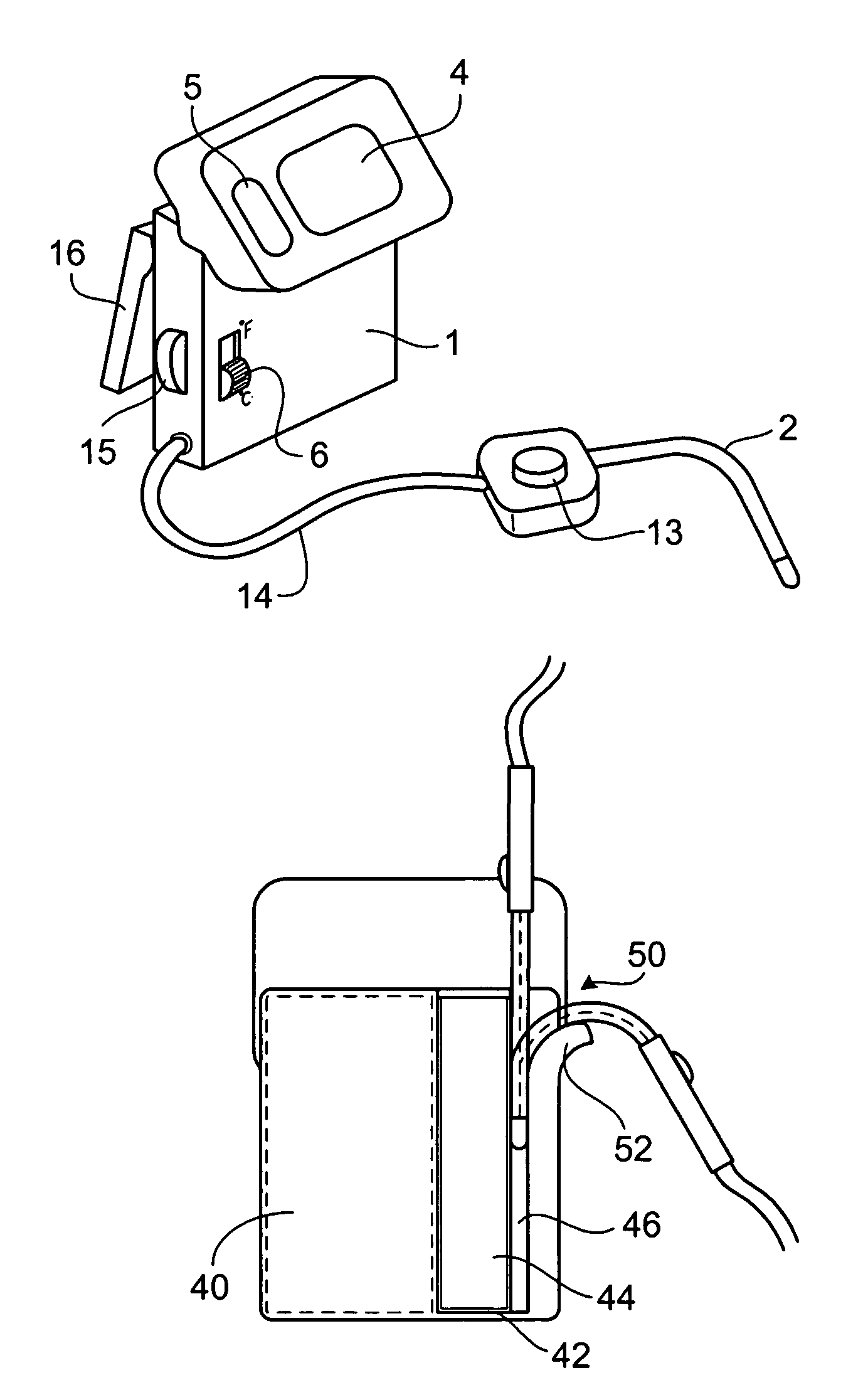

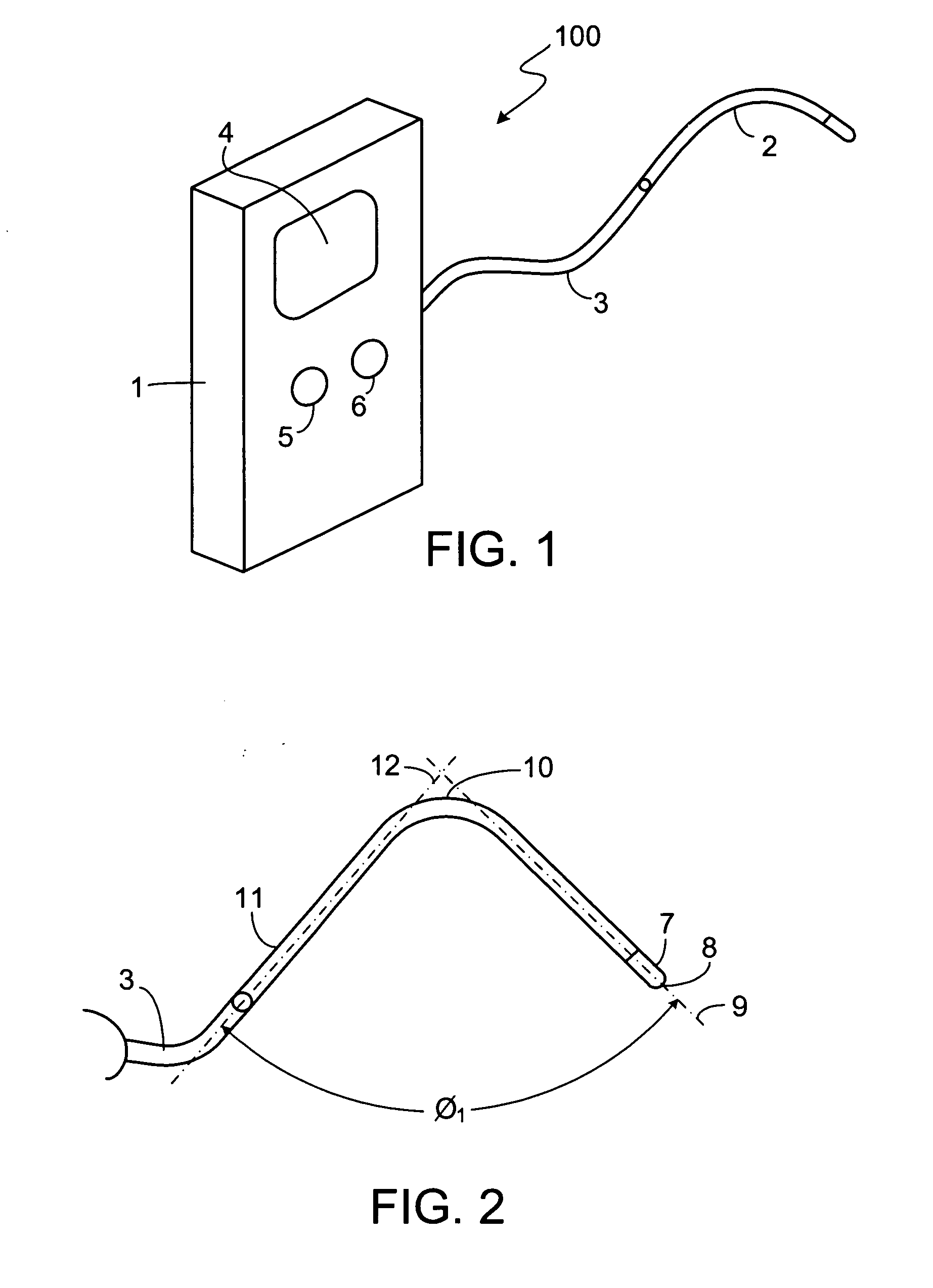

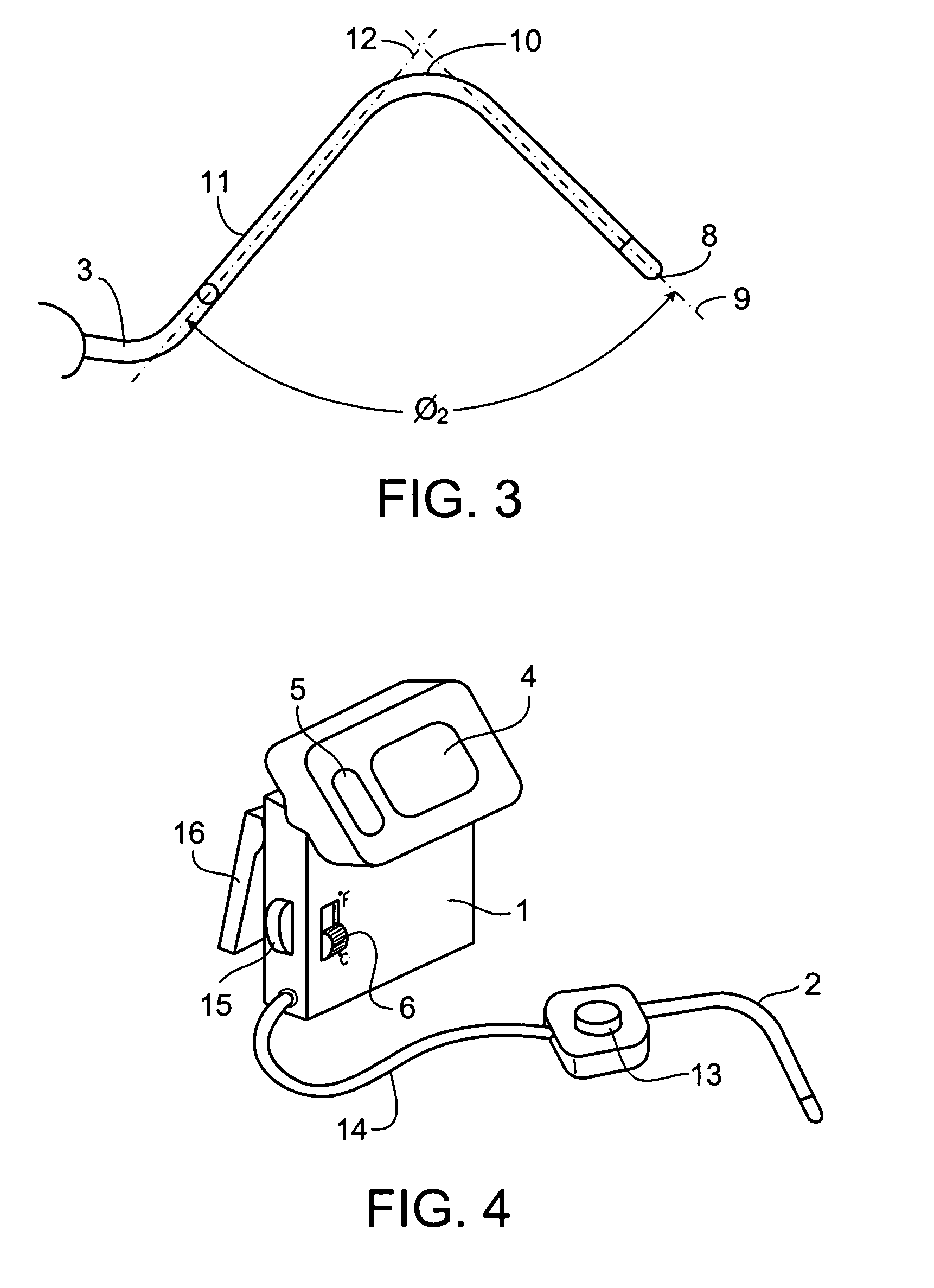

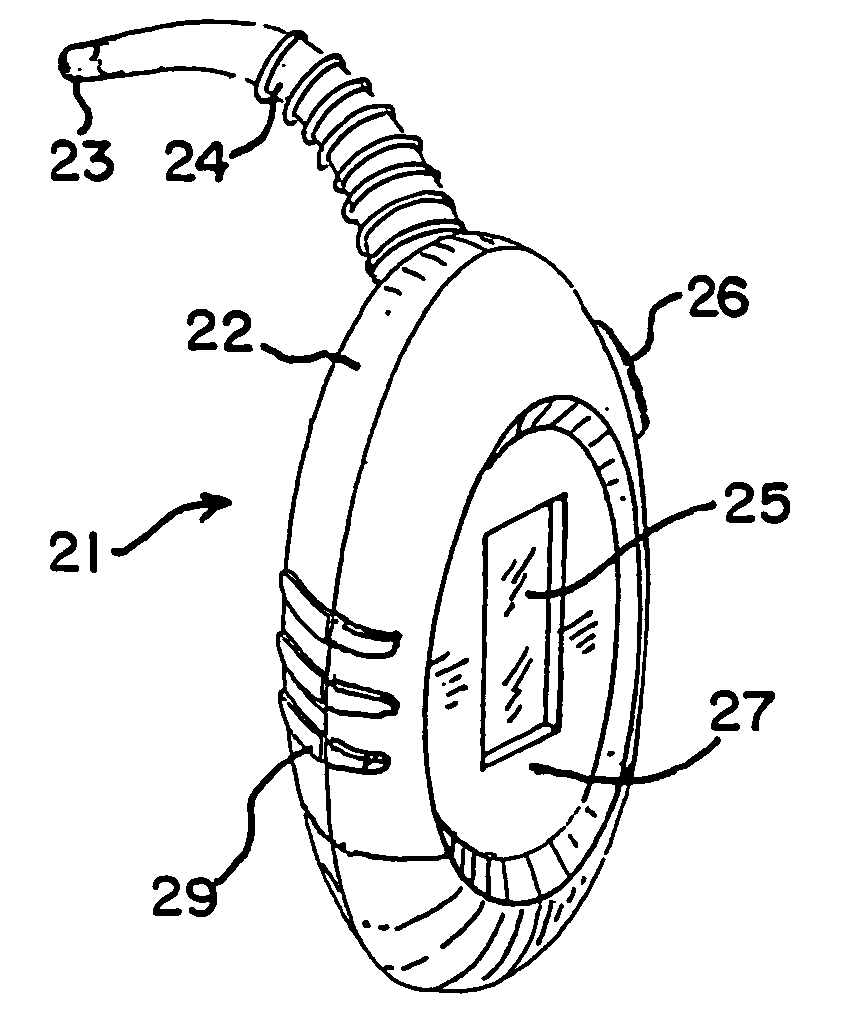

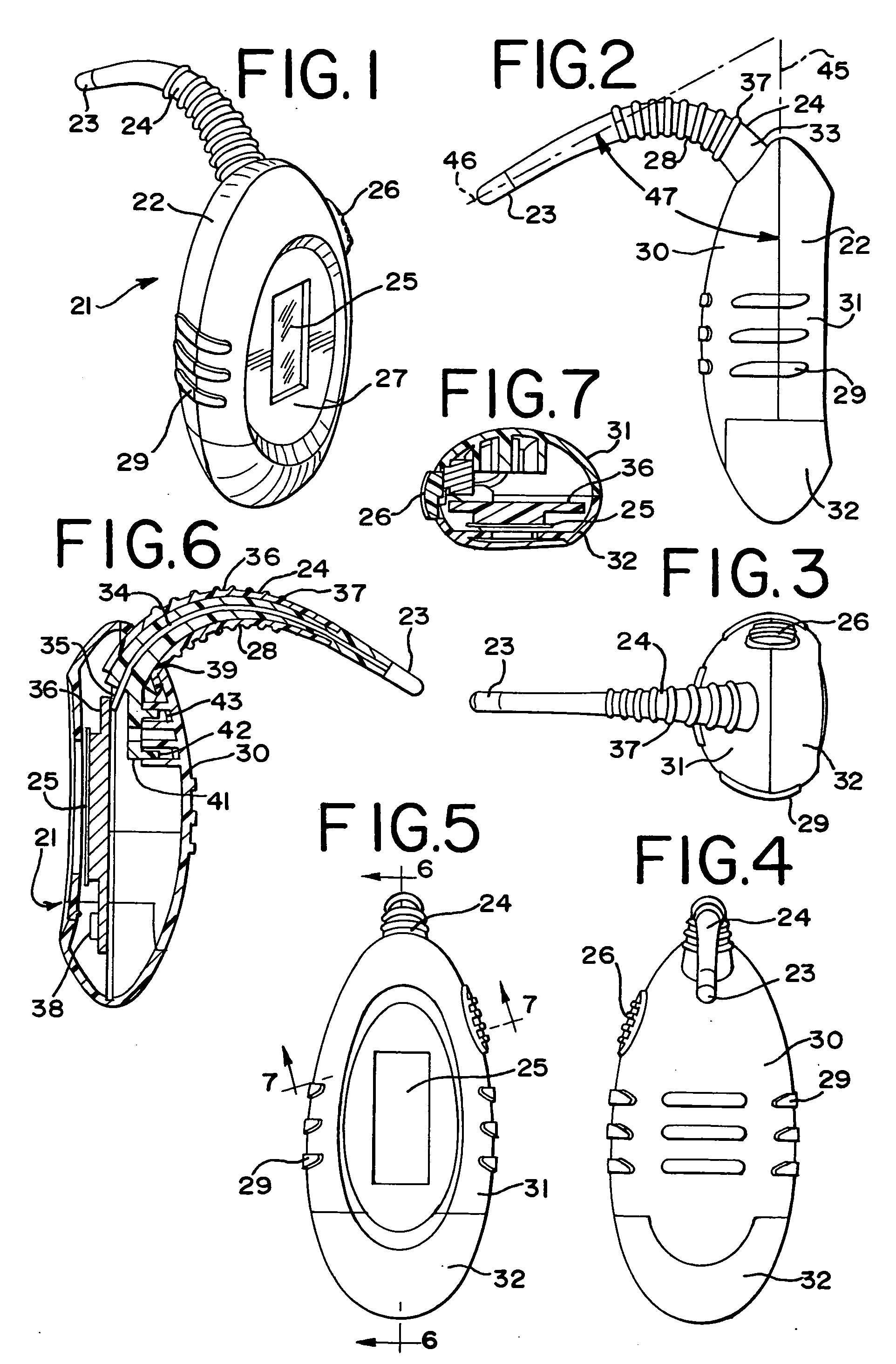

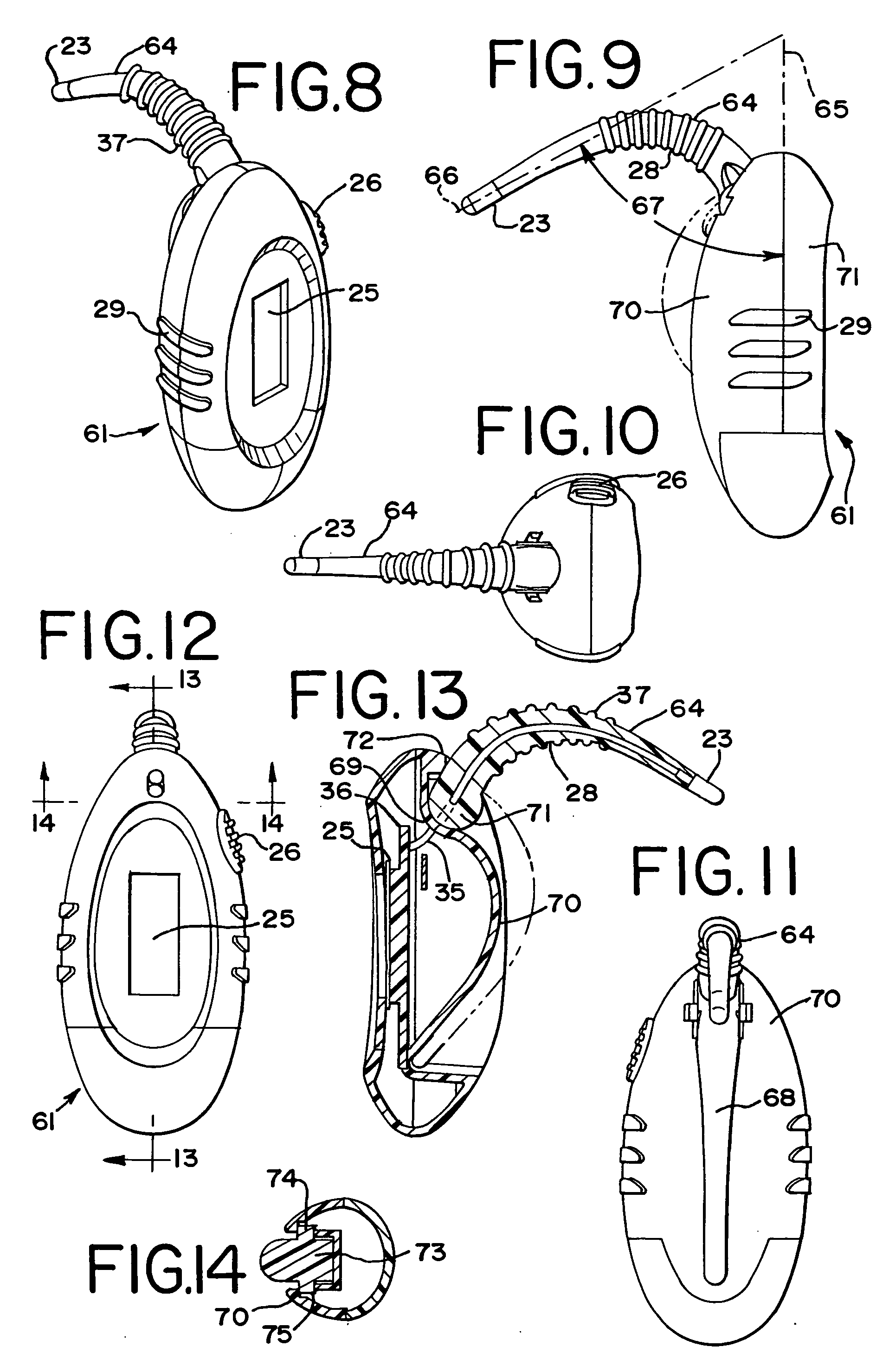

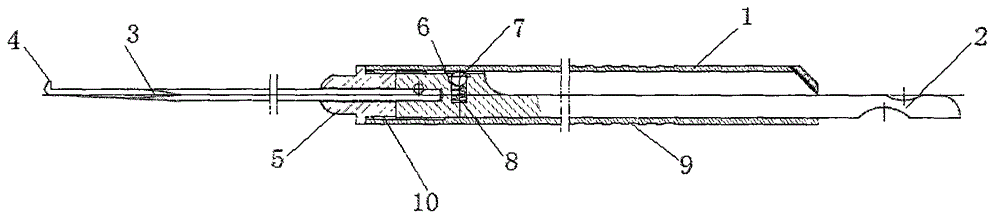

Digital thermometer for measuring body temperature

InactiveUS7036984B2Improve accuracySuitable for useThermometer detailsThermometers using electric/magnetic elementsLinear configurationDisplay device

