Locking mechanism

A locking and two-level locking technology, which is applied in the field of rail transit, can solve the problems that the locking mechanism cannot be opened and closed, the left and right spaces are not enough, and the connecting rod mechanism is stuck, etc., and the manufacturing process is simple and the structure is safe and reliable. , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

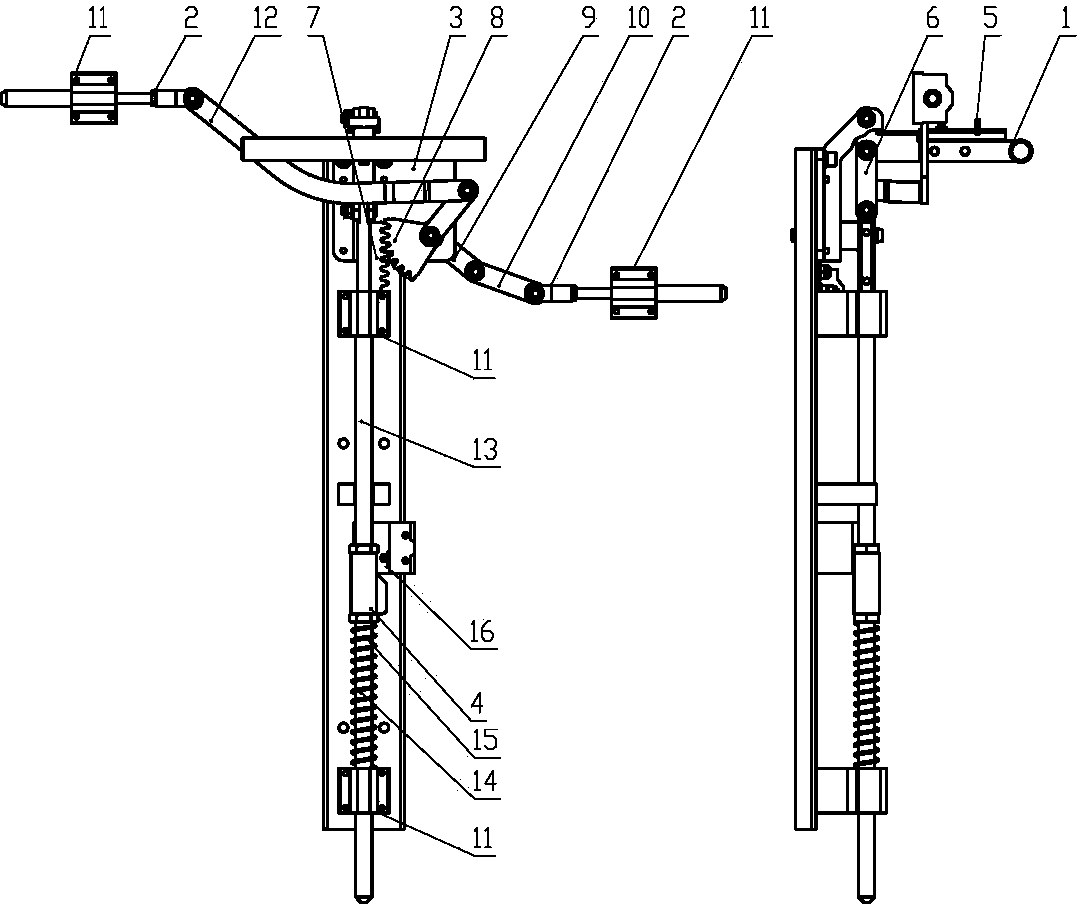

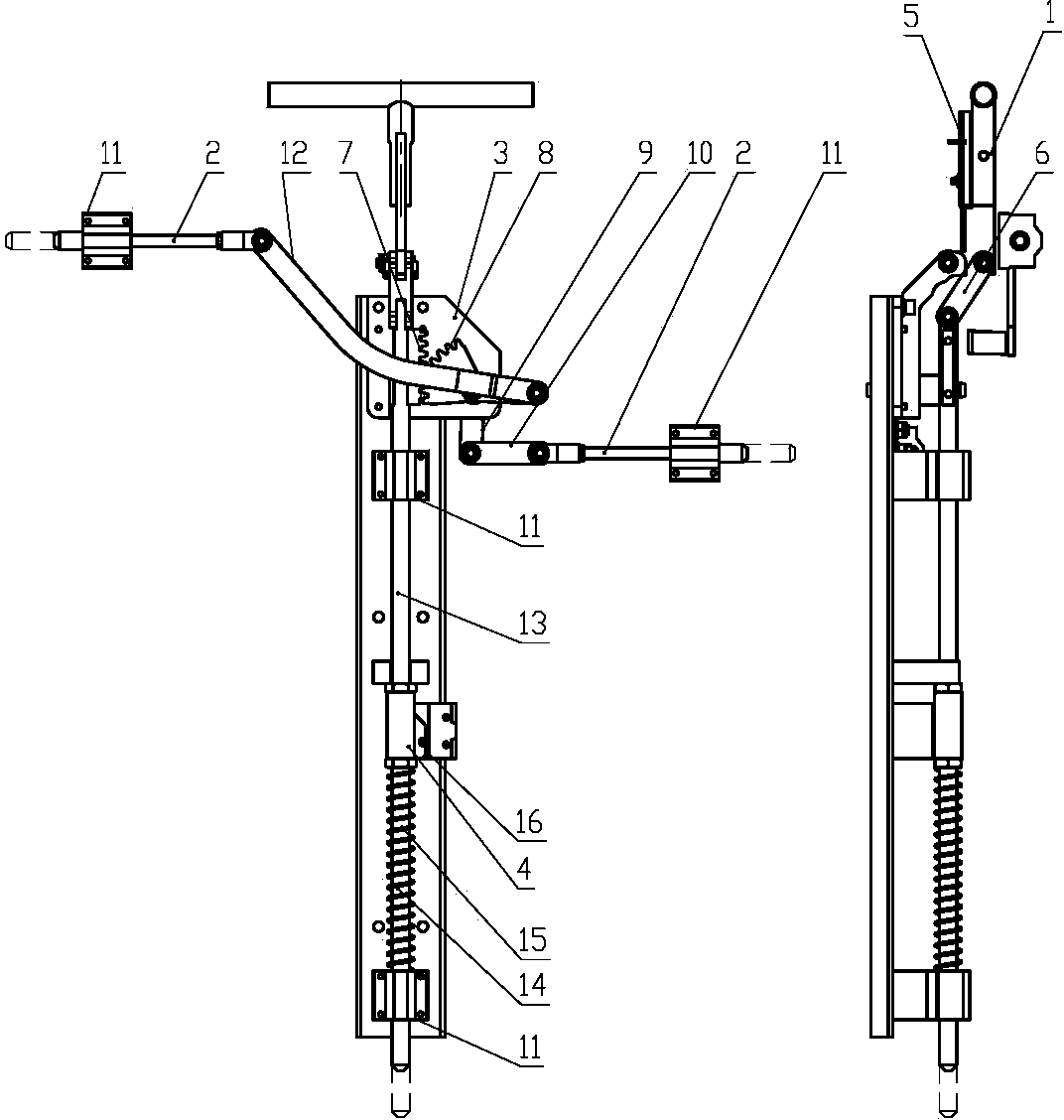

[0009] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

[0010] Reference attached figure 1 and attached figure 2 , an embodiment of the present invention: when the lock handle composition 1 rotates upwards to a vertical position, the bolt connecting plate 6 is pulled by the lock handle to move upward, and the lower bolt connecting rod 13 is pulled by the bolt connecting plate 6 to move upward, because the lower bolt The connecting rod 13 is limited by the linear bearing 11 and can only keep moving up and down. The lower dead bolt connecting rod 13 moves upward, and the tooth bar 7 and the lower dead bolt 14 installed on the lower dead bolt connecting rod 13 move upward together, together with the tooth bar 7 The meshed gear 8 rotates under the drive of the rack 7, the right driving link 9 rotates with the gear 8, and driven by the right driven link 10 and the left driven link 12, the left and right side bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com