Nearby suction type range hood

A range hood and near-suction technology, applied in the field of kitchen appliances, can solve the problems of unfavorable impeller working ability, difficulty in overcoming pipeline resistance, lack of noise reduction measures, etc., to achieve large negative pressure gradient, small size, and compact fan structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

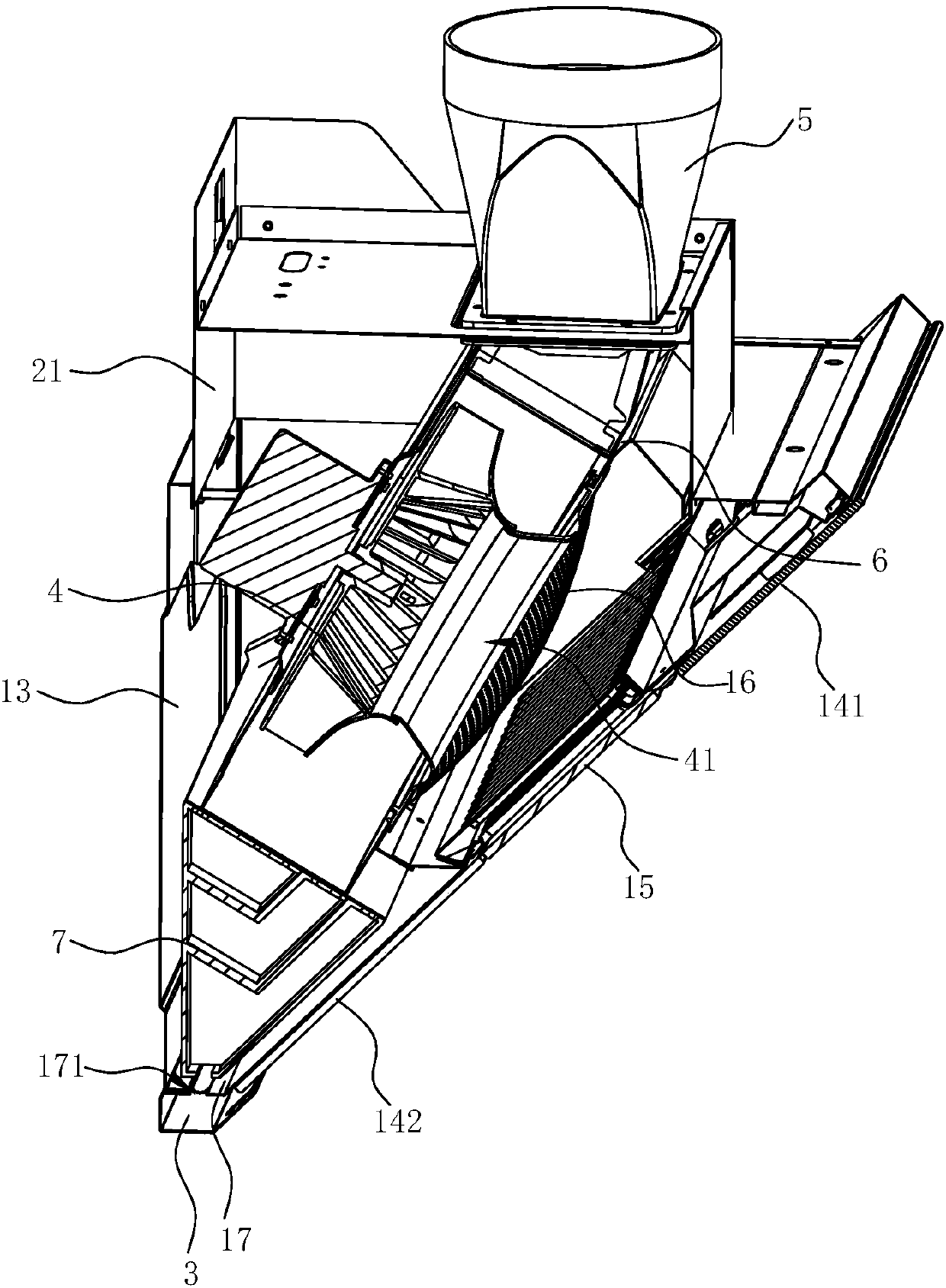

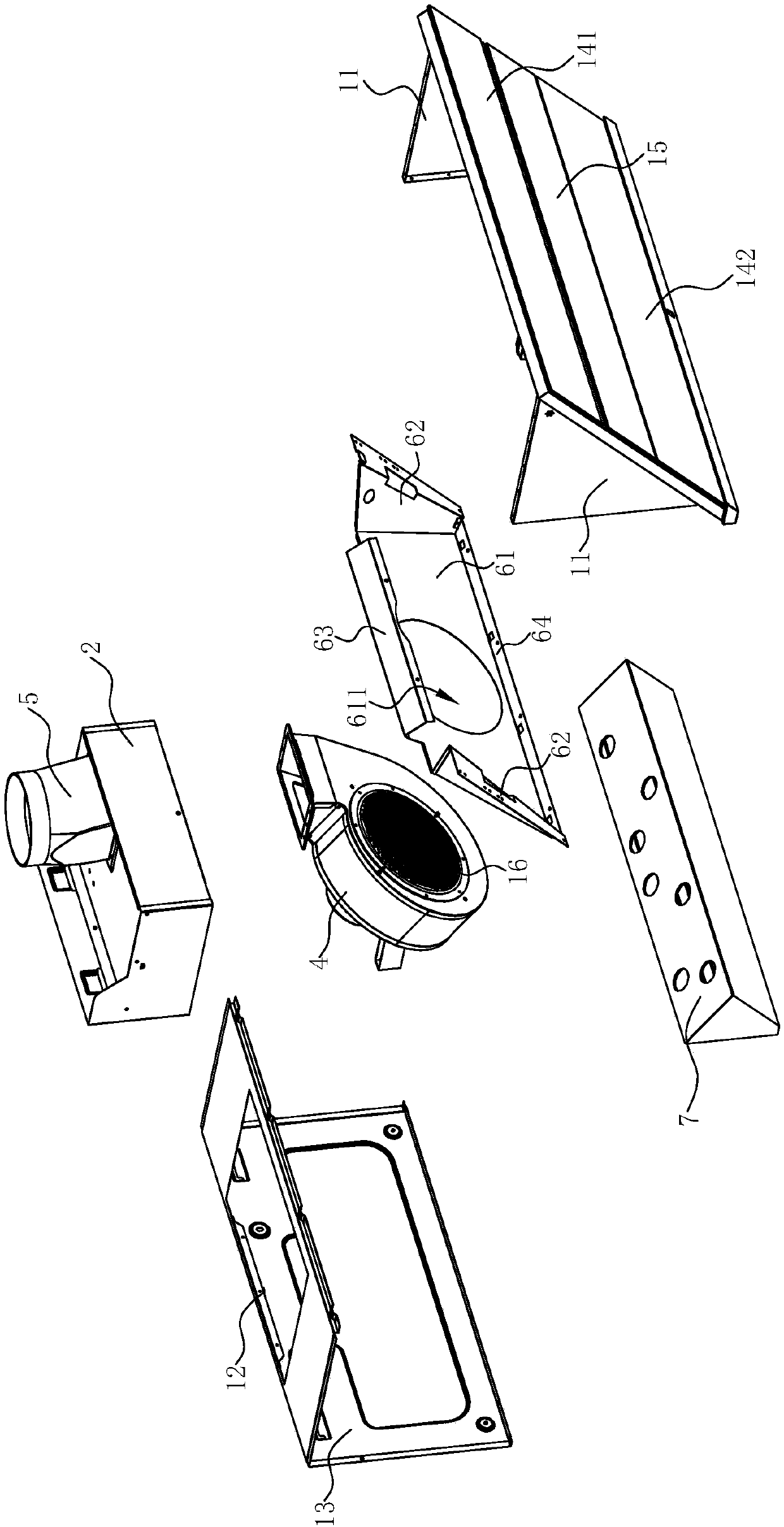

