Refrigeration cycle device

A refrigeration cycle and refrigerant technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem that the filter is not easy to set, and achieve the effect of good shunt characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

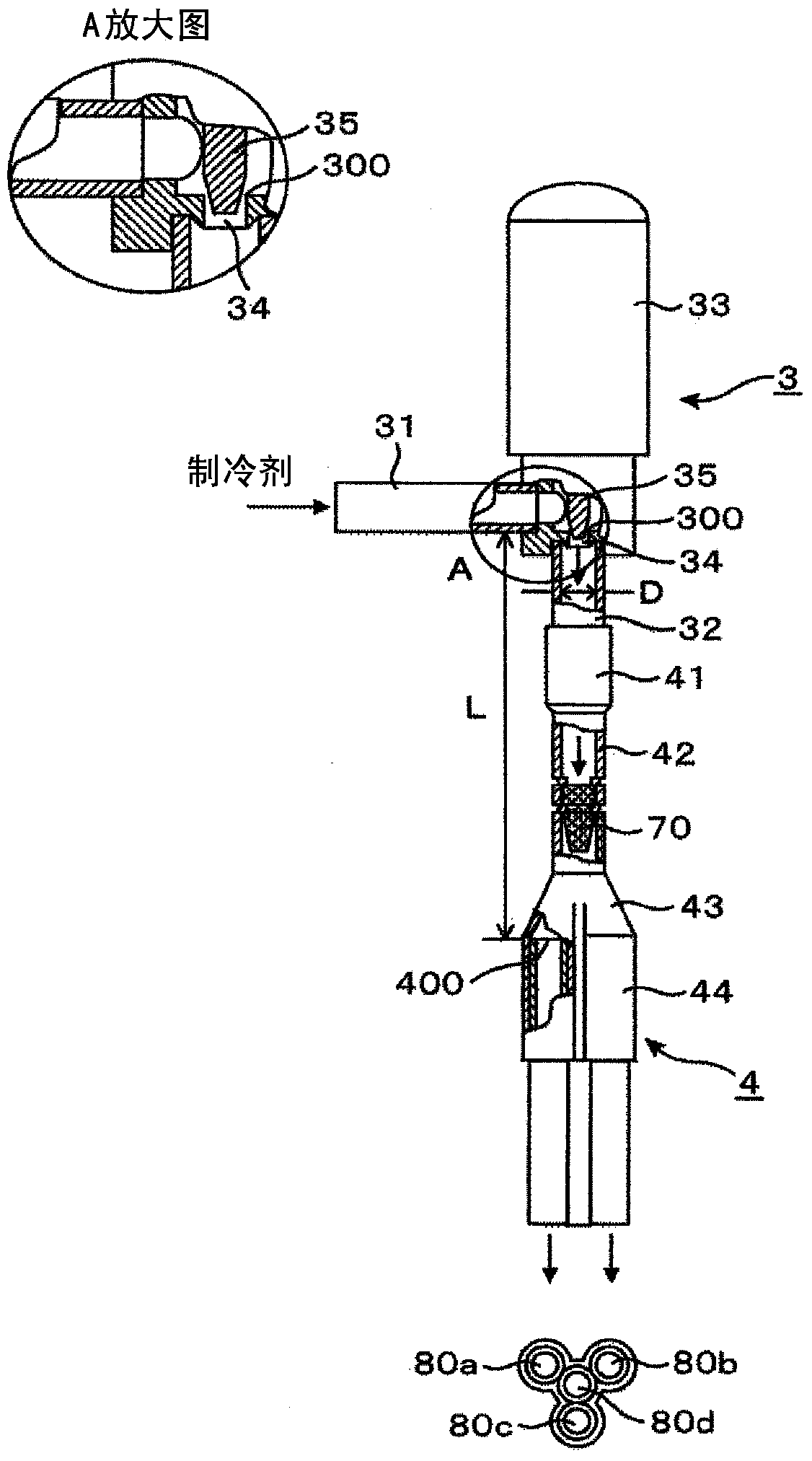

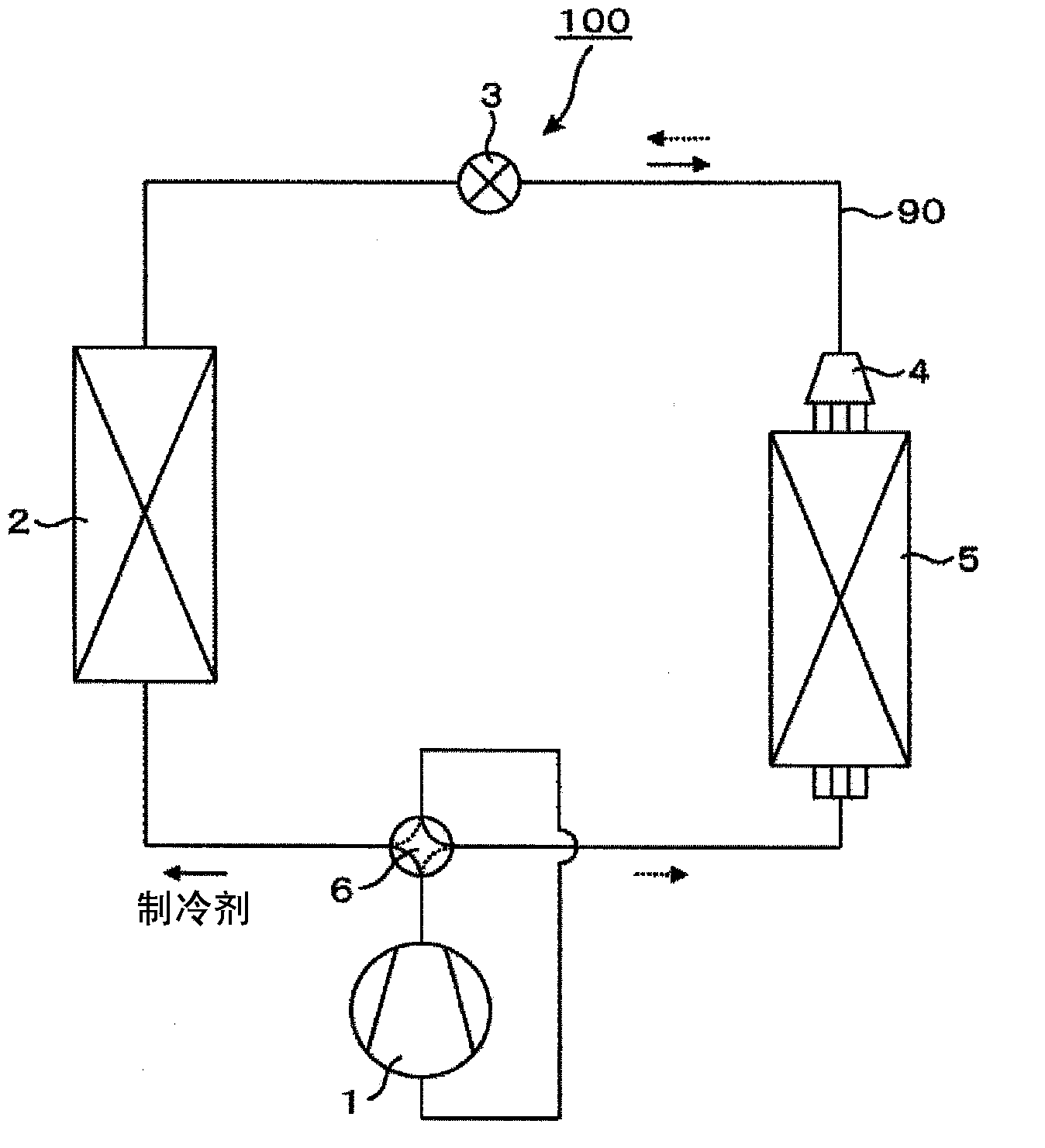

[0028] figure 2 It is an example of a configuration diagram of a refrigeration cycle device 100 according to this embodiment, for example, a room air conditioner. Here, reference numeral 1 is a compressor, reference numeral 2 is a first heat exchanger, reference numeral 3 is an expansion valve, reference numeral 4 is a refrigerant flow divider, and reference numeral 5 is a second heat exchanger , Reference numeral 6 is a four-way valve. The above-mentioned essential devices are connected by refrigerant piping to constitute the refrigeration cycle apparatus 100 .

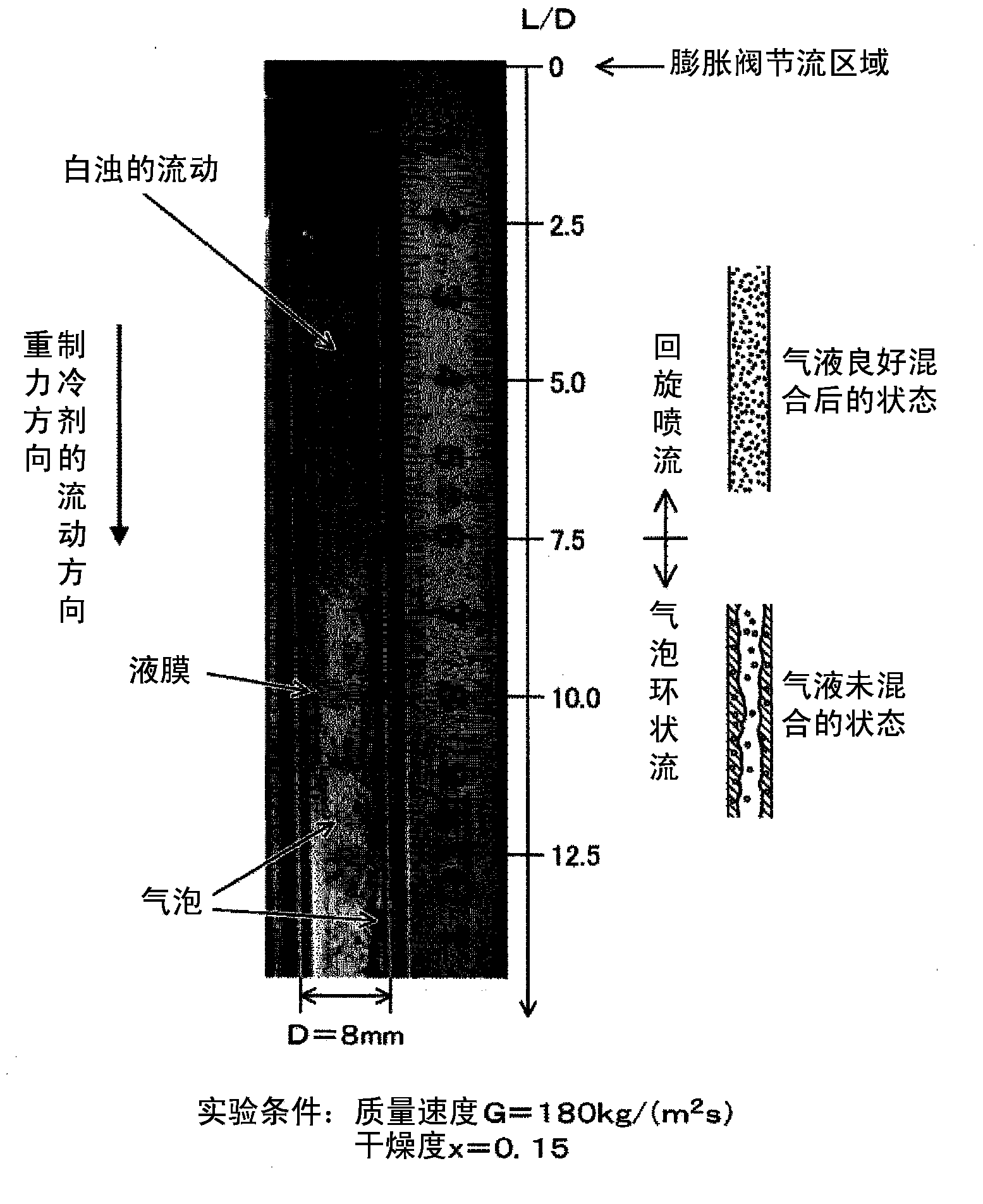

[0029] The first heat exchanger 2 functions as a condenser, and the second heat exchanger 5 functions as an evaporator, and the refrigerant flows through compressor 1→first heat exchanger 2→expansion valve 3→refrigerant flow divider 4 →Second heat exchanger 5→The order of compressor 1 (indicated by the solid arrow) In the case of internal circulation in the refrigeration cycle device 100, the refrigerant after pas...

Embodiment 2

[0056] Figure 10 An example of a configuration diagram of a refrigeration cycle device 101 according to Embodiment 2, such as a box-type air conditioner, is shown. Here, reference numeral 1 is a compressor, reference numeral 2 is a first heat exchanger, reference numerals 3a and 3b are expansion valves, reference numerals 4a and 4b are refrigerant flow dividers, and reference numeral 5 is a second heat exchanger. In the second heat exchanger, reference numeral 6 is a four-way valve, and reference numeral 91 is a connecting pipe. Wherein, both the first heat exchanger 2 and the second heat exchanger 5 have a multi-channel structure.

[0057] When the first heat exchanger 2 functions as a condenser and the second heat exchanger 5 functions as an evaporator, as indicated by the solid line arrow in the figure, the flow is split through the first heat exchanger 2 The liquid refrigerant joined in the tank 4a passes through the expansion valve 3a and the connection pipe 91, is dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com