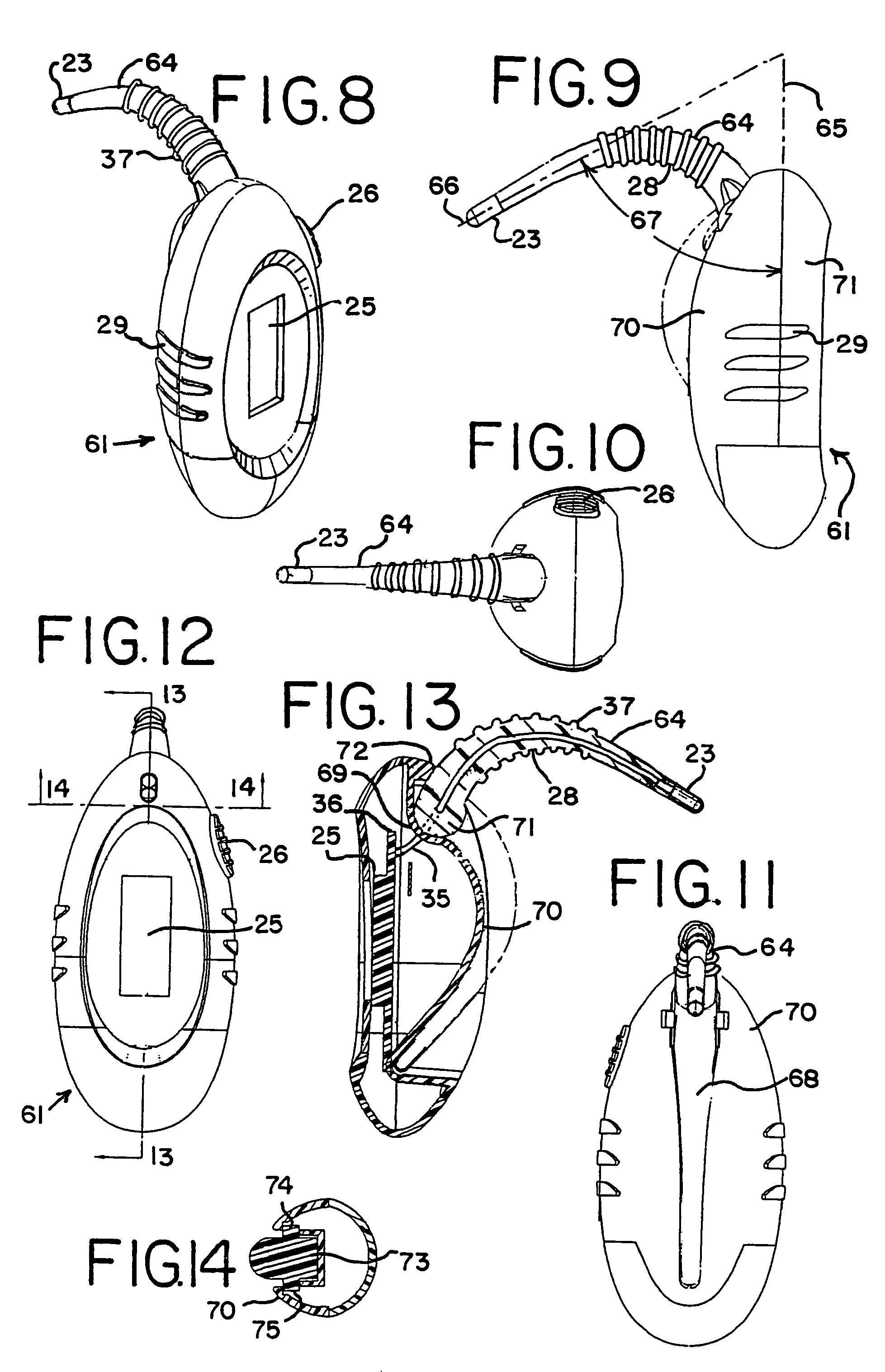

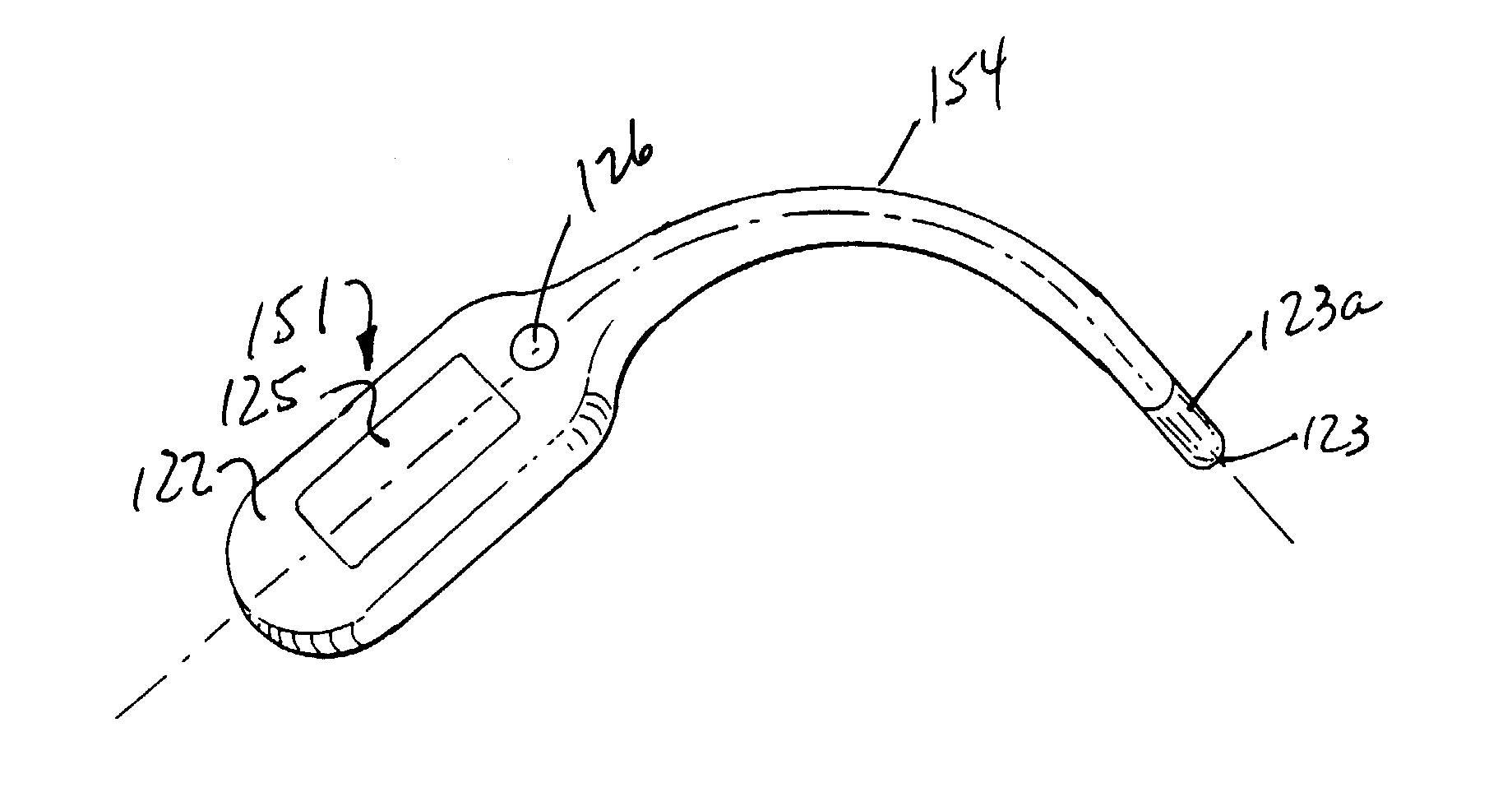

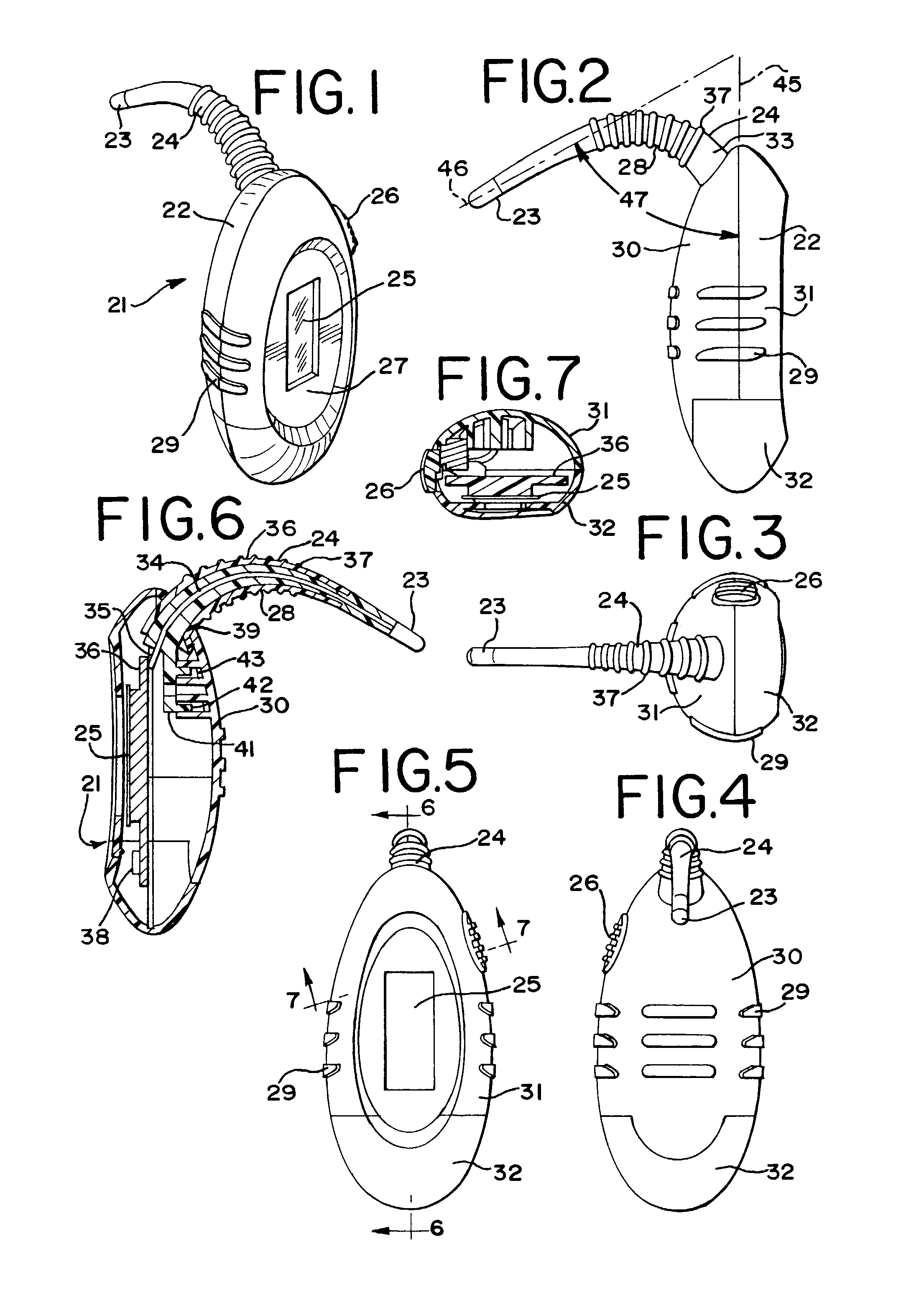

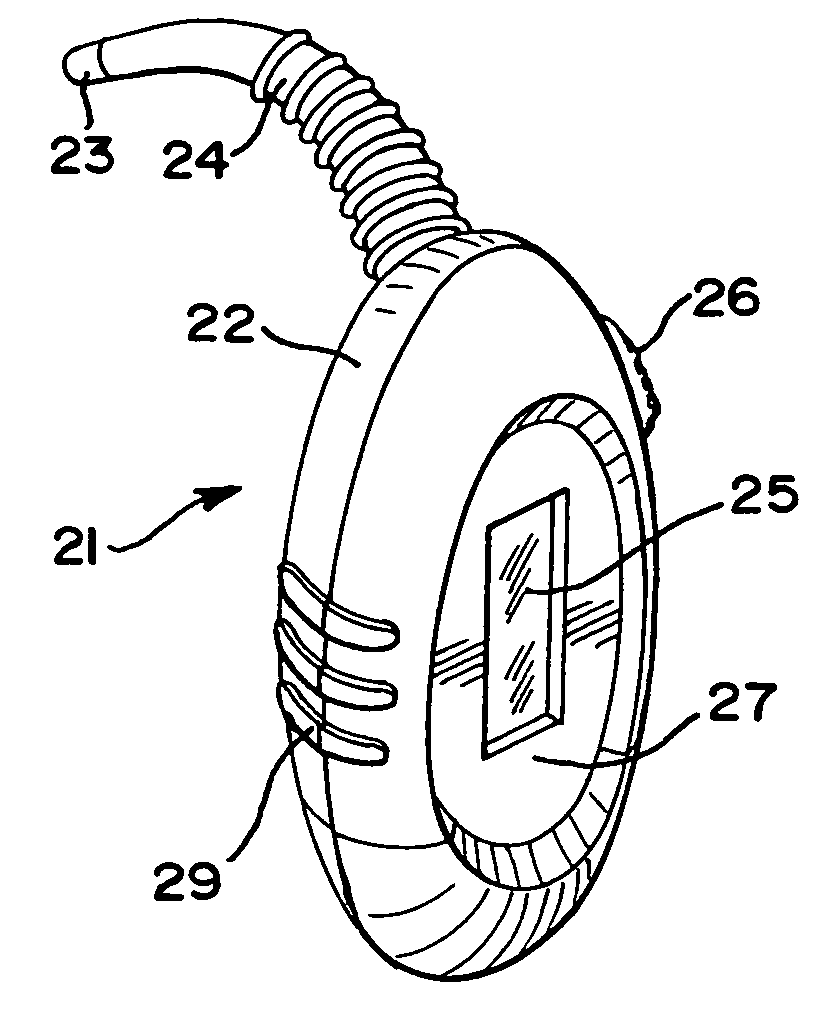

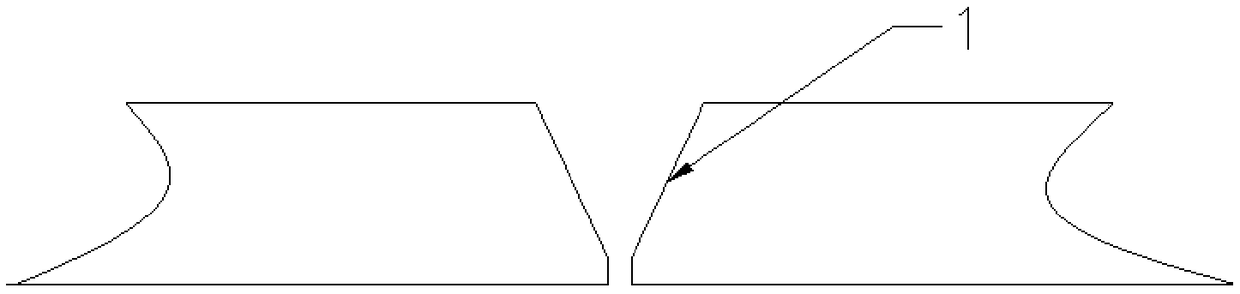

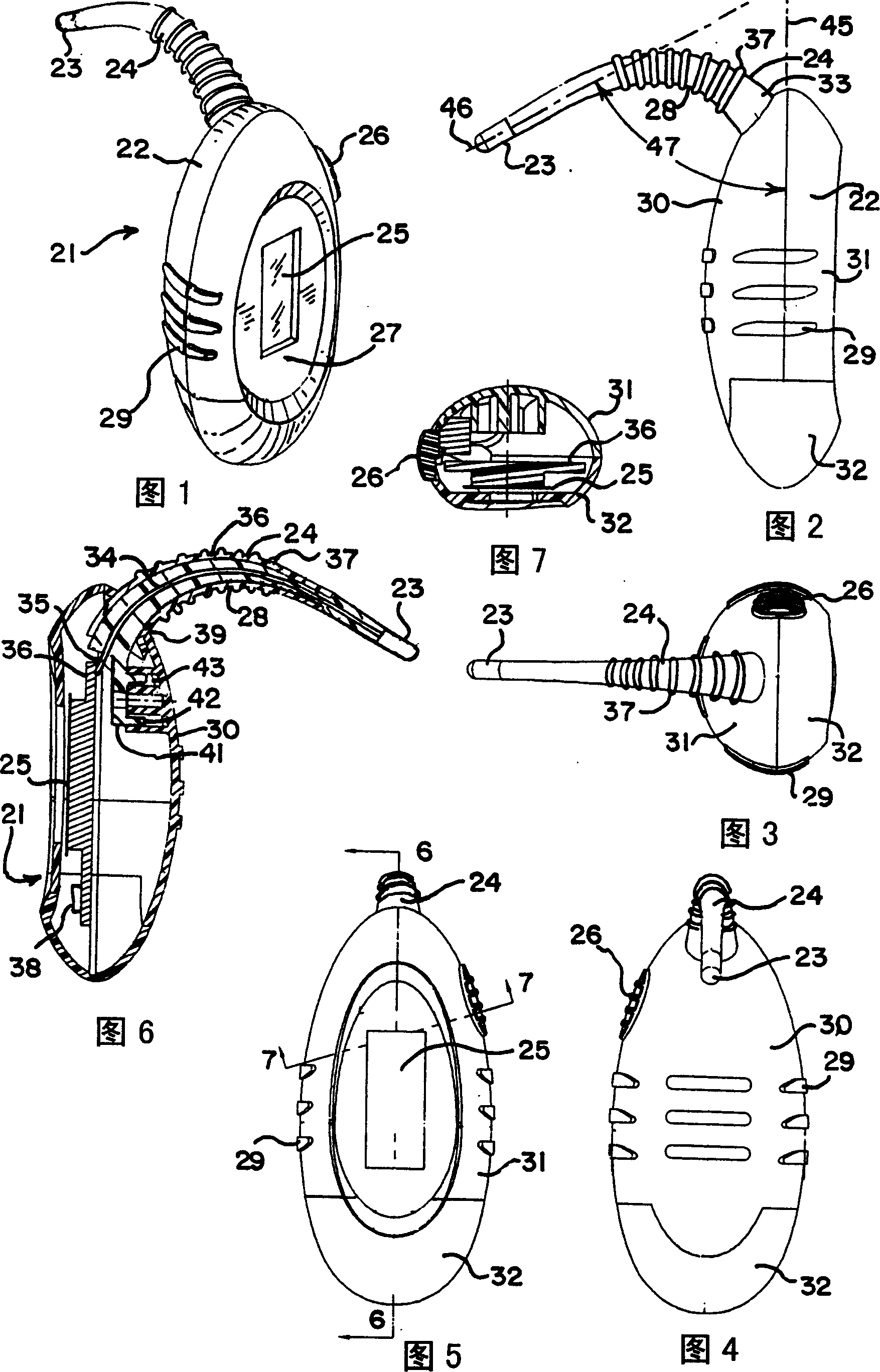

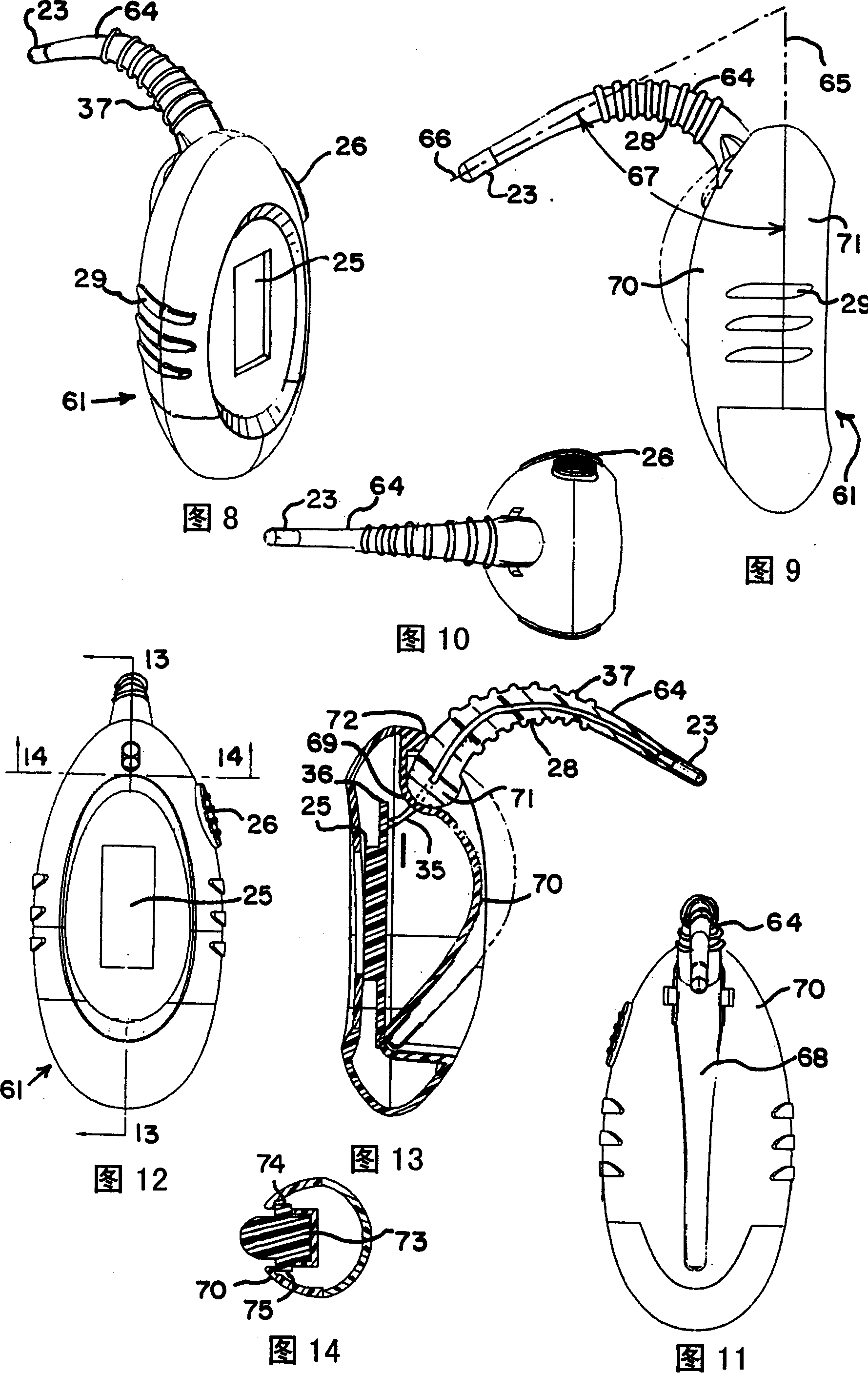

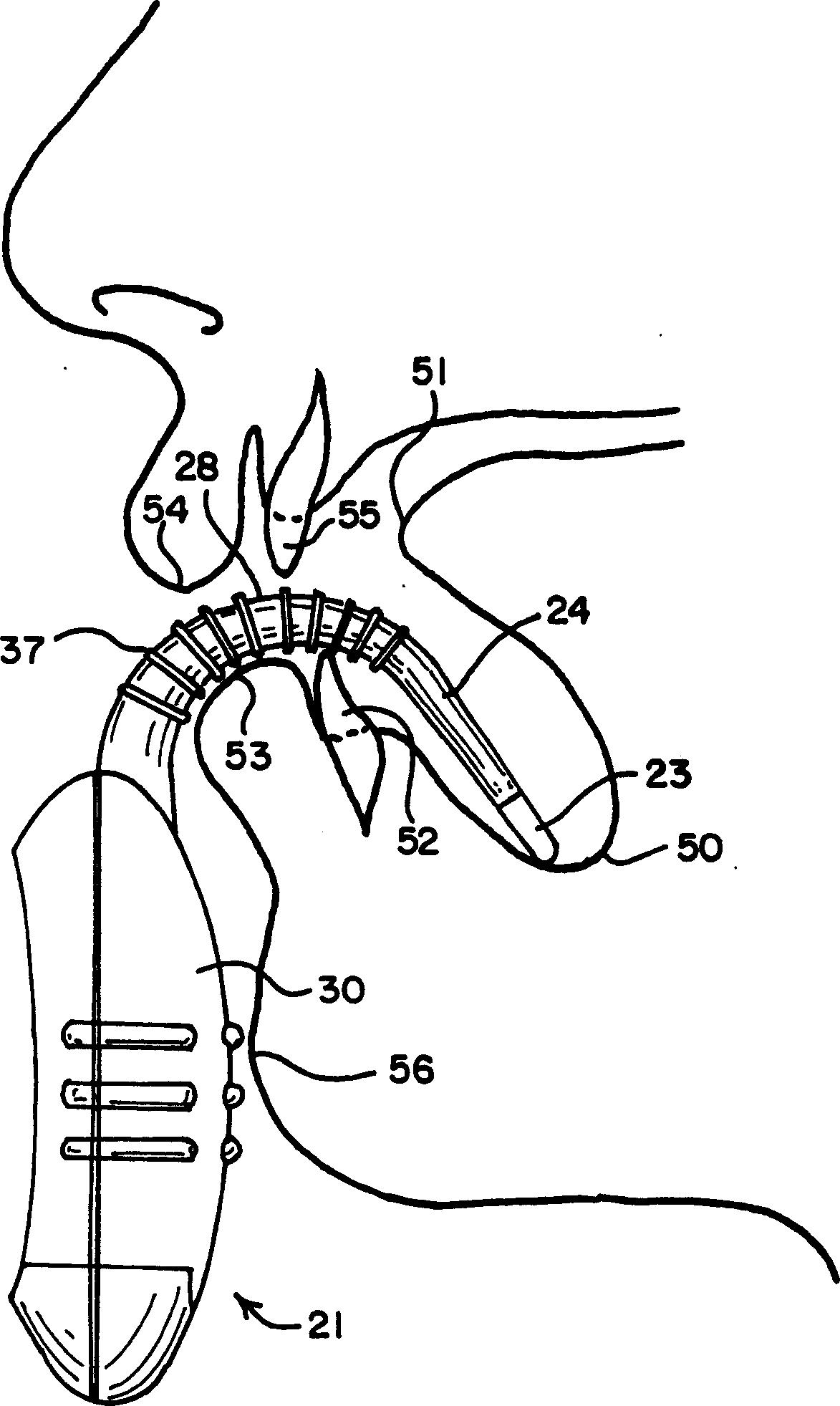

A digital thermometer with enhanced conformity to the anatomy, such as in and around the mouth of a human being. A non-linear probe has a temperature sensor at a first end adapted to be inserted into the mouth and under the tongue. An intermediate portion of the probe is shaped to rest on the lower lip and / or teeth. The probe may also be flexible such that it may be bent into the desired non-linear configuration prior to use, in which case the intermediate portion of the probe may be linear prior to use. A display component displays the measured temperature. Electronic circuitry receives a temperature signal from the temperature sensor, translates the signal into a value representative of the measured temperature, and provides the translated value to the display for displaying the temperature.

Owner:LINDON GROUP

Digital thermometer for measuring body temperature

InactiveUS7060037B2Improve balanceImprove consistencyBody temperature measurementDiagnostic recording/measuringDigital thermometersDisplay device

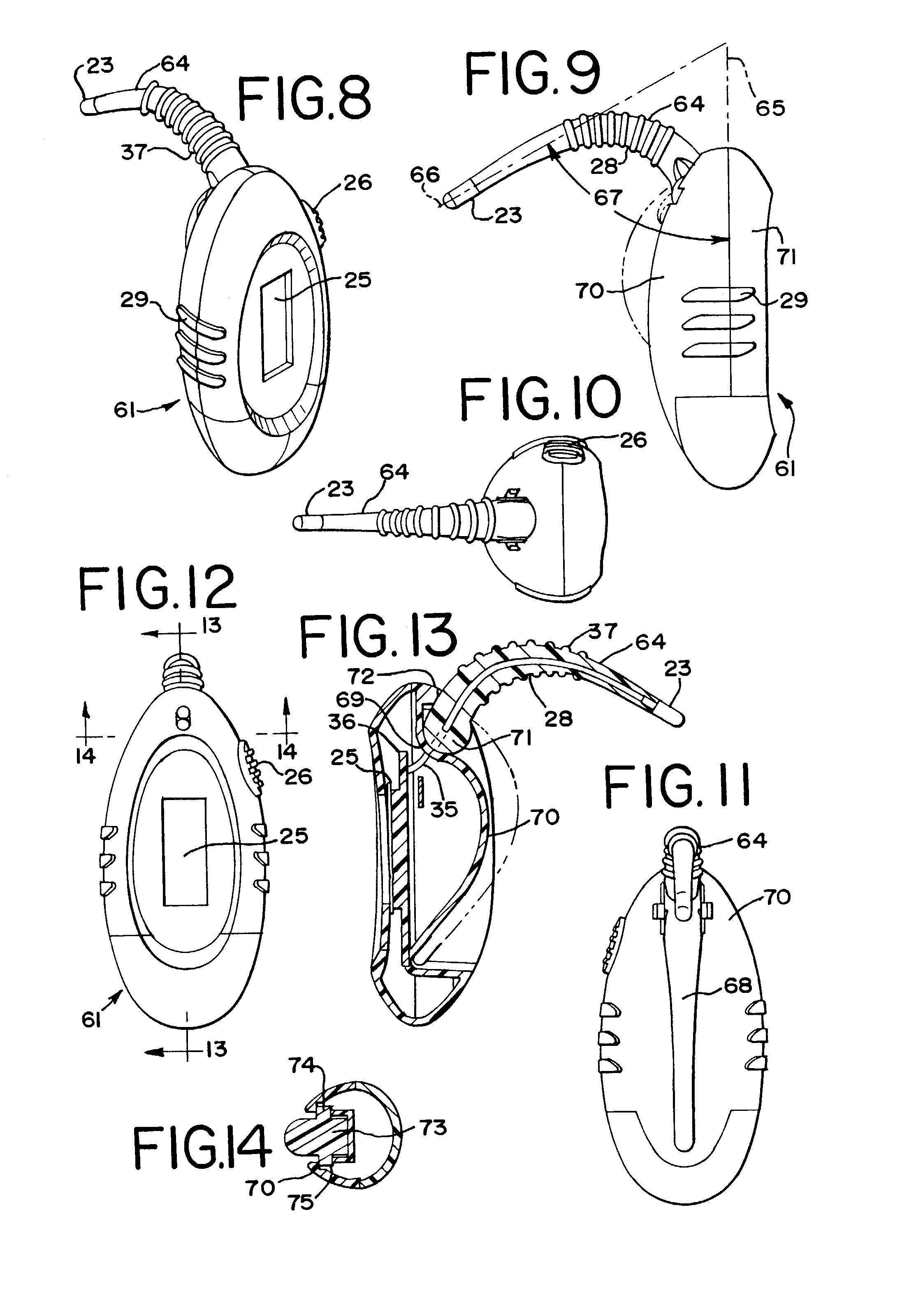

A digital thermometer with enhanced conformity to the anatomy, such as in and around the mouth of a human being. A non-linear probe has a temperature sensor at a first end adapted to be inserted into the mouth and under the tongue, and a downwardly disposed housing portion at the second end. An intermediate portion of the probe is shaped to rest on the lower lip and / or teeth. The probe can be rotatably or pivotally attached to the housing to protect the probe by being recessed in the housing when not in use and / or to adjust to any size mouth. A plurality of ribs at the intermediate portion of the probe can be included to contact the lips and / or teeth for greater positional stability of the thermometer. A display component displays the measured temperature. Electronic circuitry receives a temperature signal from the temperature sensor, translates the signal into a value representative of the measured temperature, and provides the translated value to the display for displaying the temperature.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC +1

