Release equipment

A technology of throwing hands and locking parts, which is applied in the direction of wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of poor working stability, complex locking mechanism structure, easy to get out of the locked state, etc., and achieves easy processing and manufacturing, The effect of improving reliability and stability and simplifying steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

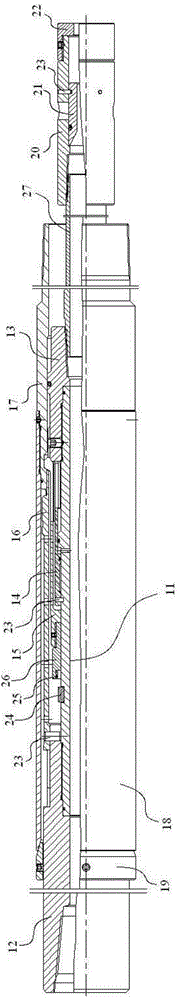

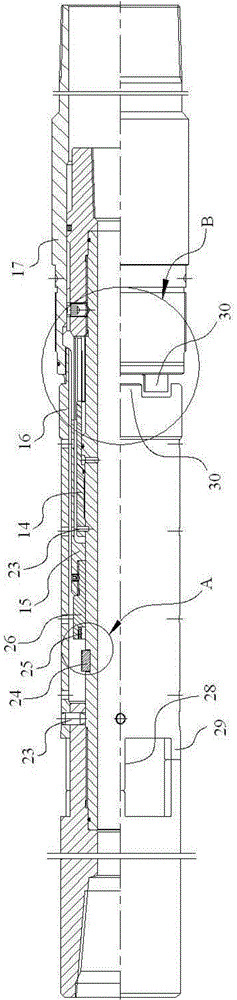

[0025] figure 1 The structure of the embodiment of the hands-dropping device of the present invention is schematically shown. figure 2 Schematically shows the structure of the throwing mechanism of the present invention.

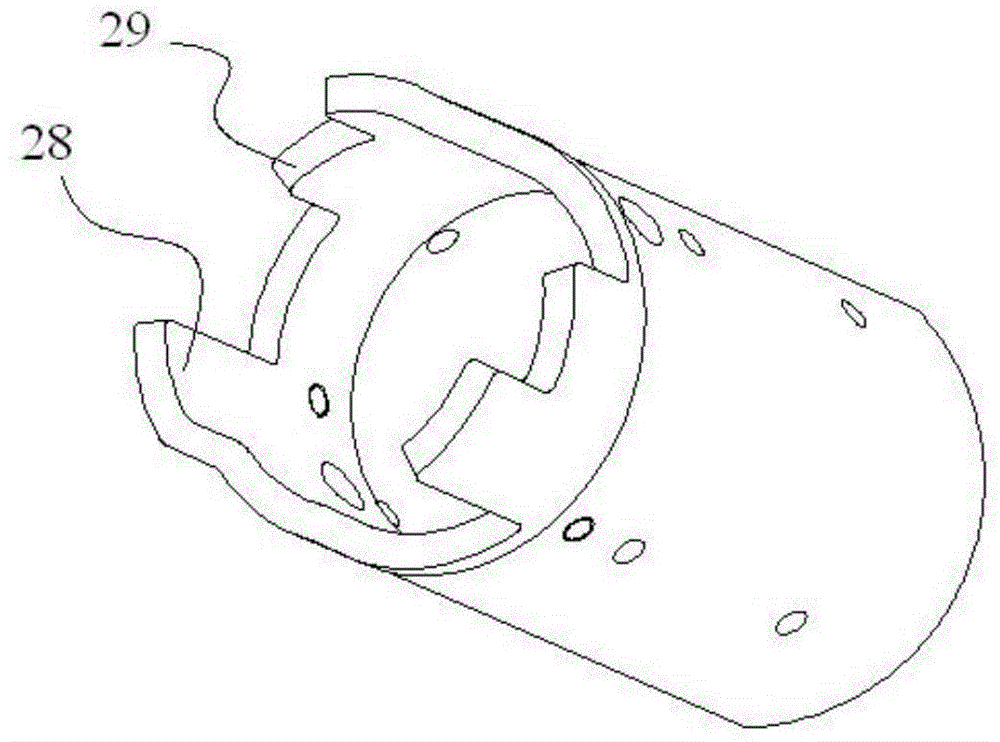

[0026] Such as figure 1 Shown, the embodiment of the hand-dropping device of the present invention mainly includes a hand-dropping mechanism, a protective structure and a removable ball seat. Wherein, the hand-losing mechanism includes a mandrel 11 , an upper joint 12 , a lower joint 13 , a locking mechanism, a hydraulic cylinder 14 , a sleeve 15 , a torque sleeve 16 and a torque joint 17 . The protection structure includes a protection piece 18 and a protection piece 19, wherein, in one embodiment, the protection piece 18 is a protection cylinder, and the protection piece 19 is a sand-proof cap. The ball seat includes a ball seat shell 20 , a ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com