Jig for linear probes

A probe and line-type technology, applied in the field of fixtures for line-type probes, can solve the problems that line-type probes cannot touch, line-type probes cannot slide, etc., and achieve the effect of restraining movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

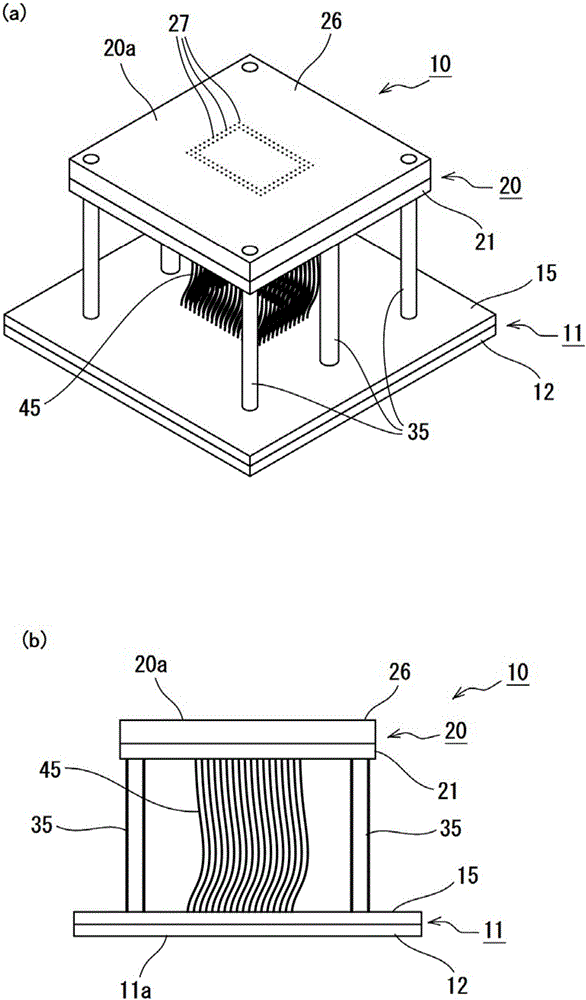

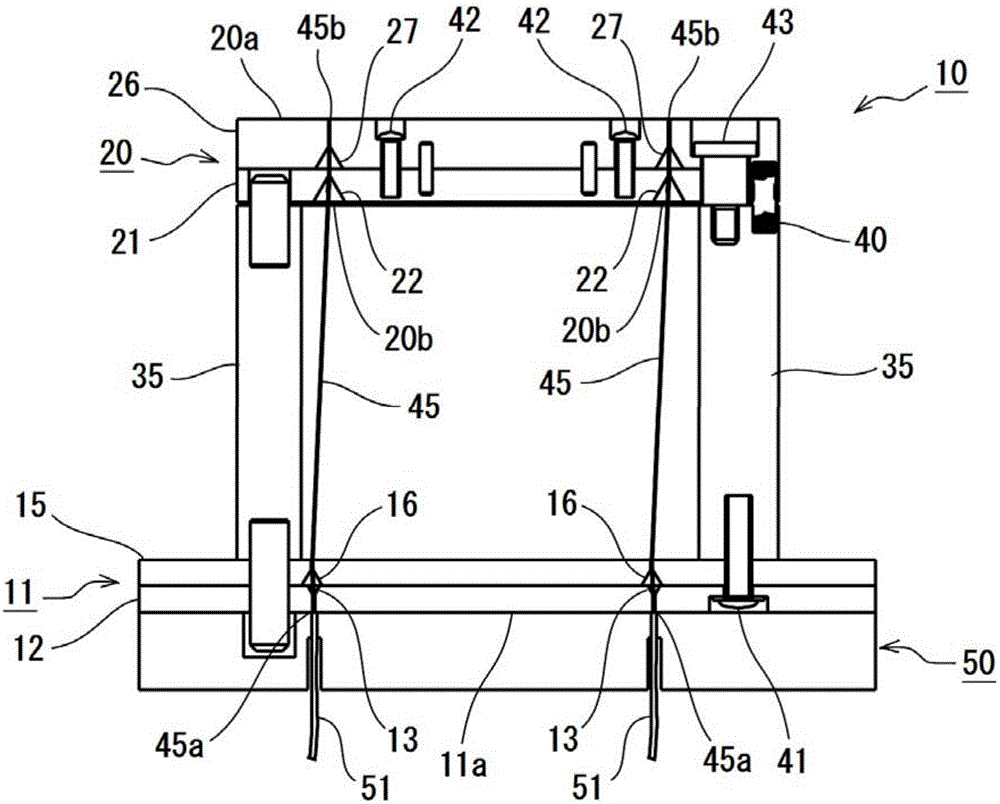

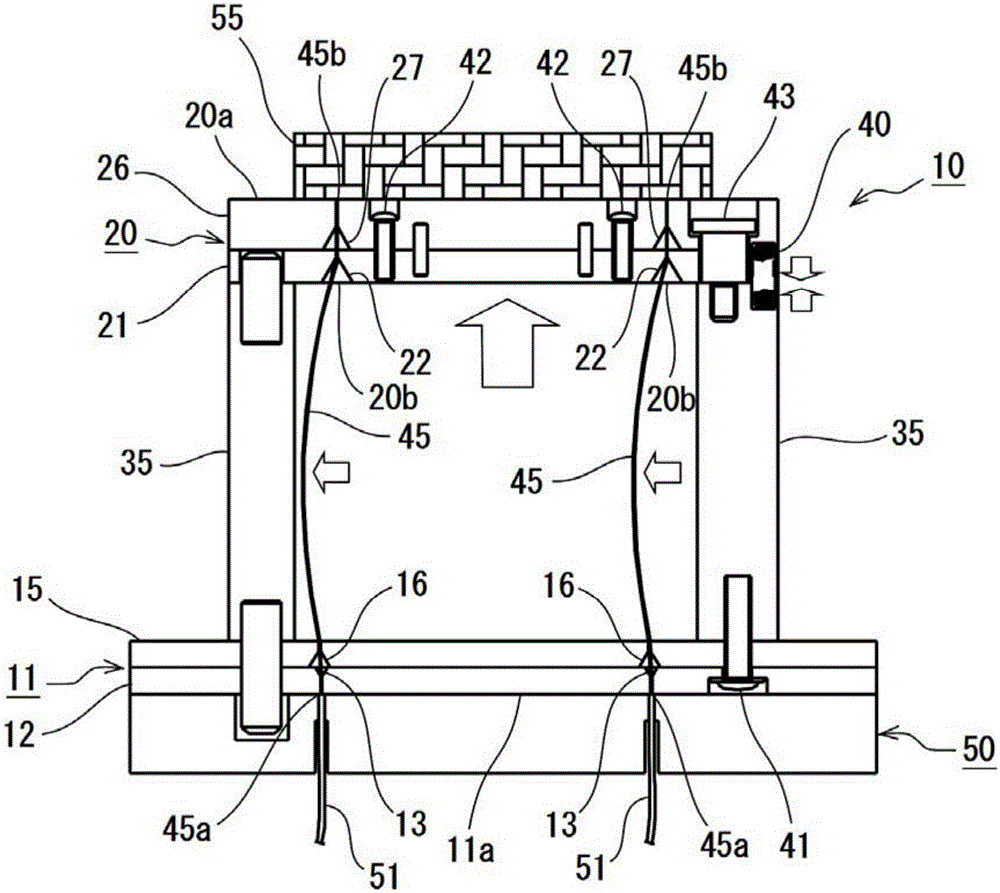

[0032] Embodiments of the present invention will be described with reference to the drawings.

[0033] The wire probe jig 10 of the present embodiment is a member for holding the wire probe 45 used for substrate inspection, and is arranged between the inspection target substrate 55 and the electrode substrate 50 . Such as figure 1 As shown, the jig 10 for a wire probe holds a plurality of wire probes 45 so that the wire probes 45 do not come into contact with each other. When using the jig 10 for a linear probe, the other side of the jig 10 for a linear probe is fixed to the surface of the electrode substrate 50 with one surface of the jig 10 for a linear probe fixed. The surface is pressed against a substrate 55 to be inspected such as a semiconductor integrated circuit, so that both ends of the held wire probe 45 come into contact with the terminals of the electrode substrate 50 and the substrate 55 to be inspected, respectively.

[0034] Such as figure 2 As shown in FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com