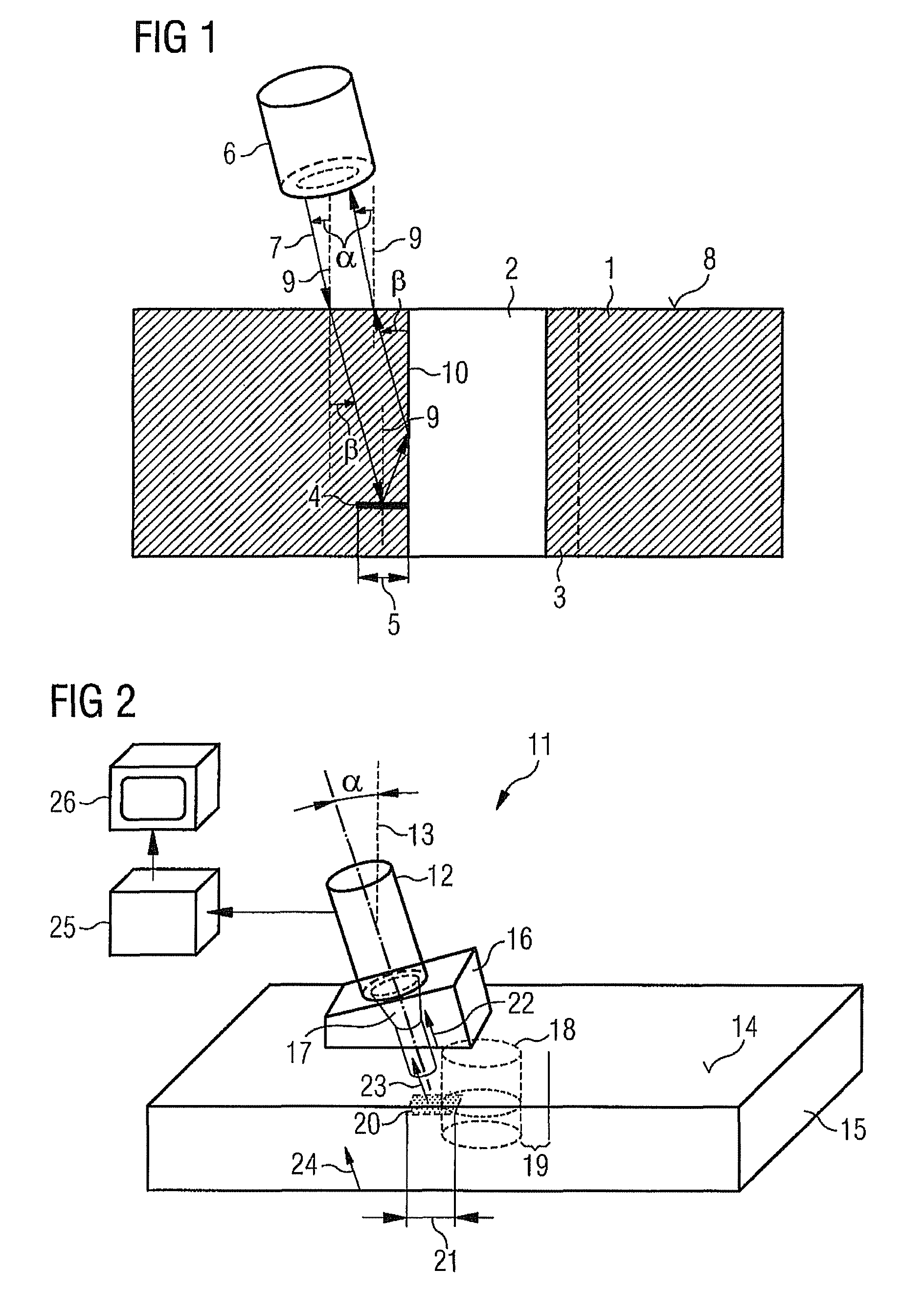

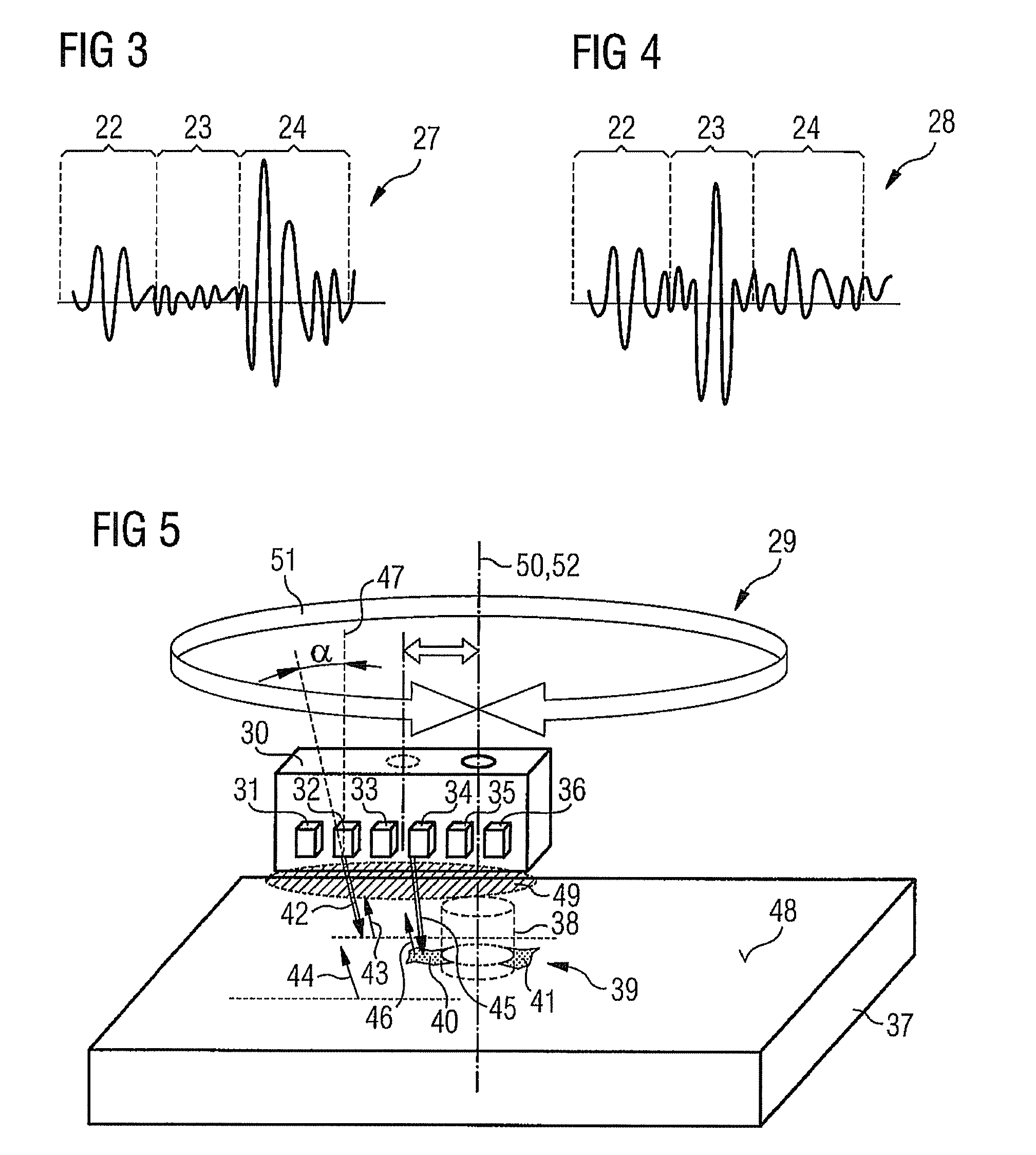

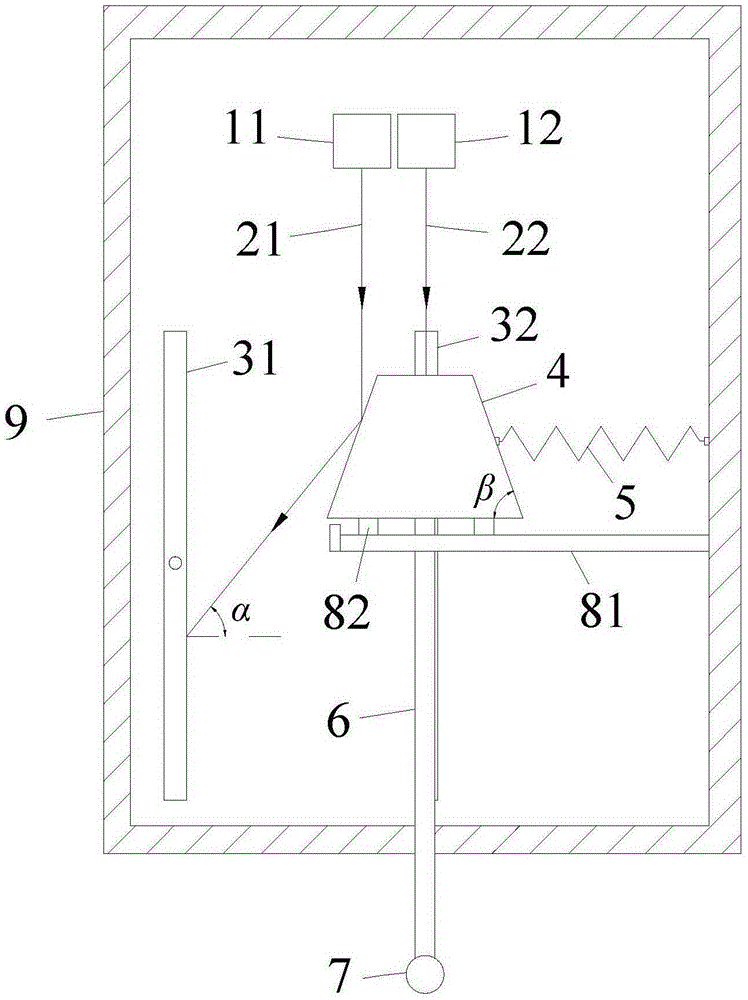

Device for detecting a flaw in a component

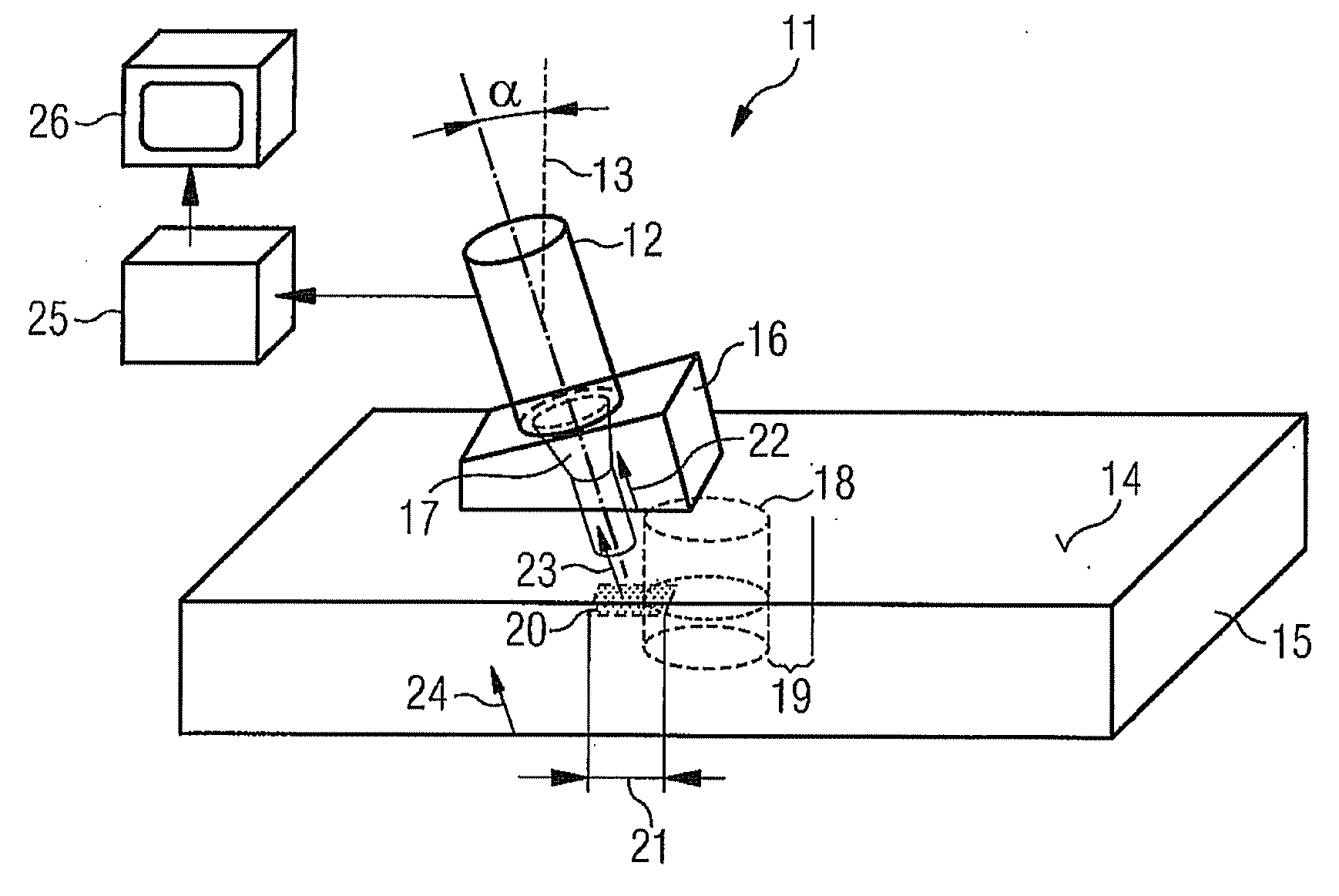

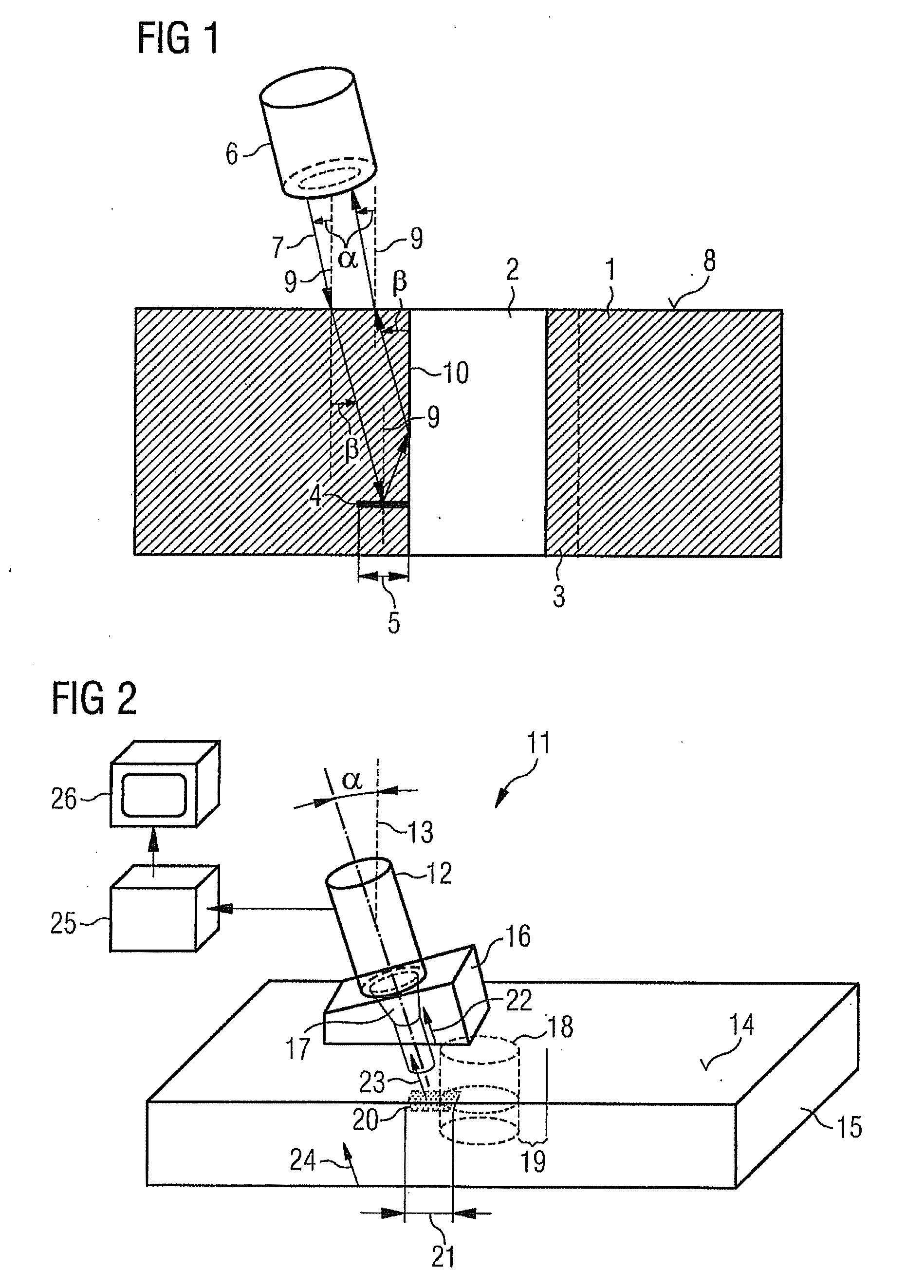

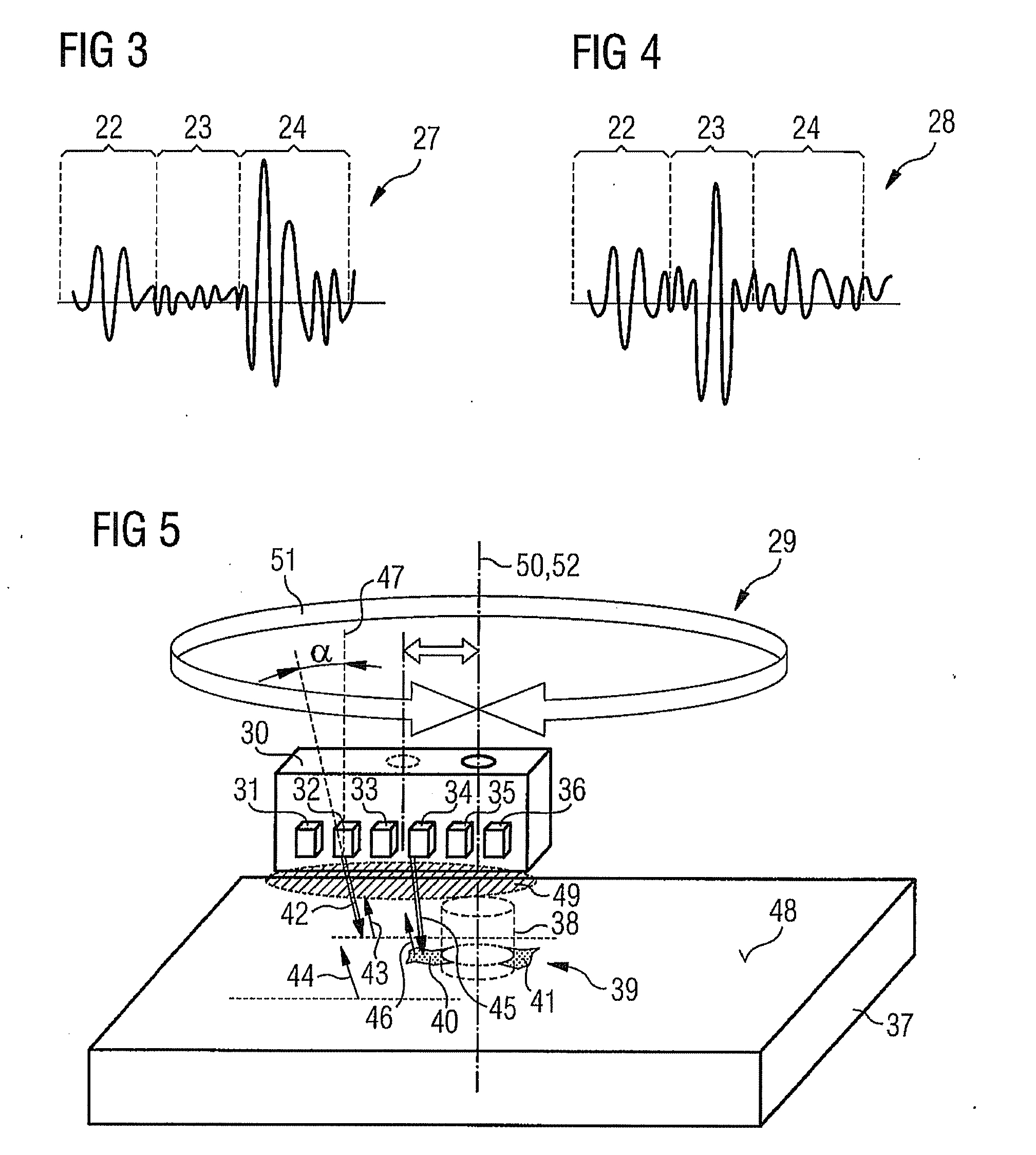

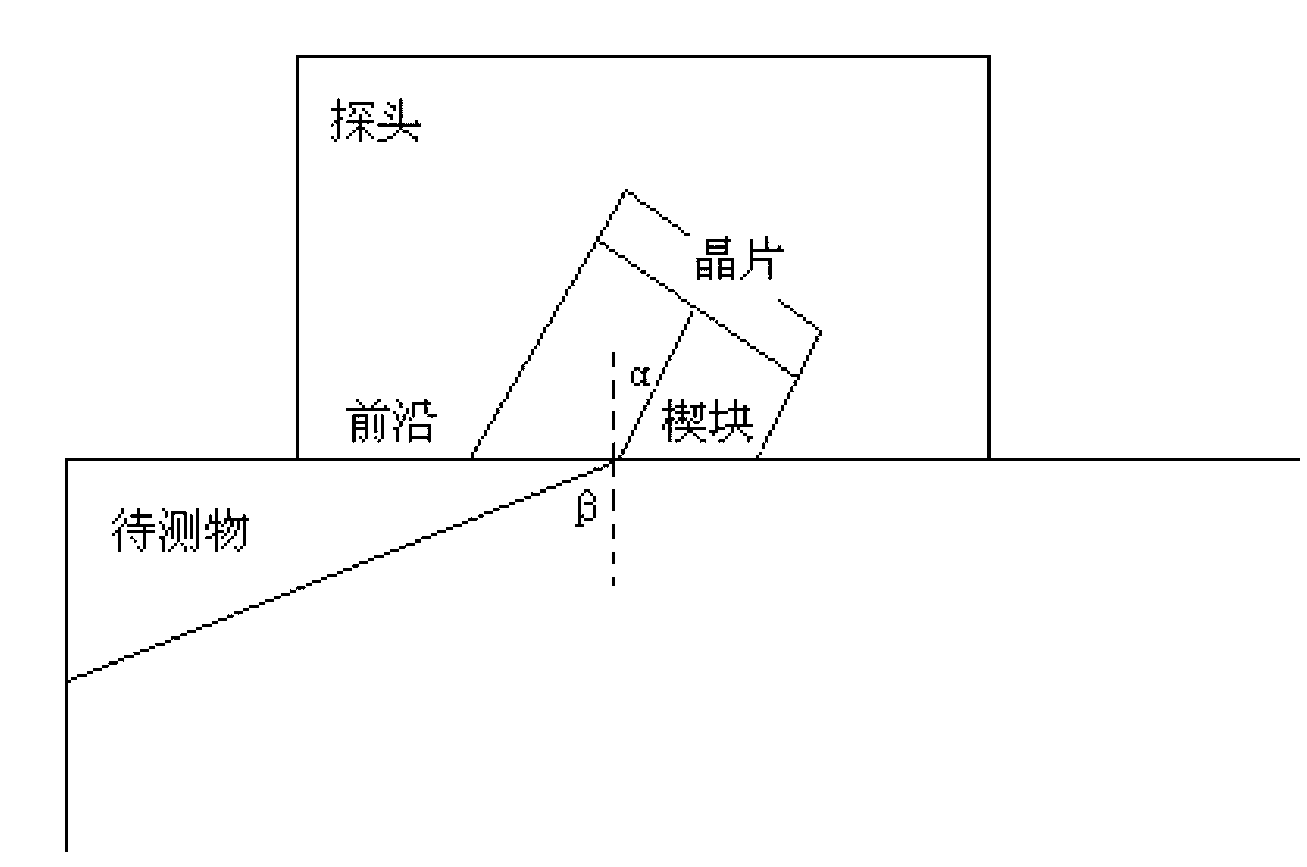

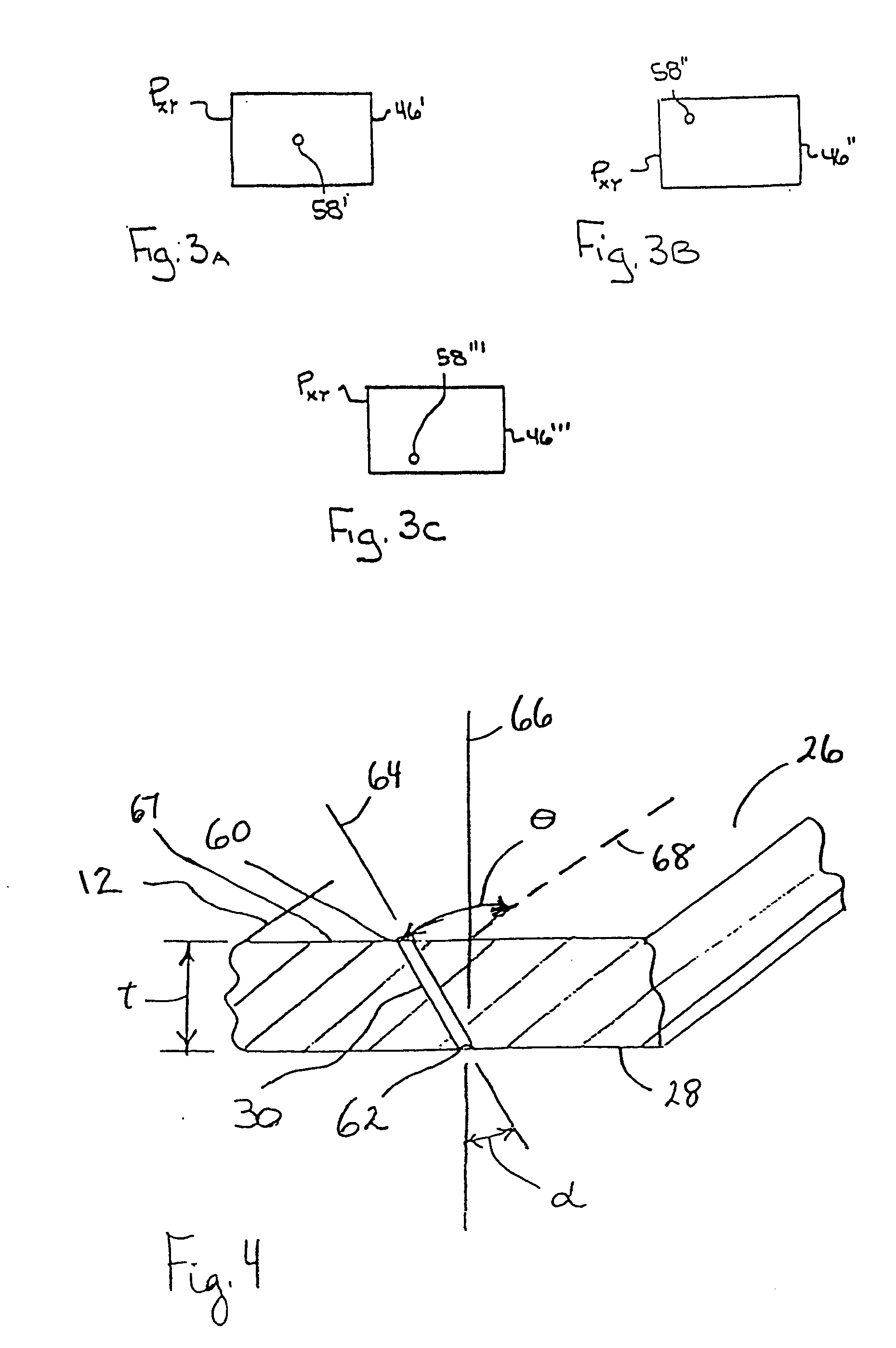

InactiveUS20100107768A1Reliable detectionMultiple-port networksAnalysing solids using sonic/ultrasonic/infrasonic wavesFiberAngle of incidence

The invention relates to a device for detecting a flaw in a fibre-reinforced component, in particular delamination in a bearing region of a hole, by means of at least one probe, wherein an ultrasound field is emittable and detectable by means of the at least one probe. The ultrasound field is coupled according to the invention to the component at an angle of incidence α of greater than 0° from a normal of an upper side of a component. The oblique radiation enables a higher degree of resolution to be achieved when detecting delamination in the bearing region of holes. Further variants of the device operate using at least one linear probe received in a self-positioning holder. The rotating linear probe is composed of a plurality of individual vibrator elements which are arranged at regular intervals behind one another.

Owner:AIRBUS OPERATIONS GMBH

Digital thermometer for measuring body temperature

InactiveUS7052471B2Improve balanceImprove consistencyThermometer detailsBody temperature measurementDisplay deviceLinear configuration

A digital thermometer with enhanced conformity to the anatomy, such as in and around the mouth of a human being. A non-linear probe has a temperature sensor at a first end adapted to be inserted into the mouth and under the tongue, and a downwardly disposed housing portion at the second end. An intermediate portion of the probe is shaped to rest on the lower lip and / or teeth. The probe is preferably integrally molded with the housing. The probe may also be flexible such that it may be bent into the desired non-linear configuration prior to use. Such a flexible probe may have an internal stiffener with a softer plastic overmold. A display component displays the measured temperature. Electronic circuitry receives a temperature signal from the temperature sensor, translates the signal into a value representative of the measured temperature, and provides the translated value to the display for displaying the temperature.

Owner:MEDPORT +1

Digital thermometer for measuring body temperature

InactiveUS20060189884A1Improve balanceImprove consistencyBody temperature measurementDiagnostic recording/measuringDisplay deviceLinear configuration

A digital thermometer with enhanced conformity to the anatomy, such as in and around the mouth of a human being. A non-linear probe has a temperature sensor at a first end adapted to be inserted into the mouth and under the tongue, and a downwardly disposed housing portion at the second end. An intermediate portion of the probe is shaped to rest on the lower lip and / or teeth. The probe is preferably integrally molded with the housing. The probe may also be flexible such that it may be bent into the desired non-linear configuration prior to use. Such a flexible probe may have an internal stiffener with a softer plastic overmold. A display component displays the measured temperature. Electronic circuitry receives a temperature signal from the temperature sensor, translates the signal into a value representative of the measured temperature, and provides the translated value to the display for displaying the temperature.

Owner:LUSSIER SHERIN B +2

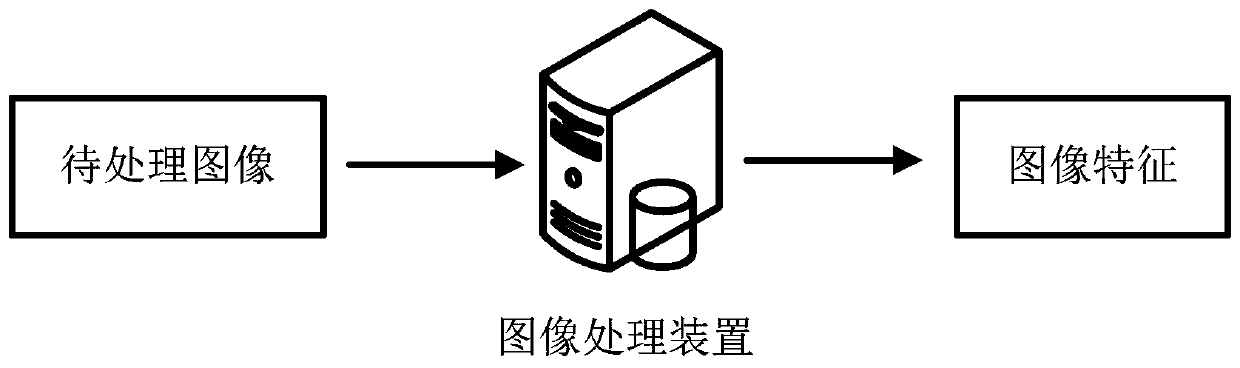

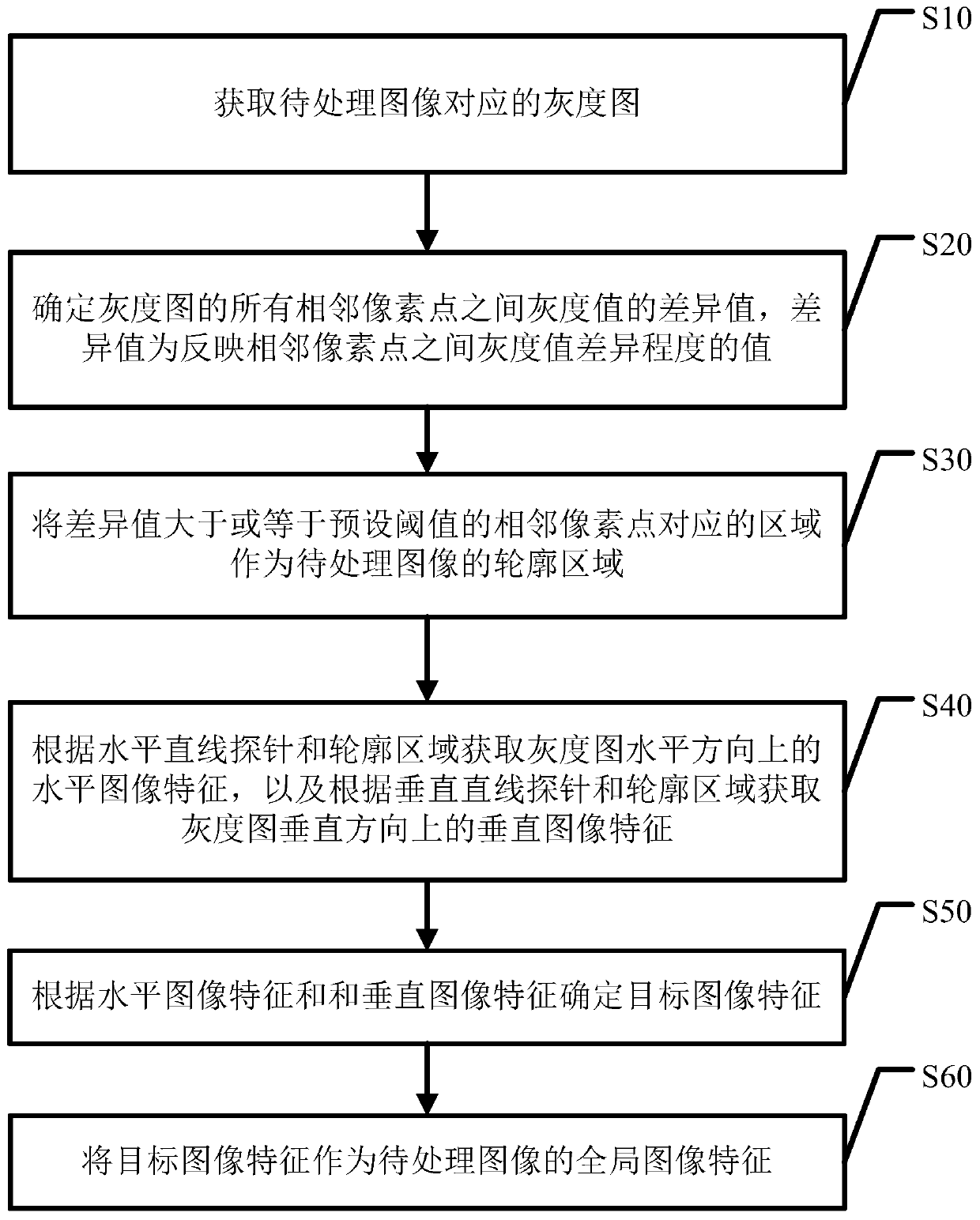

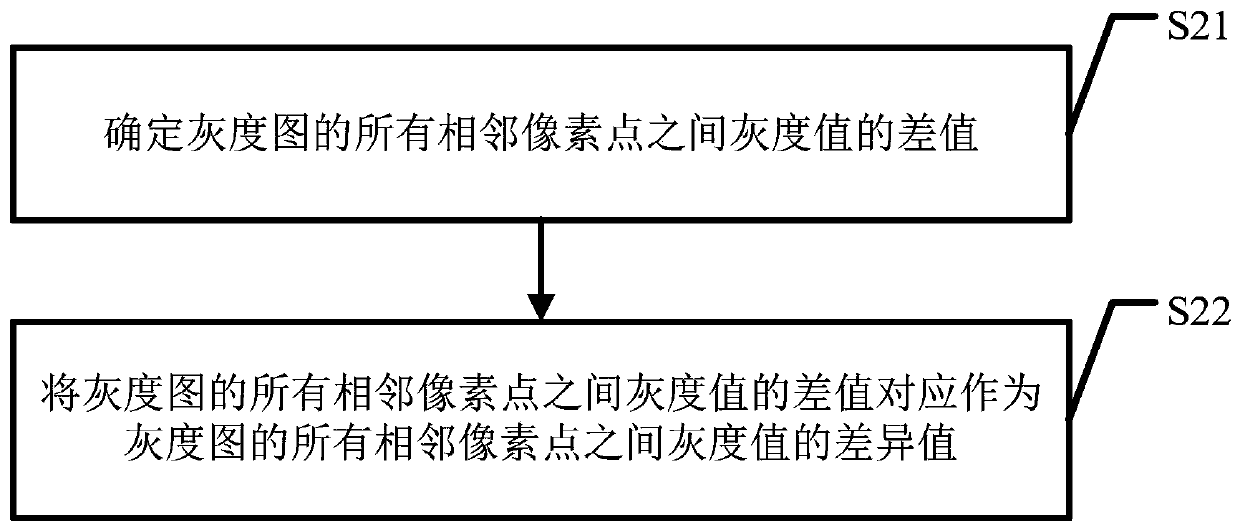

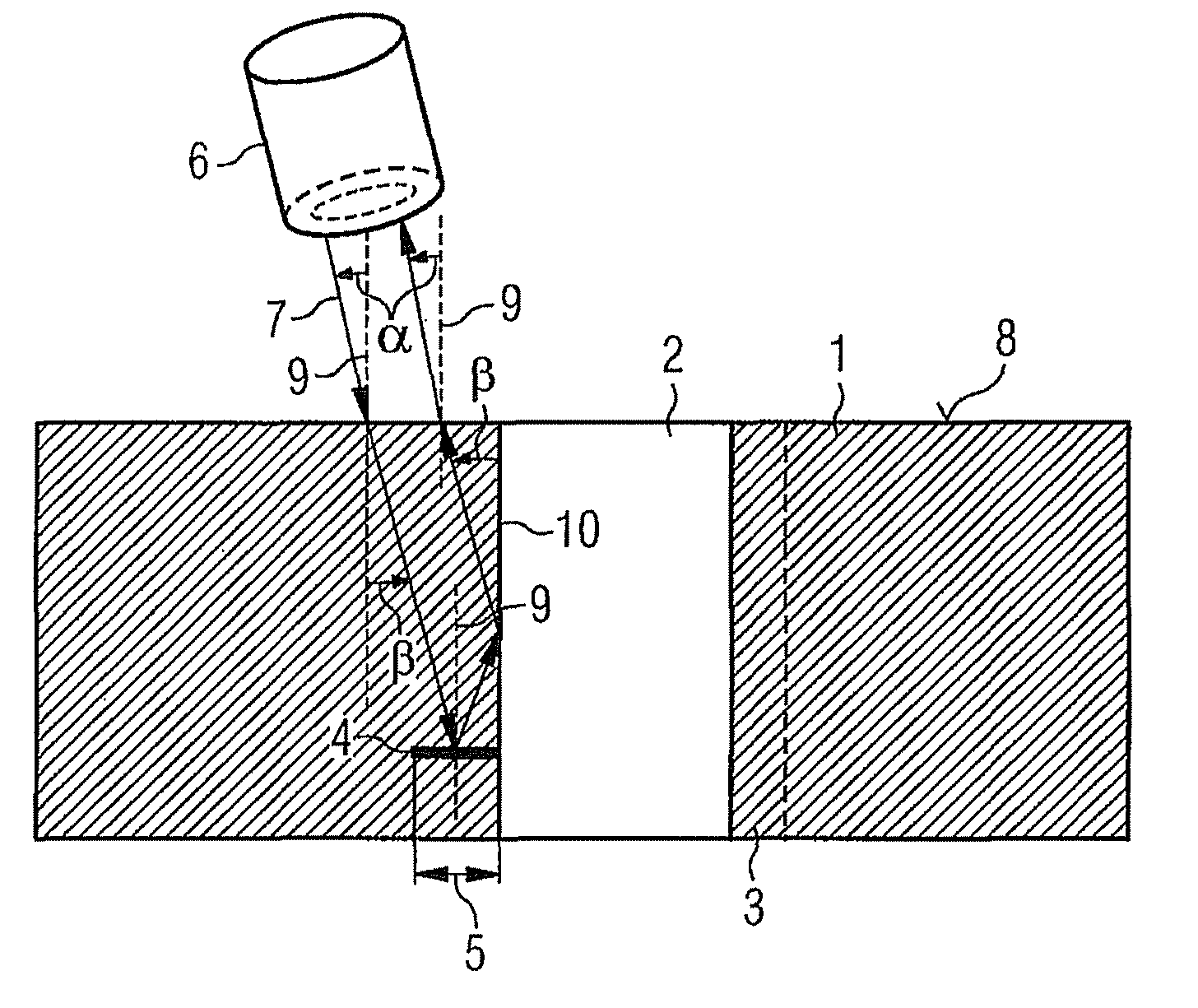

Image processing method and device, computer equipment and storage medium

PendingCN109711419AReduce time complexityReduce space complexityCharacter and pattern recognitionImaging processingFeature extraction

