Fluid distribution system

A fluid, one-to-one technology, used in liquid distribution, transportation or transfer devices, distribution devices, special distribution devices, etc., can solve problems such as inability to achieve one-to-many automatic docking, unclean pipeline cleaning, and hidden quality problems. The mechanism is ingeniously designed, the structure is simple and reliable, and the effect of increasing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

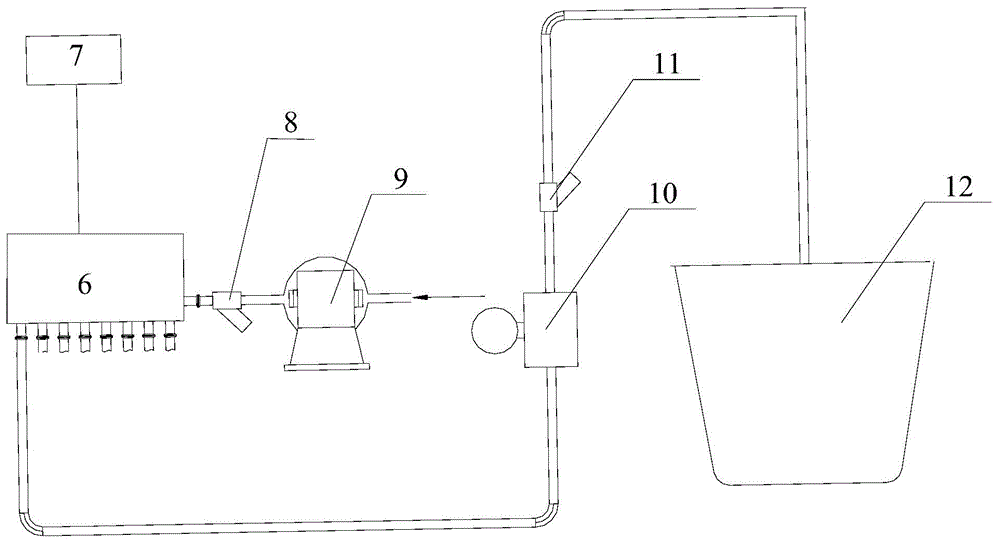

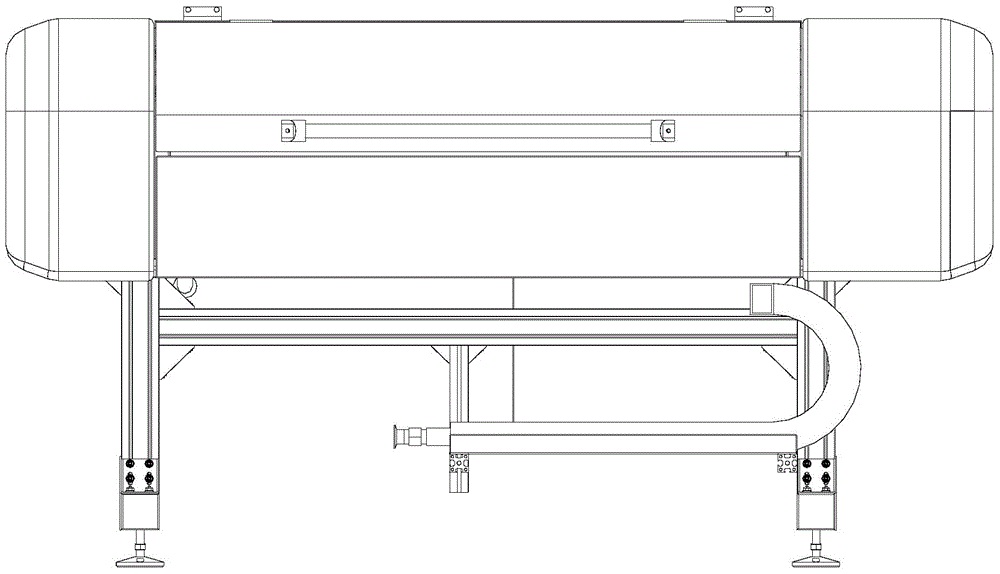

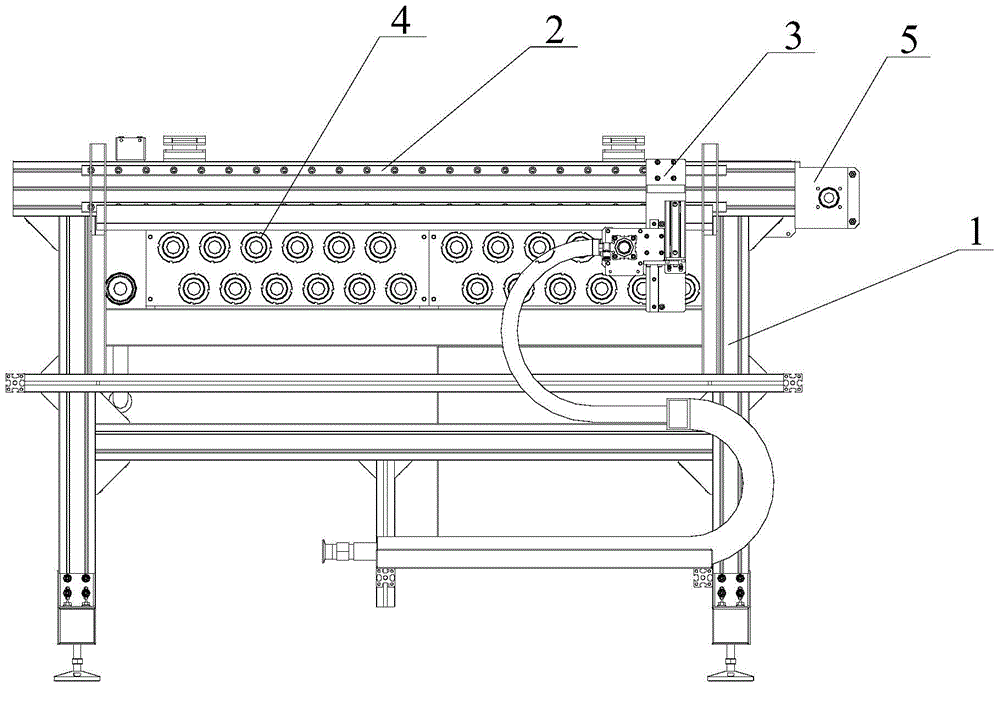

[0029] Such as figure 1 As shown, the fluid distribution system of the present invention includes a feeding device, a one-to-many automatic docking device 6 connected to the feeding device, and an output device connected to the one-to-many automatic docking device 6. A feed pump 9 connected to the feed source and a feed valve 8 connected to the output port of the feed pump 9 , one end of the outlet of the feed valve 8 is connected to the docking mechanism 3 in the one-to-many automatic docking device 6 . One end of the feed valve 8 is connected with the output port of the feed pump 9, and the other end is connected with the L-shaped pipeline 40 in the docking mechanism 3 in the one-to-many automatic docking device 6 extending from the moving fast 39 to one end. The output device includes a flow meter 10 connected to the pipeline joint 4 through a pipeline, a discharge valve 11 connected to the outlet of the flow meter 10 , and a mother liquid storage tank 12 connected to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com