Hub type brake

A hub-type brake and housing technology, which is applied in the field of brake devices, can solve the problems of affecting the safe braking of vehicles, laborious manual operation of swinging arms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

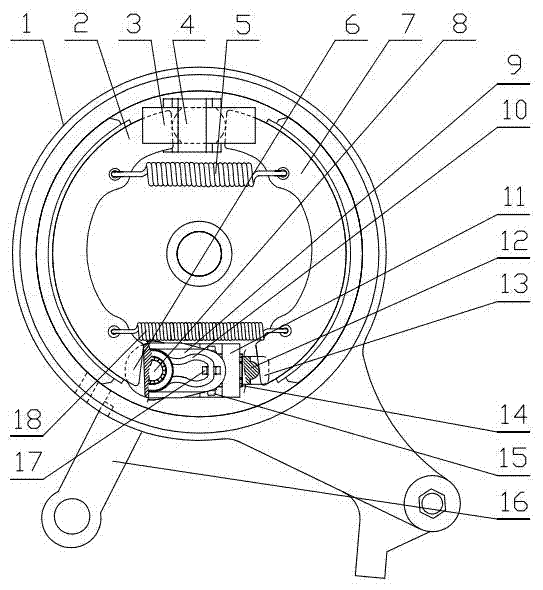

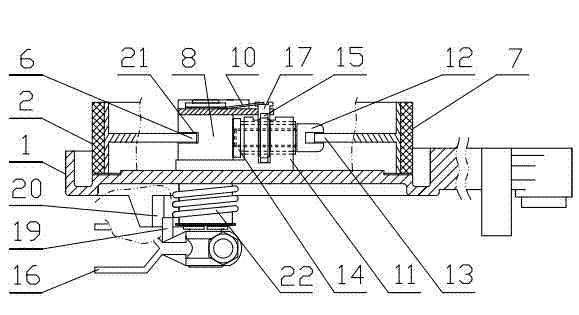

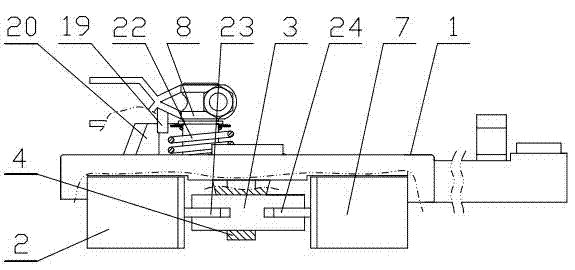

[0016] figure 1 , figure 2 and image 3 Among them, a hub-type brake includes a housing 1, a rocker arm 16, a torsion spring 22, a left friction plate 2 and a right friction plate 7 that are movably arranged on the housing 1. The rear end of the housing 1 is provided with a rear fixing seat 4 , and a rear return spring 5 and a front return spring 18 are provided between the left friction plate 2 and the right friction plate 7 . The front end of the shell 1 is provided with a front fixed seat 11, and a movable spline nut 14 is arranged in the front fixed seat 11, and a spline ratchet 15 is arranged on the spline nut 14, and an adjusting bolt 12 is arranged in the spline nut 14, and when adjusting The bolt 12 is provided with a slide groove matched with the front end 13 of the right friction plate. Above-mentioned hub type brake also contains rocker shaft 8 and slide shaft 3. The rocker shaft 8 is installed in the through hole provided in the housing 1 and matched with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com