The invention discloses an image processing method and device, computer equipment and a storage medium. The time complexity and the space complexity in image feature extraction are effectively reduced. The method comprises the steps of obtaining a grayscale image corresponding to a to-be-processed image; determining a difference value of gray values between all adjacent pixel points of the gray-scale image, wherein the difference value is a value reflecting a gray value difference degree between the adjacent pixel points; Taking an area corresponding to the adjacent pixel points of which the difference values are greater than or equal to a preset threshold value as a contour area of the to-be-processed image; according to a horizontal linear probe and the contour area, acquiring horizontalimage characteristics of the gray scale image in the horizontal direction, and according to a vertical linear probe and the contour area, acquiring vertical image characteristics of the gray scale image in the vertical direction; determining a target image feature according to the horizontal image feature and the vertical image feature; and taking the target image feature as a global image feature of the to-be-processed image.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

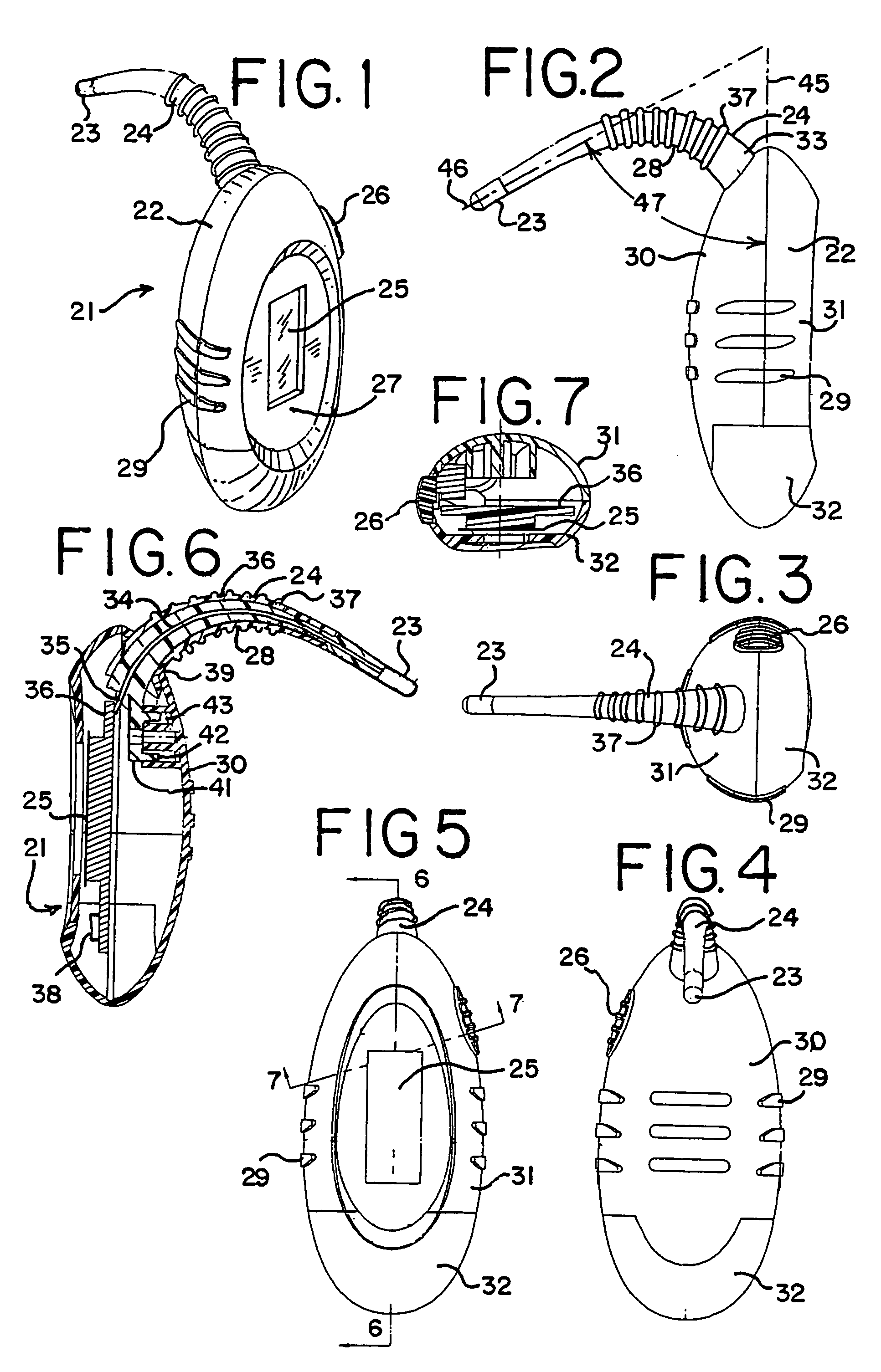

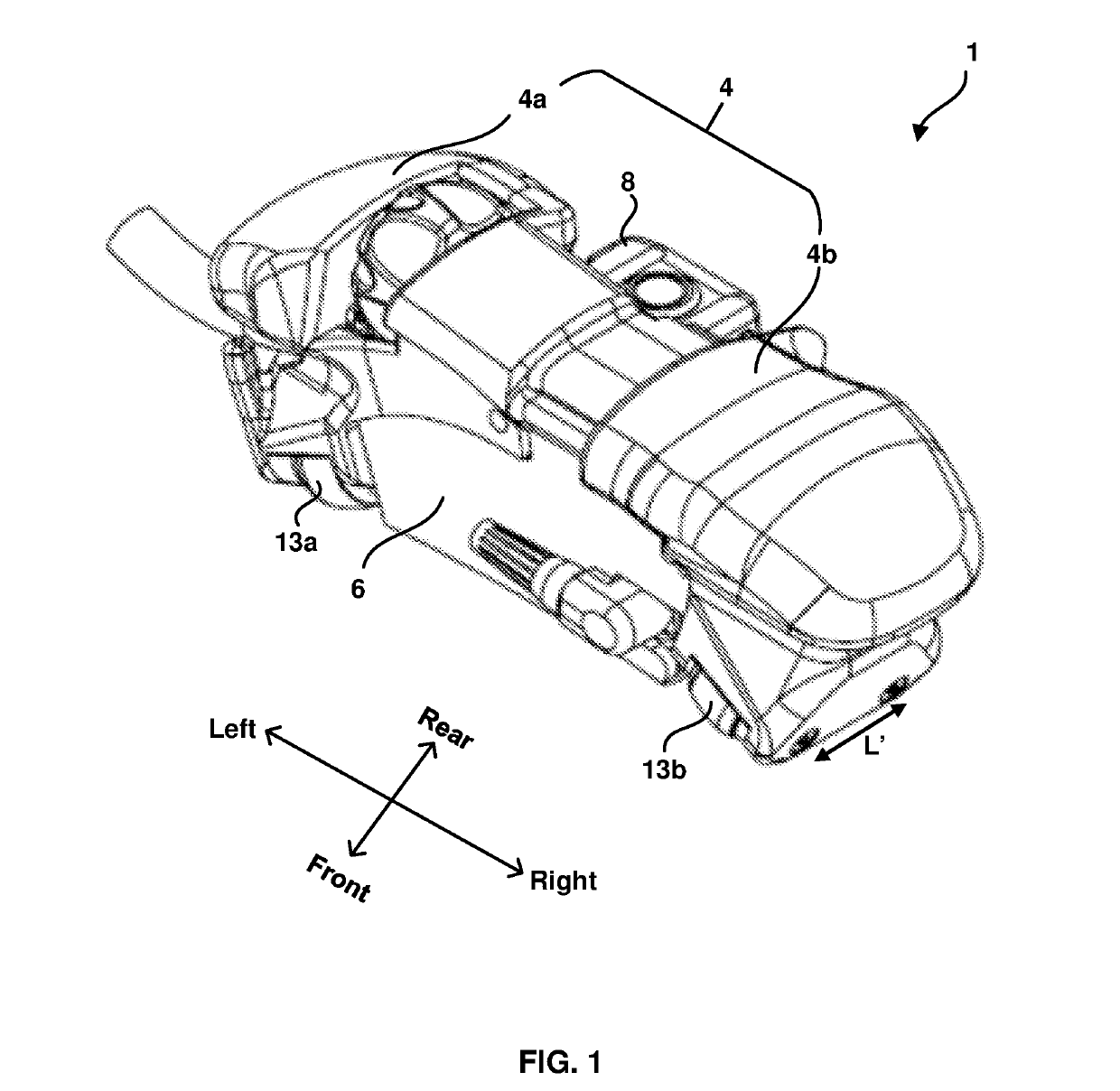

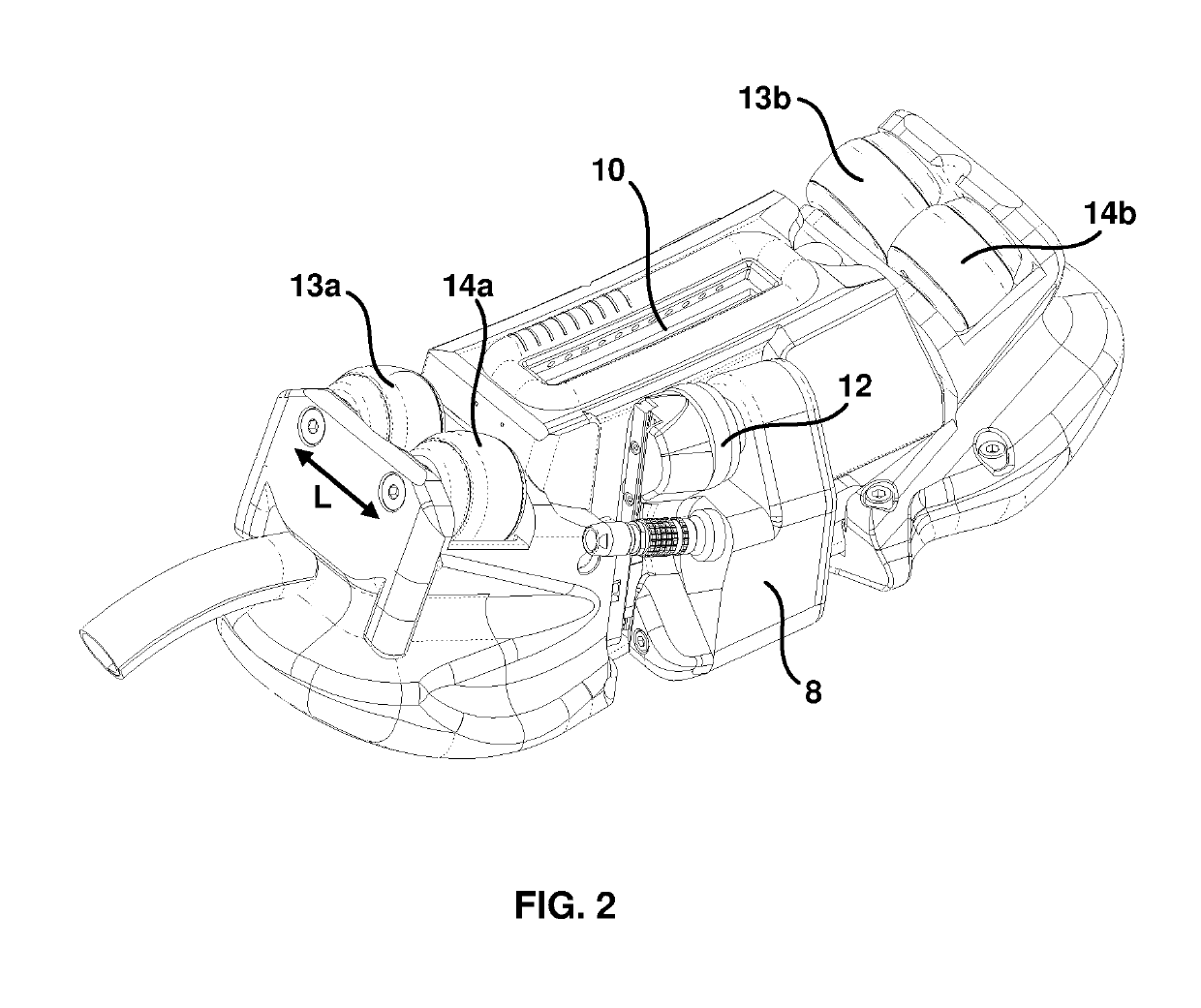

Ultrasonic scanner with interchangeable wedge and flexible probe

ActiveUS20190128856A1Reliably mapping defectMaterial analysis using sonic/ultrasonic/infrasonic wavesData acquisitionEngineering

An ultrasound probe assembly comprises a housing and a wedge, wherein wedges configured for pipes of different diameter may be easily interchanged in the assembly. Four wheels are attached to the housing, there being a front wheel pair and a rear wheel pair. Wheels of each pair are positioned on either side of a linear probe array, wherein the distance between wheels in each pair in a direction perpendicular to the array length is as small as possible. A position encoder monitors the position of the assembly during scanning, and a push lock switch is used to disable the encoder and the data acquisition while indexing to a new scan position on the pipe.

Owner:OLYMPUS SCI SOLUTIONS AMERICAS +1

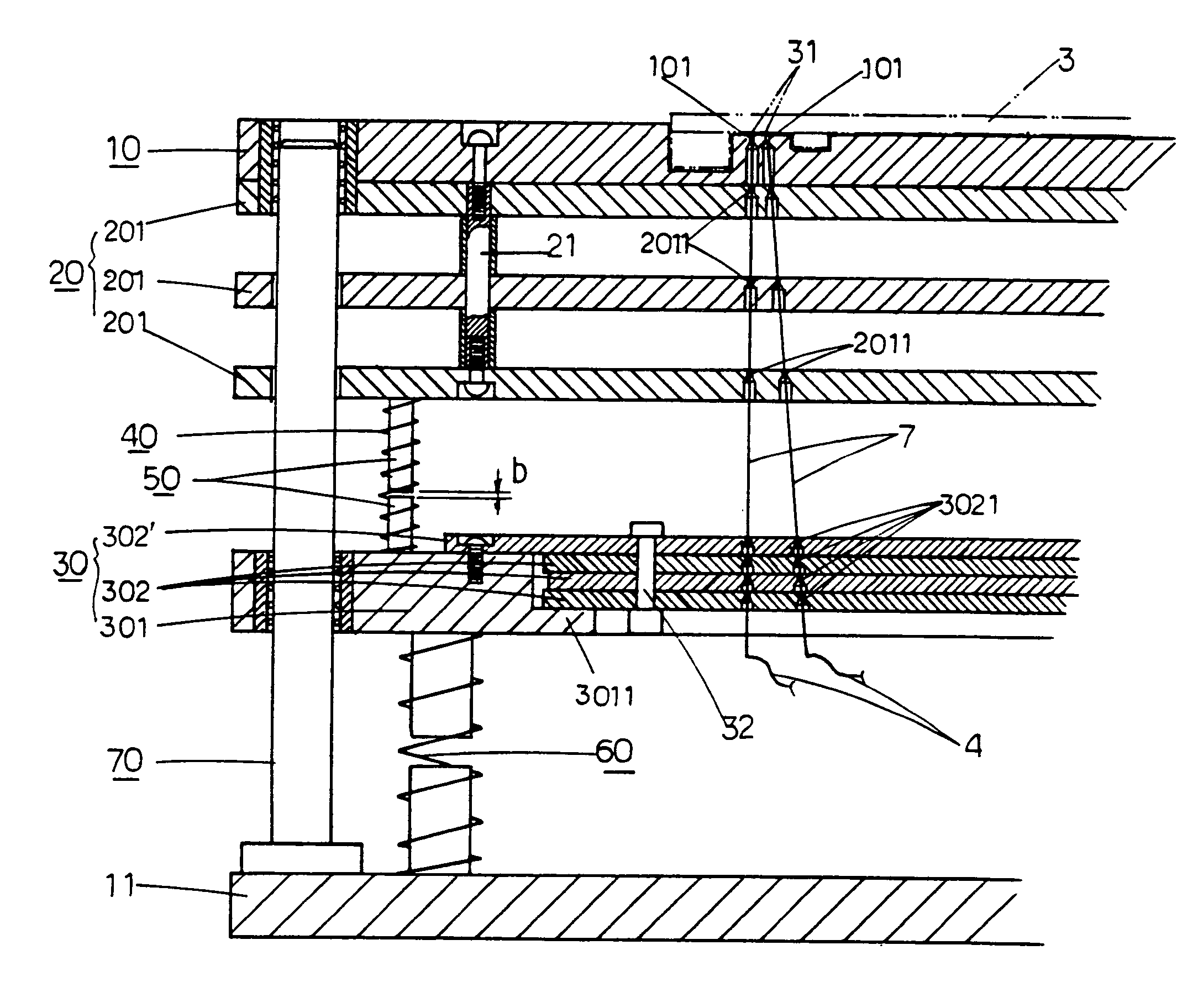

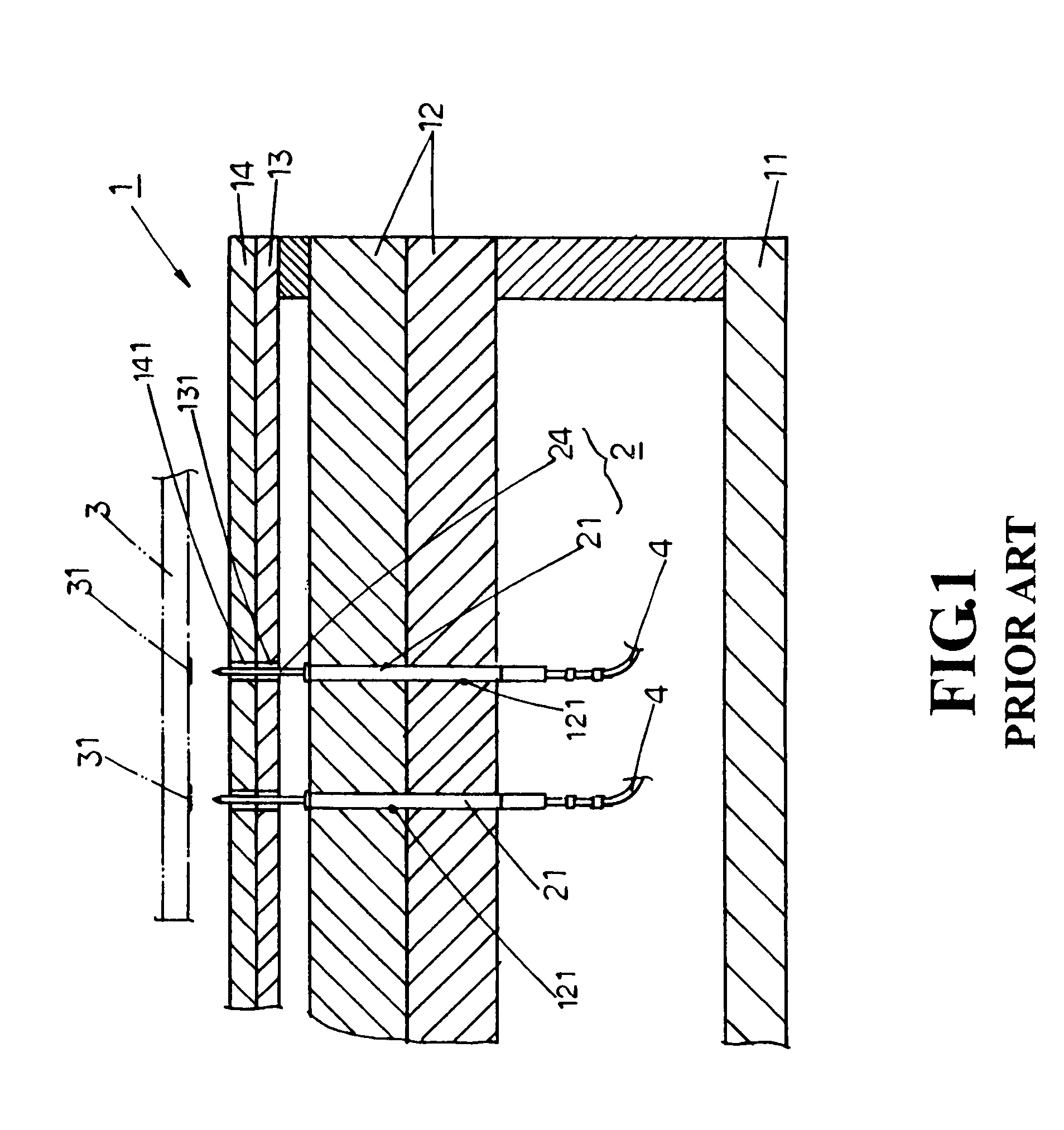

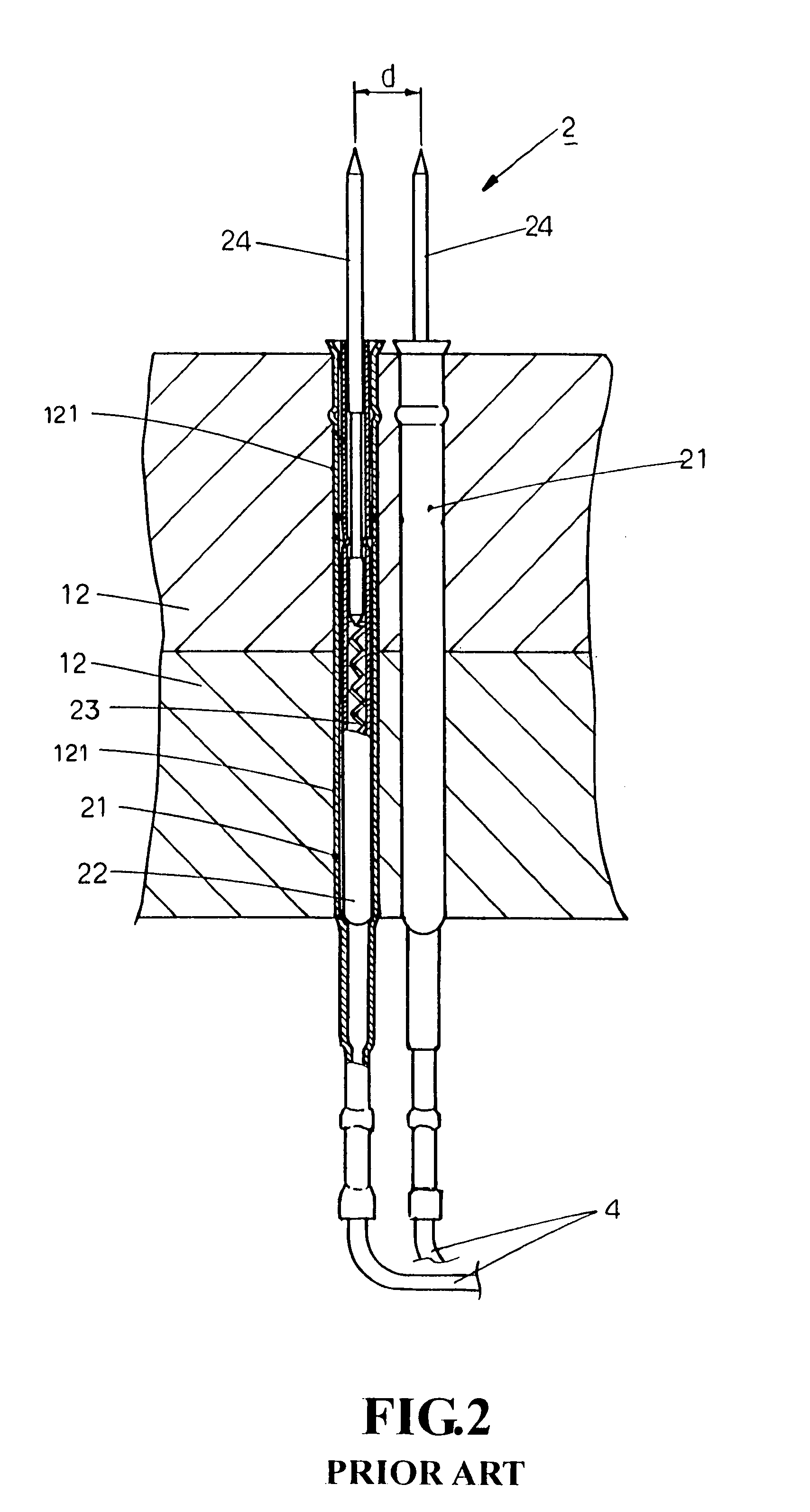

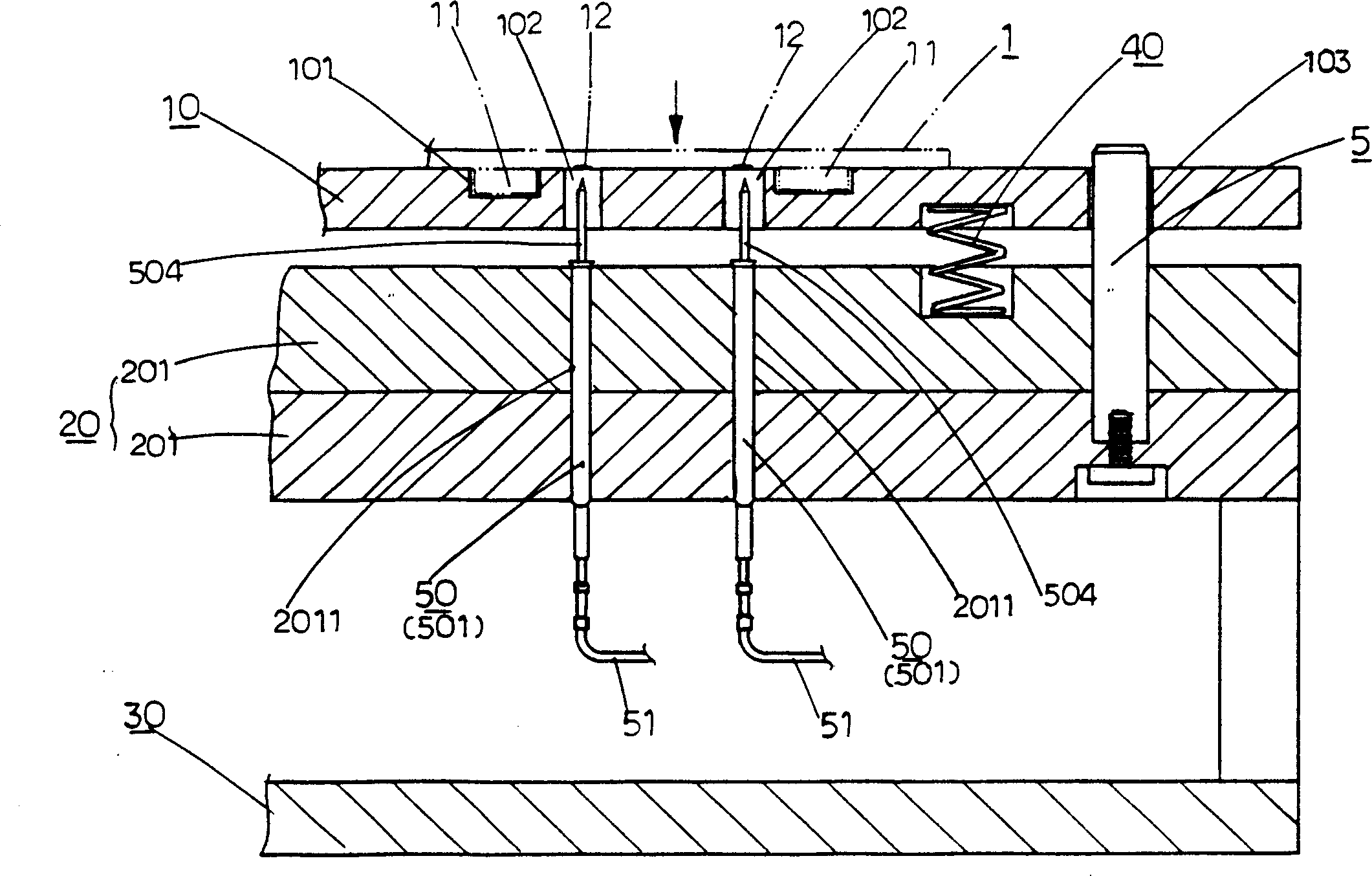

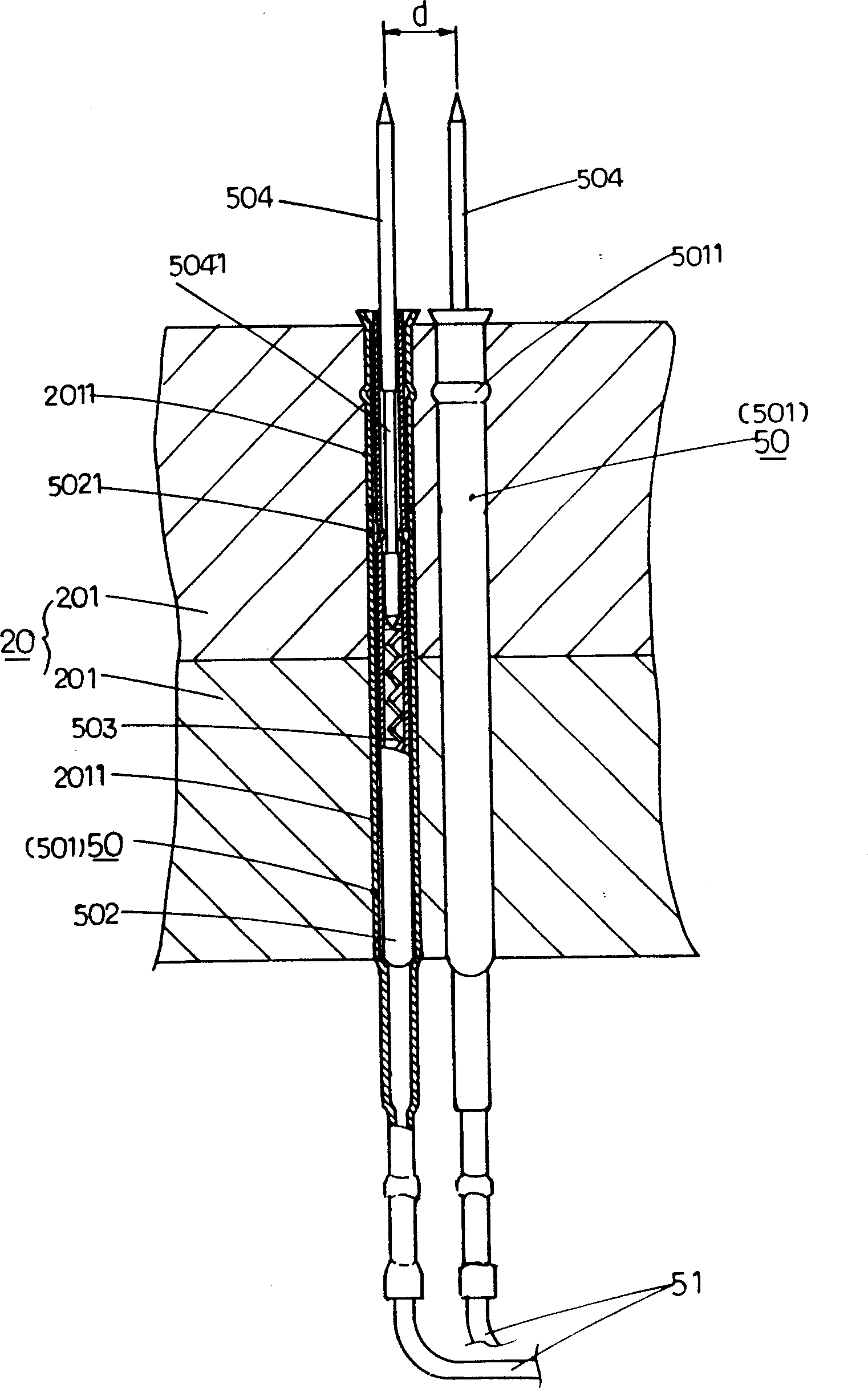

Various electrical characteristics and small test point testing module

InactiveUS6963210B1Improve test stabilityEasy to assembleElectrical measurement instrument detailsContactless circuit testingCushioningEngineering

