Vacuum belt dehydrator and combined type filtering cloth scraper thereof

A vacuum belt and combined technology, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve the problems of affecting the separation effect, blocking the filter cloth, hidden safety hazards, etc., to prevent wear, prevent jamming, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

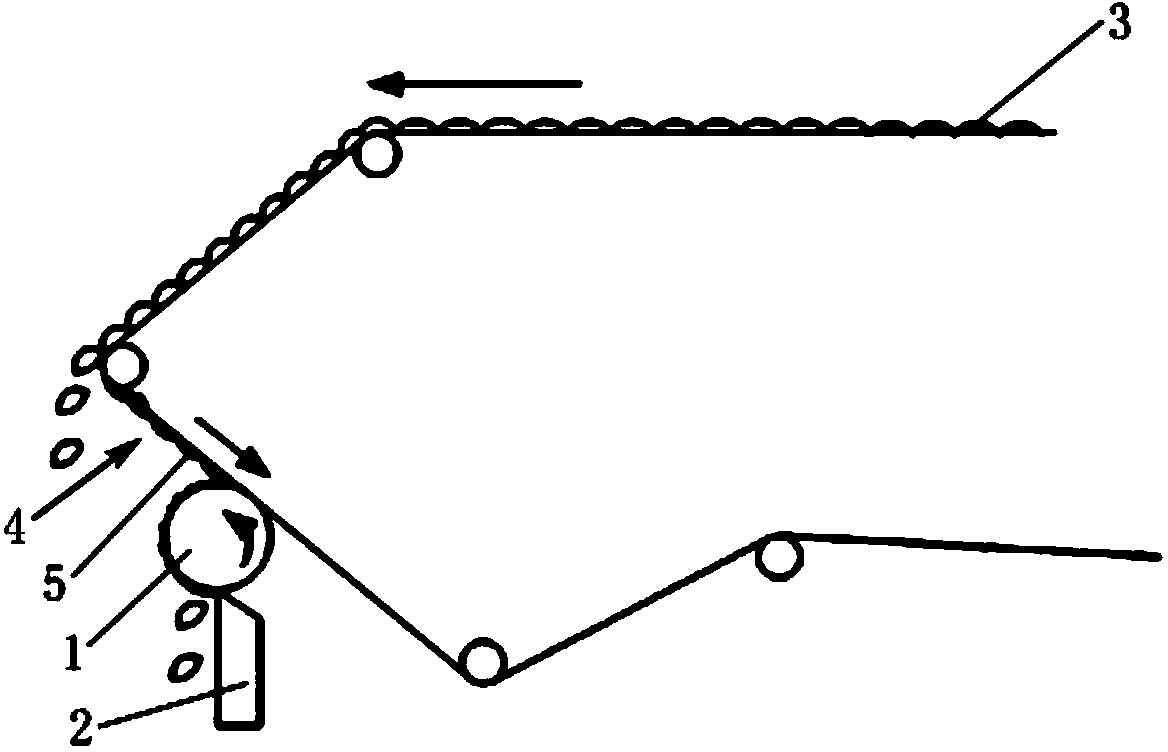

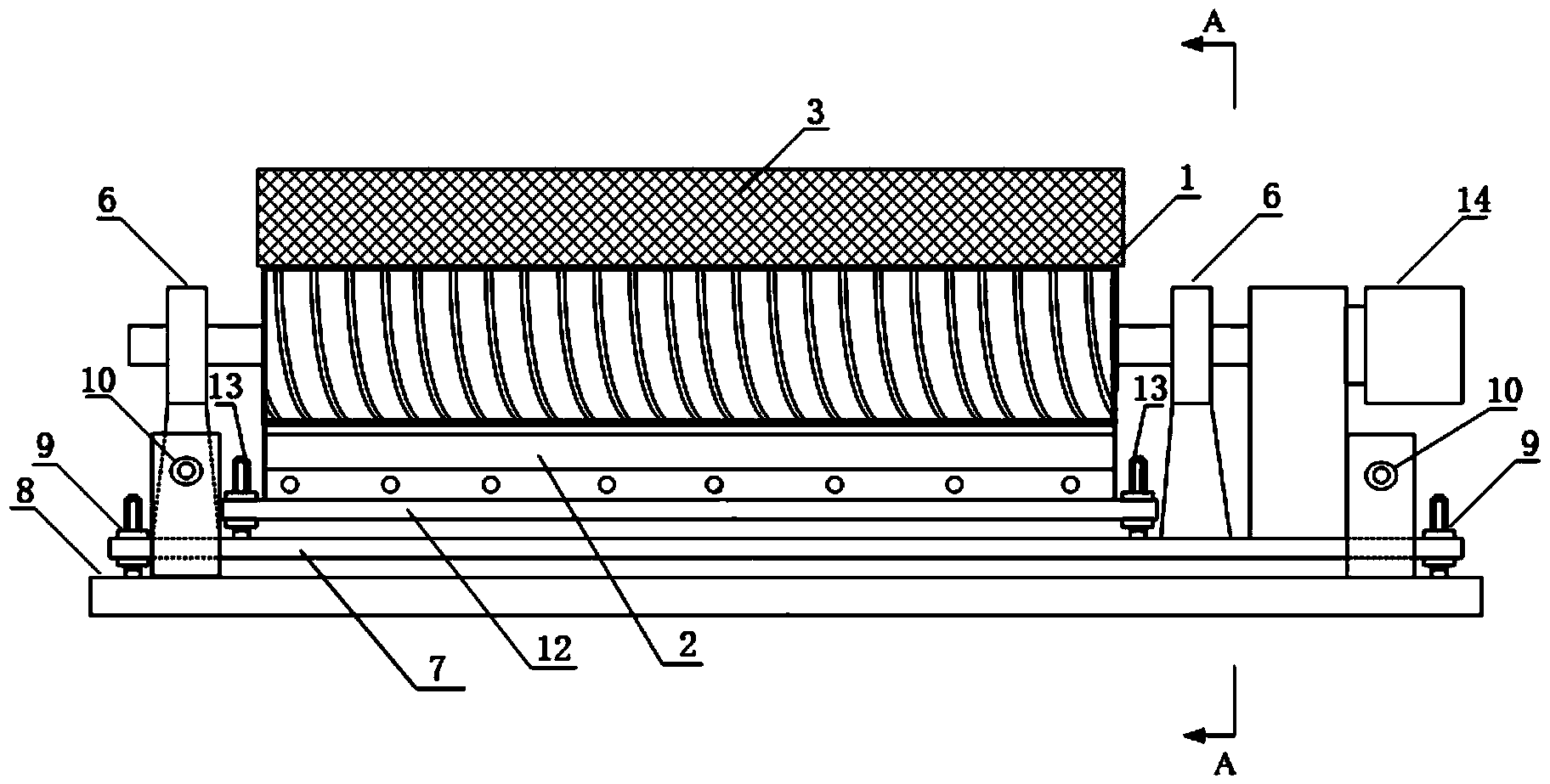

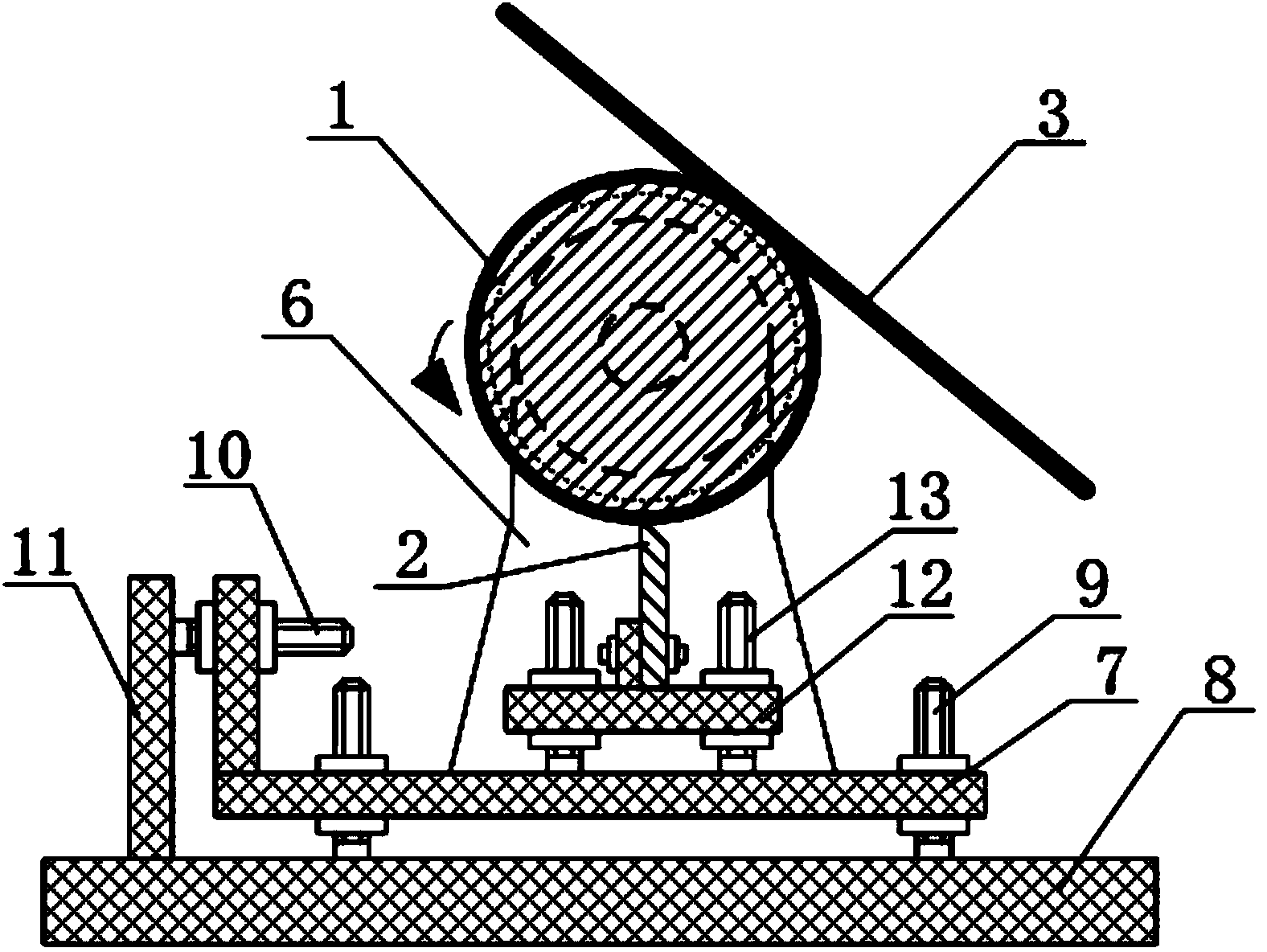

[0032] According to one aspect of the present invention, the present invention provides a combined filter cloth scraper for a vacuum belt dehydrator, the combined filter cloth scraper includes a drum scraper 1 and a flat scraper 2, wherein the outer peripheral surface of the drum scraper 1 is in contact with the vacuum belt dehydrator The material bearing surface 5 of the return section 4 of the filter cloth 3 cooperates so that the material adhered to the material bearing surface 5 can be scraped off by the rotation of the drum scraper 1, and the flat scraper 2 cooperates with the outer peripheral surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com