Proportional feeding and air locking device for powdery material

A powdered material and proportional technology, which is applied in the field of chemical engineering, can solve the problems of unsatisfactory air lock function and inability to realize the function of proportional distribution of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below with reference to the drawings and specific examples.

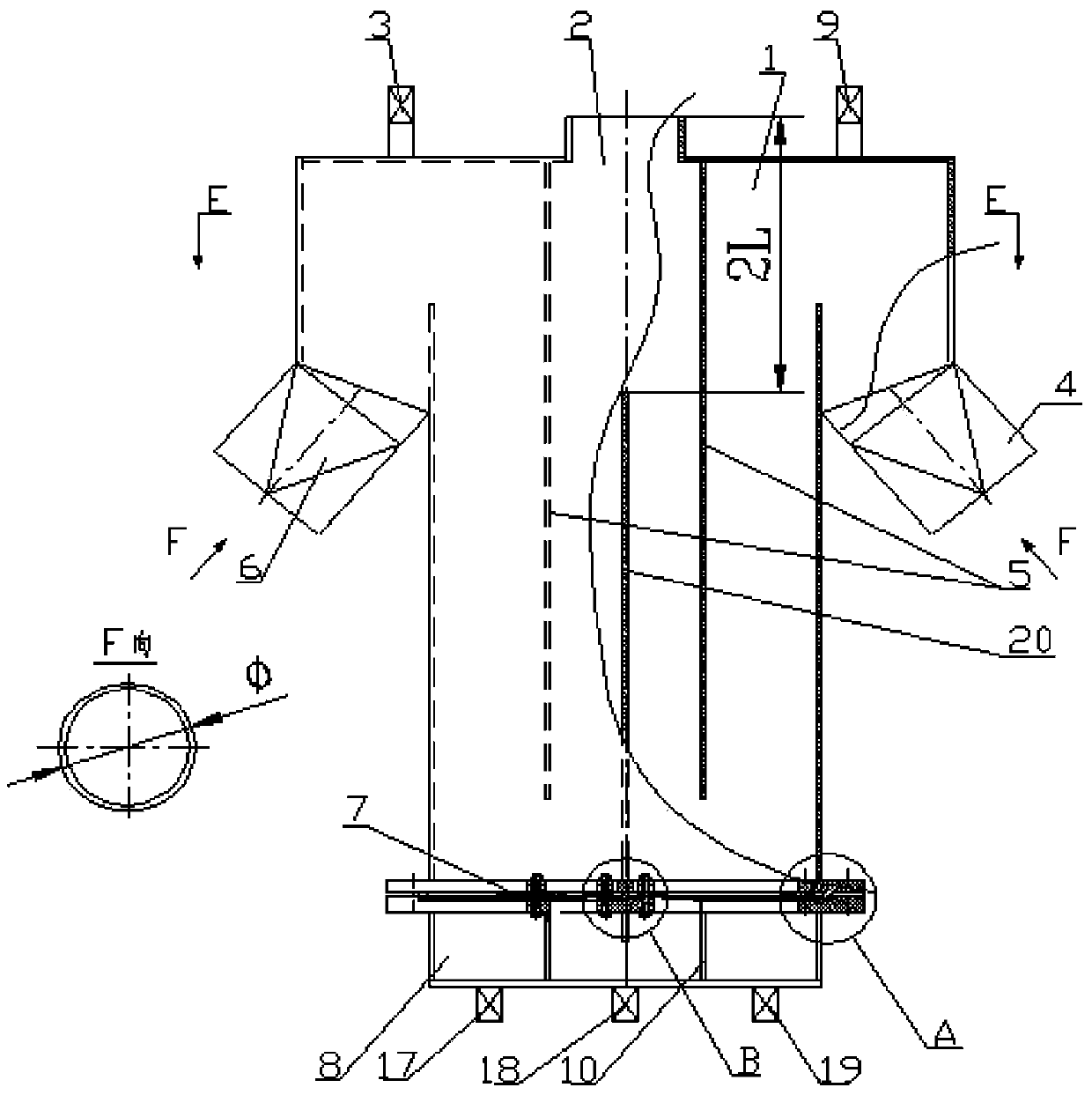

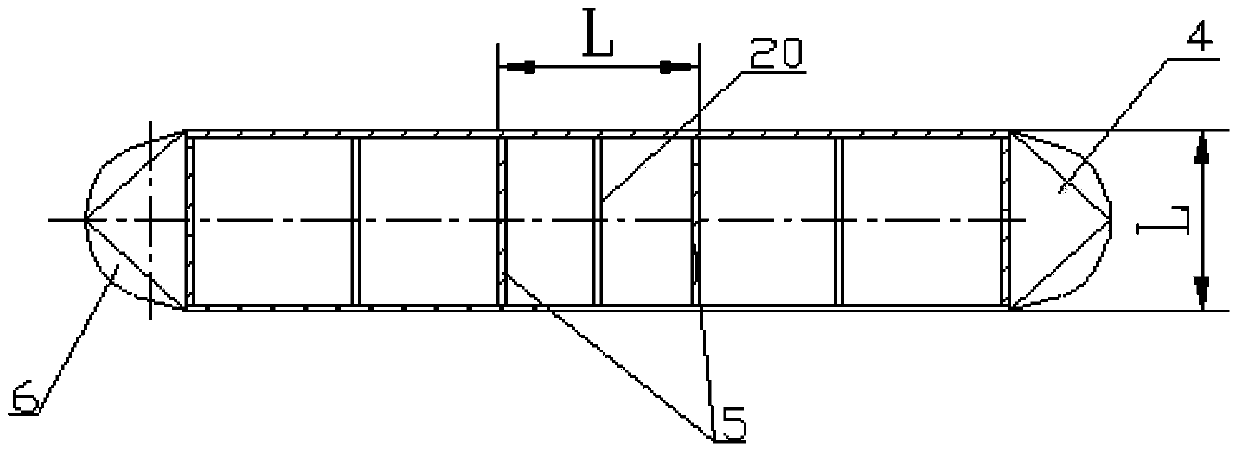

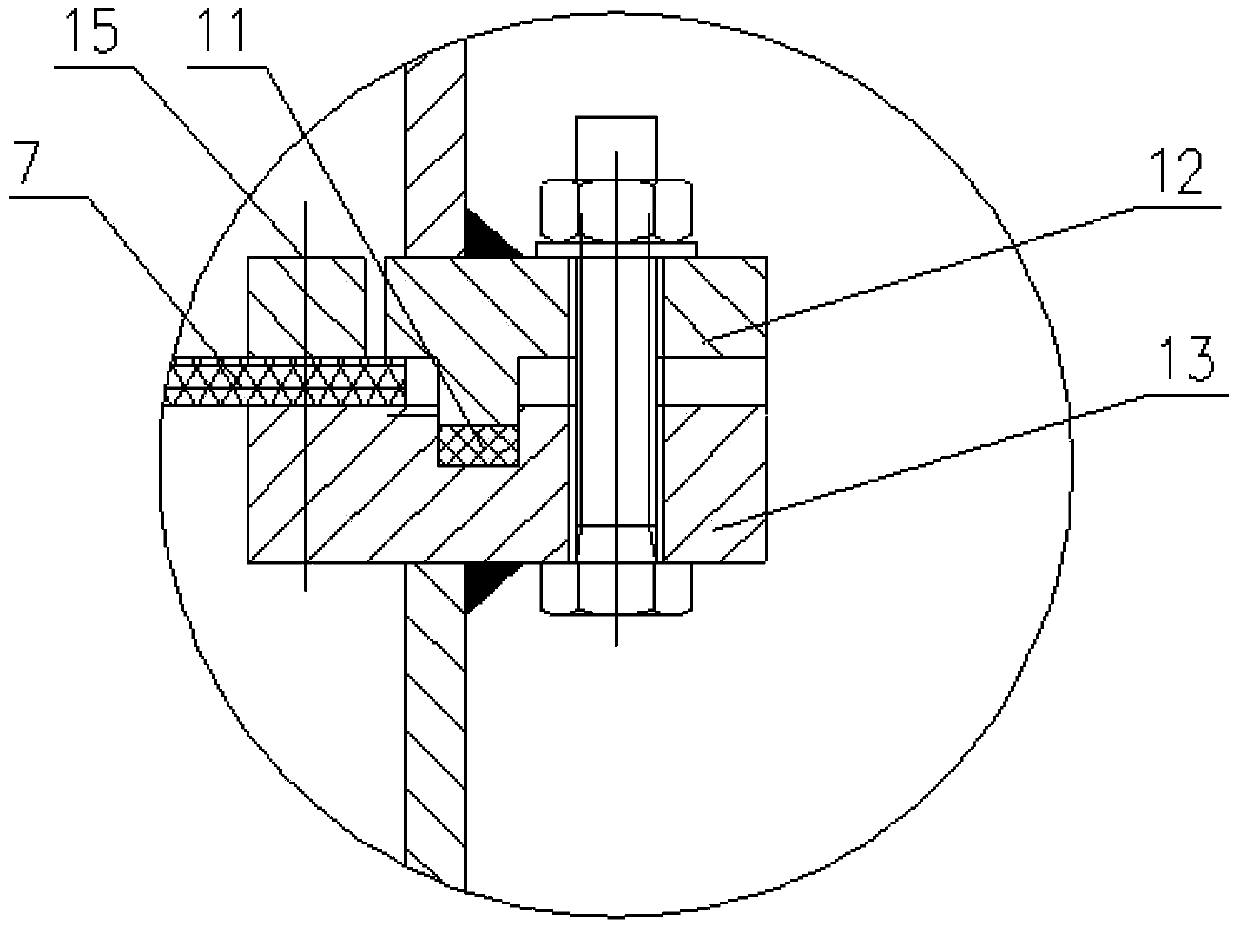

[0011] Such as figure 1 As shown, a material proportional distribution and air lock device includes a rectangular housing 1, three partitions inside the rectangular housing, and an air chamber 8. The rectangular housing 1 is made by welding As a whole, the rectangular shell 1 has a feed opening in the middle of the top plate, and a feed pipe 2 is welded; the rectangular shell 1 has two-thirds of the height from the bottom of the upper plate 12 on both sides of its length. A discharge pipe 4 and B discharge pipe 6 with an outlet downward and in the shape of a square tube. A discharge pipe 4 and B discharge pipe 6 are opposed to each of the rectangular housing 1 and the top plate is symmetrically installed with A discharge pipe. Valve 3 and B outlet valve 9; each side of the bottom of the rectangular housing 1 is sealed and welded to the upper pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com