Ceiling type range hood

A range hood, top suction technology, applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of low smoking efficiency, inconvenient disassembly and assembly, etc., to enhance the ability to absorb oil fume, convenient and quick disassembly, assembly and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

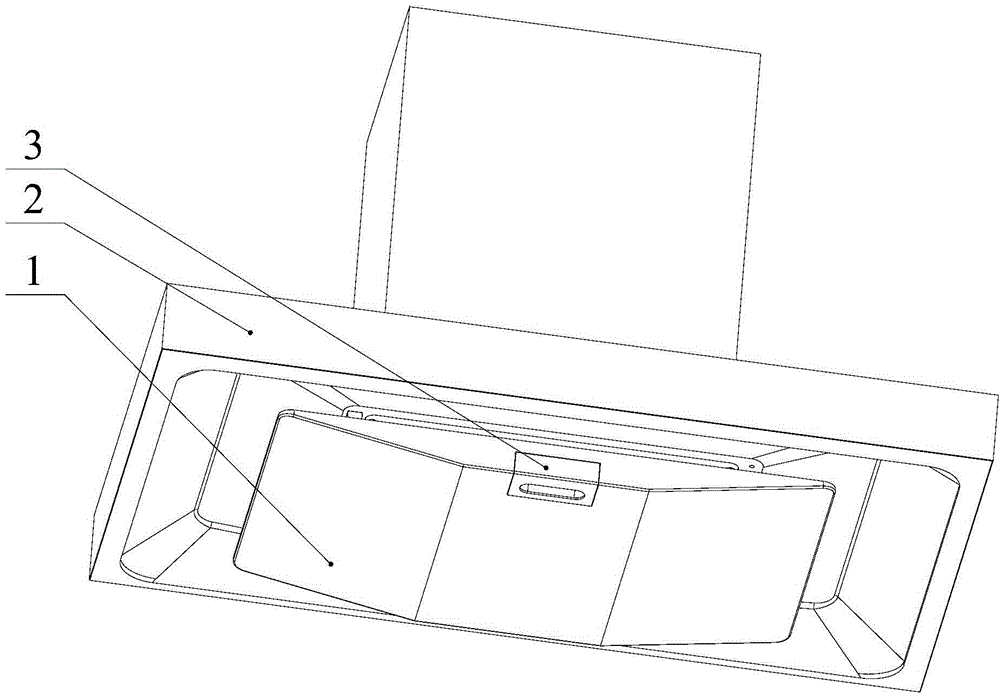

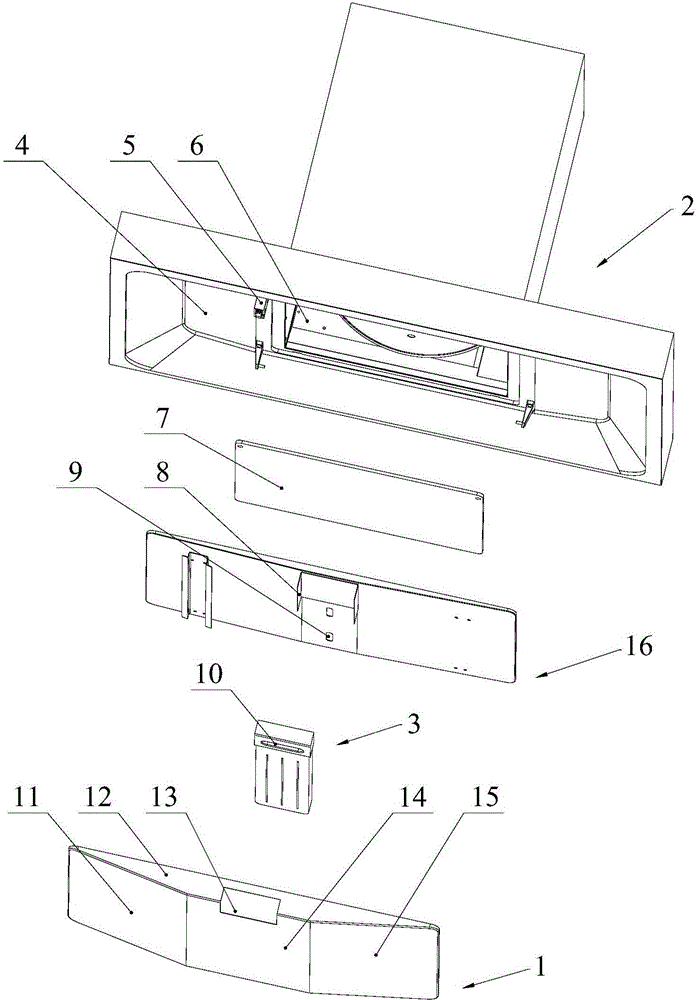

[0031] Such as figure 1 , 2 As shown, a top-suction range hood includes a smoke collection hood 2 and an air inlet 6 arranged on the bottom surface 4 of the smoke collection hood, and also includes:

[0032] Safety net 7 is arranged on the air inlet;

[0033] The oil collecting plate 16 is arranged directly below the air inlet, and is fixed with the bracket 5 fixed on the bottom surface 4 of the smoke collecting hood. The oil collecting plate and the bottom surface where the air inlet is located form four side air intake passages, and the middle part of the oil collecting plate is concave And the lower recess has an oil outlet 9;

[0034] The shroud 1 is arranged on the lower surface of the oil collecting plate;

[0035] The extractable oil collecting box 3 is arranged on the shroud, and the open end of the extractable oil collecting box is opposite to the oil outlet.

[0036] Such as figure 2 As shown, the wind deflector 1 includes a bottom plate 14 and a front wall pla...

Embodiment 2

[0040] The bracket in this embodiment is an adjustable bracket, and other structures are consistent with Embodiment 1.

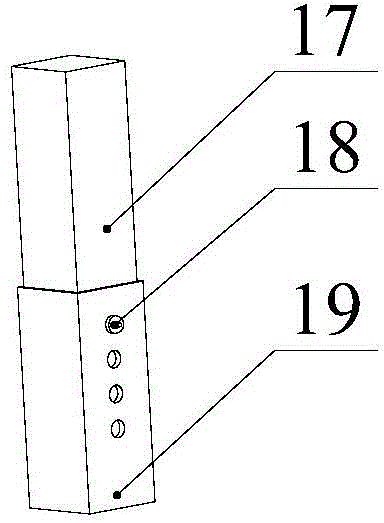

[0041] Such as image 3 As shown, the adjustable support includes an upper frame 17 and a lower frame 19 that are slidably inserted, and a positioning pin 18 is arranged between the upper frame and the lower frame. The height of the channel is the distance between the oil collecting plate and the bottom surface of the smoke collecting hood, that is, the height of the adjustable bracket. By adjusting the corresponding upper and lower shelves, the height of the channel can be adjusted, making the range hood more applicable when installing Strong, can adjust the height of the channel according to the specific situation, to ensure that the range hood has the greatest range hood effect.

[0042] The invention can guide the oil fume through the guide cover, and guide the oil fume to all directions of the channel. Because the channel is four-sided air intake, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com