Loaded board test method

A test method and board mounting technology, which are applied in electronic circuit testing, single semiconductor device testing, electrical measurement, etc., can solve the problems of cumbersome, inaccurate assembly technology levels, and insufficient jig and probe structure for actual needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

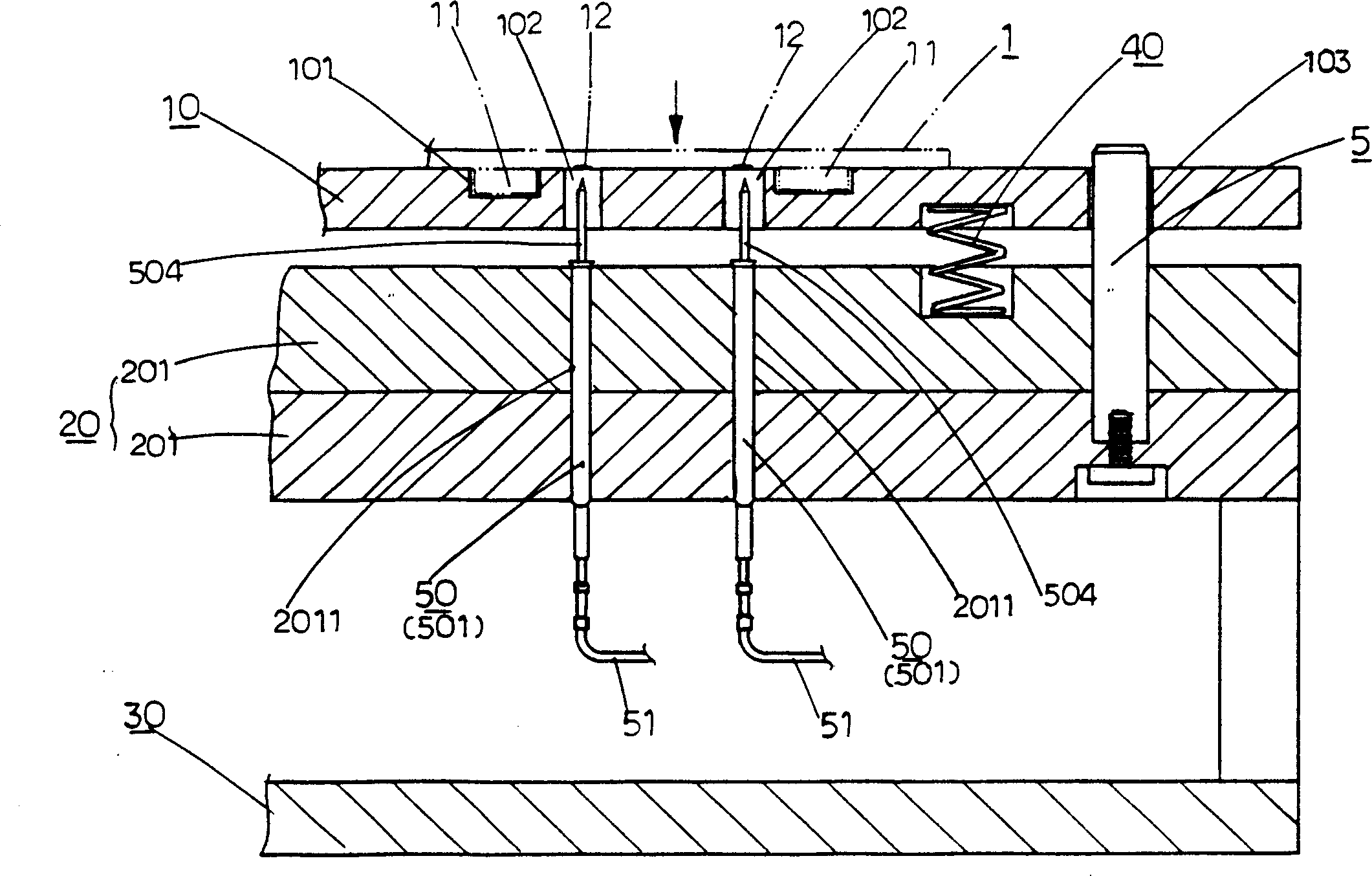

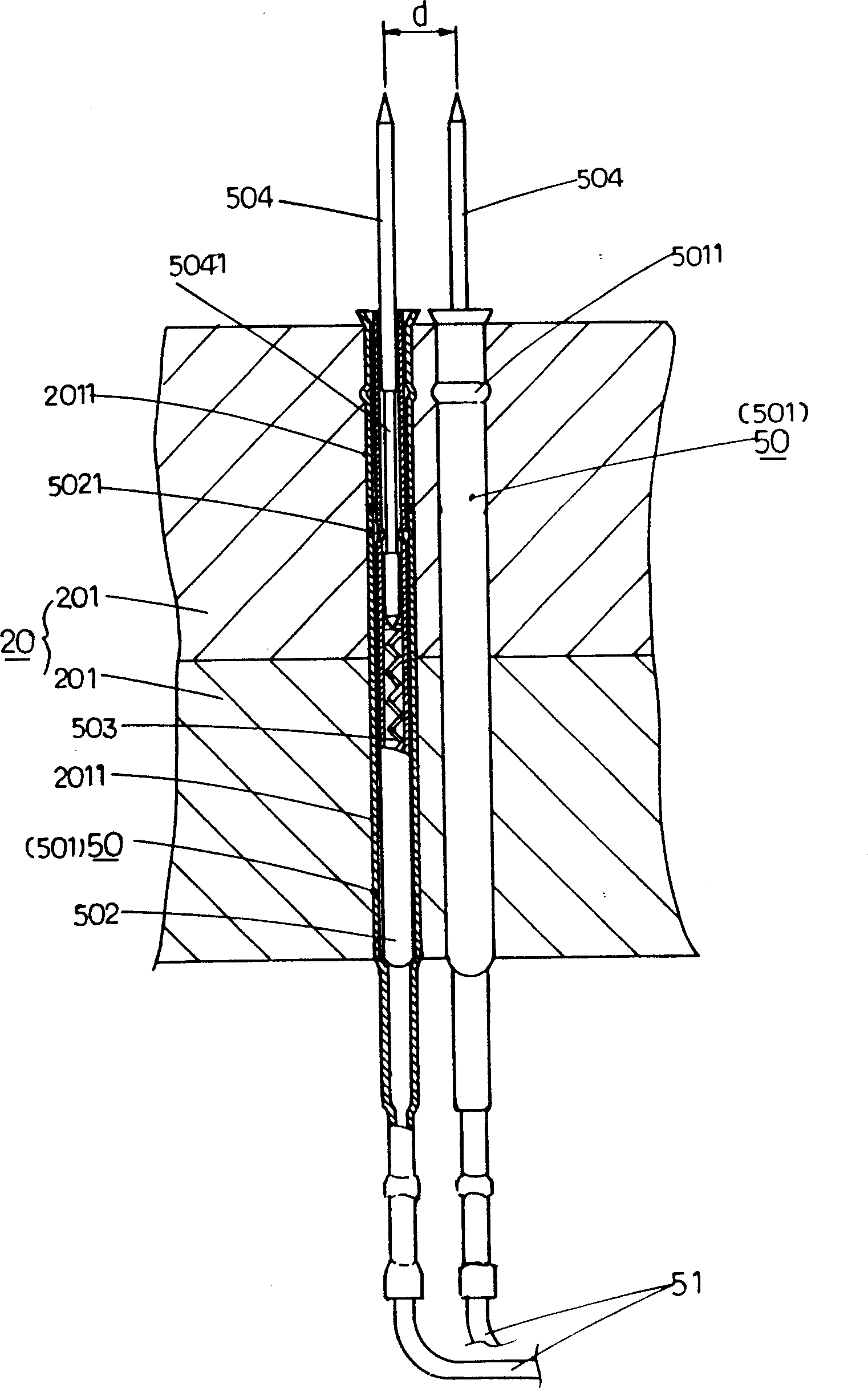