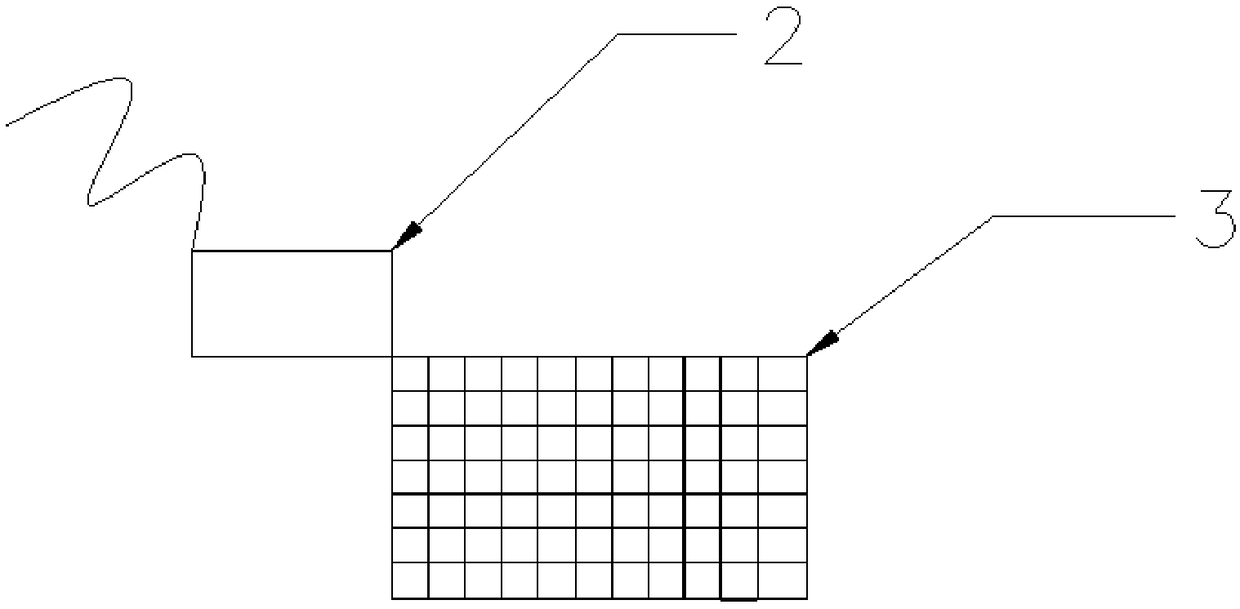

A various electrical characteristics and small test point testing module comprised of a carrier plate, a guide correction layer, a clamp pin layer, linear probes, first cushioning components, second cushioning components, travel adjustment rods, guide posts, and a base, wherein the carrier plate, the guide correction layer, and the clamp pin layer are capable of vertical ascension and descension along the same axis by means of the guide posts. The linear probes are inserted into the carrier plate, the guide correction layer, and the clamp pin layer such that their inner extremities are fixed at the clamp pin layer and their outer extremities are situated at the carrier plate position. The first cushioning components and the travel adjustment rods are disposed between the guide correction layer and the clamp pin layer, while the second cushioning components are disposed between the base and the clamp pin layer such that the carrier plate, the guide correction layer, and clamp pin layer all are supported by an elastic force and each linear probe is subjected to an equal magnitude of elastic force.

Owner:CHENG CHIN TSAI

Ultrasonic probe, bioinformation measurement device, and bioinformation measurement method

InactiveUS20140296714A1Without any changeMinimum operationElectrocardiographyHealth-index calculationMeasurement deviceBiomedical information

With an ultrasonograph, medical information of a heart could not be accurately obtained as the cardiac apex of the heart could not be recorded clearly. A biomedical information measuring device capable of obtaining accurate medical information is created by measuring an apexcardiogram in M-mode using a linear probe, and improving a data processing device so as to establish an algorithm useful in accurate evaluation so as to solve the above problem.

Owner:KUROKI SHIGEHIRO +1

Device for detecting a flaw in a component

InactiveUS8161818B2Reliable detectionMultiple-port networksAnalysing solids using sonic/ultrasonic/infrasonic wavesFiberAngle of incidence

Owner:AIRBUS OPERATIONS GMBH

Loaded board test method

InactiveCN1815241APracticalAccurate and stable detection effectElectronic circuit testingElectrical measurement instrument detailsEngineeringLinear probe

The method includes wire carrier, needle dial, linear probes, buffer element of needle dial, buffer element of probes, guard plate, and linear bearing set etc. main elements. Being combined through linear bearing set, the needle dial and the wire carrier are spaced by the buffer element of needle dial. The needle dial consists of carrier plate, multiple blocks of guiding plate, and multiple plates for movement of needle. Each linear probe in vertical or tilting position is inserted to plug seat prearranged on the carrier plate, each guiding plate, and plate for movement of needle. Head end of linear probe is corresponding to point to be tested of object to be tested, and tail end of linear probe is inserted to the support part of buffer element of probe. Being in prearranged thickness, the guard plate is setup between the wire carrier and the needle dial in order to make test reach purposes of stable and accurate test.

Owner:芽庄科技股份有限公司

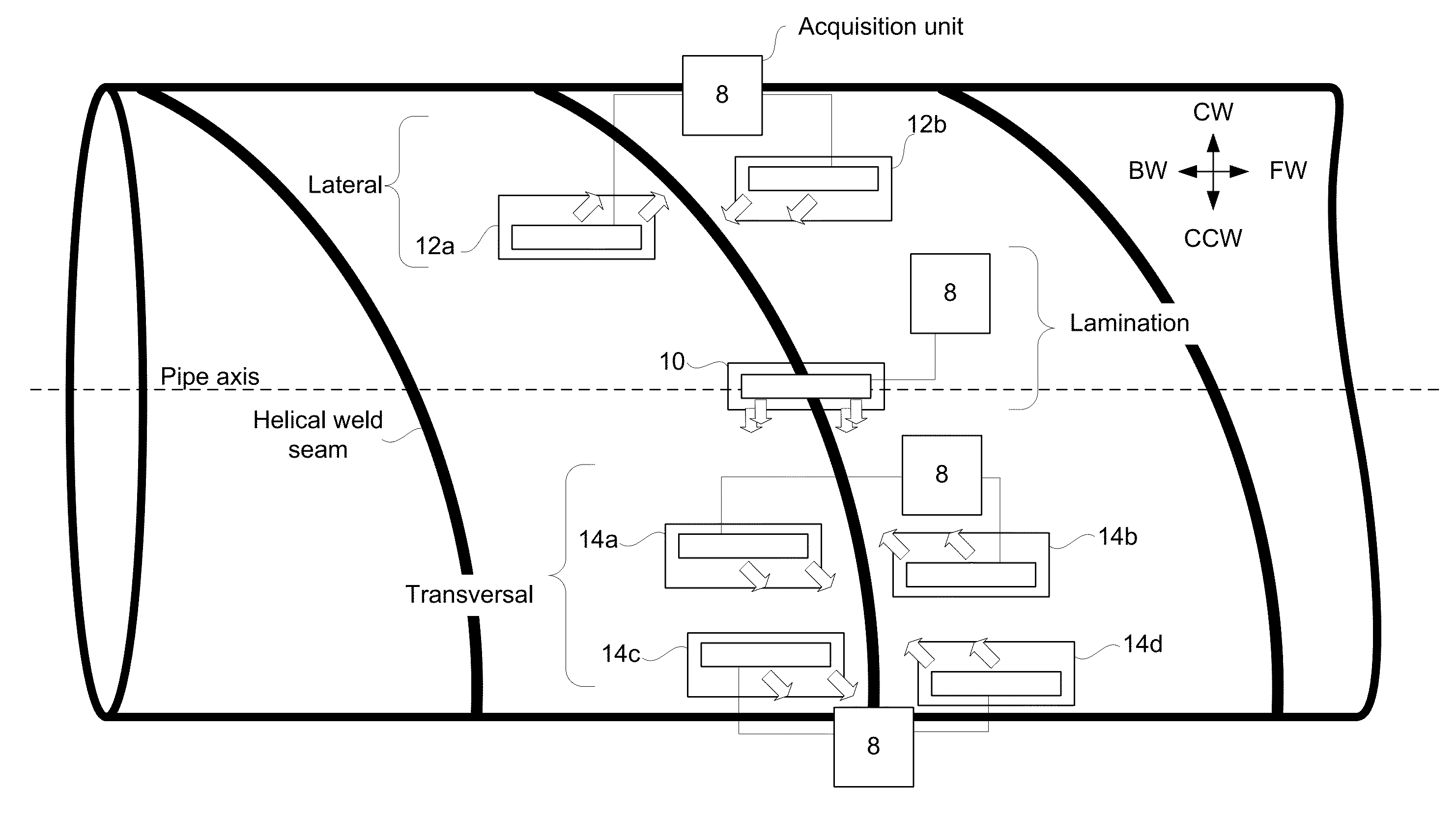

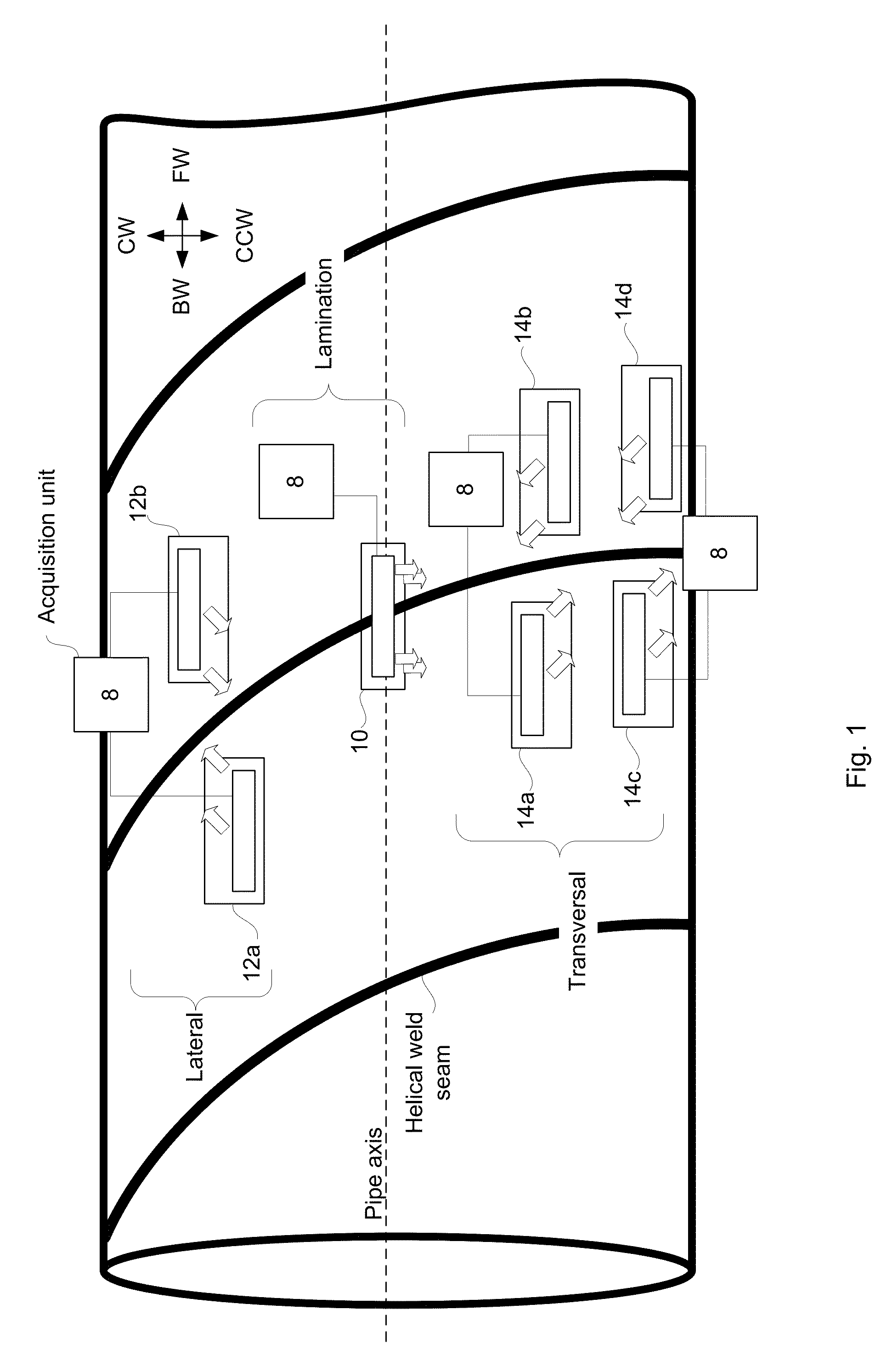

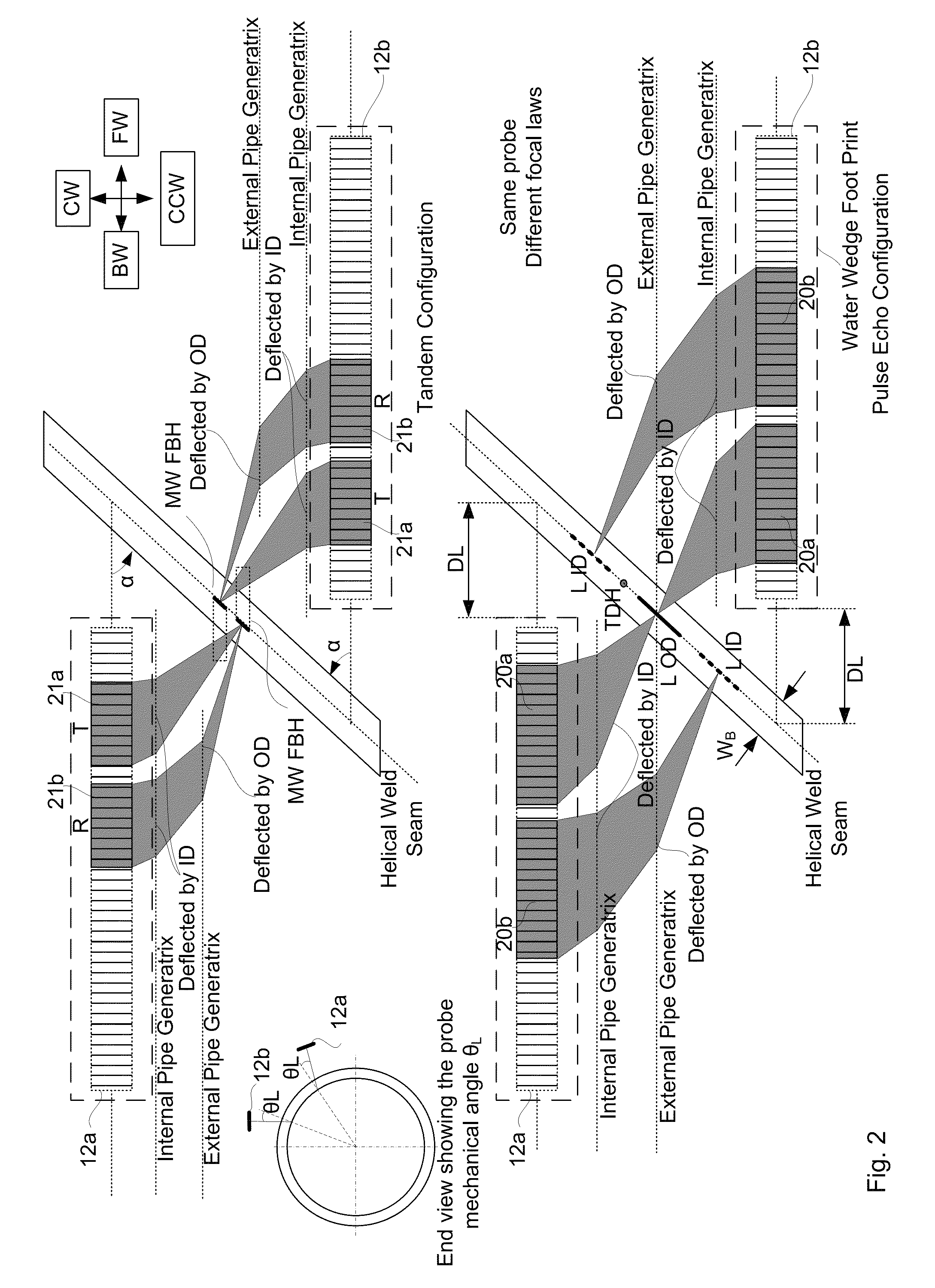

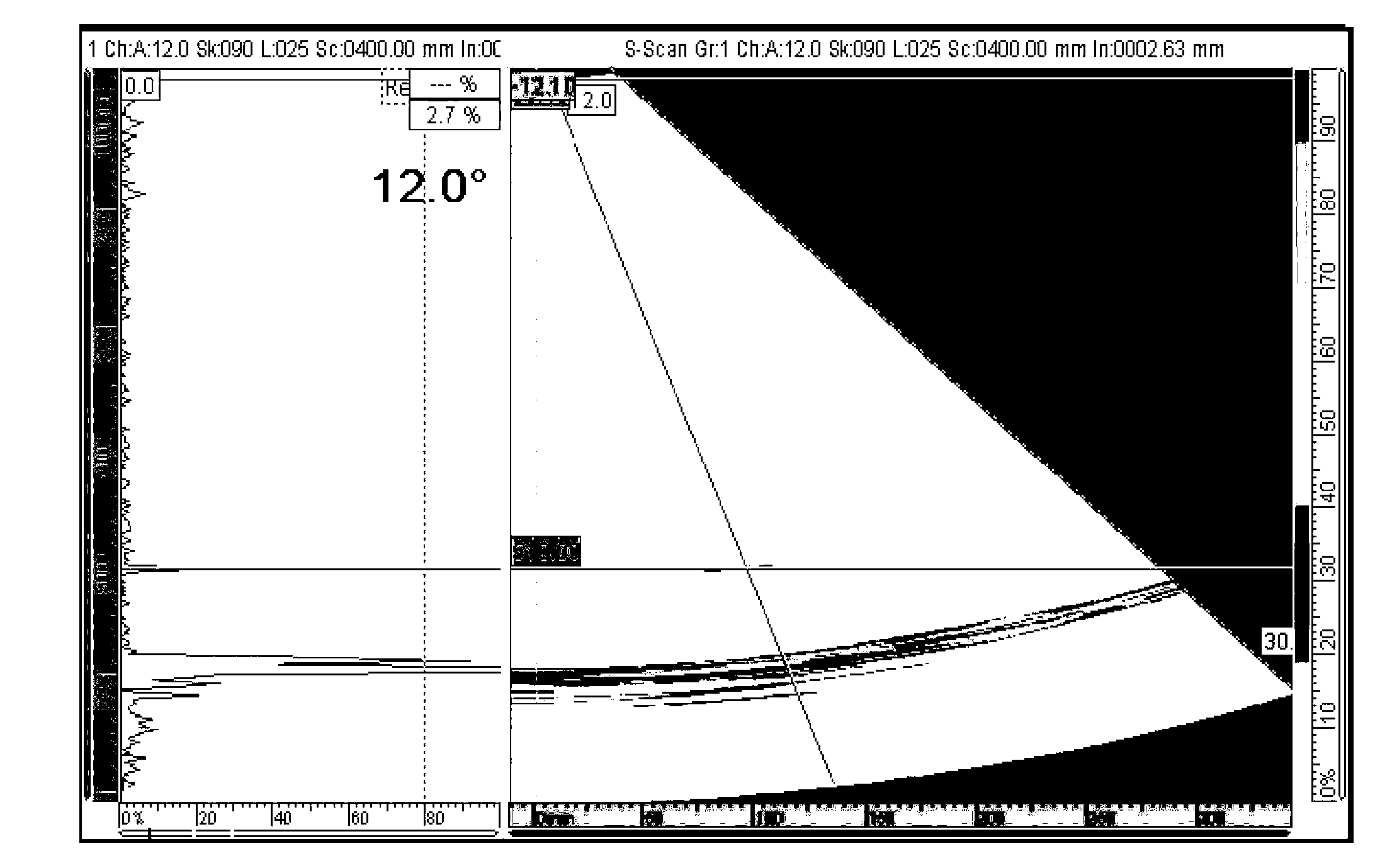

Phased array system and method for inspecting helical submerged arcs weld (HSAW)

ActiveUS9032802B2Reduce needAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceEngineeringWeld seam

A phased array system and the inspection method which is configured to inspect the weld seam of an HSAW for all standard types of flaws located both near pipe's internal and external surfaces in one scan pass, diminishing the need of making mechanical adjustment for the probes during the one pass of scan. The configuration includes the usage of at least one linear PA probe for Lamination inspection right above HAZ zone, at least one pair of PA probes for longitudinal defects inspection and holes detection and at least two pairs of PA probes for transversal defect inspections.

Owner:OLYMPUS NDT

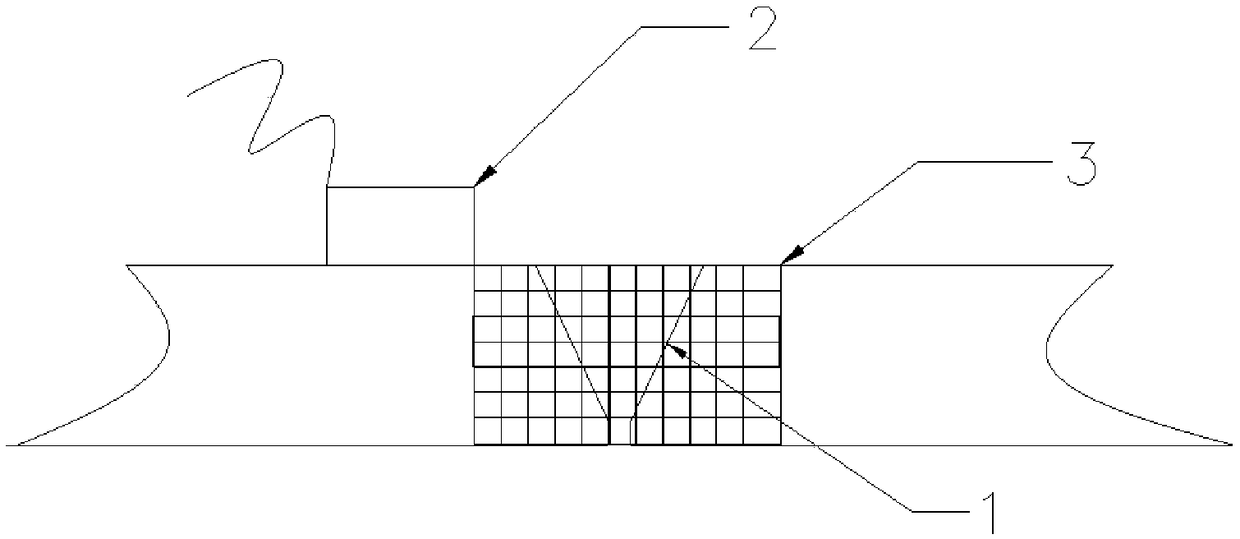

Fully-focused detection method used for coarse-grained materials and based on phased array ultrasonic flaw detector

InactiveCN108663434AReduce capacityHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveHeat-affected zone

The invention relates to technical field of non-destructive testing, in particular to a fully-focused detection technology used for coarse-grained material weld joints and based on an M2M phased arrayultrasonic flaw detector. The fully-focused detection technology includes: using the M2M phased array ultrasonic flaw detector as the detection instrument to form a rectangular scanning area on a to-be-detected workpiece, and allowing the scanning area to cover the weld joints and heat affected zone of the to-be-detected workpiece; using M2M instrument detection software to divide the weld jointsand heat affected zone of the to-be-detected workpiece into countless points, focusing each point, and collecting scanning data; using a scanning rack to detect the to-be-detected workpiece, collecting full-weld-joint scanning data, and performing quality evaluation according to related to standards. The detection technology has the advantages that the to-be-detected areas are divided into countless points by using a two-dimensional linear probe, focused detection is performed on each point, the detection sensitivity of the areas can be effectively increased, and effective detection of coarse-grained materials can be achieved; the M2M phased array ultrasonic flaw detector is used to perform optimal algorithm processing on the data, data quantity is reduced, and storage and on-site detection and analysis are facilitated.

Owner:中能建建筑集团有限公司 +2

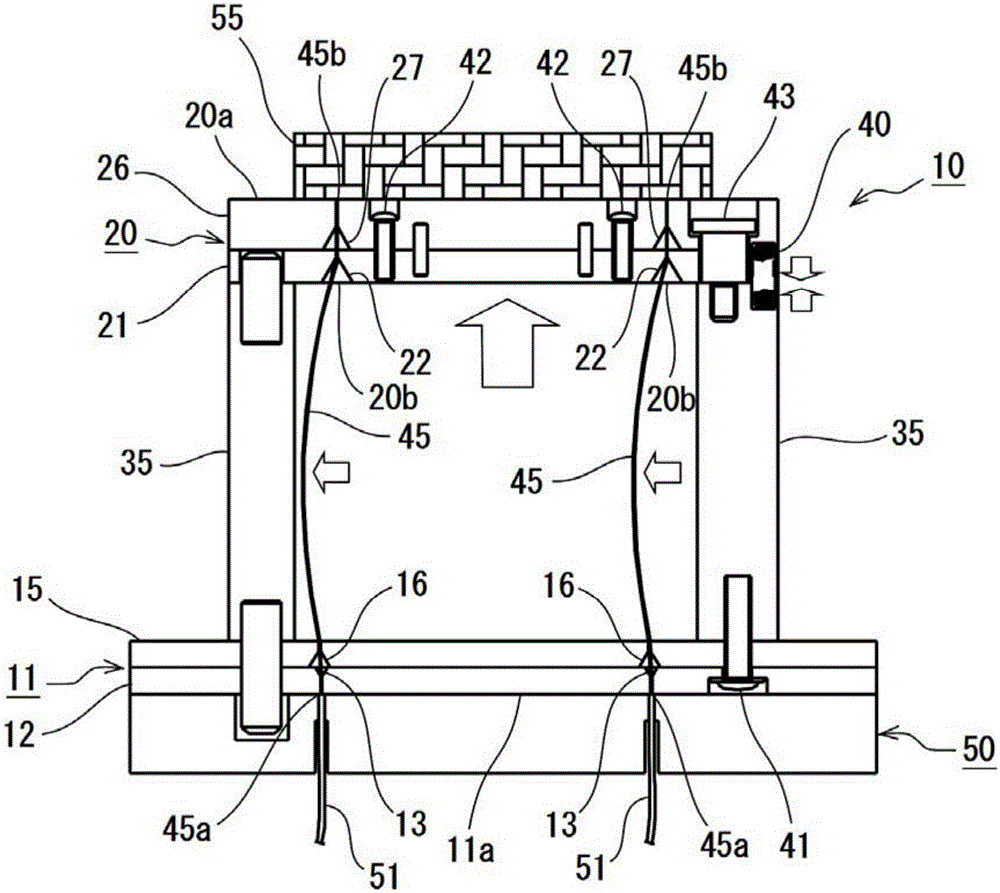

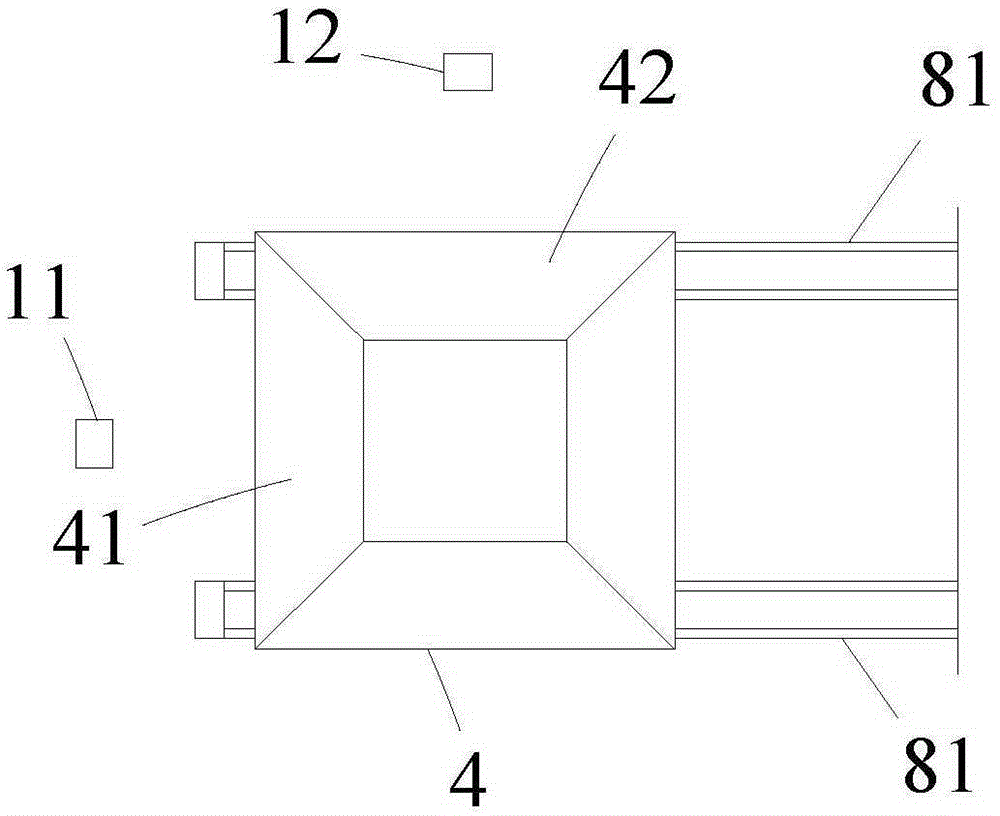

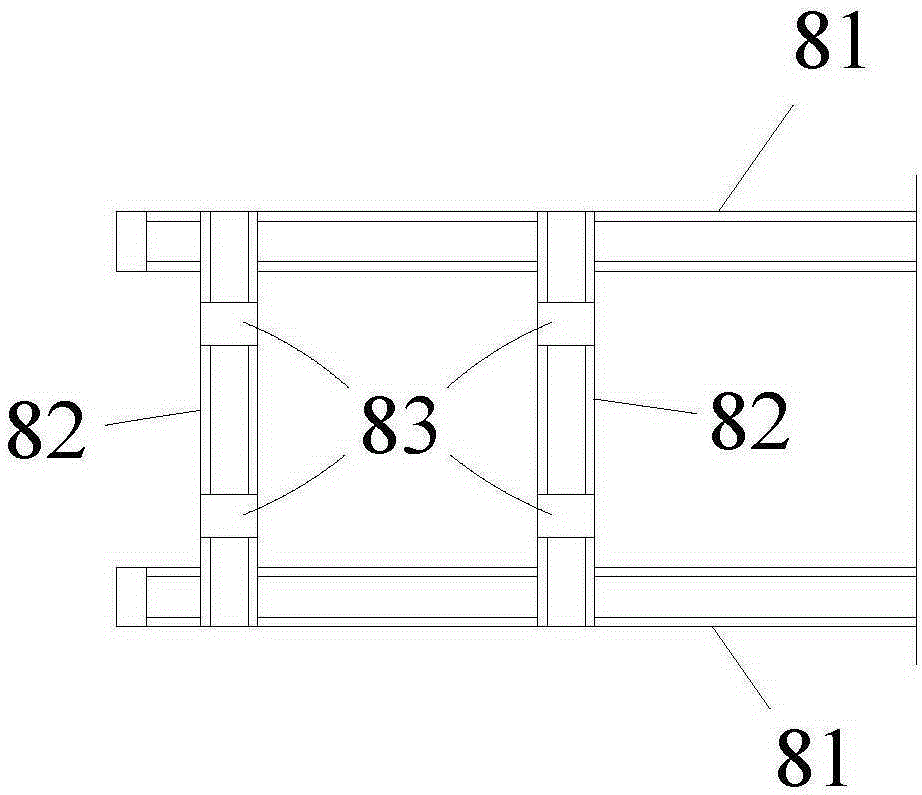

Jig for linear probes

ActiveCN105988027AReliable contactPrevent movementElectrical measurement instrument detailsElectrical testingEngineeringLinear probe

