Ultrasonic phased array nondestructive testing method for shafts of recreation facilities

An ultrasonic phased array and non-destructive testing technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as increasing manpower and material resources, and reduce manpower and material resources. The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

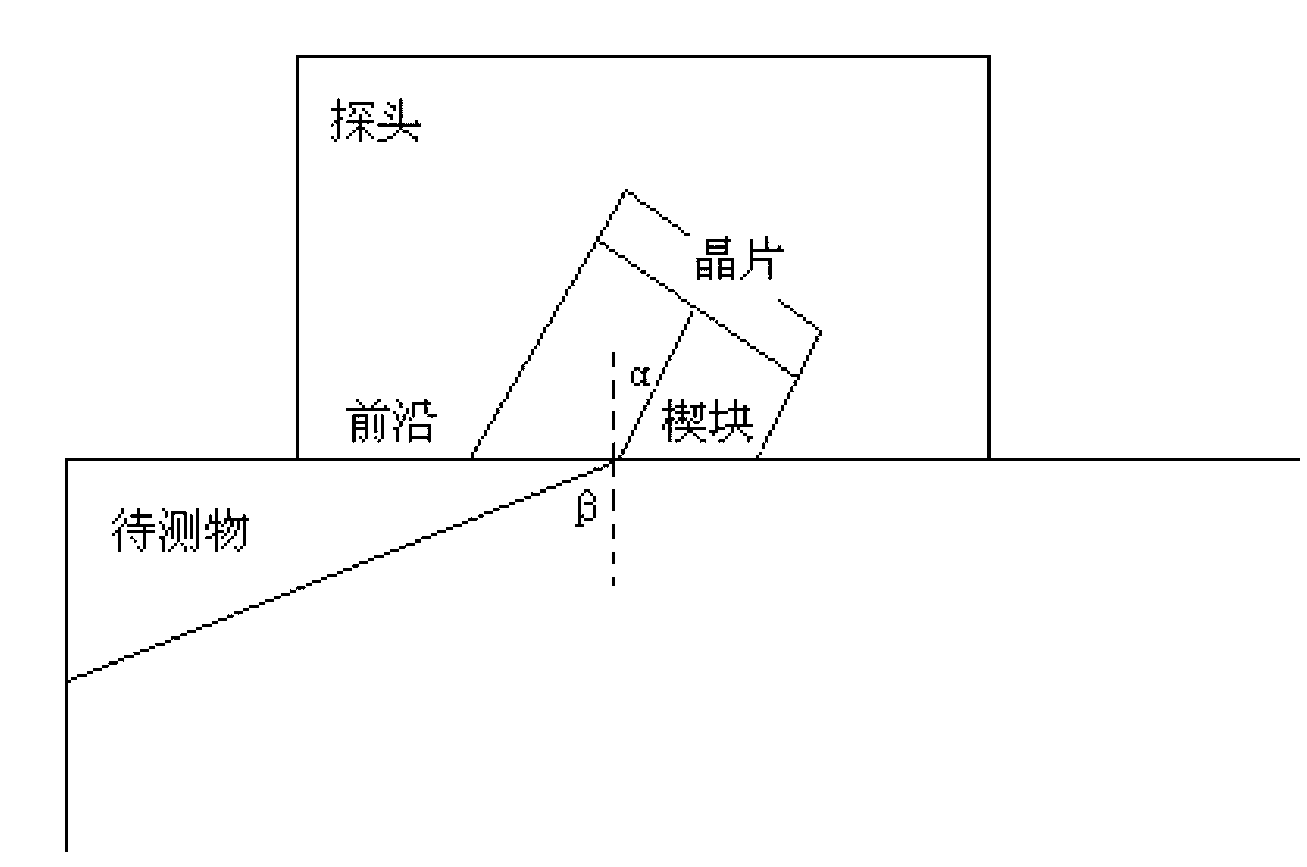

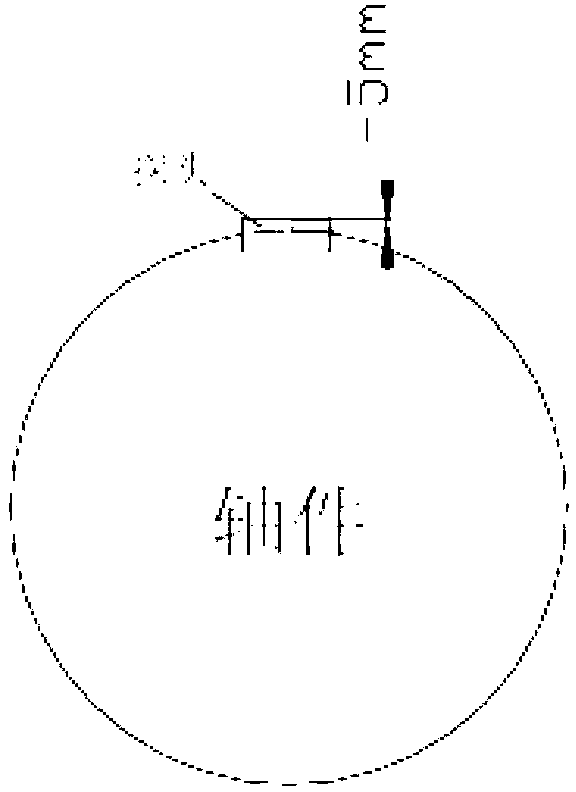

[0023] Select a linear probe with a frequency of 2MHz and 32 chips to detect a shaft with a diameter of 200mm and a length of 1000mm, and detect from the two end faces of the shaft. The sector scanning angle is set to 5-15 degrees, and each side needs to be covered The range of shaft length is 500mm. At the beginning of detection, the relative position of the probe and the shaft is as follows: figure 2 As shown, place the probe at any position on the edge of the end face of the shaft, and align the incident direction of the ultrasonic oblique probe with the outer surface of the shaft instead of the axis. 5mm is the front length of the probe. Move the probe along the circumference to detect Shaft surface defects that are closer to the end face; then move the probe to the center of the shaft for a certain distance, move the probe along the circumference, and continue to detect shaft surface defects that are a little farther from the end face; repeat the above operations until t...

