Device for detecting airtightness of fuel filter

A filter and sealing technology, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of missing detection, low efficiency, low detection reliability, etc. Achieve the effect of convenient operation, high detection efficiency and high detection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] In order to further understand the content, features, and effects of the present invention, the following examples are given to illustrate in detail as follows:

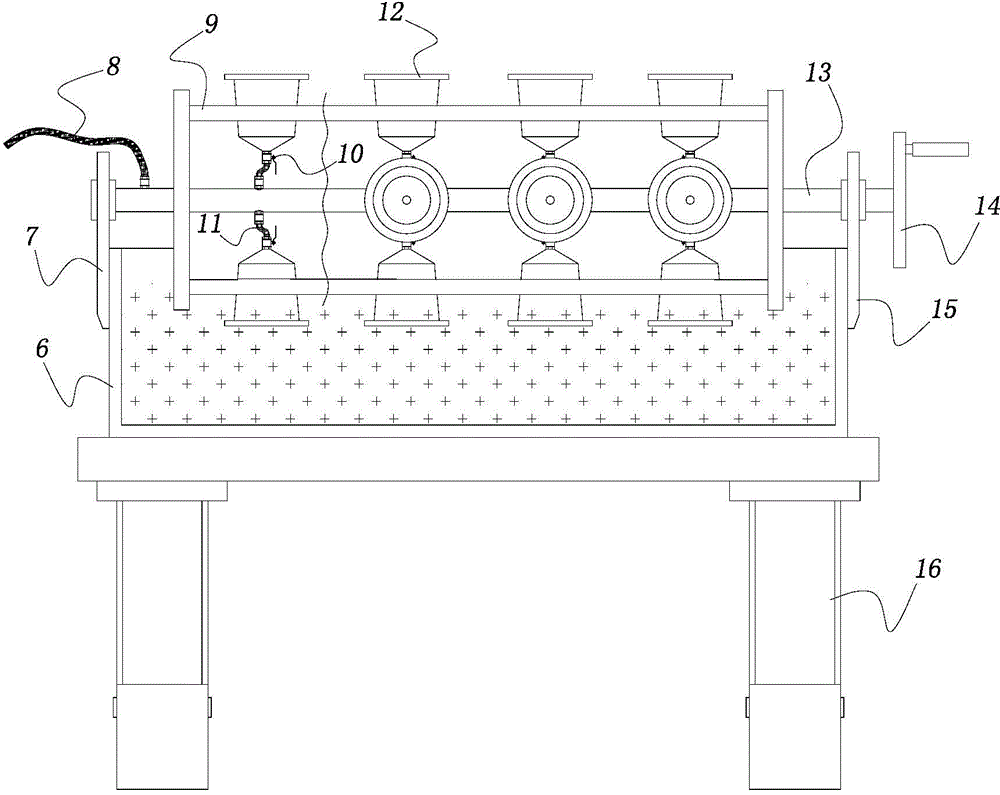

[0013] See figure 2 , The present invention includes a water tank 6 arranged on the base 16, a left shaft seat 7 and a right shaft seat 15 are respectively fixed on the left and right side walls of the water tank 6, and a hollow, two-end seal is erected between the two shaft seats The blocked rotating shaft 13 has a compressed air pipe 8 connected to the side wall at one end and a hand wheel 14 at the other end. The hand wheel 14 is used to drive the rotating shaft 13 to rotate, and the compressed air pipe 8 is connected to a compressed air source and guides the compressed air into the inner cavity of the rotating shaft 13.

[0014] A rotating cage 9 composed of end plates at both ends and a plurality of cross bars erected between the end plates is fixedly connected to the rotating shaft 13, and each cross bar of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com