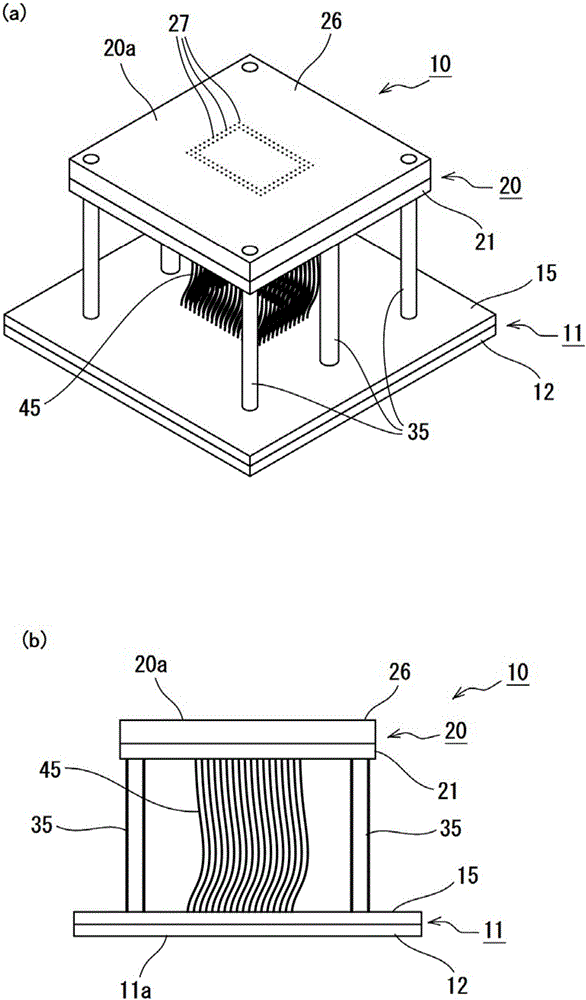

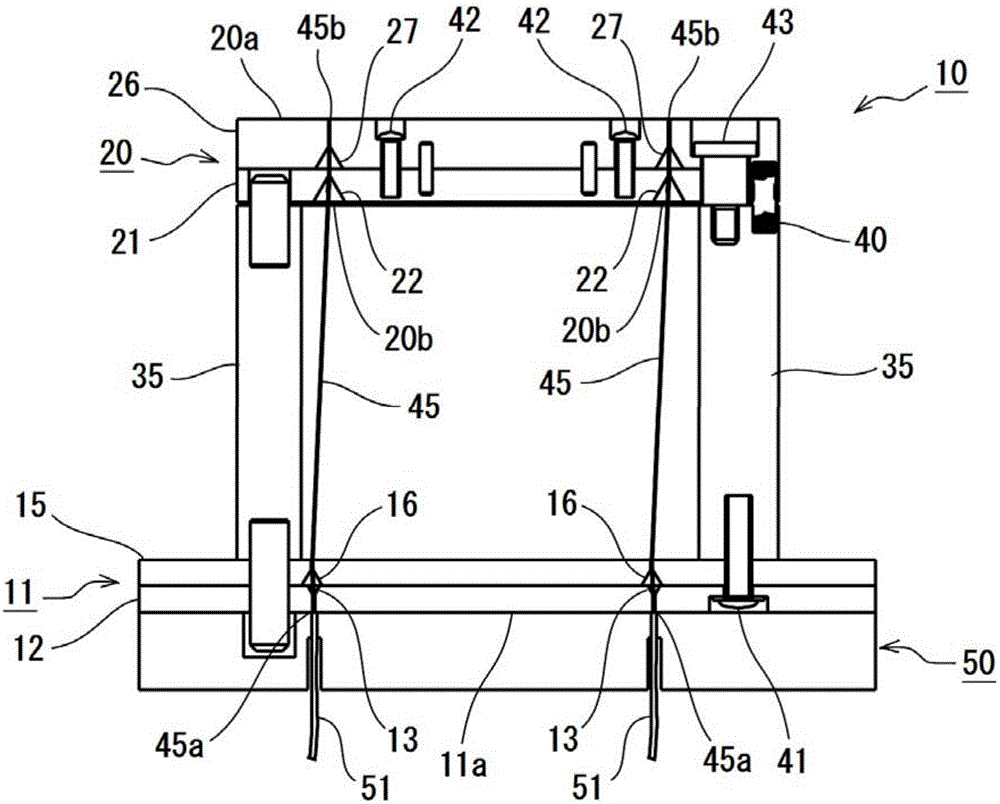

The invention provides a jig for linear probes, which enables two terminals of the linear probe to be in reliable contact with a terminal of an electrode substrate and a terminal of a detected substrate without producing wearing of the linear probe. A base part (11) and a top part (20) are configured in a manner of relative movement; the base part (11) maintains the rear end (45a) of the linear probe (45) and ensures the contact between the rear end part (45) and an electrode substrate (50), and the top part (20) enables a front end part (45b) to be in contact with a substrate to be detected (55); the base part (11) comprises a first bottom plate (12) and a second bottom plate (15); the first bottom plate (12) is provided with a first guiding hole (13) for the linear probe (45) to pass through; the second bottom plate (15) is provided with a second guiding hole (16) which is arranged in a manner of staggering in a predetermined direction with the center of the second guiding hole (16) opposite to the center of the first guiding hole (13).

Owner:ORGAN NEEDLE CO LTD

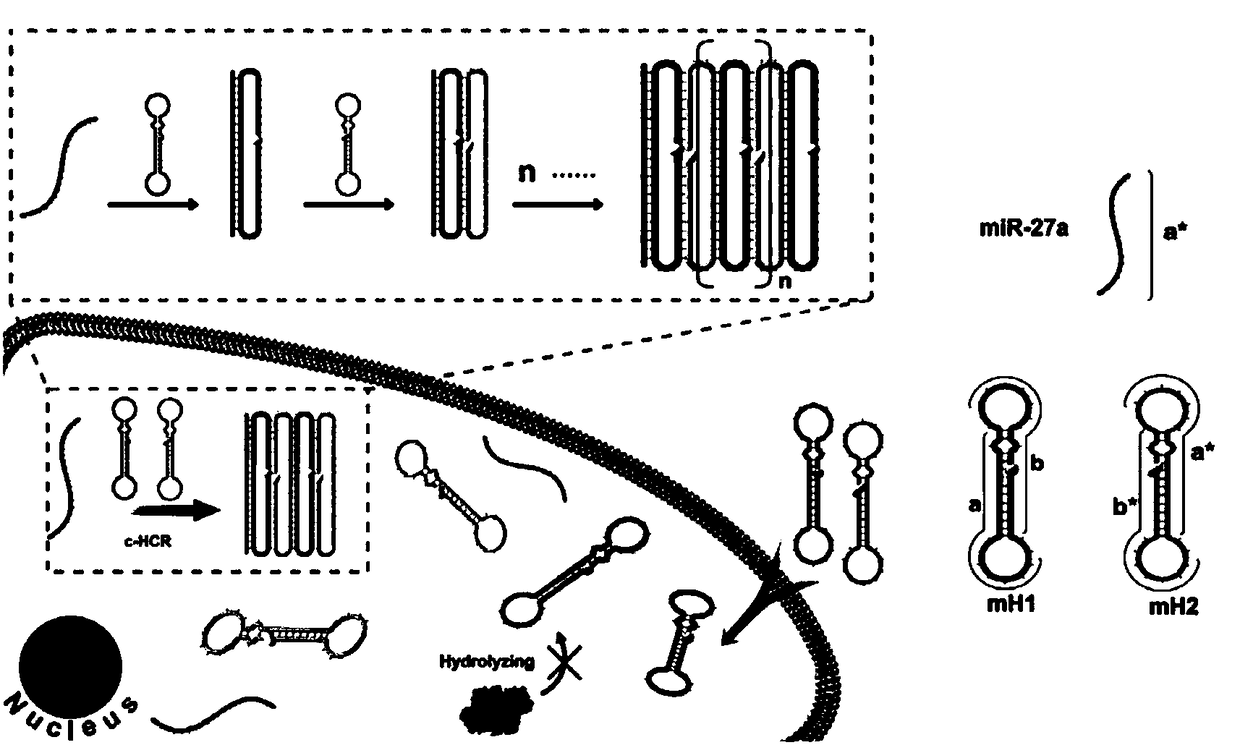

Circular dumbbell-shaped probes and application thereof

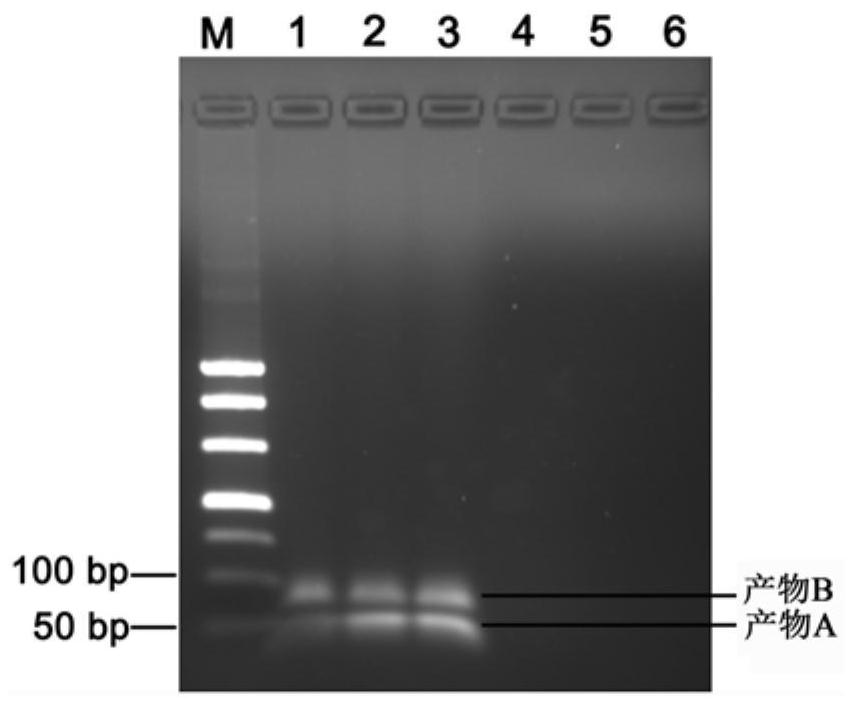

ActiveCN108300775AOvercome the defect of easy hydrolysisStrong hydrolysis resistanceMicrobiological testing/measurementHybridization reactionNucleic Acid Probes

The invention discloses circular dumbbell-shaped probes and an application thereof. Two kinds of circular dumbbell-shaped probes are designed for chain hybridization reaction amplification, so as to detect the concentration of a to-be-tested target and to be applied to in-situ imaging of target sequences in cells. Compared with the existing chain hybridization amplification method, the method hasthe advantages that the defect that linear probes or hairpin probes are easy to hydrolyze in cells is overcome, high hydrolysis resistance of circular nucleic acid probes is discovered, the circular probes are combined with a chain hybridization reaction to be applied to imaging of target sequences in living cells, false positive and background signals are reduced, and detection accuracy is improved.

Owner:SUN YAT SEN UNIV

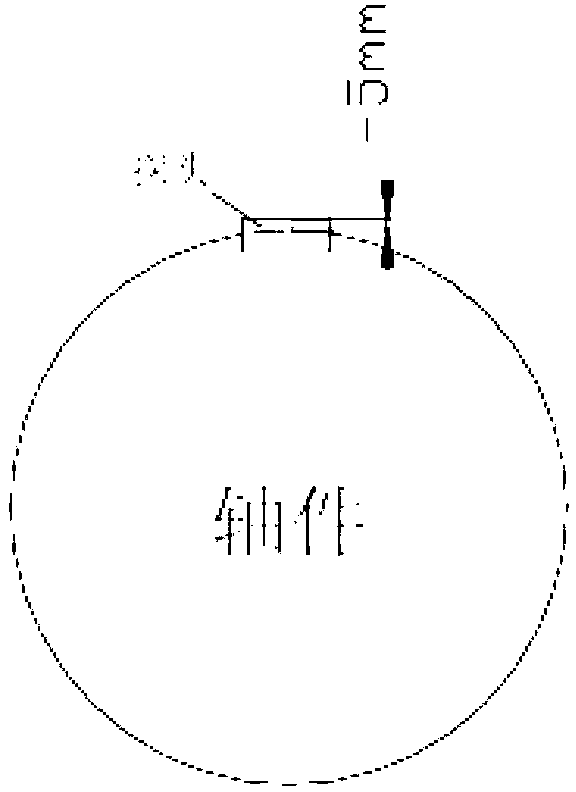

Ultrasonic phased array nondestructive testing method for shafts of recreation facilities

InactiveCN103267806AImprove detection efficiencyReduce investmentMaterial analysis using sonic/ultrasonic/infrasonic wavesRecreationUltrasonic testing

The invention discloses an ultrasonic phased array nondestructive testing method for shafts of recreation facilities. According to the method, an OmniScan MX instrument is used, a sector scanning angle is set to be less than or equal to 30 DEG, and a linear probe with frequency of 2 MHz and less than or equal to 256 wafers is selected and used for detection from two end faces of a shaft member. The shaft member is divided into corresponding different detection areas along a length direction according to the position of the phased array probe on the end faces of the shaft member and the range of the scanning angle, and the probe is utilized for scanning the areas one by one. Through selection and usage of only one linear probe and utilization of ultrasonic phased array technology, nondestructive testing of shafts with different shapes and sizes can be realized, detection efficiency is improved, the problems that probes of different models are needed for detection of different shafts and different shaft reference blocks have to be arranged for contrast test in traditional ultrasonic testing of shafts are overcome, and investment in manpower and material resources can be substantially reduced.

