A three-degree-of-freedom coaxial output mechanism with wire transmission

A technology with coaxial output and degrees of freedom, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inability to meet, increase the mass of moving parts, and limit dynamic characteristics, and achieve small rotational inertia, high speed and acceleration. Ability, Effect of High Acceleration Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

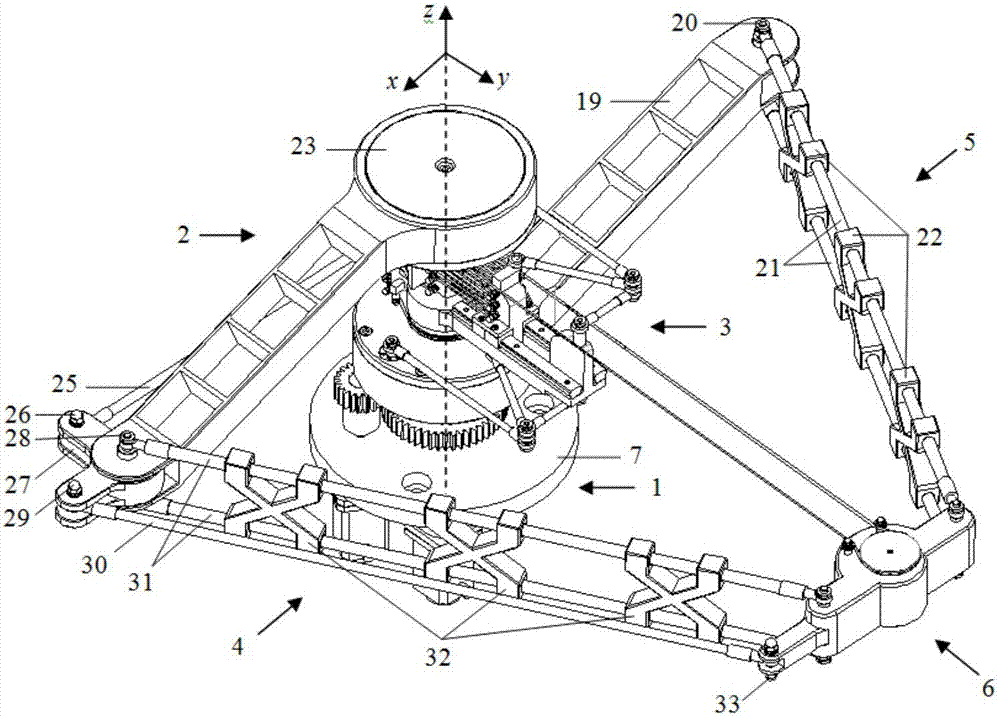

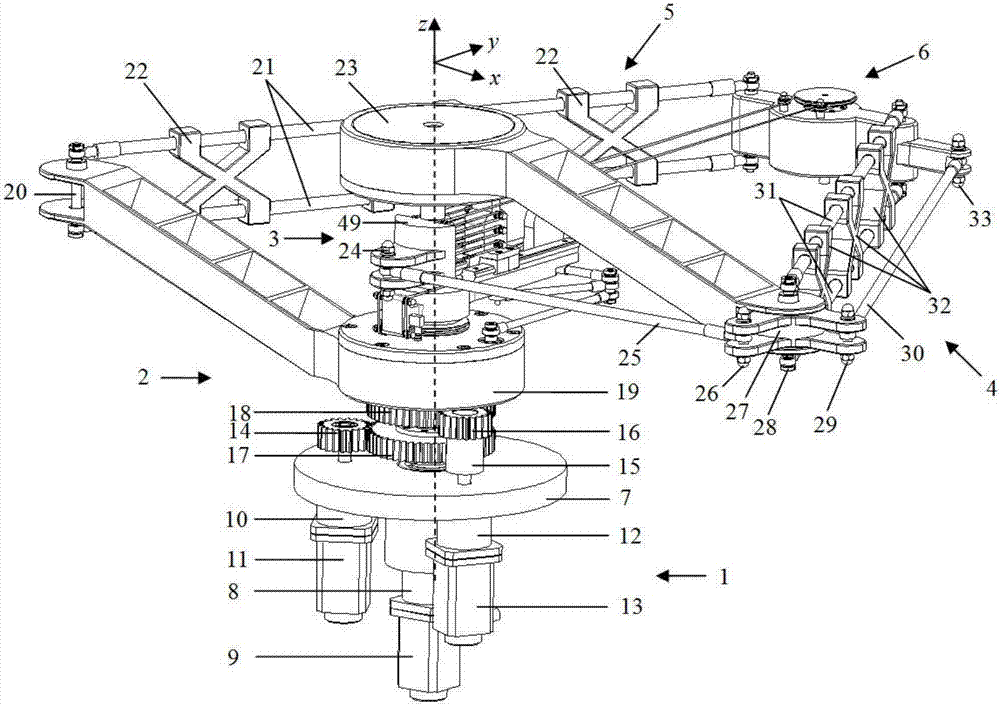

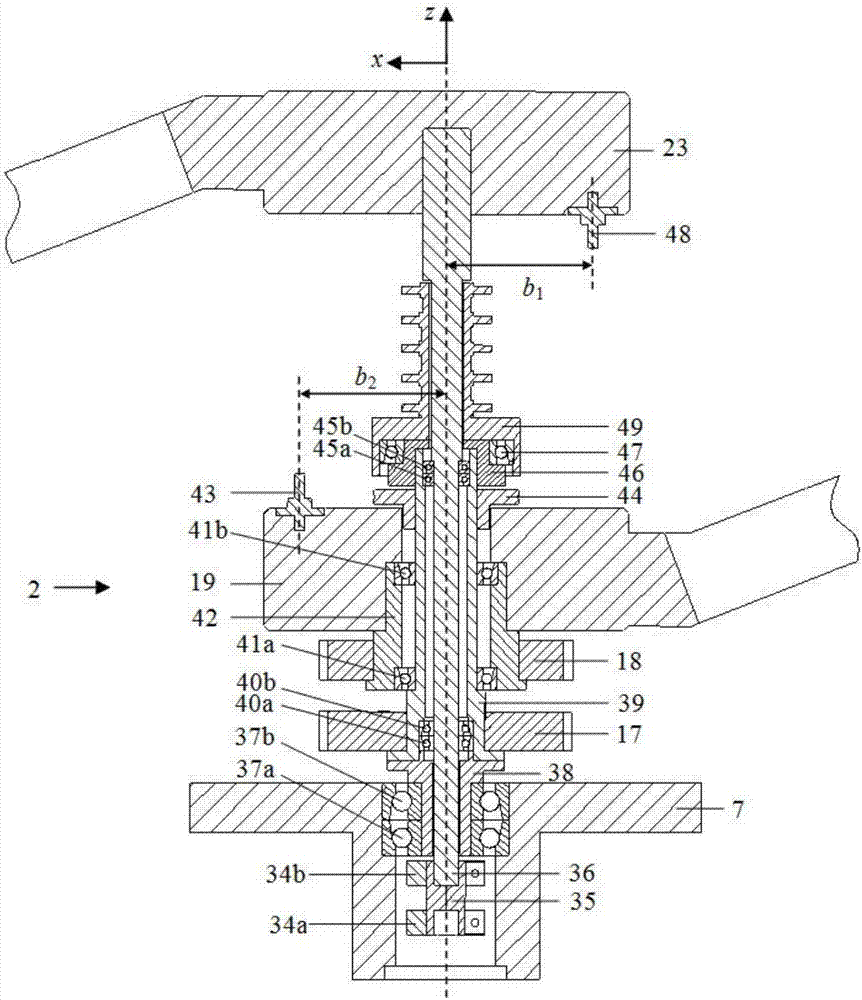

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] see Figure 1 to Figure 6 , a three-degree-of-freedom coaxial output mechanism with wire transmission, including a vertically arranged central transmission shaft 36, said central transmission shaft 36 is supported by a horizontally arranged base 7, and said central transmission shaft 36 is decelerated by a first Driven by a gear 8, the first gear reducer 8 is installed on the base 7, and the first gear reducer 8 is driven by a first motor 9.

[0019] A first active arm 23 , a follower frame 49 , a second hollow shaft 39 and a second active arm 19 are sequentially installed on the central transmission shaft 36 from top to bottom.

[0020] The first active arm 23 is fixed on the top of the central transmission shaft 36, the second hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com