example 2

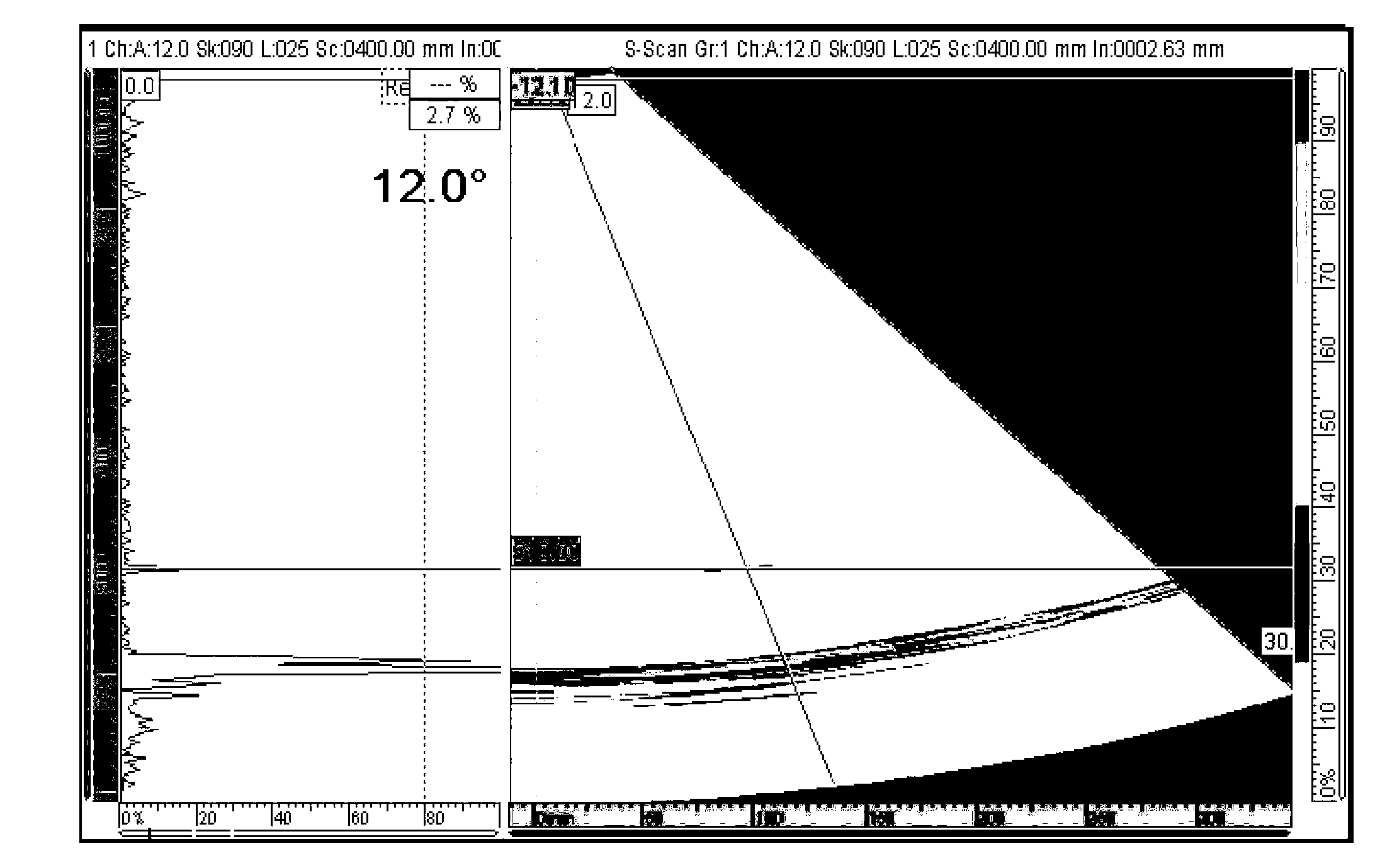

[0025] Select a linear probe with a frequency of 2MHz and 128 chips to detect a shaft with a diameter of 150mm and a length of 800mm, and detect from the two end faces of the shaft. The range of shaft length is 400mm. At the beginning of detection, the probe is placed on the edge of the end face of the shaft, and the probe is moved along the circumference to detect the surface defects of the shaft that are closer to the end face; then the probe is moved to the center of the shaft for a certain distance, and the probe is moved along the circumference to continue to detect defects that are slightly farther from the end face. Shaft surface defects; repeat the above operations until the detection range can cover the shaft surface 400mm long from the end face. It is found that there is a defect at 351mm from one end of the shaft, and the instrument displays the results as follows Figure 4 shown.

example 3

[0027] Select a linear probe with a frequency of 2MHz and 64 chips to detect a shaft with a diameter of 100mm and a length of 500mm, and detect from the two end faces of the shaft. The sector-shaped scanning angle is set to 10-25 degrees, and each side needs to be covered The range of shaft length is 250mm. At the beginning of detection, the probe is placed on the edge of the end face of the shaft, and the probe is moved along the circumference to detect the surface defects of the shaft that are closer to the end face; then the probe is moved to the center of the shaft for a certain distance, and the probe is moved along the circumference to continue to detect defects that are slightly farther from the end face. Shaft surface defects; repeat the above operations until the detection range can cover the shaft surface 250mm long from the end face. It is found that there is a defect at 151mm from one end of the shaft, and the instrument displays the results as follows Figure 5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com