A short-term overload test method and test machine for chip components

A short-term overload and test method technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of inconvenience to pick up and put down by hand, low production efficiency, unstable test conditions, etc., to achieve stable test quality, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the method of the present invention, now describe in detail in conjunction with a preferred embodiment of the present invention shown in the accompanying drawings, but said embodiment is only for illustration and explanation purposes, can not be used to limit the patent protection scope of the present invention .

[0032] A test method for short-term overload of chip components, said method comprising the steps of:

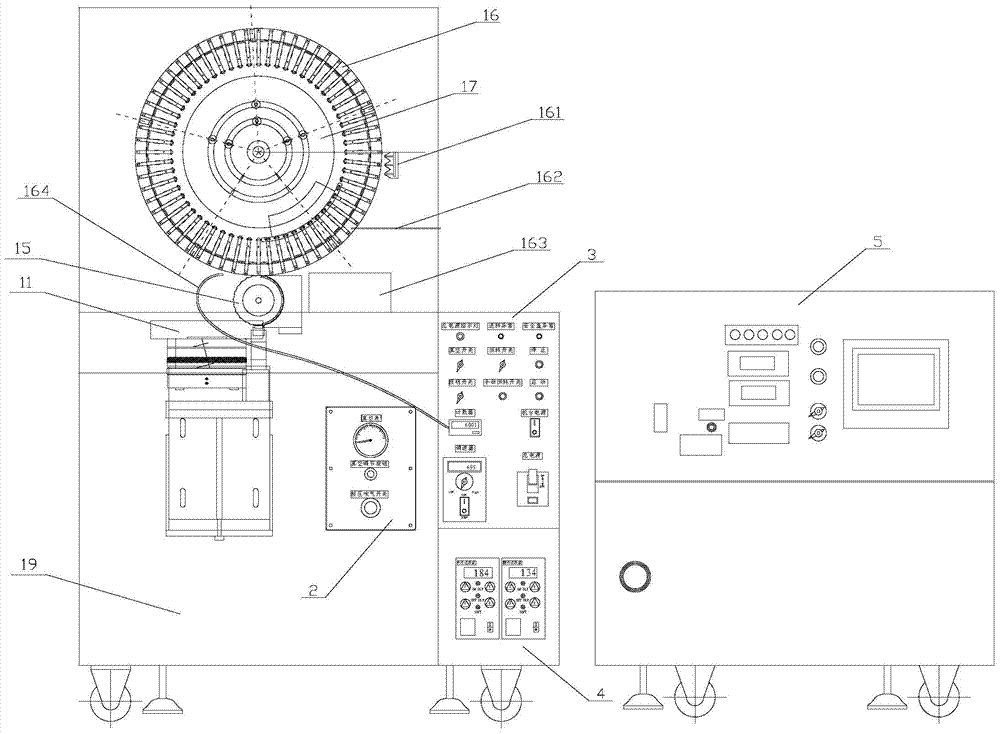

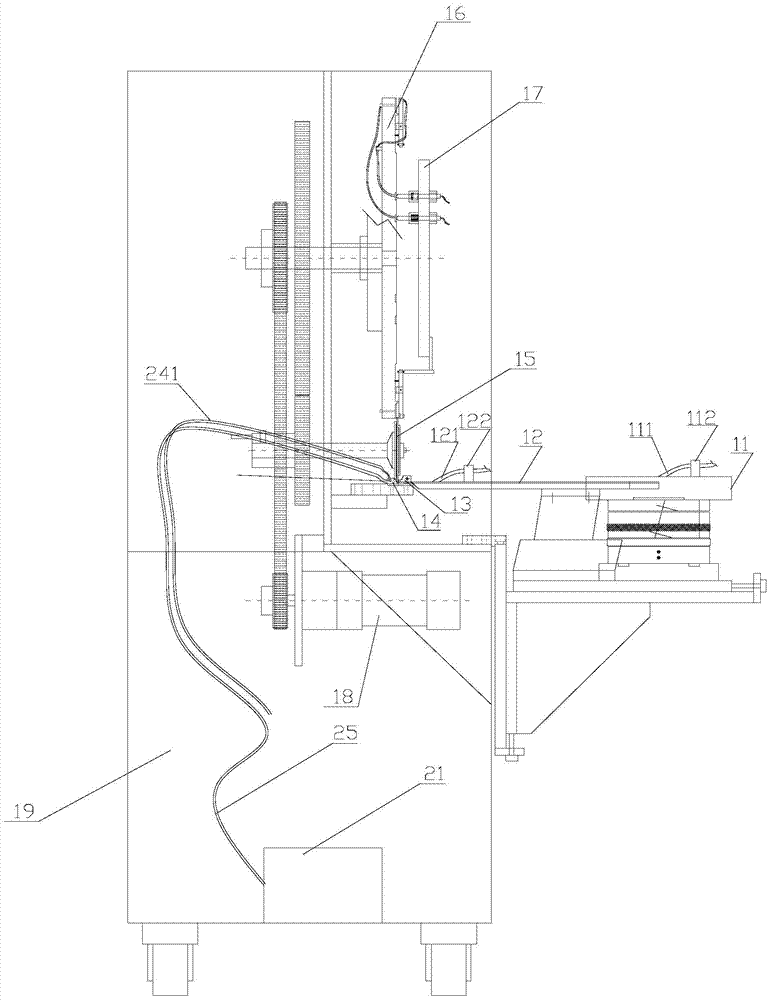

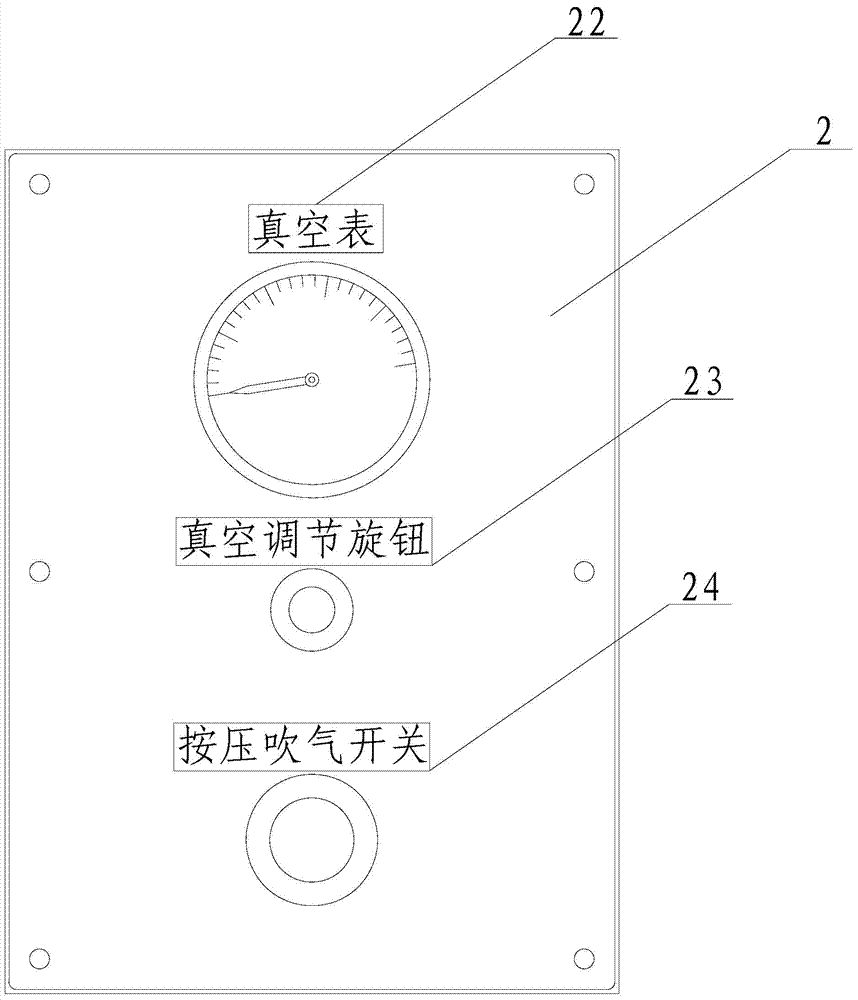

[0033] ① Prepare a device 1 for conveying chip components, the device 1 for conveying chip components includes: a circular vibrating feeding tray 11, a flat groove vibrating feeder 12, a feeding track 13, a vacuum suction device 14, an upper The tooth plate assembly 15, the material retrieving test disk assembly 16, the brush cam support plate assembly 17, the electric drag assembly 18, and the frame 19; It is disclosed in the new patent application; the device 1 for conveying chip components is configured as follows: the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com