Welding tooling for load switch or breaker casing assembly

A load switch and welding tooling technology, which is applied in the direction of electric switches, welding equipment, auxiliary welding equipment, etc., can solve the problems of welding size deviation, long axial size of the shell, scrapping of the shell, etc., to ensure accurate welding size and positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

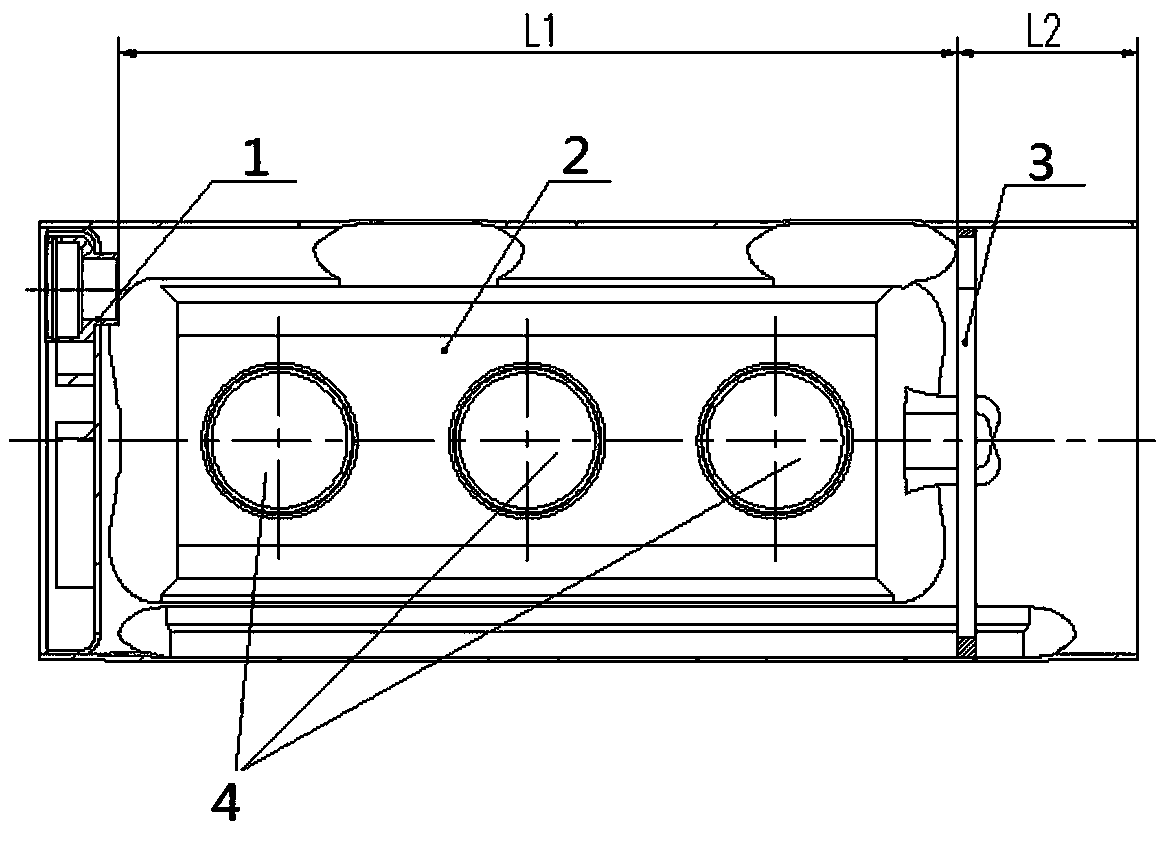

[0033] Examples of welding tooling for load switch or circuit breaker housing assembly Figure 9~14 Shown: In this embodiment, the object used by the welding tool is the circuit breaker housing assembly.