Owner:TIANJIN SPECIAL EQUIP INSPECTION INST

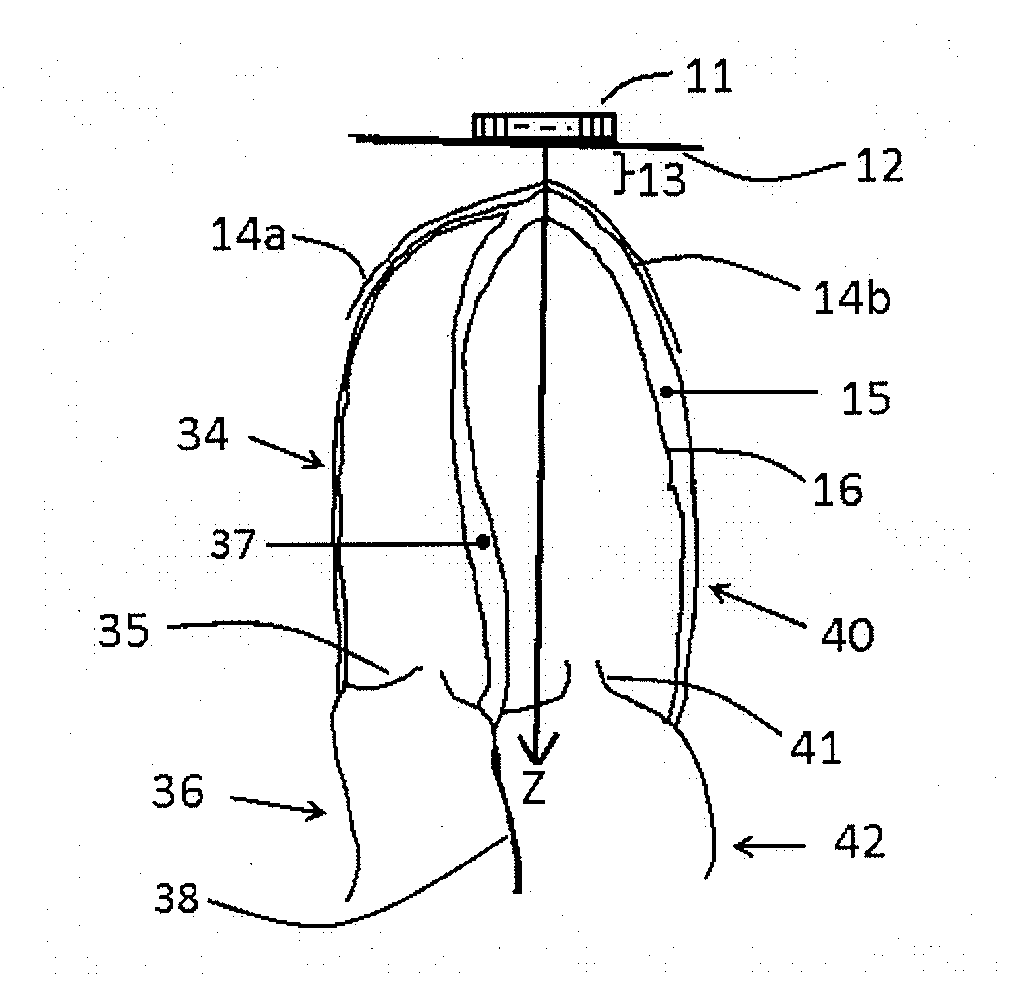

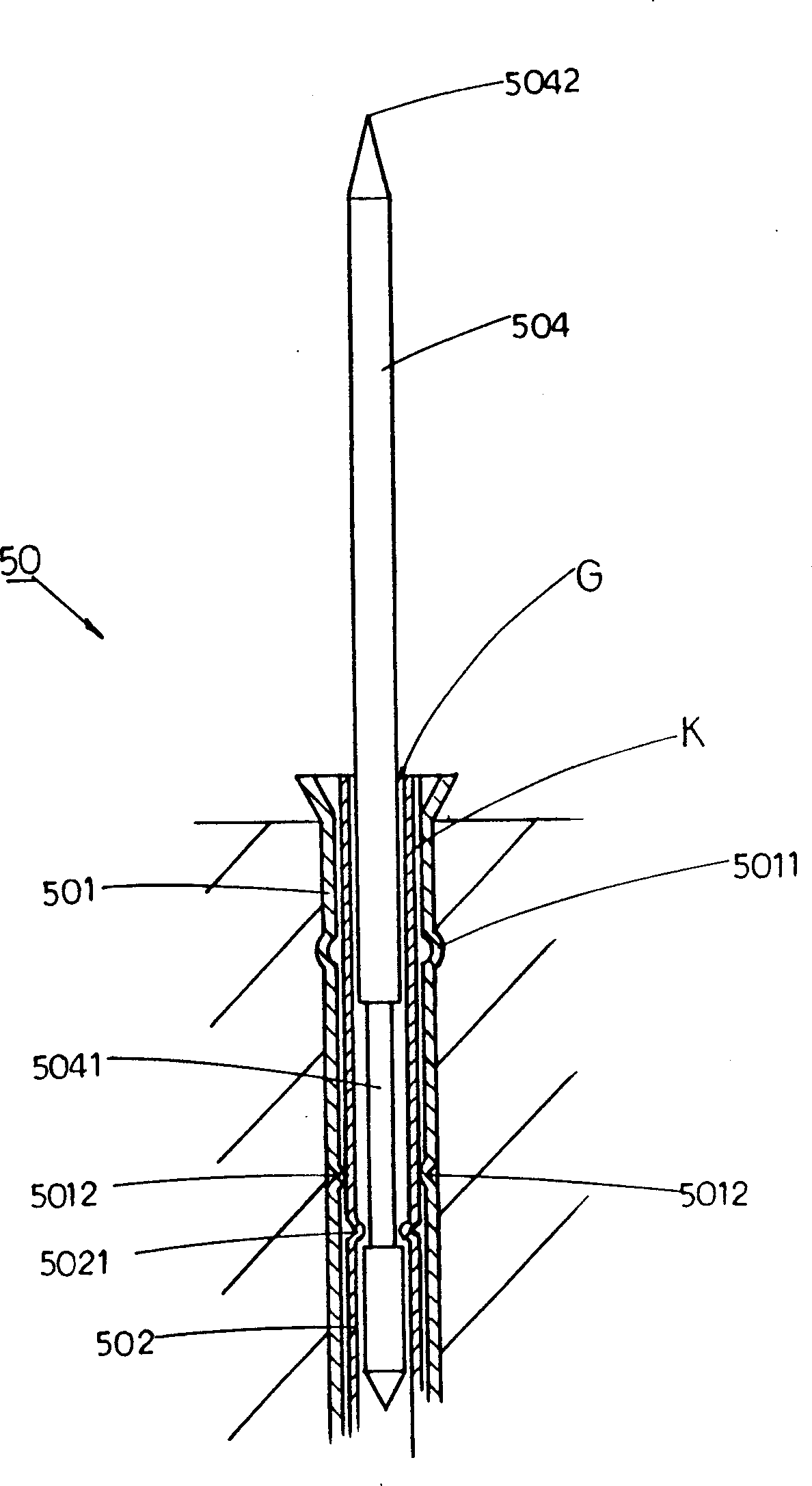

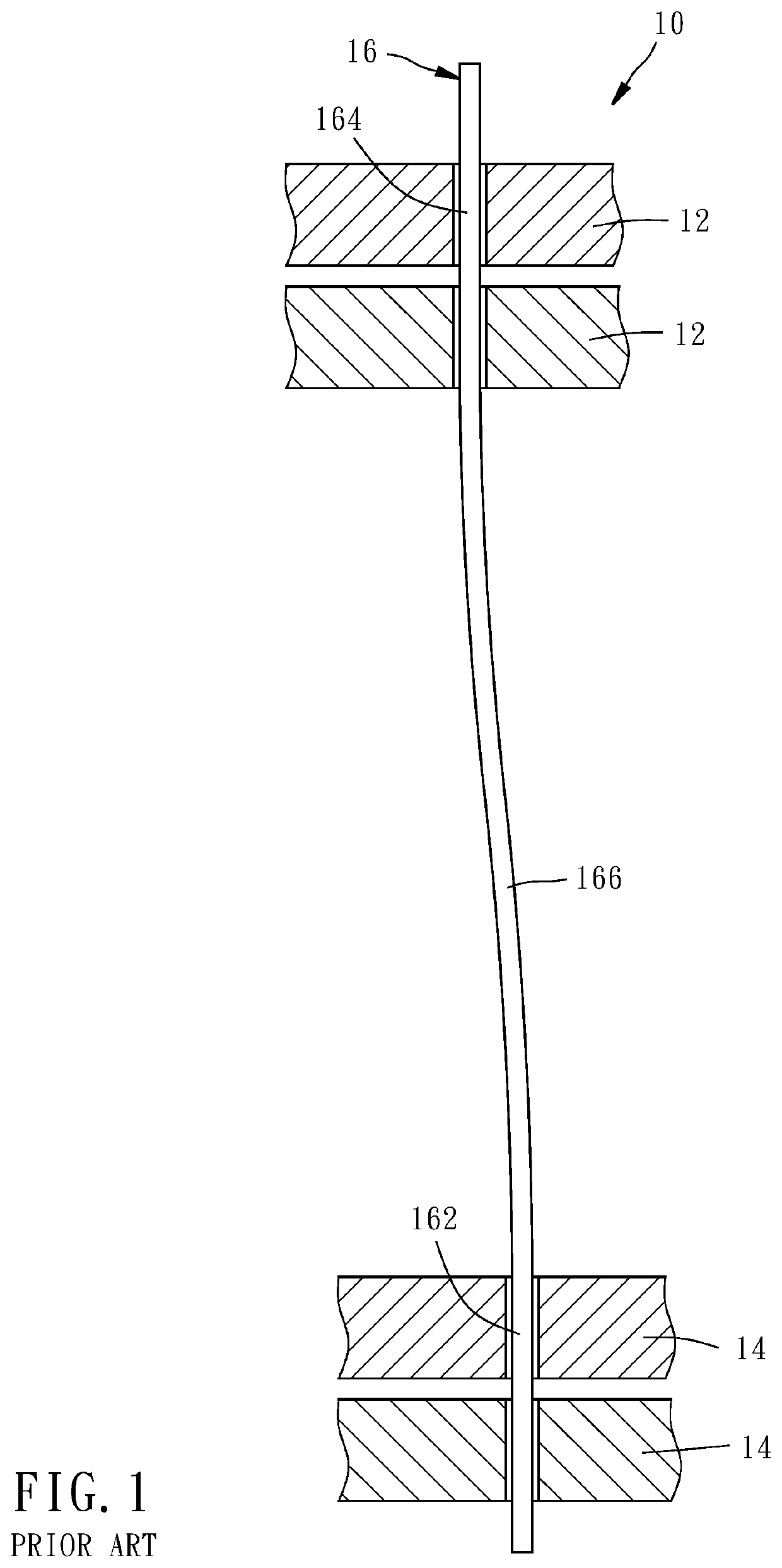

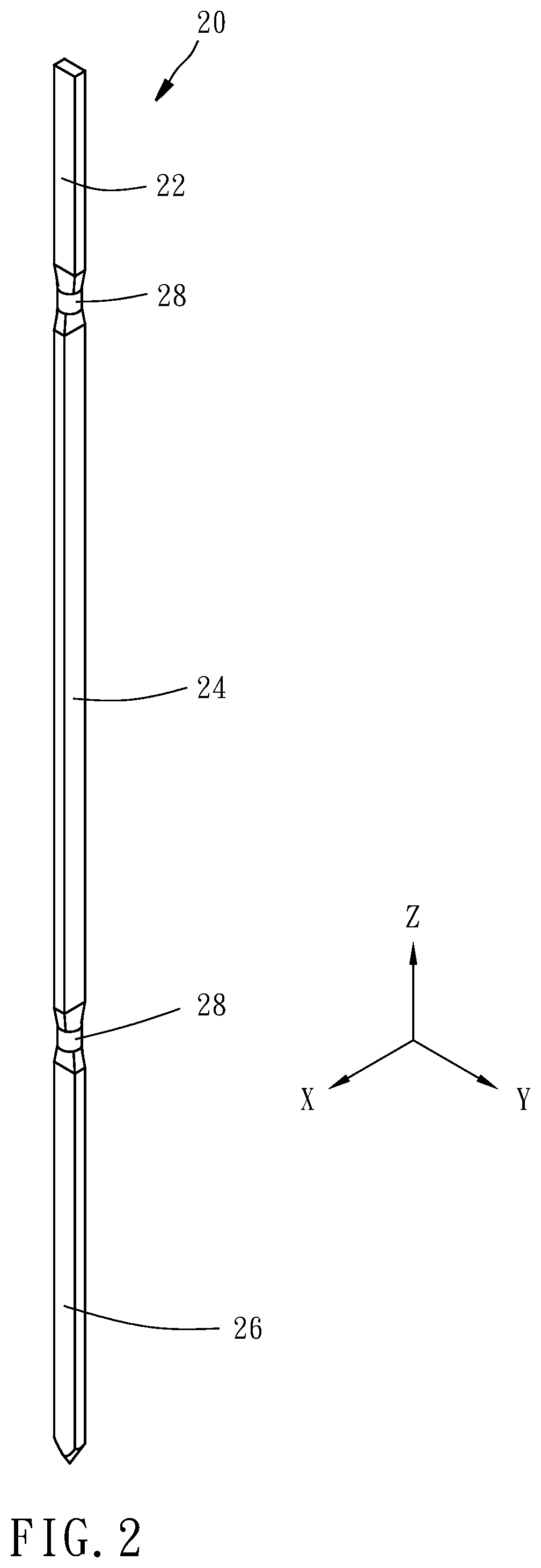

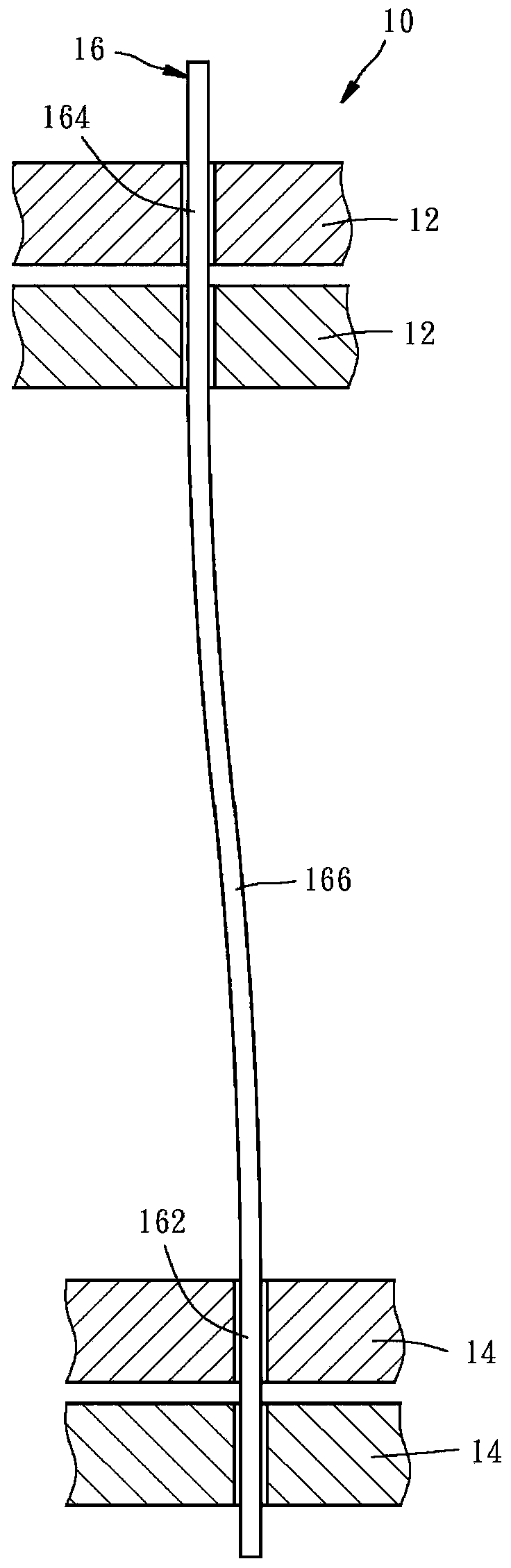

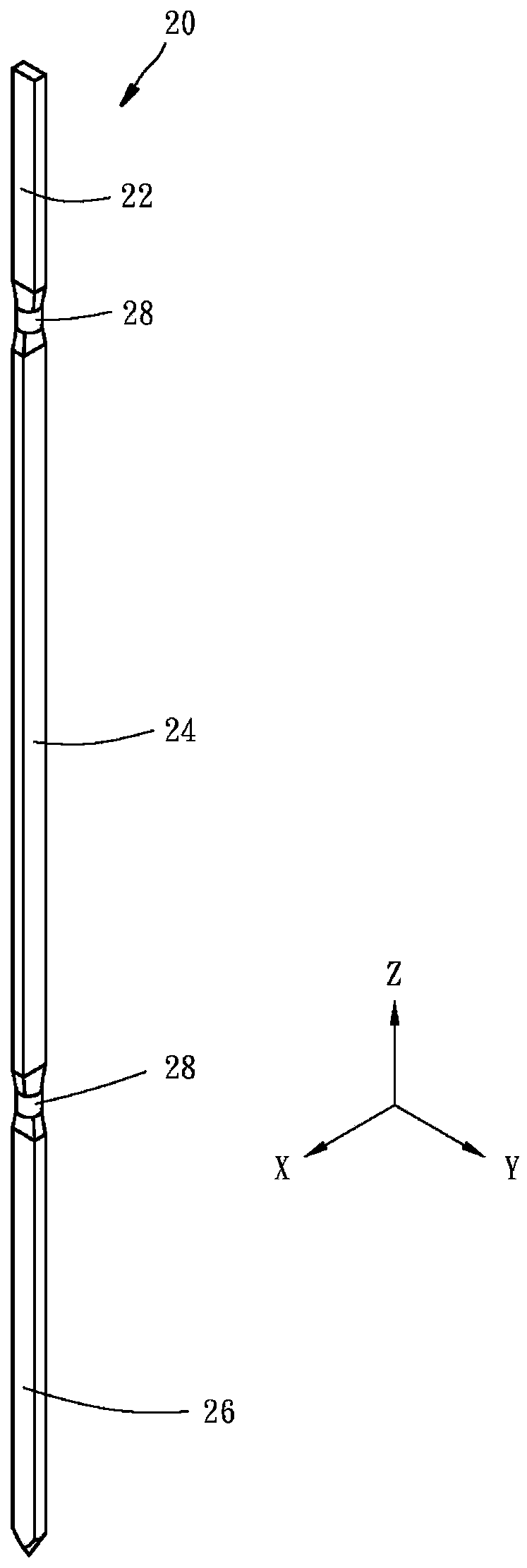

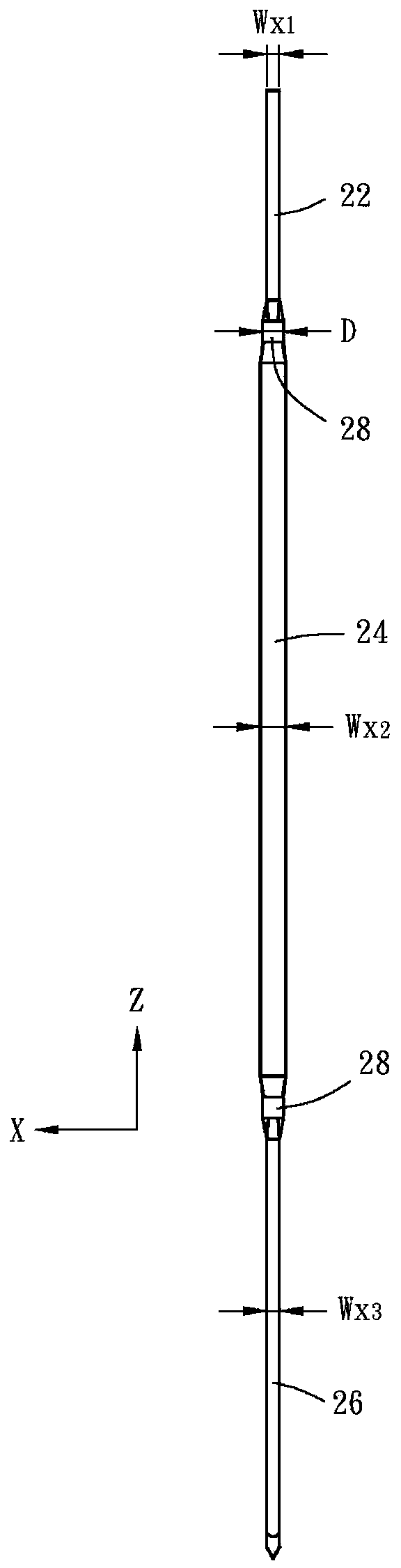

Probe head with linear probe

ActiveUS20200011898A1Avoiding self-rotation of the probeAvoiding probe dropElectrical measurement instrument detailsElectrical testingEngineeringMechanical engineering

A probe head includes a linear probe which is flattened at at least one of tail, body and head portions thereof and thereby defined with first and second width axes, along which each of the tail, body and head portions is defined with first and second widths, and upper and lower die units having upper and lower installation holes respectively, wherein the tail and head portions are inserted respectively, which are offset from each other along the second width axis so that the body portion is curved. The first and second widths of the body portion are respectively larger and smaller than the first and second widths of at least one of the tail and head portions. As a result, the probes of the same probe head are consistent in bending direction and moving behavior and prevented from rotation, drop and escape.

Owner:MICROELECTRONICS TECH INC

Ultrasonic probe, bioinformation measurement device, and bioinformation measurement method

InactiveCN103687549ACorrect health informationElectrocardiographyHealth-index calculationBiological bodyMeasurement device

Conventional ultrasonic diagnostic devices have been unable to clearly image the apex of the heart and unable to accurately obtain health information pertaining to the heart. To resolve the aforementioned problem, provided is a bioinformation measurement device that can accurately obtain health information by using a linear probe to measure an M-mode apex cardiogram, improving a data processing device, and establishing a useful algorithm for accurate evaluation.

Owner:サンヨウ総研 +1

Drilled bone hole depth measuring device

InactiveCN106137206AAccurate measurementAccurate readingSurgeryDiagnostic recording/measuringBiomedical engineeringLinear probe

The invention belongs to the technical field of medical instruments and particularly relates to a drilled bone hole depth measuring device. The drilled bone hole depth measuring device comprises a linear probe capable of being inserted into a drilled bone hole, a cylinder and a scale ruler. The probe is installed in a probe sleeve, and a right-angle hook used for positioning the outer surface of the far end of the drilled bone hole is arranged at the far end of the probe. The near end of the probe sleeve is installed in the cylinder through a plug with the far end in a spherical surface shape. The scale ruler is installed in the cylinder, the far end of the scale ruler is connected with a probe cylinder in an inserted mode, the near end of the scale ruler stretches out of the cylinder, a blind hole is formed in the scale ruler in the radial direction, a spring and a ball are arranged in the blind hole from bottom to top, a section of clamping groove is formed in the inner wall of the far end of the cylinder, and the ball is connected with the clamping groove in a sliding mode. By means of the drilled bone depth measuring device, medical personnel can accurately read measurement values, and thus the depth of the bone hole can be easily and accurately measured.

Owner:TIANJIN KANGLIER BIOTECH

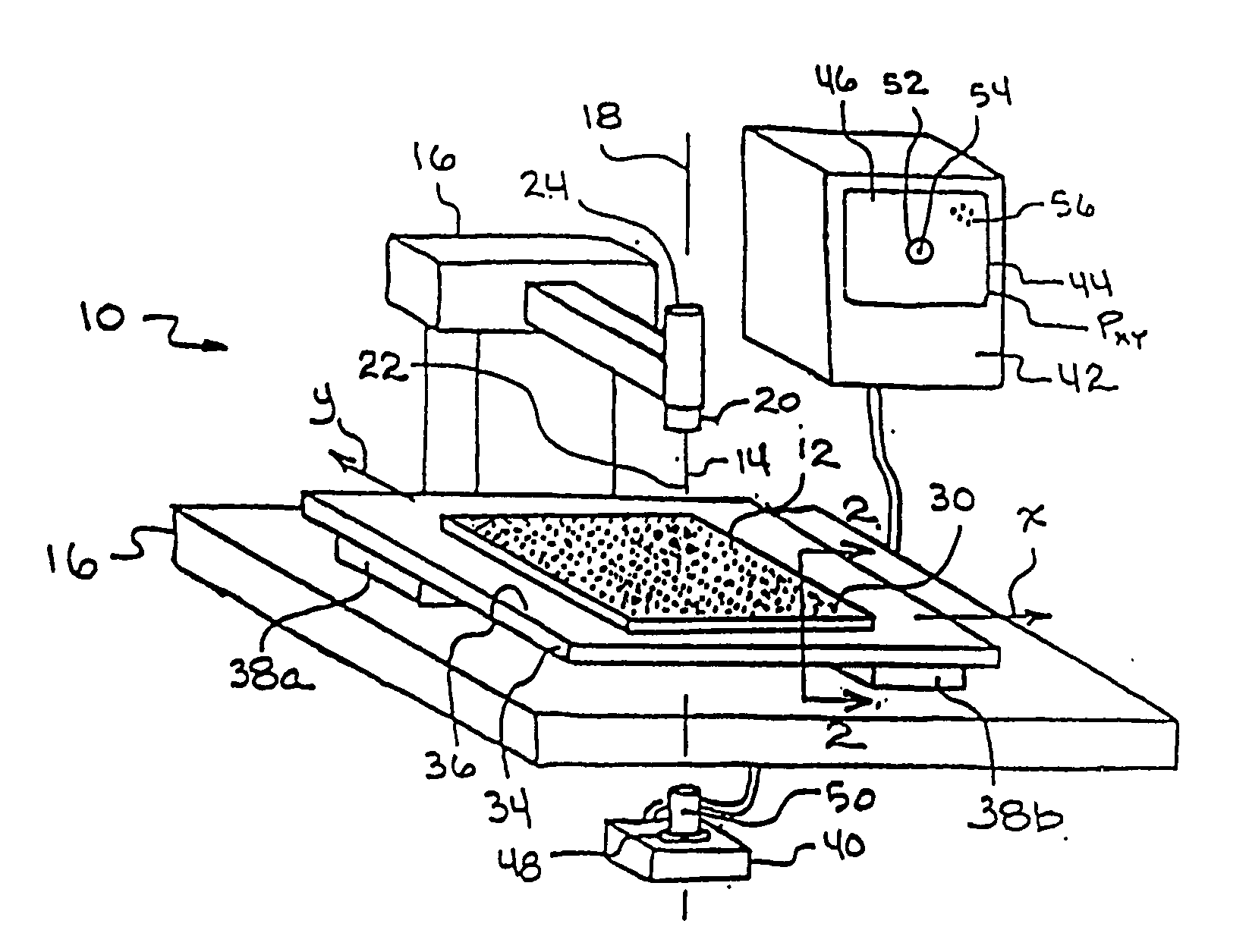

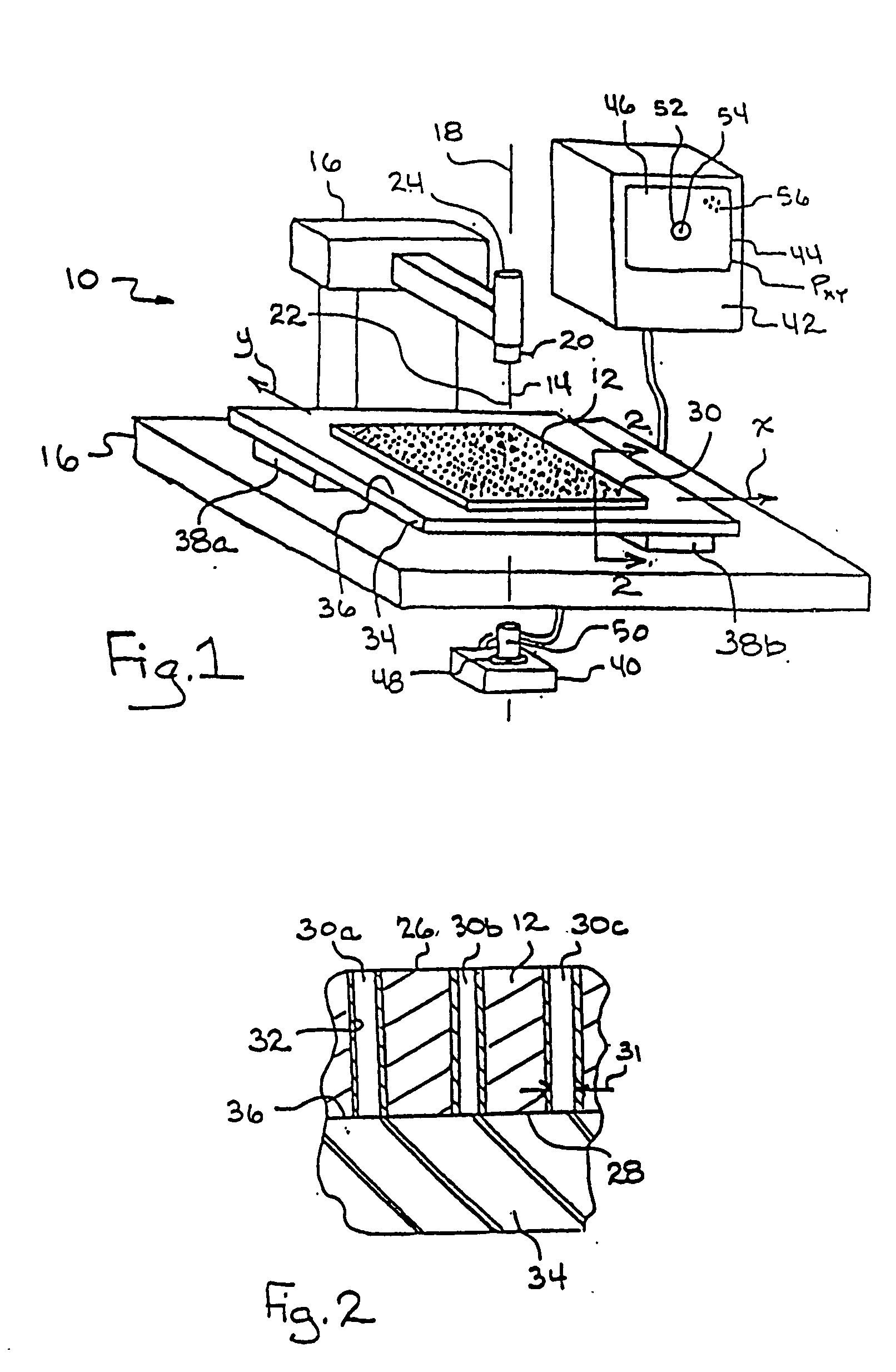

Positioning system for moving a selected station of a holding plate to a predetermined location for interaction with a probe

InactiveUS20050118707A1Move preciselyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringWorkstation

A device for positioning the tip of an elongated probe (14) at a selected station of a holding plate (12) includes motors to move the holding plate and a supporting stage within a coordinate plane (mxy). The elongated probe is also movable along a linear probe axis that is orientated normal to the coordinate plane (mxy). A camera creates a pixel image of an optical marker placed on the stage. The image defines a coordinate plane (pxy). To relate the coordinate plane (pxy) to the coordinate plane (mxy), the optical marker is moved to successive locations in the mxy plane and a pixel image is obtained at each location. Using the pixel images, a computer calculates the relationship between coordinate planes and uses the relationship to signal the motors to move the holding plate in the mxy plane and position the selected station on the probe axis for interaction with the probe.

Owner:DIVERSA

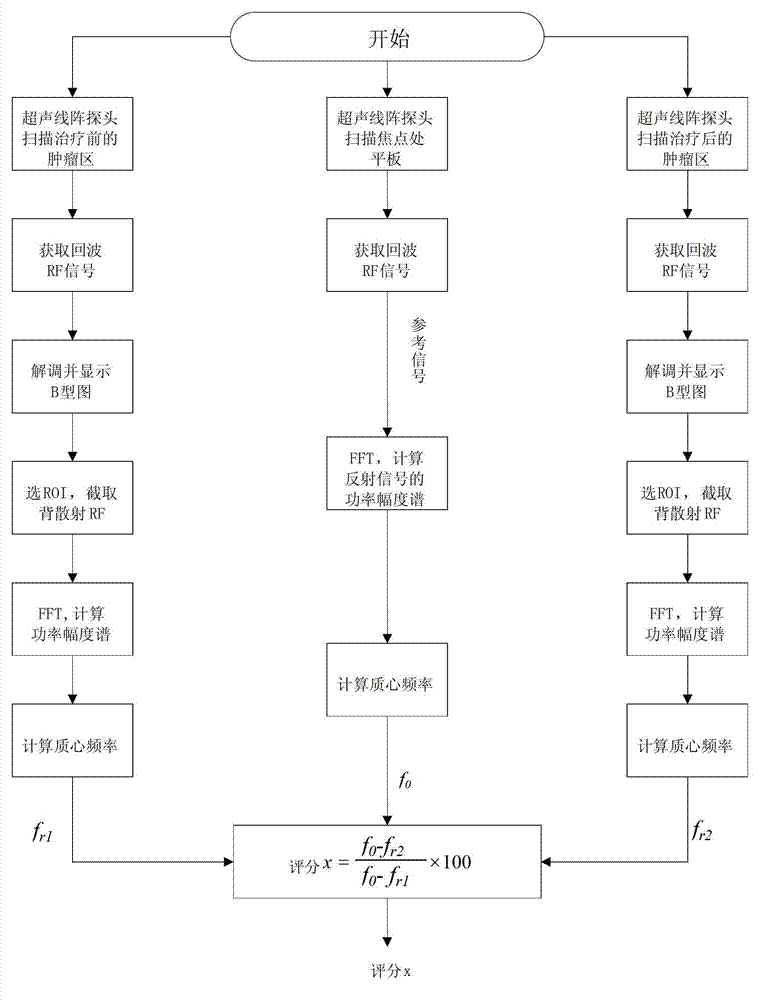

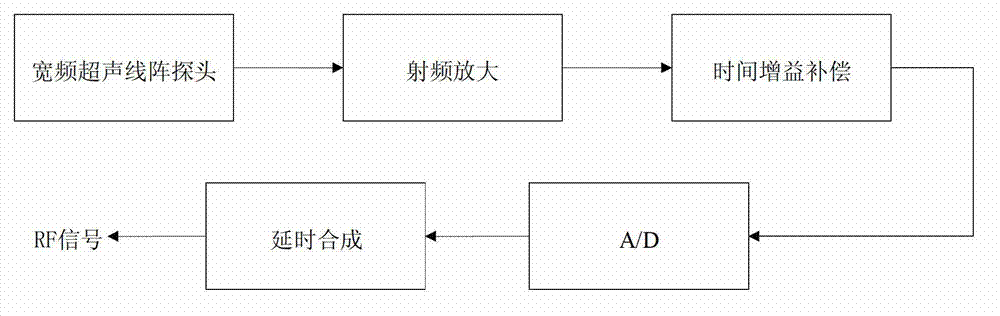

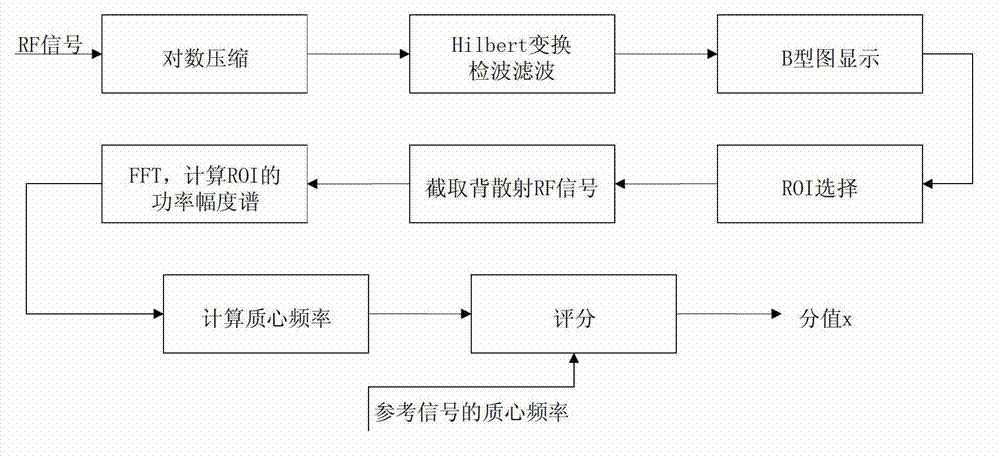

Tumor chemotherapy early curative effect evaluation method based on ultrasonic backscatter radio-frequency analysis

InactiveCN103040487AImprove the utilization of medical resourcesDon't Miss Chemotherapy OpportunitiesOrgan movement/changes detectionUltrasonic/sonic/infrasonic dianostic techniquesChemotherapy effectsTime–frequency analysis

The invention discloses a tumor chemotherapy early curative effect evaluation method based on ultrasonic backscatter radio-frequency analysis, comprising the following steps: (1) scanning a tumor area to be detected by a broad-band ultrasonic linear probe, and using the same probe to obtain echo radio-frequency RF signals before and after chemotherapy respectively; (2) demodulating and obtaining a B-type diagram; (3) selecting an interesting area ROI of tumors in the B-type diagram, and intercepting backscatter radio-frequency RF signals; (4) calculating the power amplitude spectrum of the ROI; (5) calculating centroid frequency; (6) obtaining plane reflection signal as reference signal at a focal point, and calculating the centroid frequency; and (7) calculating the score of curative effect according to the centroid frequency of the reference signal before and after chemotherapy obtained from the above steps, and evaluating the early curative effect of tumor. The method provides a concept of evaluating the chemotherapy effect of tumor according to the change of tumor microstructure in the early period of chemotherapy, and provides objective basis for evaluating the curative effect of tumor chemotherapy.

Owner:SOUTH CHINA UNIV OF TECH

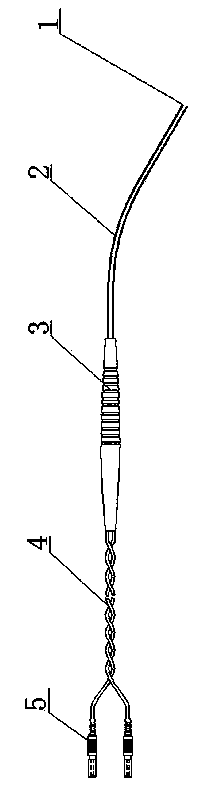

Disposable bipolar probing needle

The invention discloses a disposable bipolar probing needle which comprises a lead with a plug and two parallel probing needle bodies. A handle is arranged at positions where the probing needle bodies are connected with the lead. The disposable bipolar probing needle is characterized in that the probing needle bodies are parallel on a horizontal plane in the direction of the handle, each probing needle body is divided into two parts including a needle head and a needle rod, and each needle rod is of an arc-shaped structure. Each needle rod has radian, thereby being capable of entering an operative wound better, so that the problem that a linear probing needle structure of an existing disposable bipolar probing needle is inconvenient to probe small wounds and operative positions with angles and prone to causing damage to the operative wound.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER

Digital thermometer

InactiveCN1456869AEasy to understandThermometer detailsThermometers using electric/magnetic elementsDisplay deviceElectron

Owner:MEDPORT

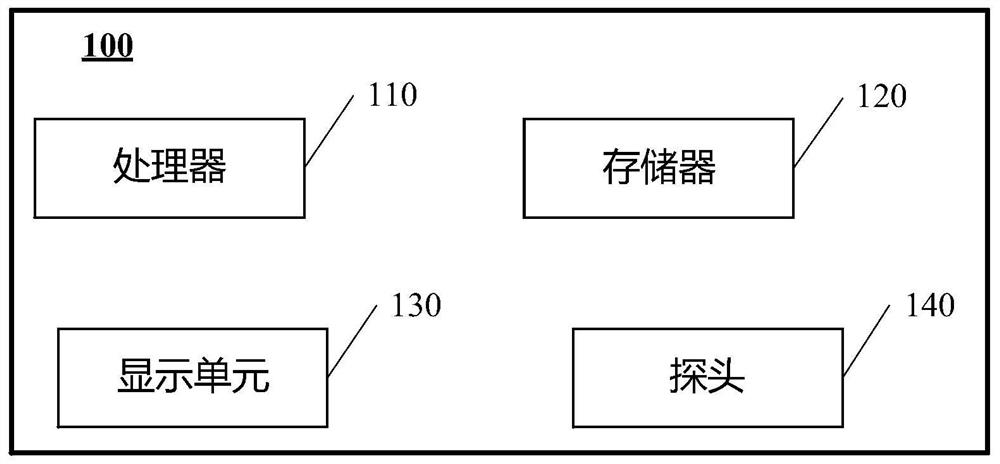

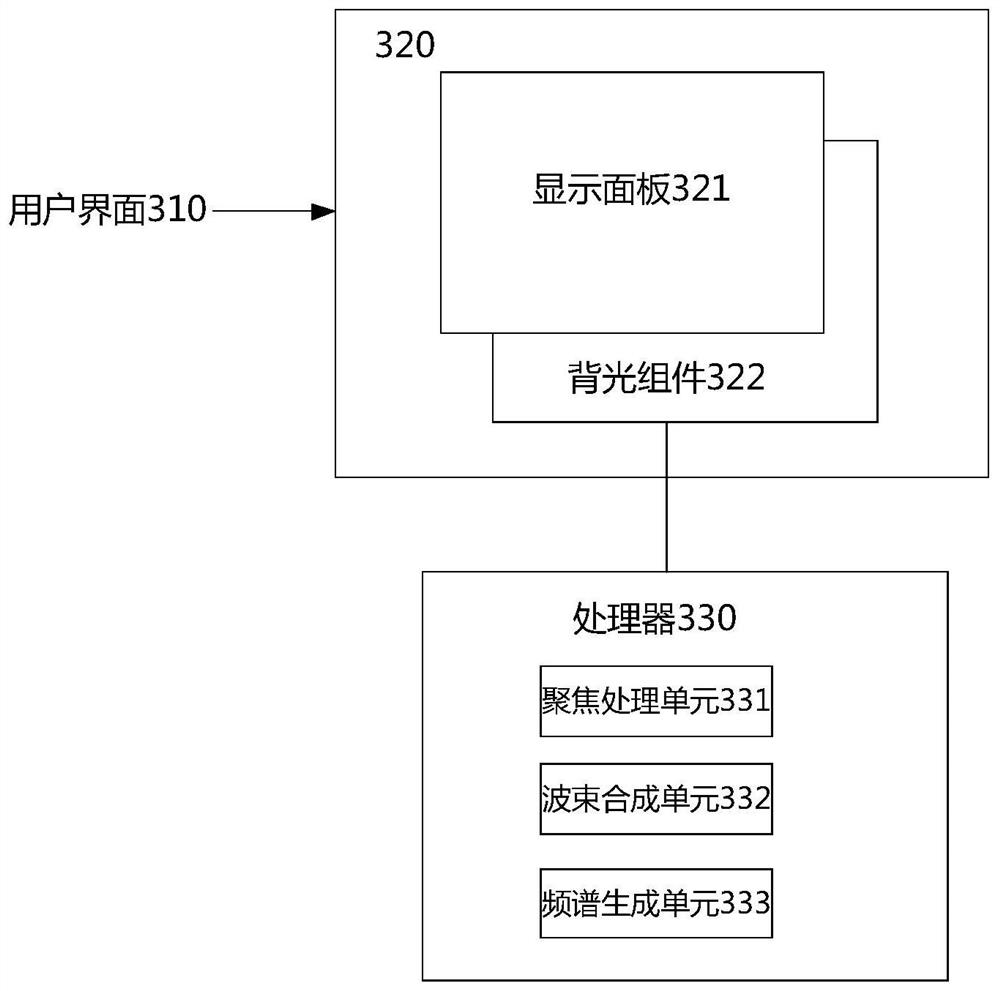

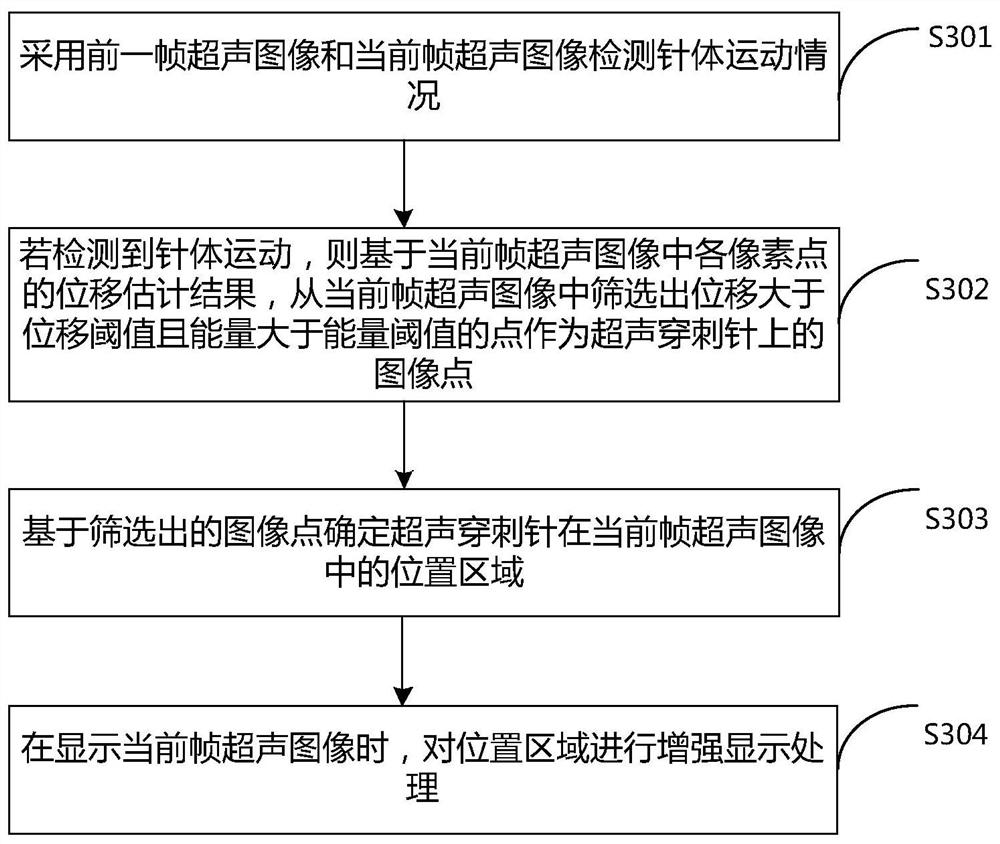

Position information processing method of ultrasonic puncture needle, ultrasonic equipment and storage medium

ActiveCN113040878AEasy to handleReal-time detectionSurgical needlesTrocarInformation processingRadiology

The invention relates to the technical field of ultrasonic data processing, and discloses a position information processing method of an ultrasonic puncture needle, ultrasonic equipment and a storage medium. The method comprises the following steps that a previous frame of ultrasonic image and a current frame of ultrasonic image are adopted to detect the movement condition of a needle body, and when the movement of the needle body is detected, on the basis of a displacement estimation result of each pixel point in the current frame of ultrasonic image, points with the displacement larger than a displacement threshold value and the energy larger than an energy threshold value are screened out from the current frame of ultrasonic image to serve as image points on the ultrasonic puncture needle, and then the position area of the ultrasonic puncture needle in the current frame of ultrasonic image is obtained. Therefore, the method for detecting the ultrasonic puncture needle, which is accurate in real time and can be applied to a linear probe and a non-linear probe, can be provided.

