A combined hedge trimming tool support mechanism

A technology of a hedge trimming tool and a support mechanism, which is applied to the equipment for trimming hedges, etc., can solve the problems of single trimming mode and inability to meet demands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

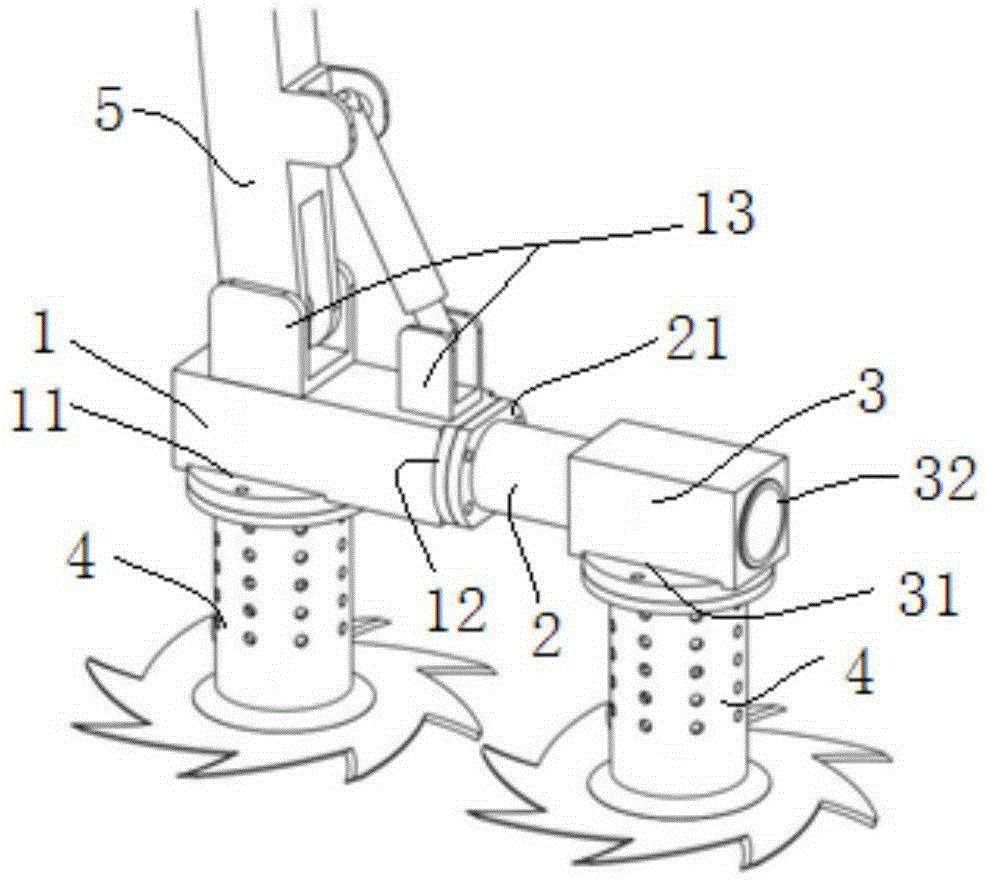

[0024] Such as figure 1 As shown, the combined hedge trimming tool support mechanism according to the specific embodiment of the present invention includes: a main fixed beam 1, a combined fixed beam 3, and a connecting rod 2; the main fixed beam 1 is in the shape of a rectangle, and its upper end is provided with a mounting seat 13 , the driving mechanism 5 of the hedge can be fixedly connected with the mounting seat 13, the lower end is provided with a tool installation slot 11, and is connected with the hedge tool 4 through the tool installation slot 11, and one end of the main fixed beam 1 is provided with a first flange 12, and a number of first bolt holes are provided on the first flange 12;

[0025] The combined fixed beam 3 is rectangular, and its lower end is provided with a tool installation slot 31, and the two ends are respectively provided with a combined beam slot 32; the connecting rod 2 is tubular, and one end is provided with a second flange 21, and the second...

