Fully-focused detection method used for coarse-grained materials and based on phased array ultrasonic flaw detector

A technology of ultrasonic flaw detection and detection method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave for material analysis, analyzing materials, and using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problem of detection sensitivity and data processing that cannot solve the detection of coarse-grained materials , Coarse crystal grains, poor signal-to-noise ratio, etc., to achieve the effect of facilitating storage and on-site detection and analysis, optimizing sensitivity and resolution, and reducing the size of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

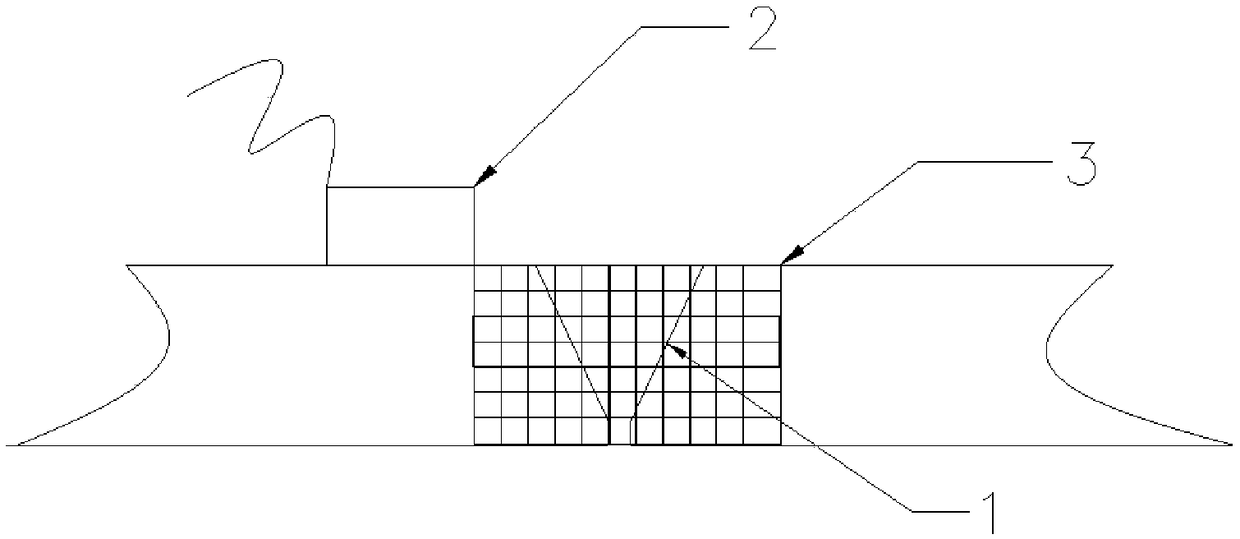

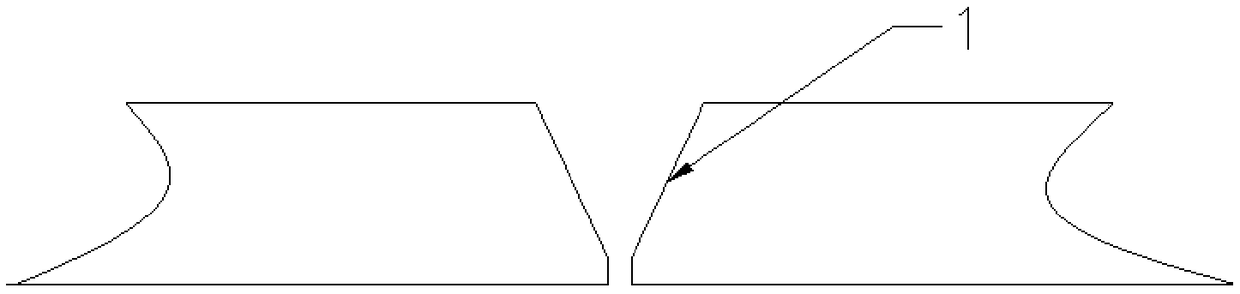

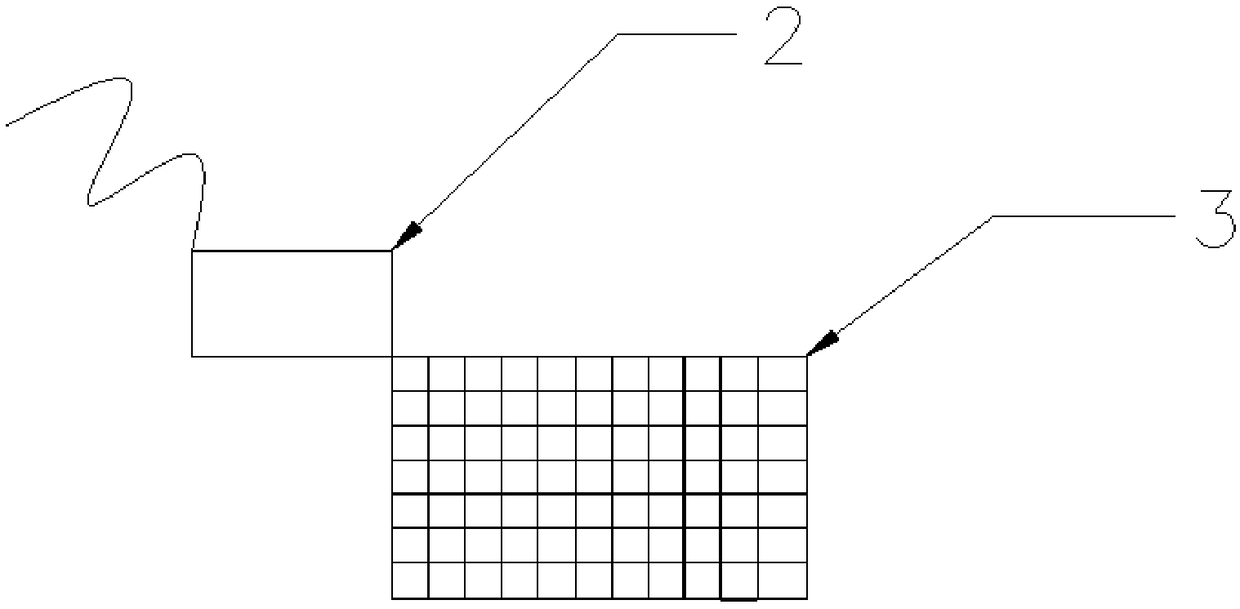

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, and the following examples are only to illustrate the present invention rather than limit it.

[0022] According to the workpiece to be inspected, the phased array ultrasonic testing probe is selected. In order to ensure the full-focus phased array technology, a two-dimensional phased array probe with more than 32 chips is generally used, and the following steps are performed in sequence:

[0023] (1) Calibration of probes and instruments:

[0024] Calibration of phased array ultrasonic instrument performance: the horizontal linearity deviation of the M2M phased array ultrasonic testing instrument does not exceed 1%, and the vertical linear deviation of the phased array ultrasonic testing instrument does not exceed 3%.

[0025] Calibration of Phased Array Ultrasound Probes:

[0026] a) The difference betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com