[0025] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

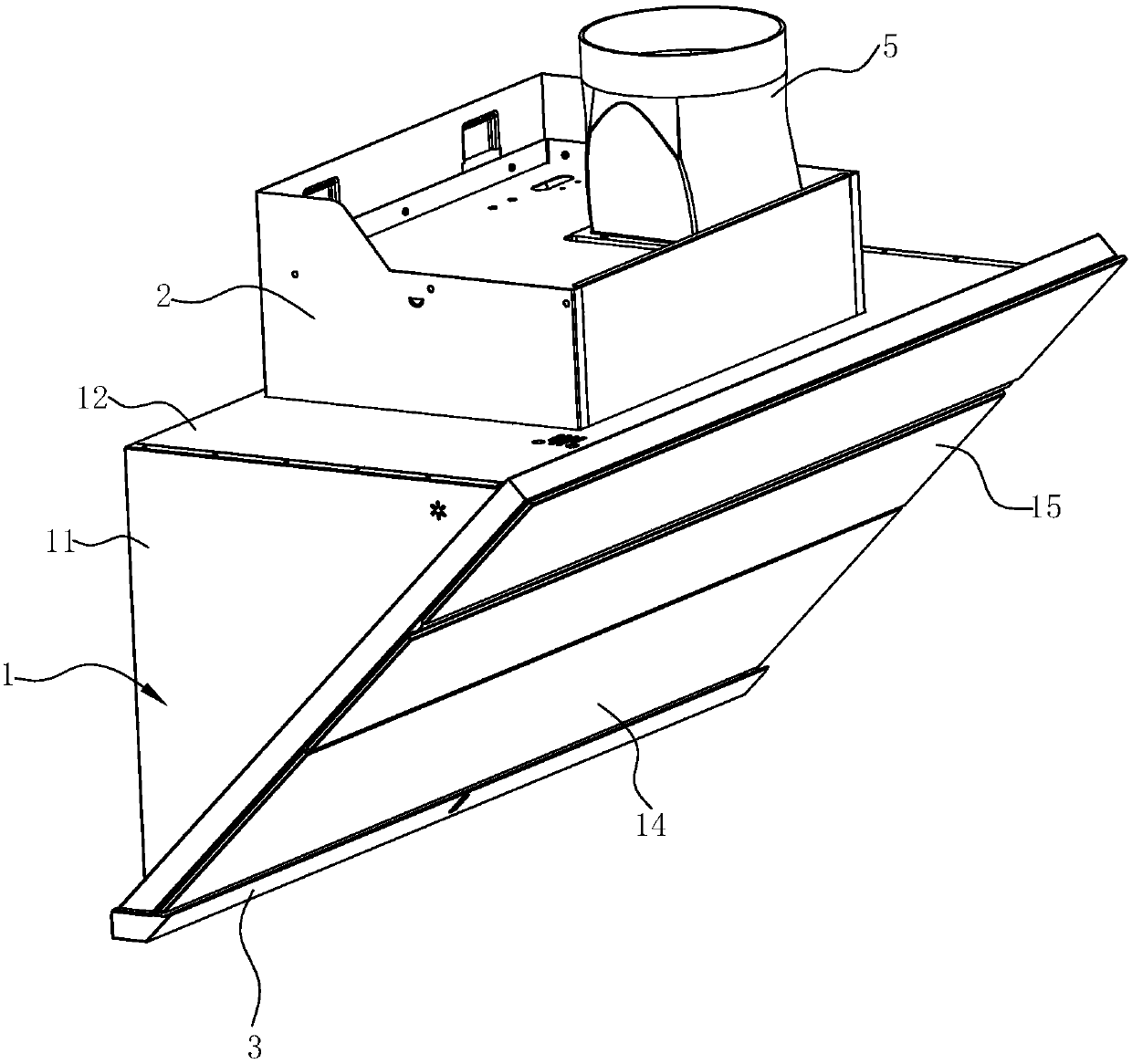

[0026] See Figure 1 ~ Figure 3 , A near suction range hood, comprising a casing 1 and a casing 2 located above the casing 1. For ease of description, in the following, "front", "rear", "left", "right", "up" "Down" refers to the position of the range hood relative to the user when the user uses the range hood, and does not limit the structure.

[0027] In this embodiment, the housing 1 includes a first side plate 11 on the left and right sides. The front end surface of the first side plate 11 is gradually inclined backward from top to bottom, so that the front side facing the user is an inclined surface . A top plate 12 is provided at the top end between the two first side plates 11, and a rear side plate 13 is provided at the rear end between the two first side plates 11. A panel 14 is provided between the front ends of the two first side plates 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com