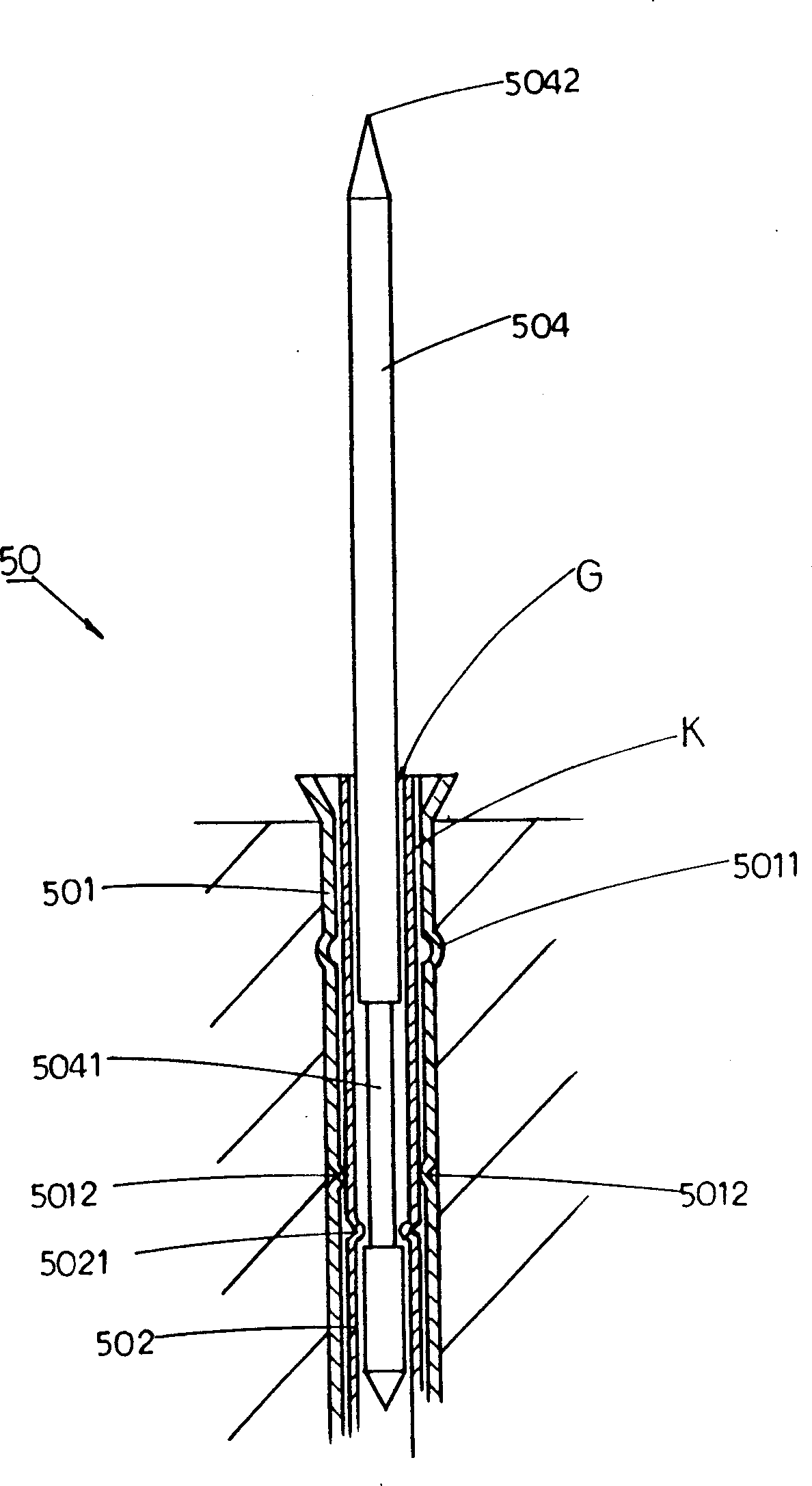

[0063] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, methods, steps, Features and their functions are described in detail below.

[0064] First, see Figure 4 As shown, it is clearly shown that a test method for a mounting board of the present invention is a method for providing precise testing for a mounting board with a small space for which electrical components have been installed. The test method has a jig, the The jig mainly includes a cable disc 20 , a machine plate 30 , a needle disc 60 , a dial buffer element 61 , a linear probe 70 , a probe buffer element 80 , a protective plate 90 and a linear bearing set 2 and other main components. in;

[0065] The dial 60 includes a carrier board 601 for positioning the mounting board 1 to be tested, on which a socket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com