A tunnel fire shutter

A technology of fire shutters and tunnels, which is applied in mining equipment, mining equipment, earthwork drilling, etc., and can solve the problems of not being able to block fire and smoke in time, high installation costs of fire shutters, high repair and maintenance costs, etc. , to achieve the effect of simple structure, low maintenance cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

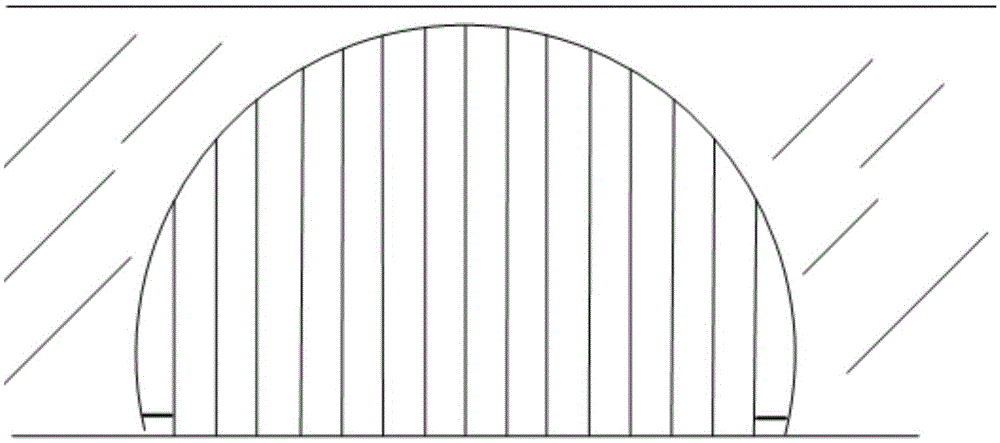

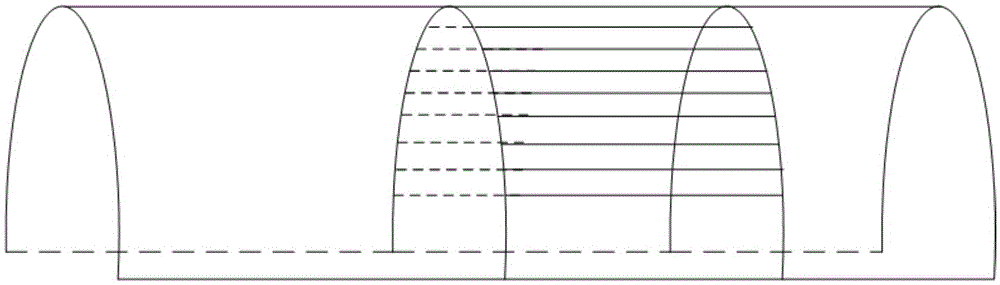

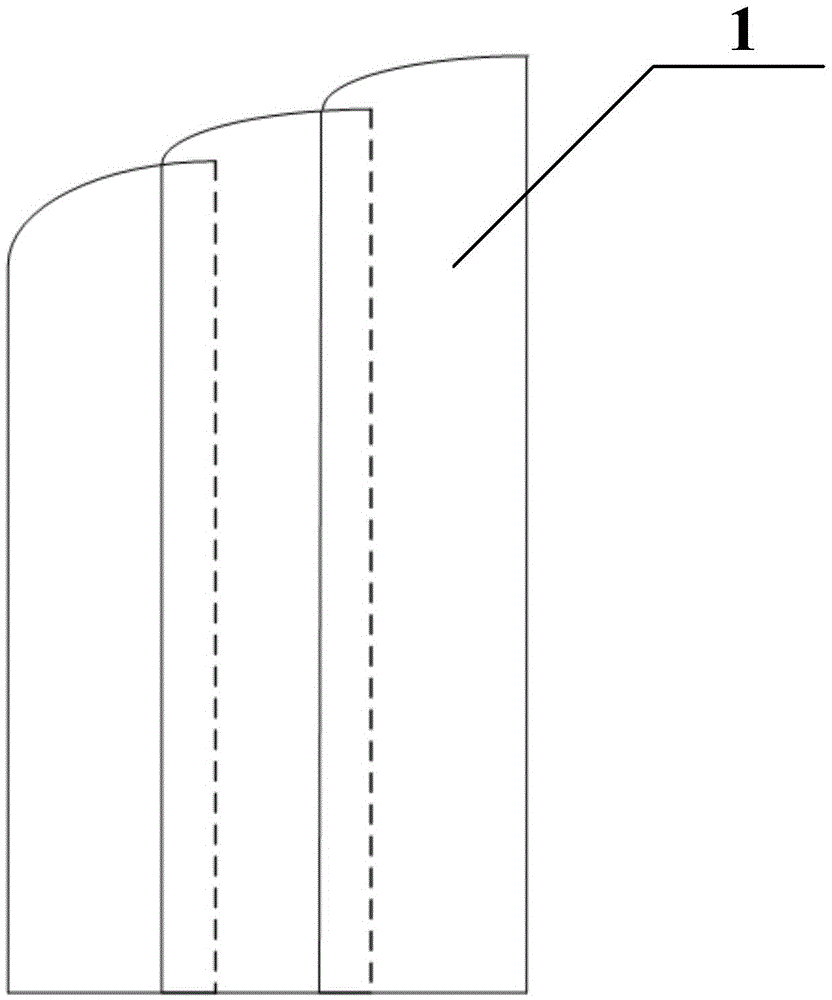

[0049] A tunnel fire shutter, such as Figure 1 to Figure 21 As shown, it includes a front-end fixing component, more than two rolling shutter sheets 1, a rear-end fixing component and a trigger device. One end of the rolling shutter sheet 1 is connected to the front-end fixing assembly, and the other end is connected to the rear-end fixing assembly, and the rolling shutter sheet 1 is partially overlapped in sequence, and the trigger device is installed in the tunnel On the wall of the hole, and connected with the roller blind sheet through the rear end fixing component.

[0050]The front-end fixing assembly includes a front-end fixing guide rail 2, a T-shaped curtain fixing part 3 and a guide rail end fastener 4. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap