Equipment and method for producing molecularly double-oriented plastic pipe

A bi-directional, plastic tube technology for applications, household appliances, tubular items, etc., which can solve problems such as thermal efficiency deterioration, high energy costs, expensive mold execution, etc., to achieve the effect of reducing cost and processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

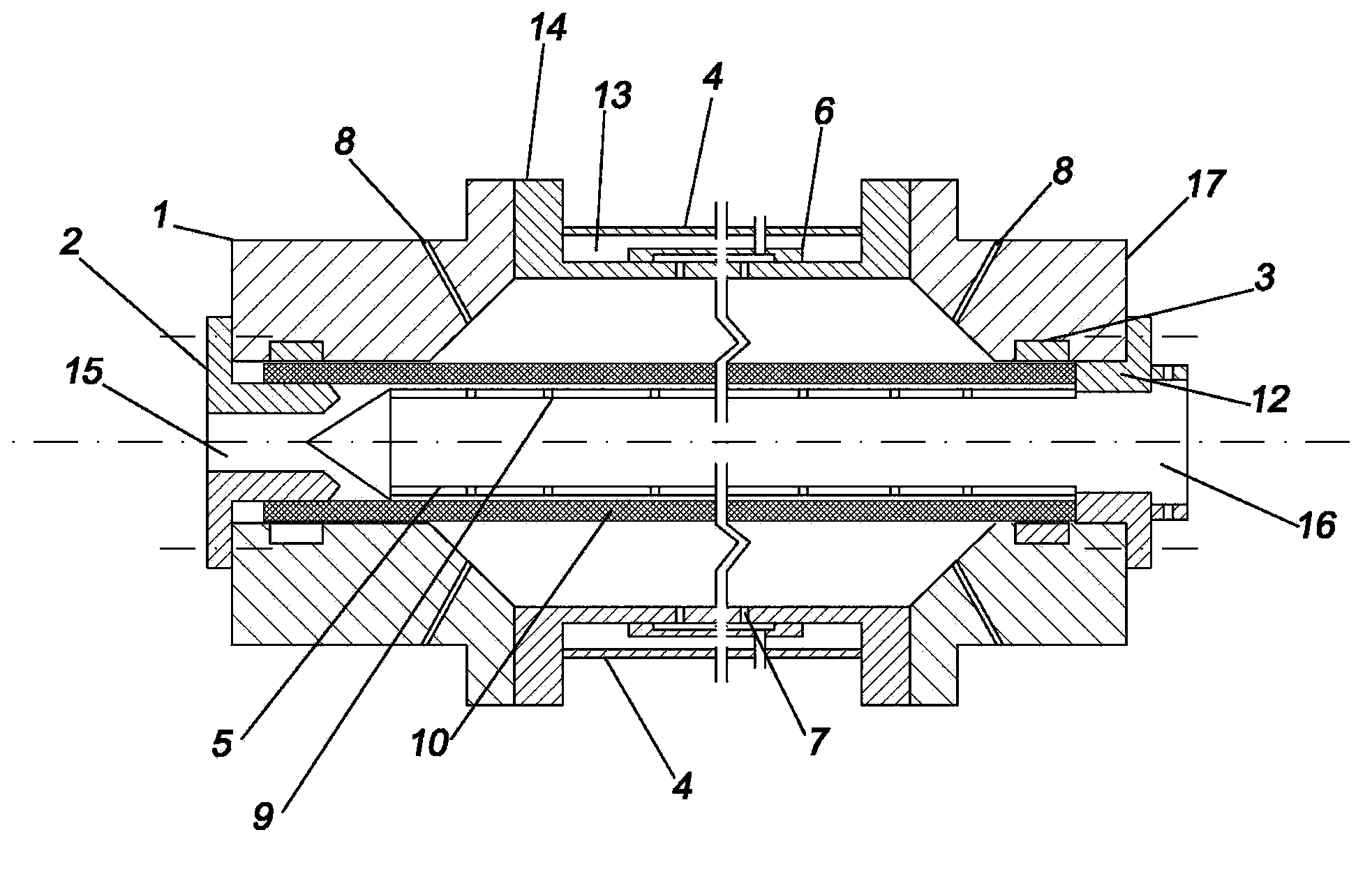

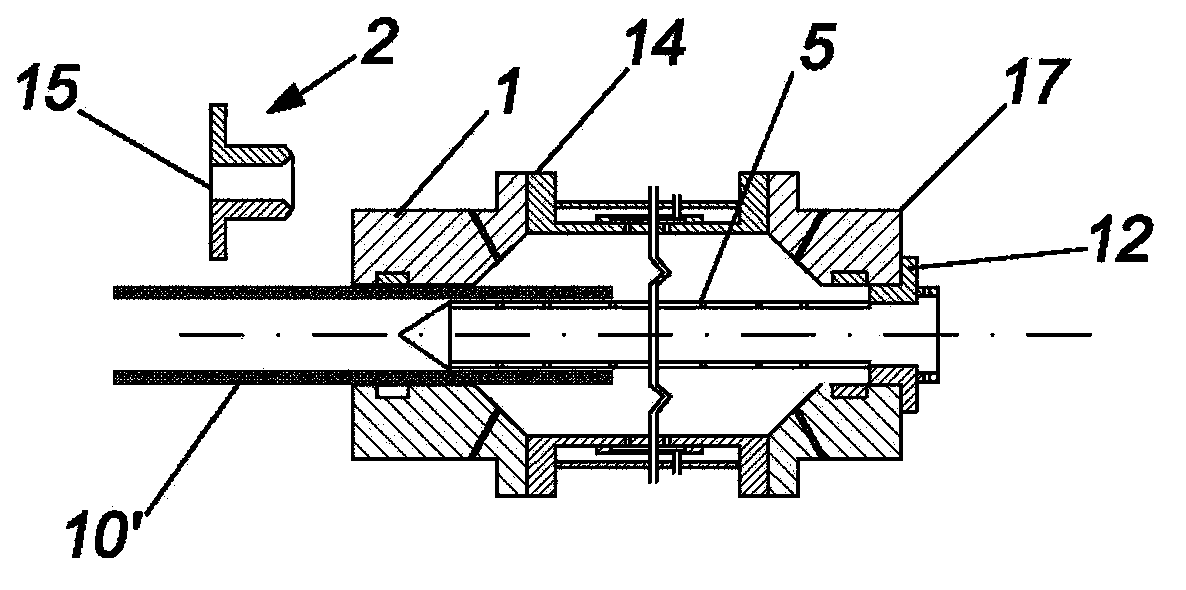

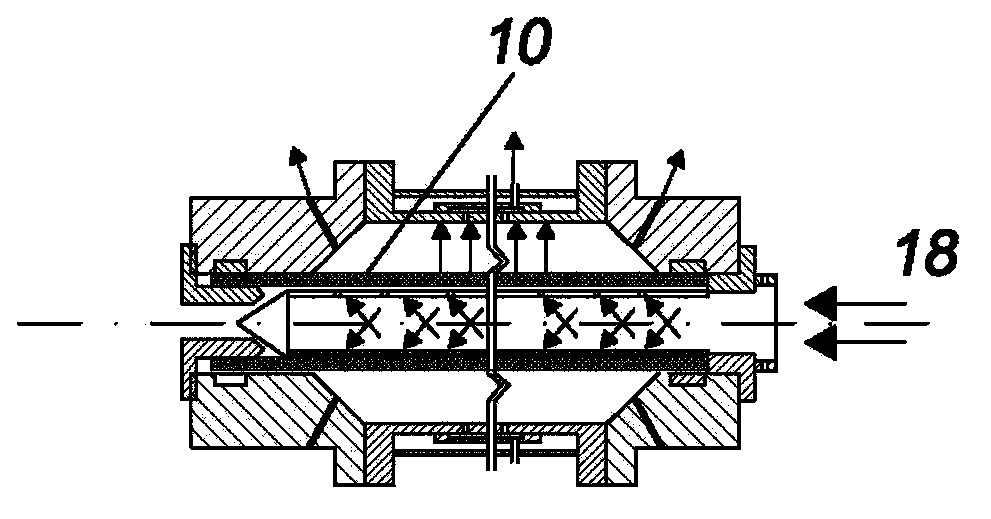

[0043] As mentioned in figure 1 It can be seen that the device of the present invention includes a complete mold formed by a first head 1, a second head 17, and a central body 14. The central body 14 communicates with the head 1 through their ends, 17 associate (associate). In these heads 1, 17, there are provided a fixing device 3 that fixes the position of the blank tube 10, and an orifice 8 made there, which makes the inside of the mold 1, 17, 14 and External communication to apply pressure or vacuum equally. The first head 1 has a reduced-size sealing bushing 2 coupled to one end of the blank tube 10 in the axial direction, and the second head 17 has a support bushing 16 .

[0044] figure 1 It is also shown that the device incorporates (including, incorporate) a rigid perforated guide device 5, which is axially located in the center of the inside of the mold 1, 17, 14 and is provided with an opening 9. The guide device 5 is fixed to the support bushing 16 by one of its end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com