A two-dimensional drilling device for plate and its processing method

A drilling device and plate technology, applied to fixed drilling machines, etc., can solve the problems of high labor intensity of operators, decreased processing efficiency, low processing efficiency, etc., achieve wide application range, improve processing efficiency and yield, and process quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

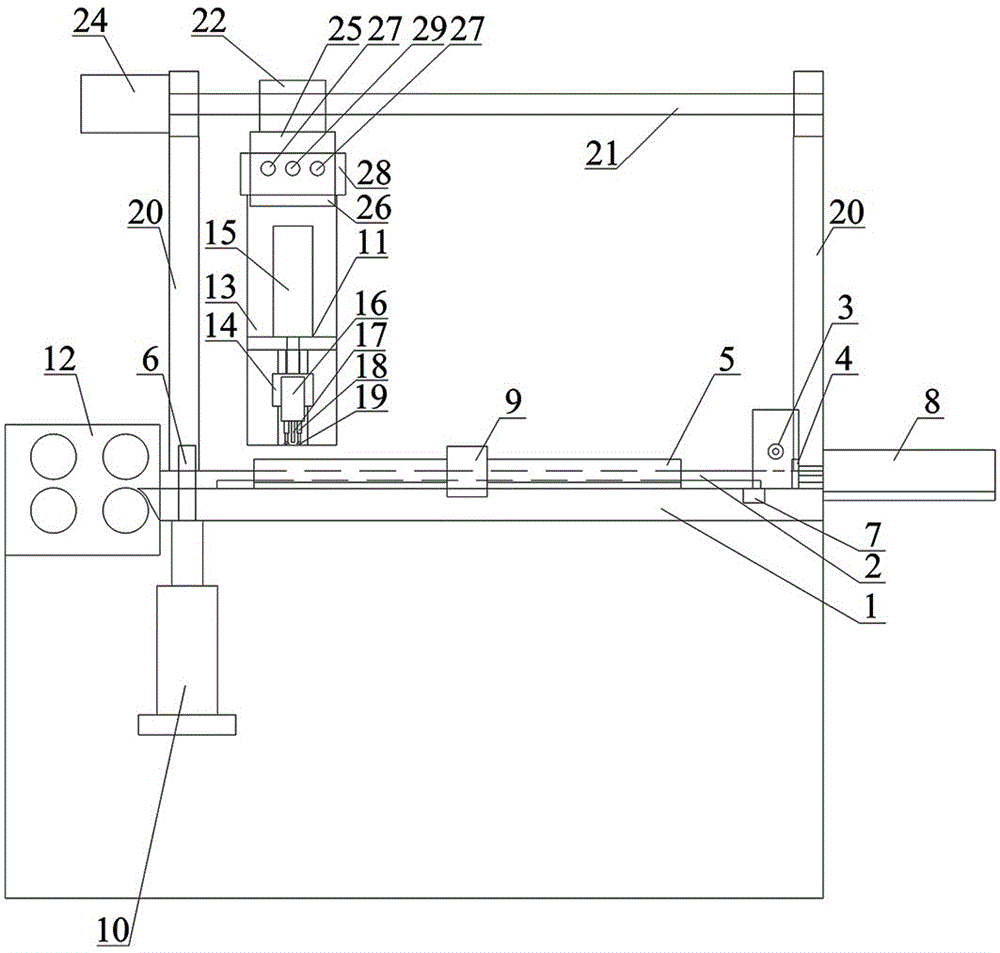

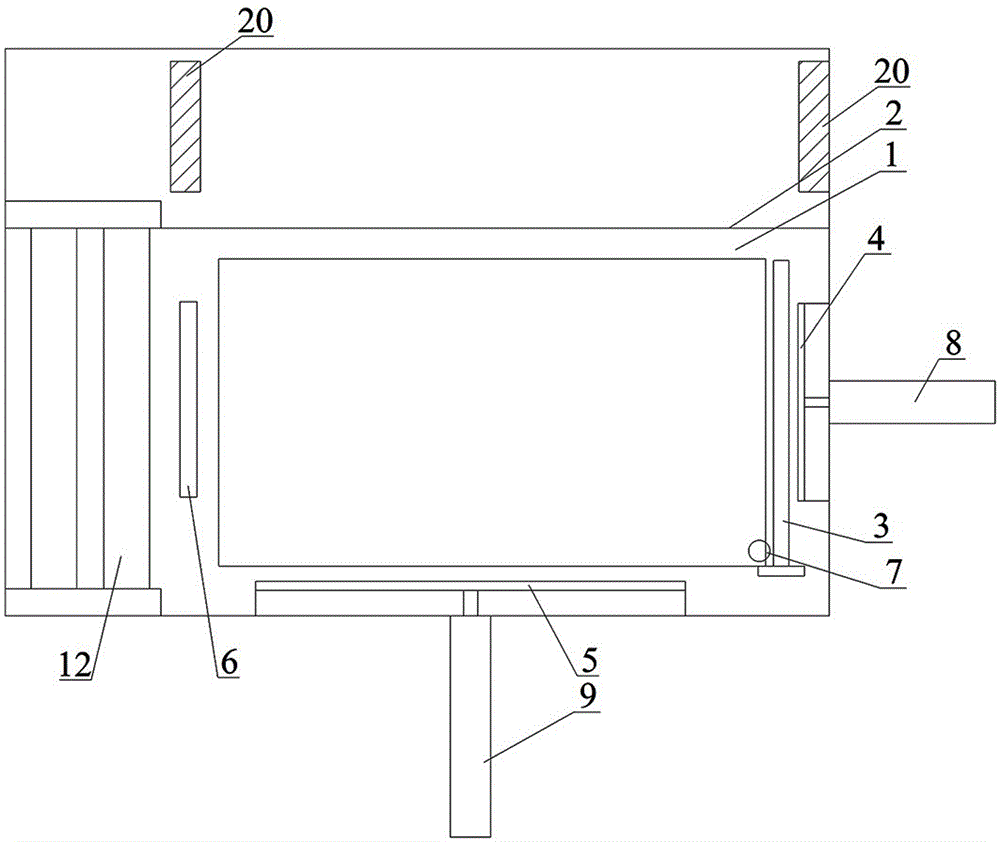

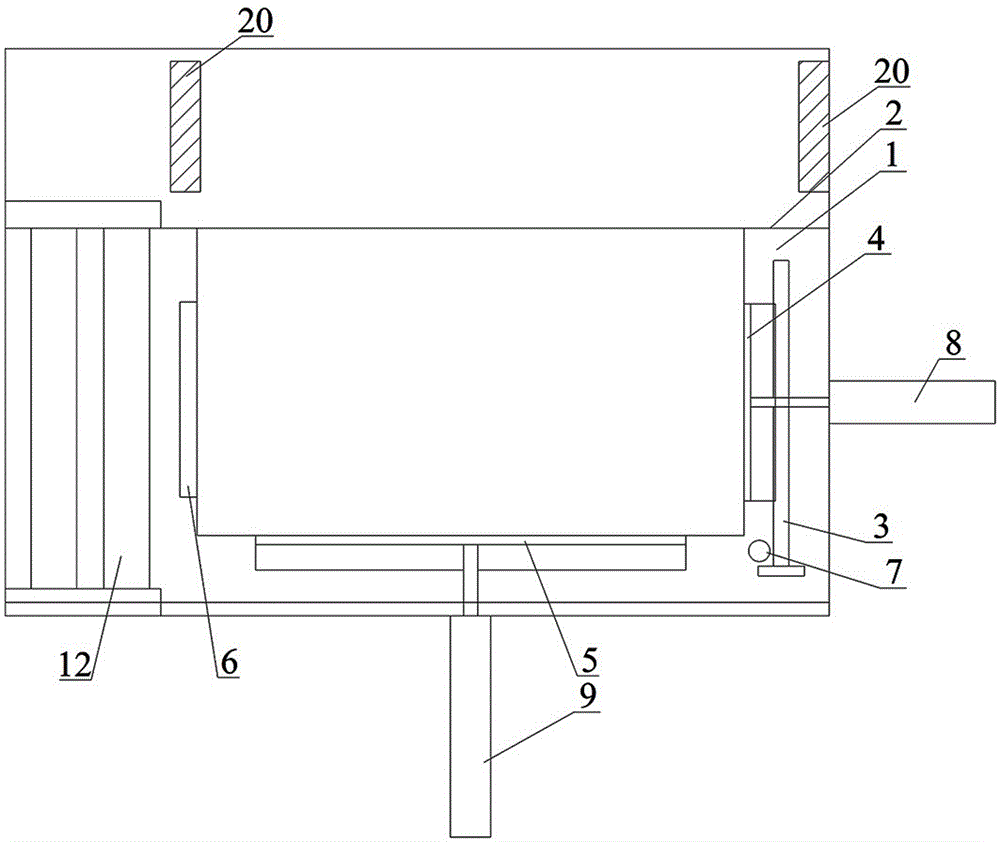

[0034] Such as figure 1 , figure 2As shown, a two-dimensional drilling device for plates includes a workbench 1 and a drilling machine 11. The rear side of the upper surface of the workbench 1 is provided with a rear stop surface perpendicular to the upper surface of the workbench 1 and located on the upper part of the upper surface. 2. The rear stop surface 2 is used to limit the rear end of the plank on the workbench 1, and the upper surface of the workbench 1 located on the front side of the rear stop surface 2 is provided with a feeding guide roller 3, Leftward jacking plate 4, backward jacking plate 5 and left limiting plate 6;

[0035] The feeding guide roller 3 and the left jacking plate 4 are all arranged on the right side of the workbench 1, and the height of the feeding guide roller 3 is higher than the left jacking plate 4, so that the left jacking plate 4 can Pass freely below the feeding guide roller 3, and the backward ejector plate 5 is arranged on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com