Spacer profiles and insulating glazing units for spacer frames of insulating glazing units with interstitial elements

A profile and frame technology, applied in the field of insulating glass units, can solve the problems of not being able to use supports, not having physical properties, not being able to support gap elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

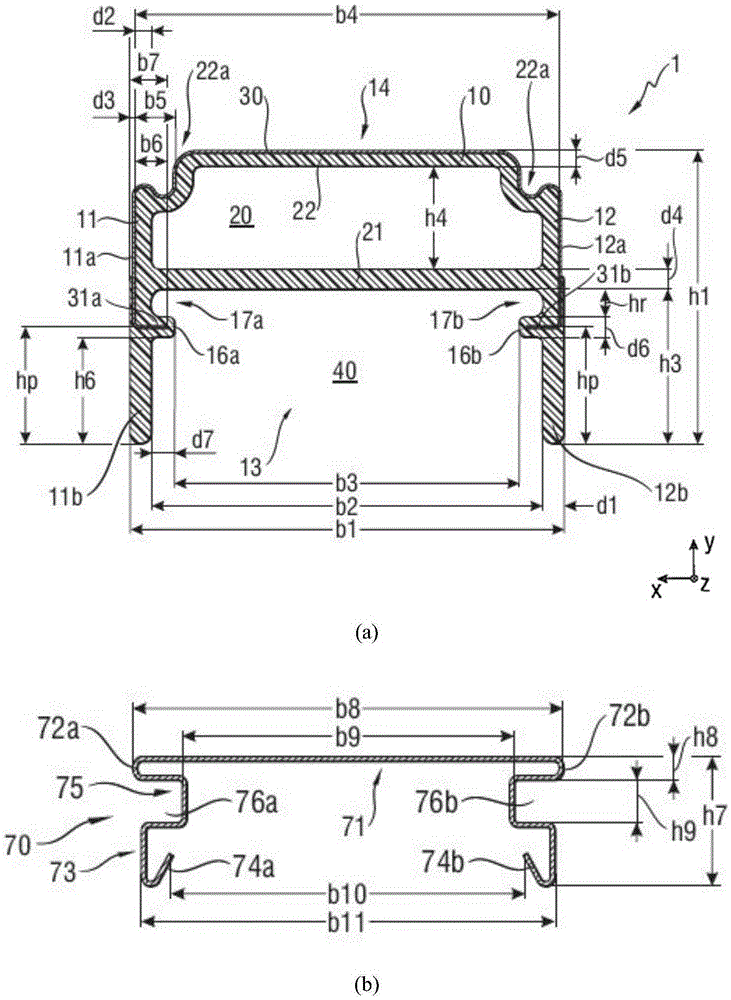

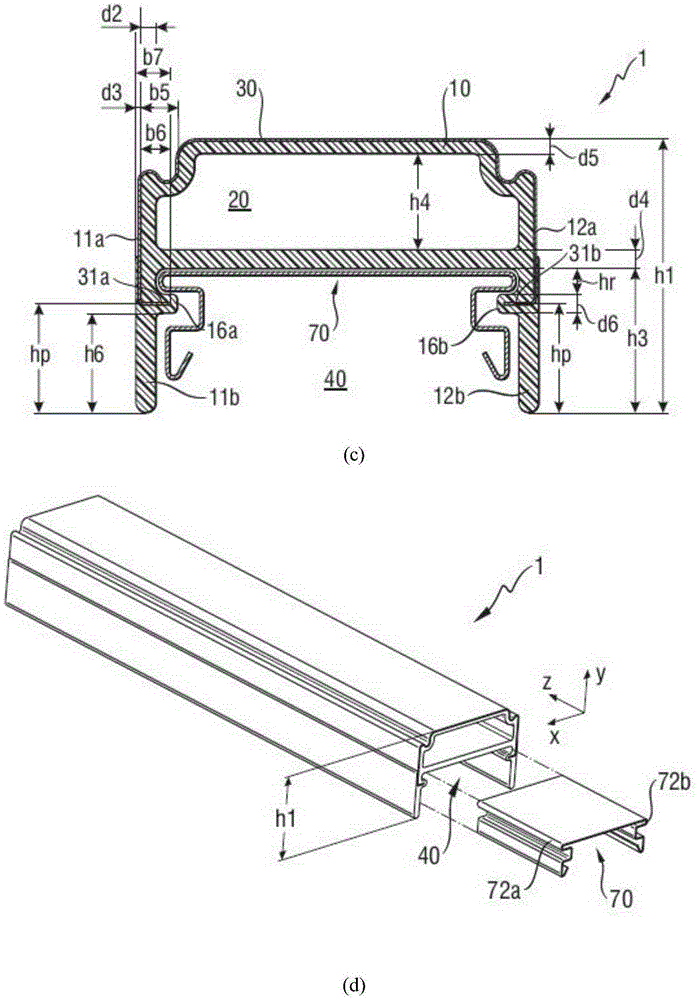

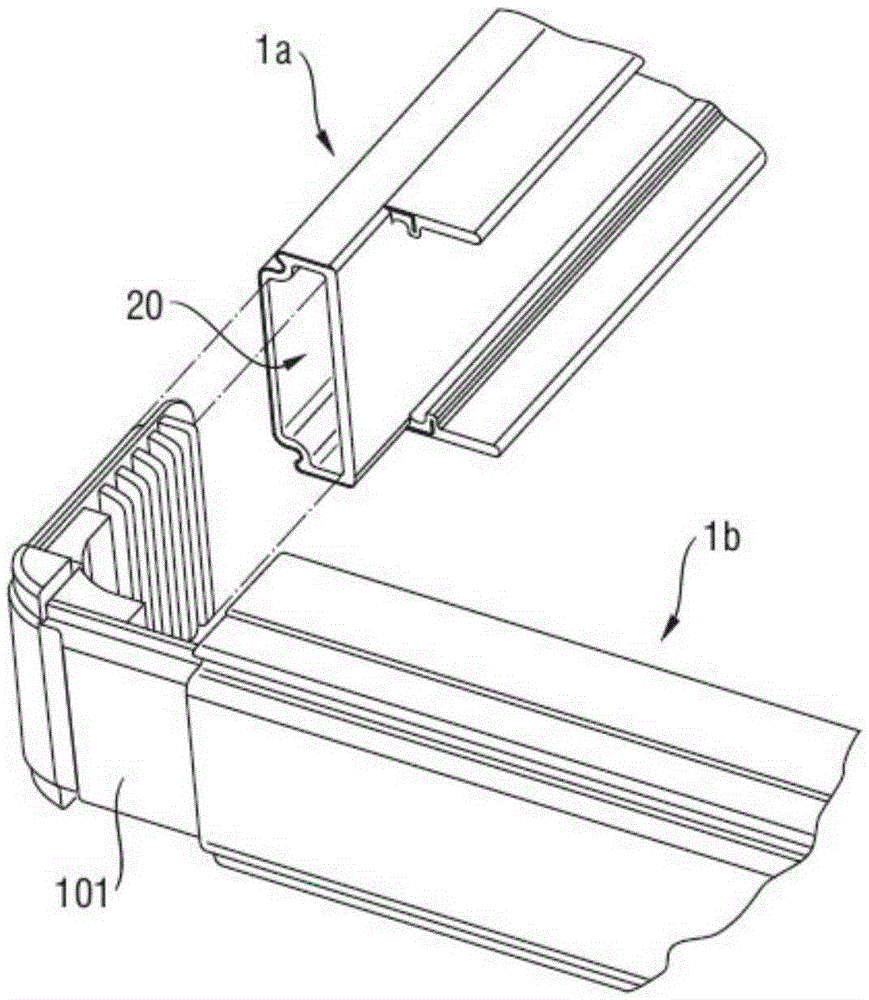

[0023] Embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. The same features / elements are marked with the same reference numerals in all figures. For the sake of clarity, not all reference numerals have been inserted in all figures. figure 1 and 8 The 3-dimensional (x,y,z) reference system shown in is applied to Figures 1 to 8 The profiles shown in , their cross-section and longitudinal orientation. The longitudinal direction corresponds to the direction z, the transverse direction corresponds to the direction x and the height direction corresponds to the direction y in relation to the profile.

[0024] will now refer to Figures 1 to 6 The spacer profile 1 according to the first embodiment and the insulating glass unit 50 using the spacer profile (in which the shutter is used as the spacer element) are described.

[0025] exist figure 1 a) and c), image 3 b), Figure 4 b), Figure 5 and Image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com