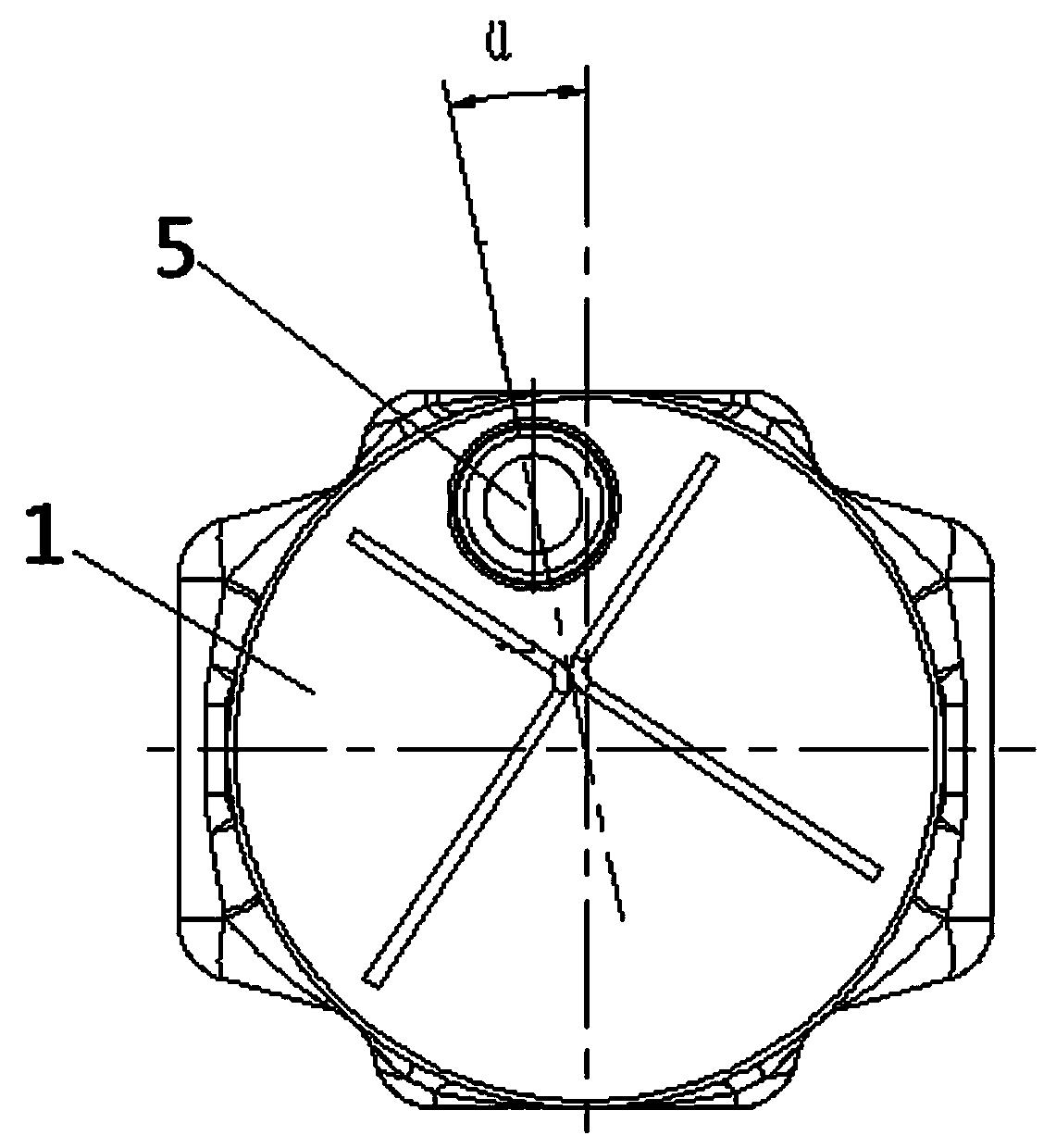

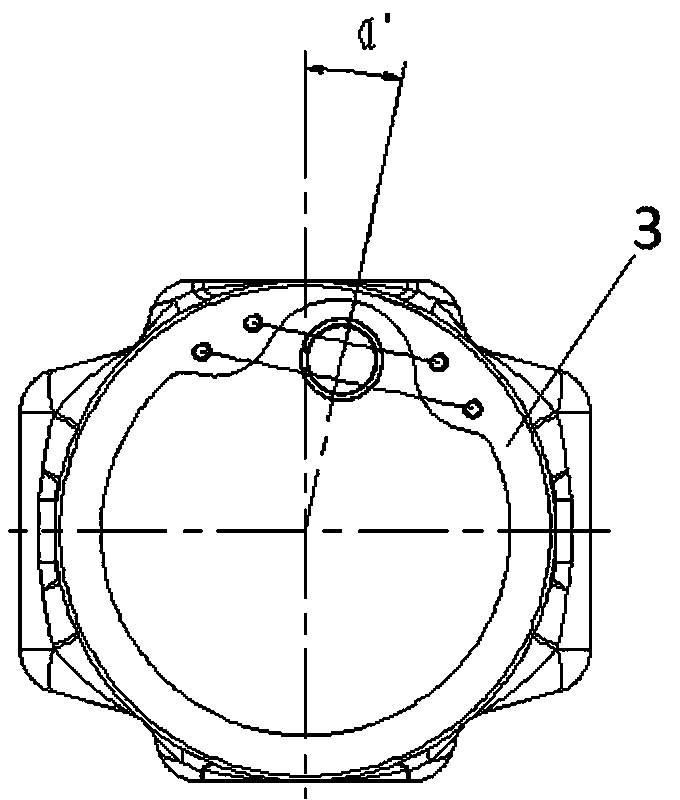

[0034]The welding tool includes two positioning units, and each positioning unit includes a pair of positioning mounting seats 20 coaxially and fixedly assembled on the two opposite electrode mounting holes of the shell, and each positioning mounting seat 20 includes a The positioning block pressing plate 13 on the outer side of the housing 10, and the positioning block 12 arranged on the inside of the positioning block pressing plate and used to coaxially fit in the corresponding electrode mounting hole, the outer peripheral surface of the positioning block 12 is provided with a large outer end diameter, The diameter of the inner end is small, and the tapered positioning section whose shape matches the tapered hole wall of the corresponding electrode installation hole. On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com