Embodiment 2

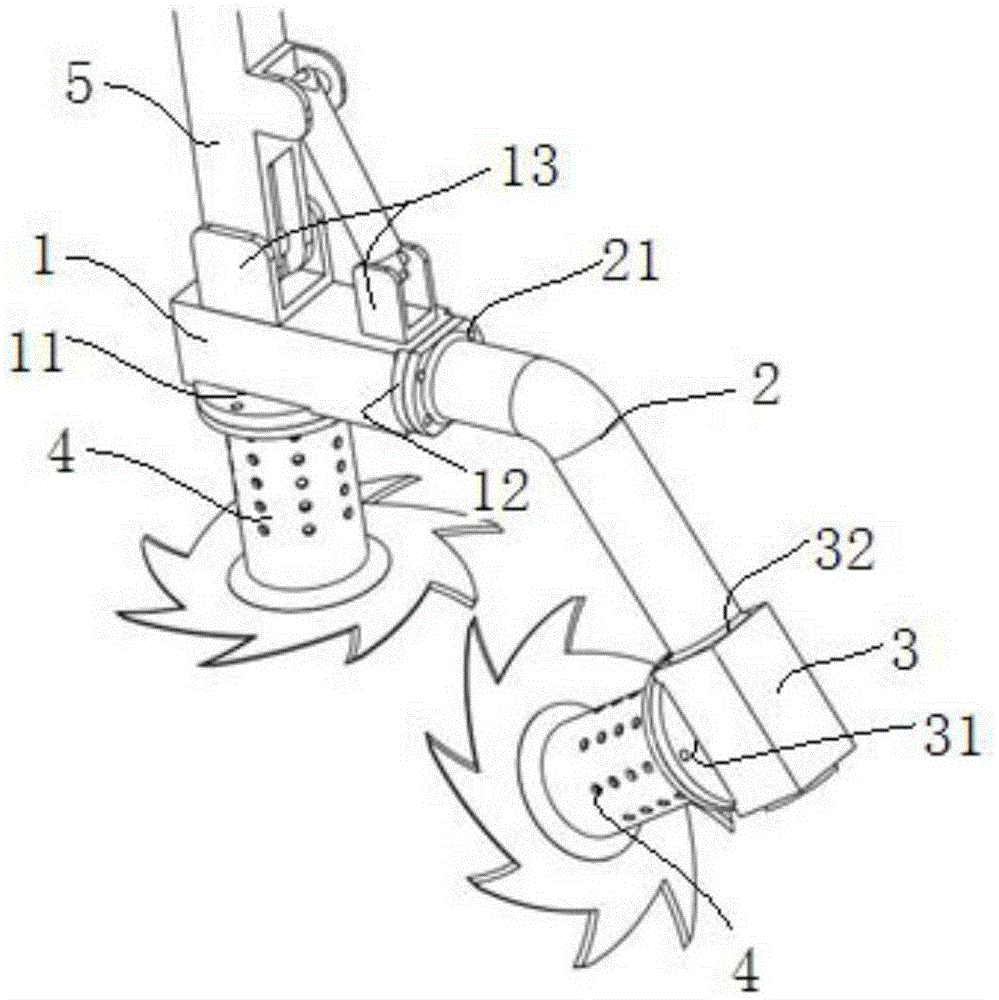

[0028] Such as figure 2 As shown, it is basically the same as the above-mentioned embodiment 1, the difference is that the connecting rod 2 connecting the main fixed beam 1 and the combined fixed beam 3 is curved, and the hedge cutter can cut out different shapes through the curved connecting rod 2 hedgerow shape.

Embodiment 3

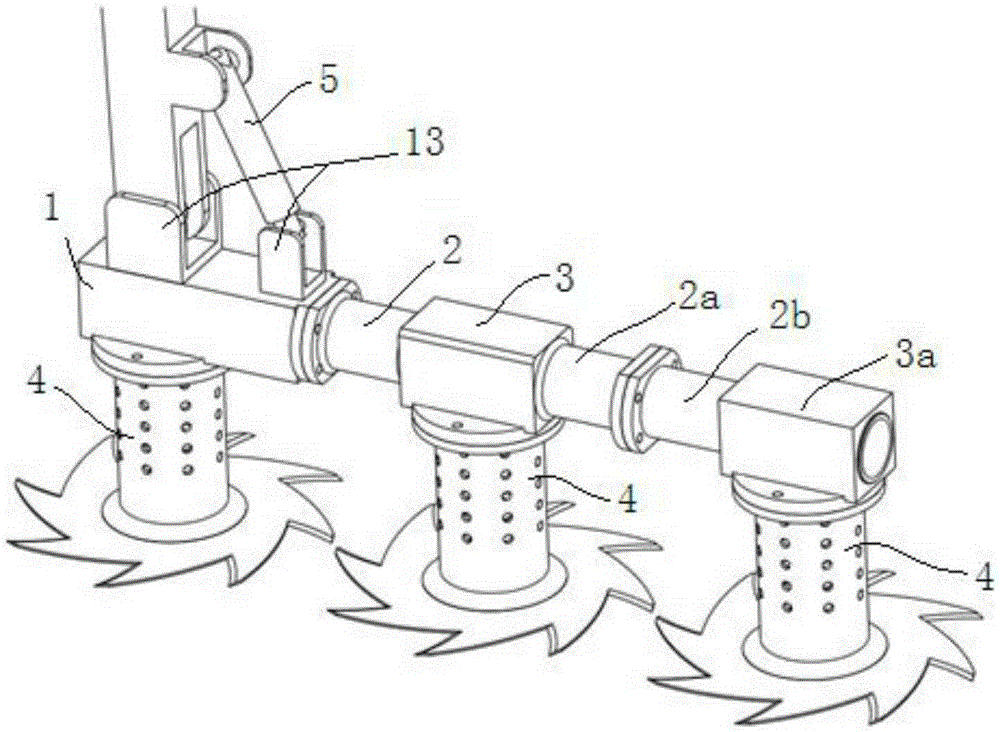

[0030] Such as image 3 As shown, according to another hedge trimming tool support mechanism according to the specific embodiment of the present invention, it is basically the same as Embodiment 1, and the difference is that a combined fixed beam 3a is added, and the combined fixed beam (3, 3a) passes through The connecting rods (2a, 2b) are connected, that is, the flanges of the connecting rods (2a, 2b) are provided with bolt holes, and one end of the connecting rods (2a, 2b) is fixed to the combined beam slot of the combined fixed beam (3, 3a) connection, and the other end of the connecting rod (2a, 2b) is fixedly connected with bolts through the bolt holes on the flange.

[0031] Through the above-mentioned combined hedge trimming tool supporting mechanism, two combined fixed beams are used, and the trimming area is larger, which is suitable for hedges that require most of the trimming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com