High voltage power cable tension clamp

A high-voltage power and cable technology, which is applied in the field of power system auxiliary tools, can solve problems such as potential safety hazards, cumbersome operation of separate cables, etc., and achieve the effects of firm and reliable grounding, strong promotion and application value, and reduced reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

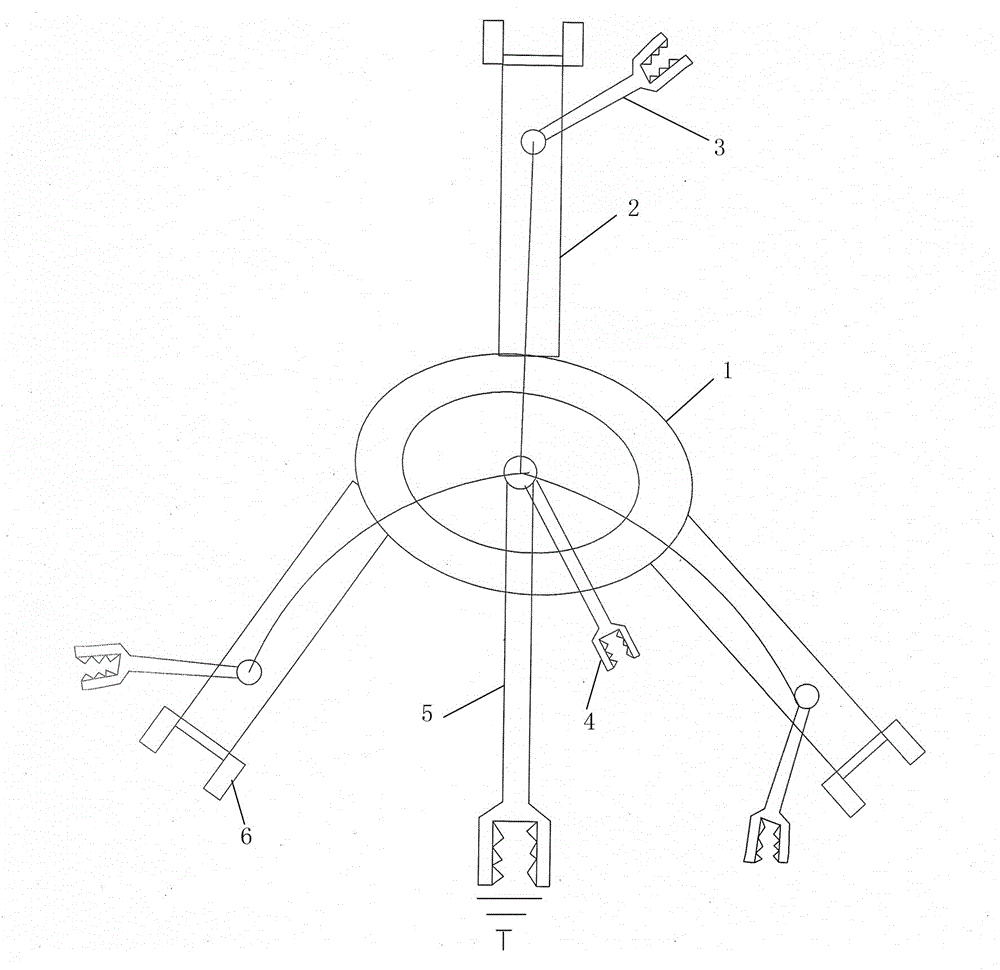

[0020] Such as figure 1 As shown, it includes insulating disc 1, insulating support rod 2, built-in grounding clamp 3, shielded wire grounding clamp 4 and grounding clamp 5; insulating disc 1 is fixed at the root of the cable, and insulating supporting rod 2 is provided with three There is an included angle between the two insulation support rods, the insulation support rod is a telescopic insulation support rod, one end of the telescopic insulation support rod is fixed on the insulation disc 1, and the other end of the telescopic insulation support rod is provided with a right-angle U-shaped support Seat 6, the inside of the telescopic insulation support rod is a cavity, the telescopic insulation support rod is set on the outside of the cable, and one end of the built-in grounding clamp 3 extends into the interior of the insulation support rod to connect with the cable; the shielded wire grounding clamp 4 and One end of the grounding wire clamp 5 is respectively connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com