Owner:QINGDAO HISENSE MEDICAL EQUIP

Novel light arm amplifying two-dimensional linear probe

ActiveCN105180814AChange positionChange angleUsing optical meansBatch processingPhotovoltaic detectors

The invention discloses a novel light arm amplifying two-dimensional linear probe. The probe comprises two laser sources for transmitting two laser beams and a probe base for reflecting the laser beams. The probe base comprises at least two reflecting surfaces, a measurement rod, and a measurement ball. The probe also comprises two photoelectric detectors for receiving the two reflected laser beams, a translation part for driving the probe base or the photoelectric detectors and the probe base to move linearly to change the positions of reflection points of the two laser beams on the reflecting surfaces, a reset part for resetting the probe base to an initial position, and a processing system for calculating and obtaining the displacement change value of the measurement ball. The probe can obtain the displacement values in two different linear directions through the two photoelectric detectors to compensate for the measurement deviation of a to-be-measured workpiece during positioning and to obtain more accurate measurement coordinates, so that the measurement precision is improved, the structure is simplified, the production cost is lowered, and batch processing and production are facilitated.

Owner:成都中科卓尔智能科技集团有限公司

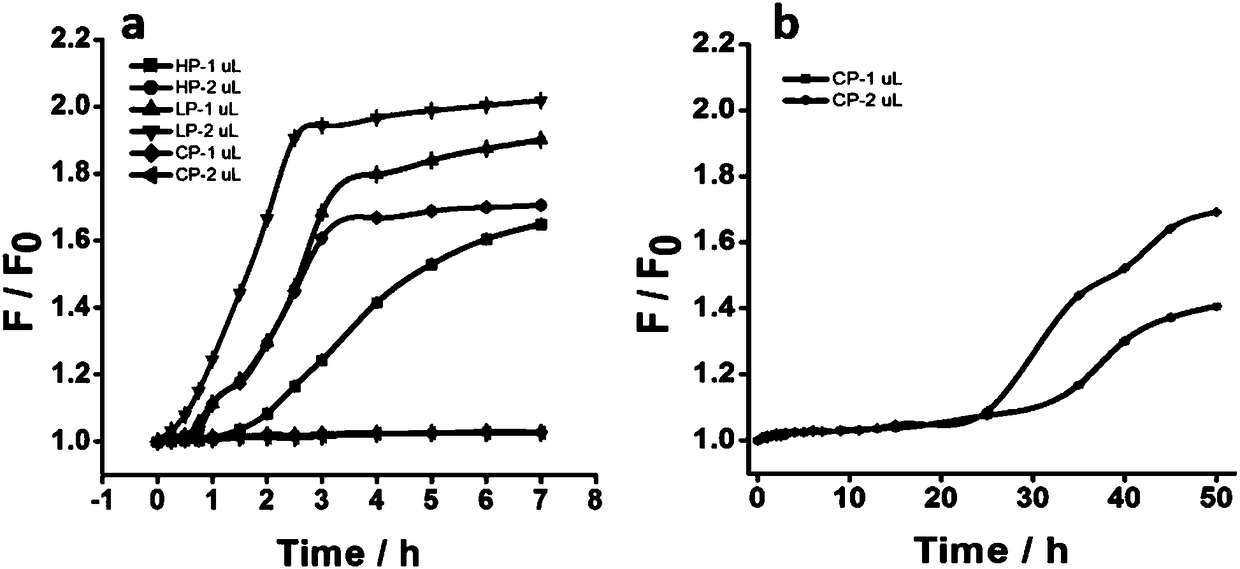

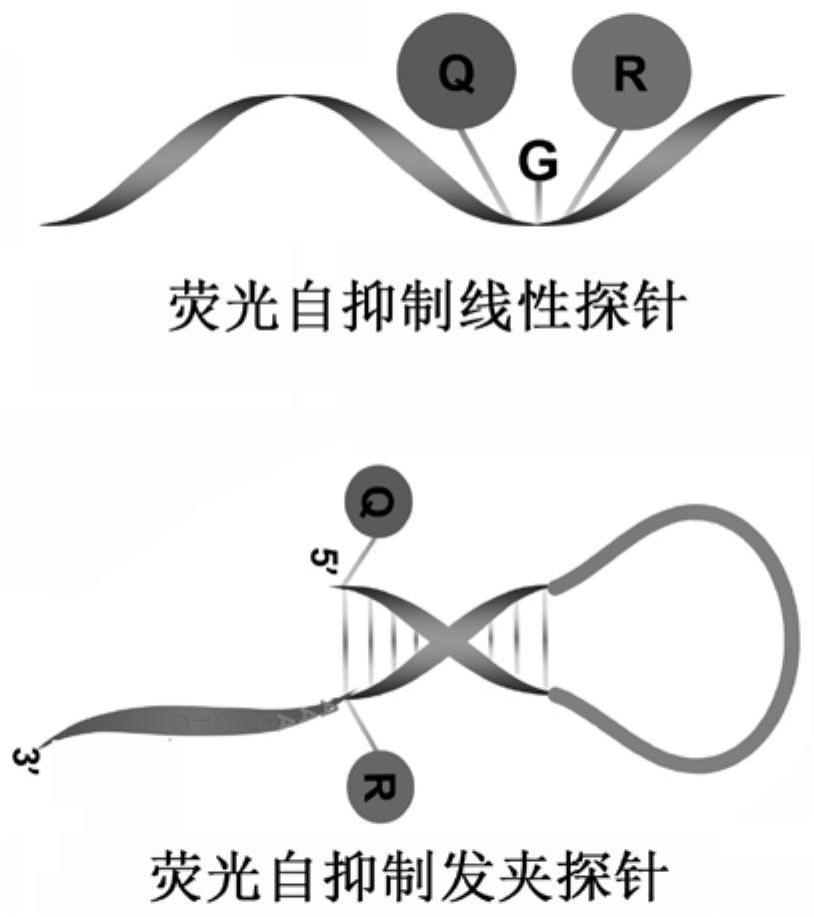

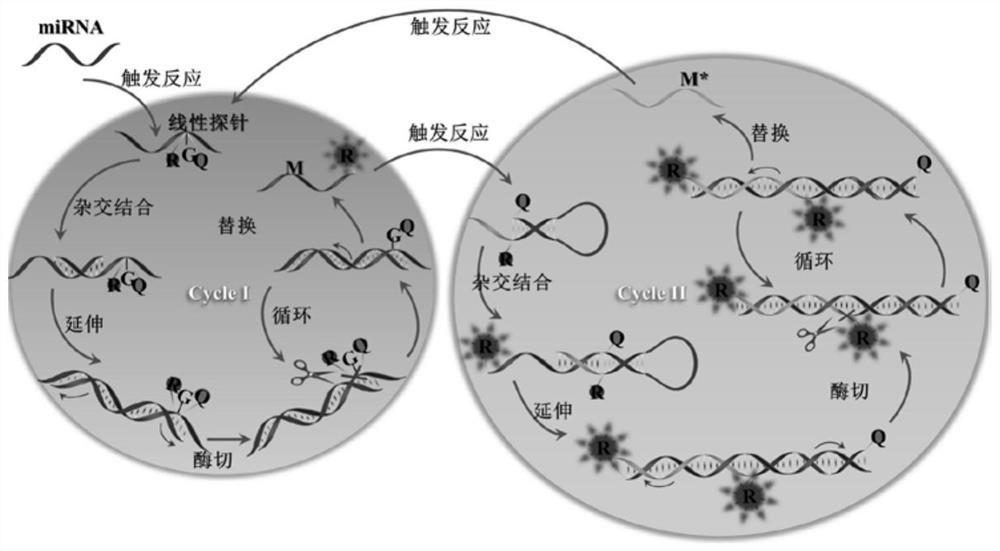

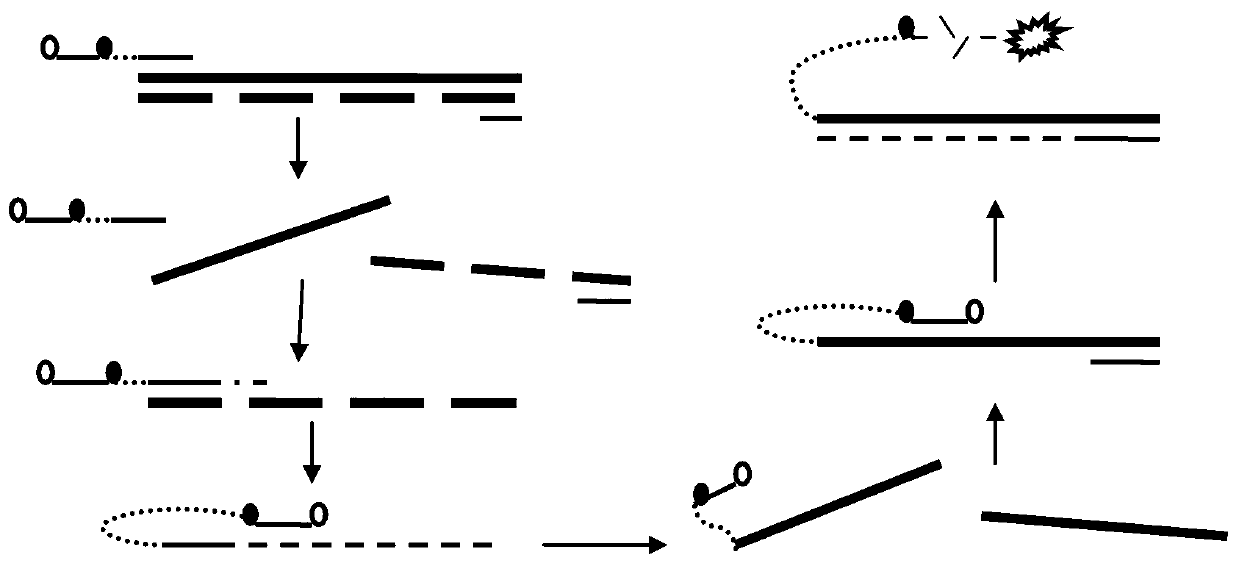

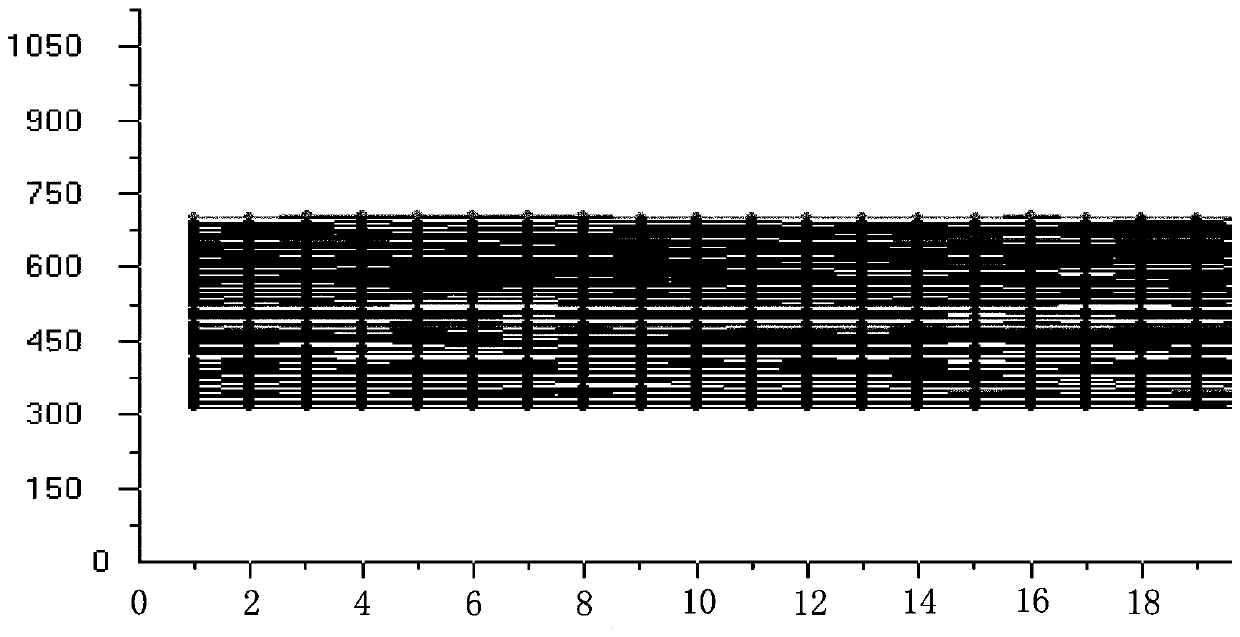

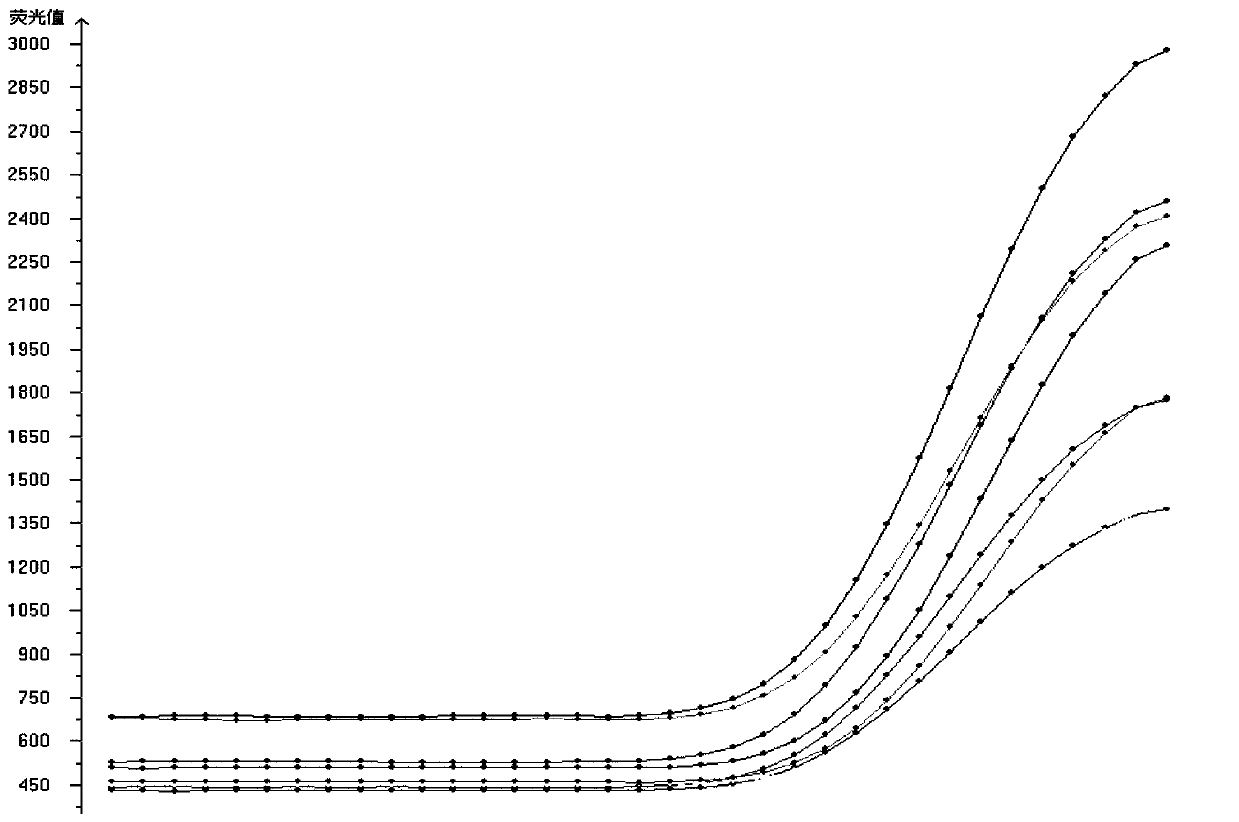

Isothermal amplification system and method based on fluorescence self-inhibition probe

PendingCN112852927AReduce background fluorescence signalImprove detection signal-to-noise ratioMicrobiological testing/measurementBiochemistryEndonuclease

The invention provides an isothermal amplification system and method of a fluorescence self-inhibition probe. The isothermal amplification system comprises a combination of two fluorescence self-inhibition probes, a Vent DNA polymerase, an Nt.BstNBI nicking endonuclease, a buffer solution, a reaction raw material and miRNA target molecules. The fluorescence self-inhibition probes comprise a fluorescence self-inhibition linear probe and a fluorescence self-inhibition hairpin probe. The invention also provides an amplification method of the isothermal amplification system. According to the fluorescence self-inhibition probe isothermal amplification system and the amplification method, background fluorescence signals of the probe can be remarkably reduced, the detection signal-to-noise ratio is greatly increased, and detection of trace miRNA targets in a sample is facilitated. Meanwhile, no complementary sequence exists between the two background-free fluorescent probes, mismatching and extension between the probes can be prevented, the detection specificity is effectively improved, false positive results are avoided, and the system and method are particularly suitable for direct detection of miRNA molecular markers in clinical samples.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

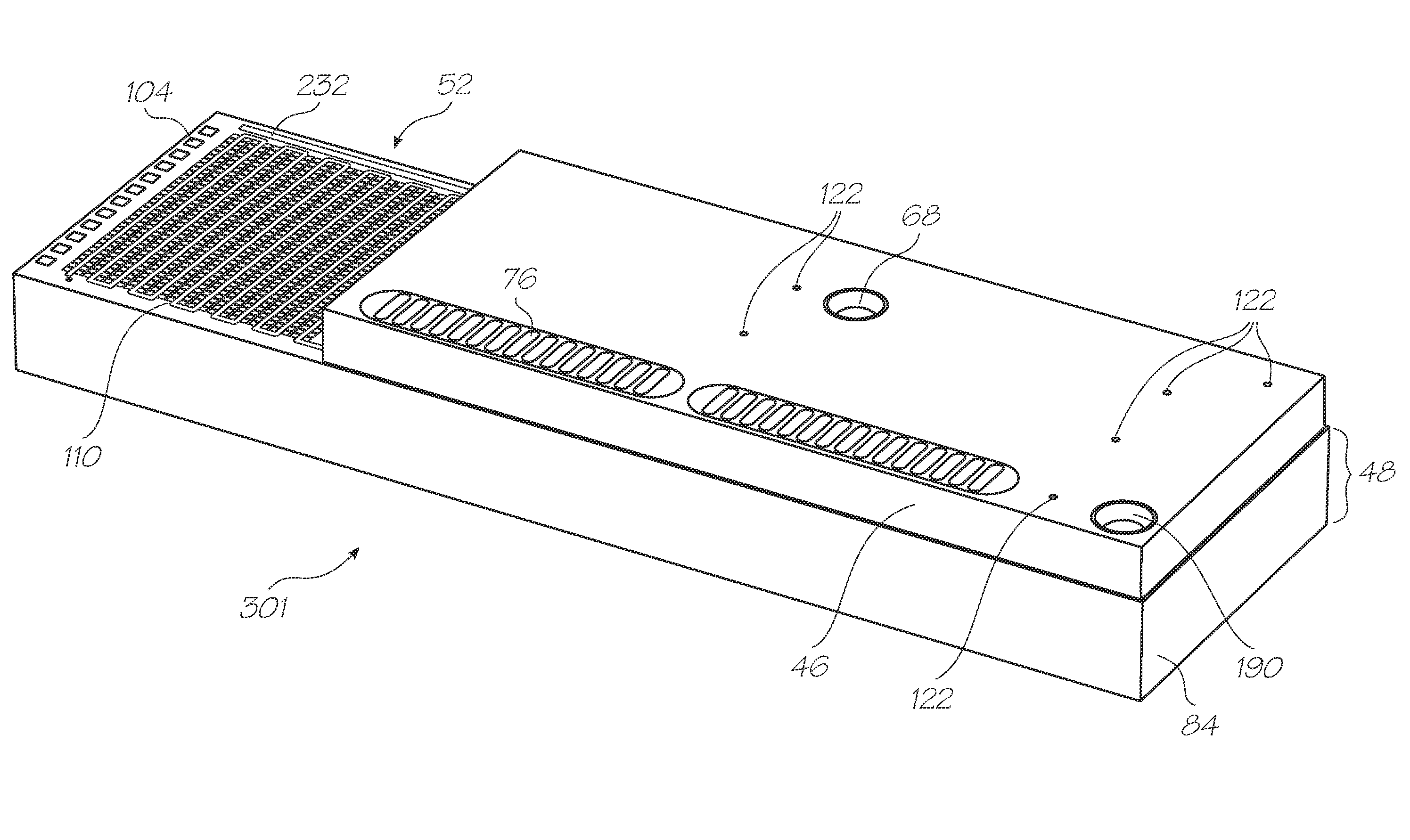

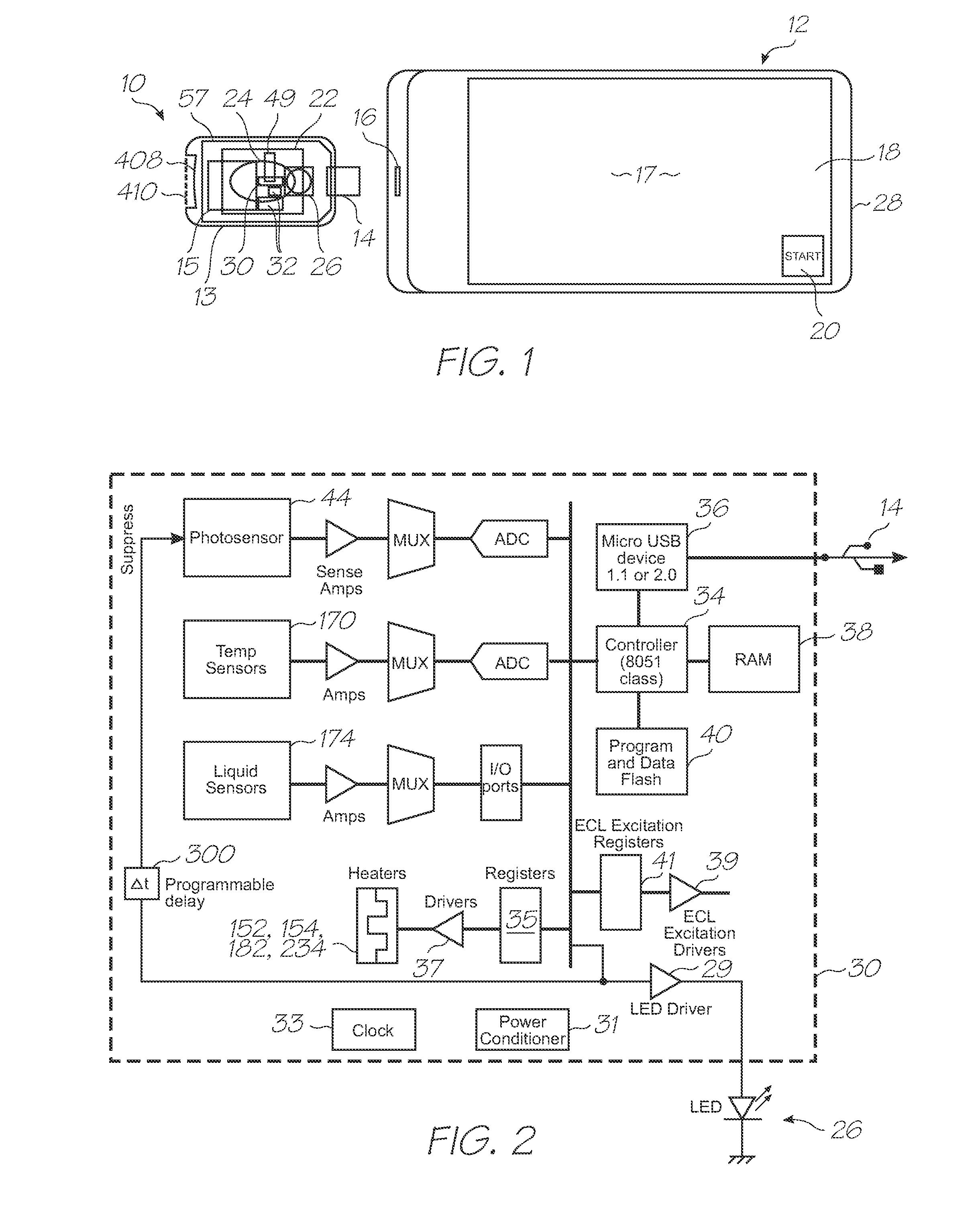

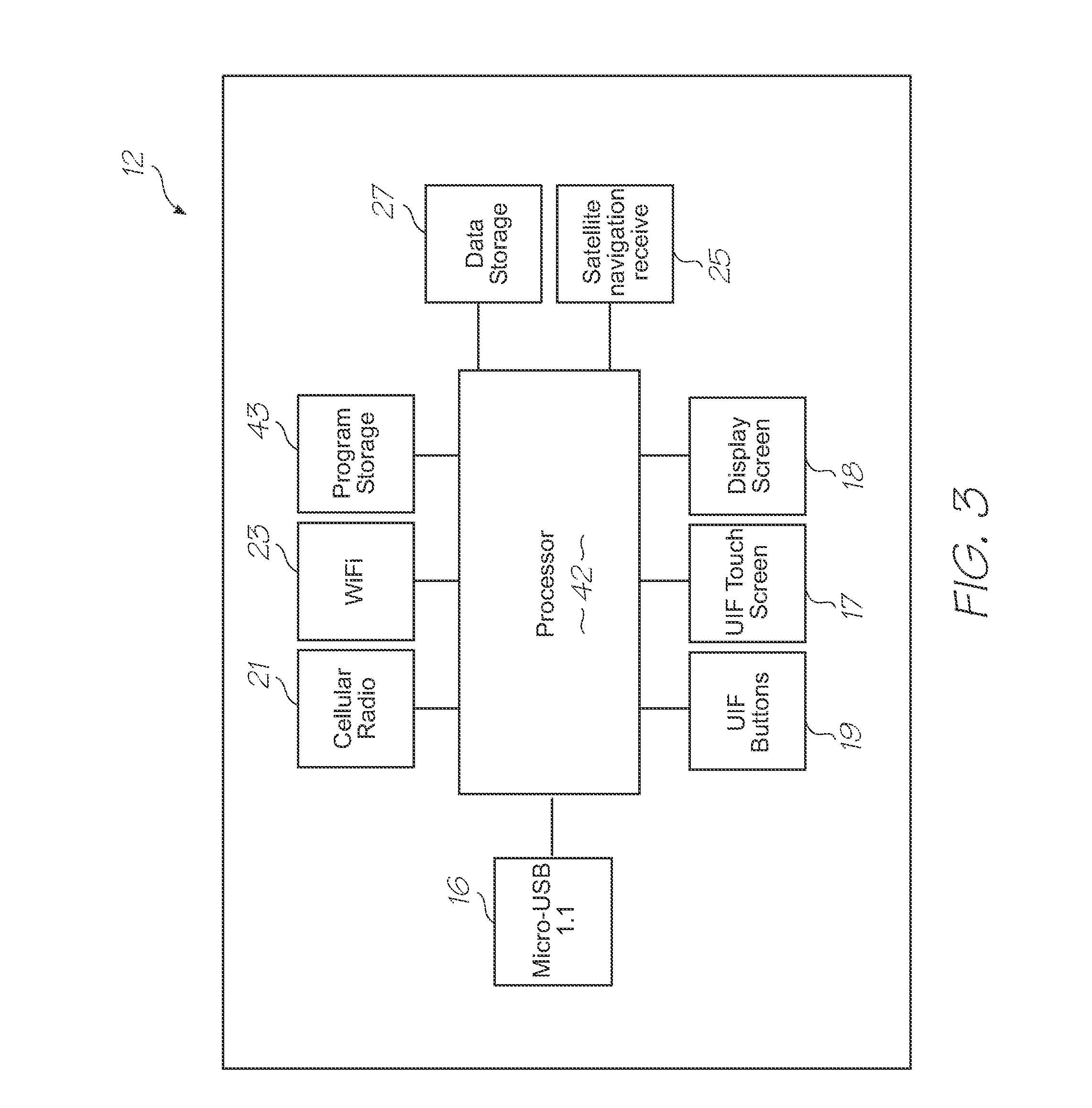

Loc for detection of hybridization of nucleic acid sequences with nucleic acid amplification using primers covalently attached to linear probes

InactiveUS20110312770A1High sensitivityStrong specificityBioreactor/fermenter combinationsValve arrangementsCMOSFluorescence

A LOC device having a supporting substrate, a primer-linked, linear probe with a nucleic acid sequence that matches a target nucleic acid sequence, and a primer for elongating against the target nucleic acid sequence to form a complementary sequence such that during use the nucleic acid sequence matching the target nucleic acid sequence anneals to the complementary sequence to change a fluorescence emission from the probe in response to an excitation light, and, CMOS circuitry on the supporting substrate, the CMOS circuitry having operative control of the excitation light.

Owner:GENEASYS

LSP (linear scorpion primer) and Kit for detecting human BRCA1 (breast cancer susceptibility gene 1) mutations

ActiveCN107312833AReduce dimerReduce the amount of primersMicrobiological testing/measurementDNA/RNA fragmentationBreast cancer susceptibility genesSignal-to-noise ratio (imaging)

The invention discloses an LSP (linear scorpion primer) and kit for detecting human BRCA1 (breast cancer susceptibility gene 1) mutations, wherein 5' end of the LSP is provided with a linear probe having different dual-fluorescent labels, 3' end is provided with a sequence fragment complementary to a template, and the two sequence fragments are linked via spacer 18; when the template exists, the LSP and the template can be extended by annealing to synthesize a template complementary chain; after the template complementary chain is synthesized, the 5' end probe portion of the LSP may bind with the chain, forming a scorpion-like shape; a downstream primer is extended along the 3' end of the template complementary chain; the probe portion is sheared under the action of a polymerase so as to emit light. The LSP of the invention has good specificity and high sensitivity, approximate genes are free of mutual interference, and detection results show higher fluorescent signal-to-noise ratio.

Owner:厦门安普利生物工程有限公司

Probe head with linear probe

ActiveCN110687325APrevent rotationReduce wearElectrical measurement instrument detailsElectrical testingEngineeringMechanical engineering

The invention relates to a probe head with a linear probe. The probe head has a linear probe, and upper and lower guide plate units having upper and lower installation holes respectively, at least oneof the tail portion, the body portion and the head portion of the linear probe being flattened and thereby defined with a first width axis and a second width axis, each of the tail portion, the bodyportion and the head portion being defined with a first width along the first width axis and a second width along the second width axis, the first width and the second width of the body portion beingrespectively larger than and smaller than the first width and the second width of at least one of the tail portion and the head portion, the tail and head portions being inserted into upper and lowerinstallation holes respectively which are offset from each other along the second width axis so that the body portion is curved. As a result, the probes of the same probe head are consistent in bending direction and moving behavior and prevented from rotation, drop and escape.

Owner:MPI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com