Flat cable compensation control method for water tank wire drawing machine

A water tank wire drawing machine and compensation control technology, applied in the field of water tank wire drawing machine production technology, can solve the problems of excessive adjustment times, wire pressing, wire clamping, irregular deformation of the I-shaped wheel, etc. The effect of flattening the time and line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

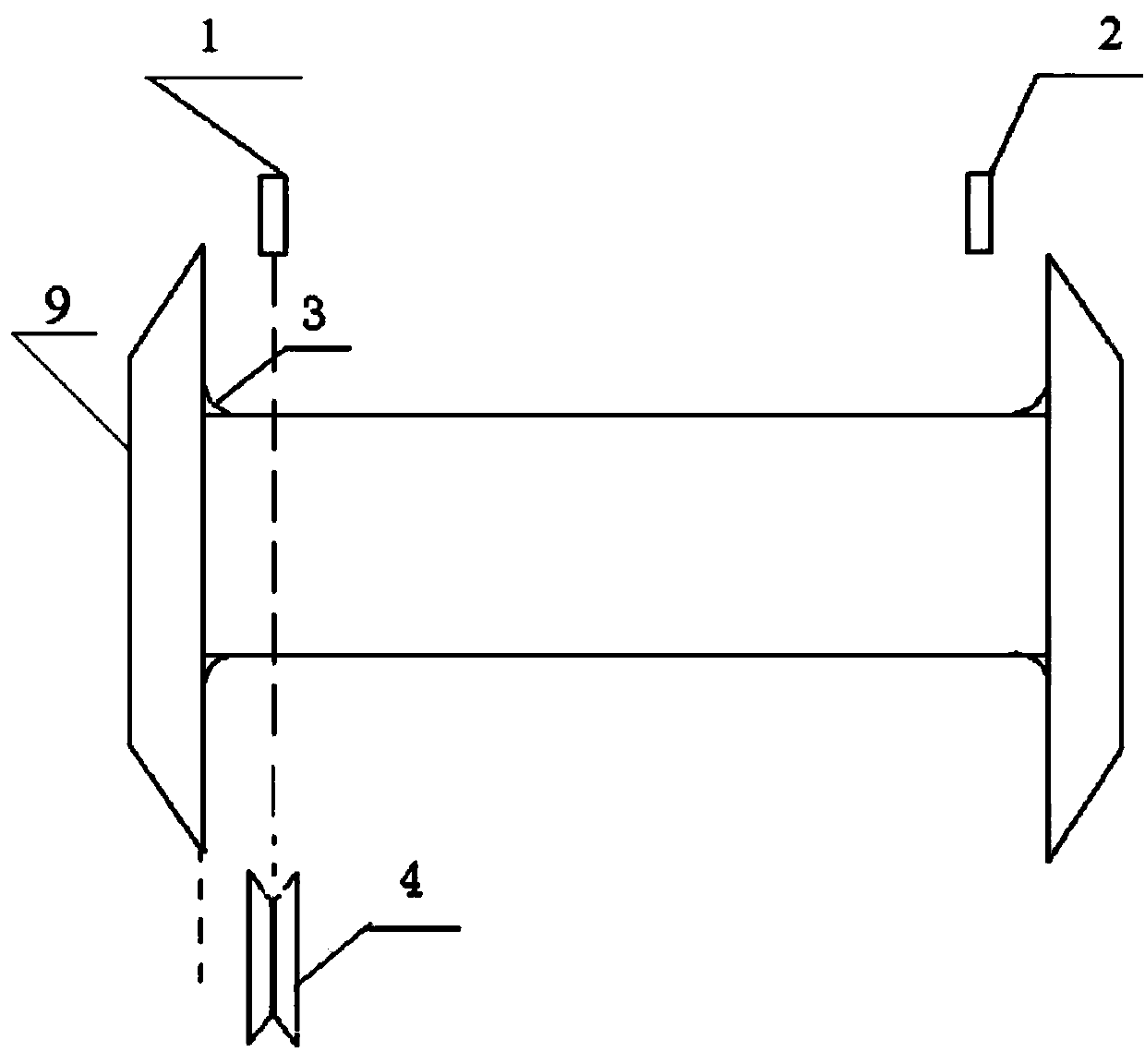

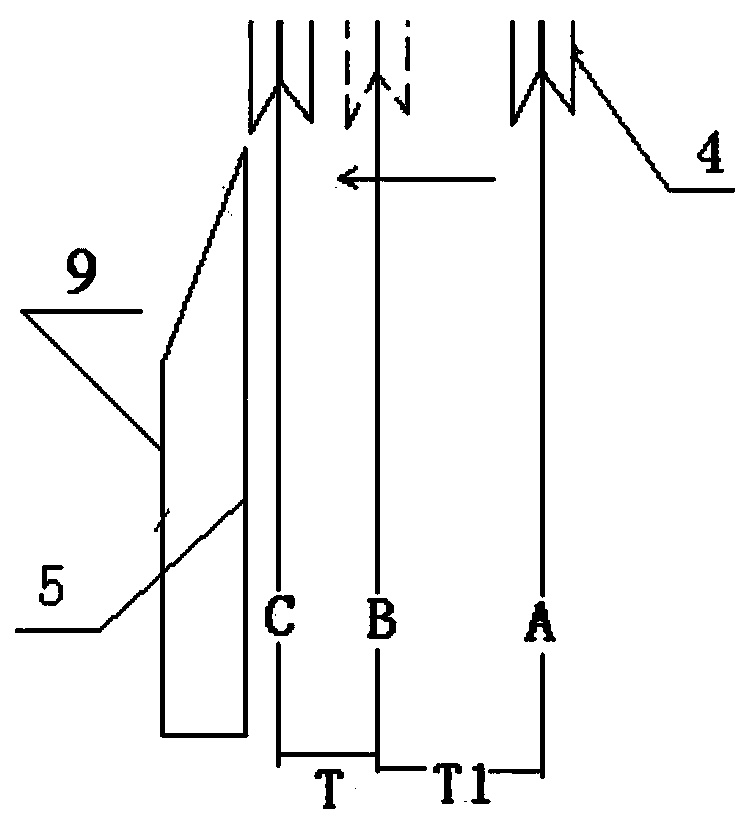

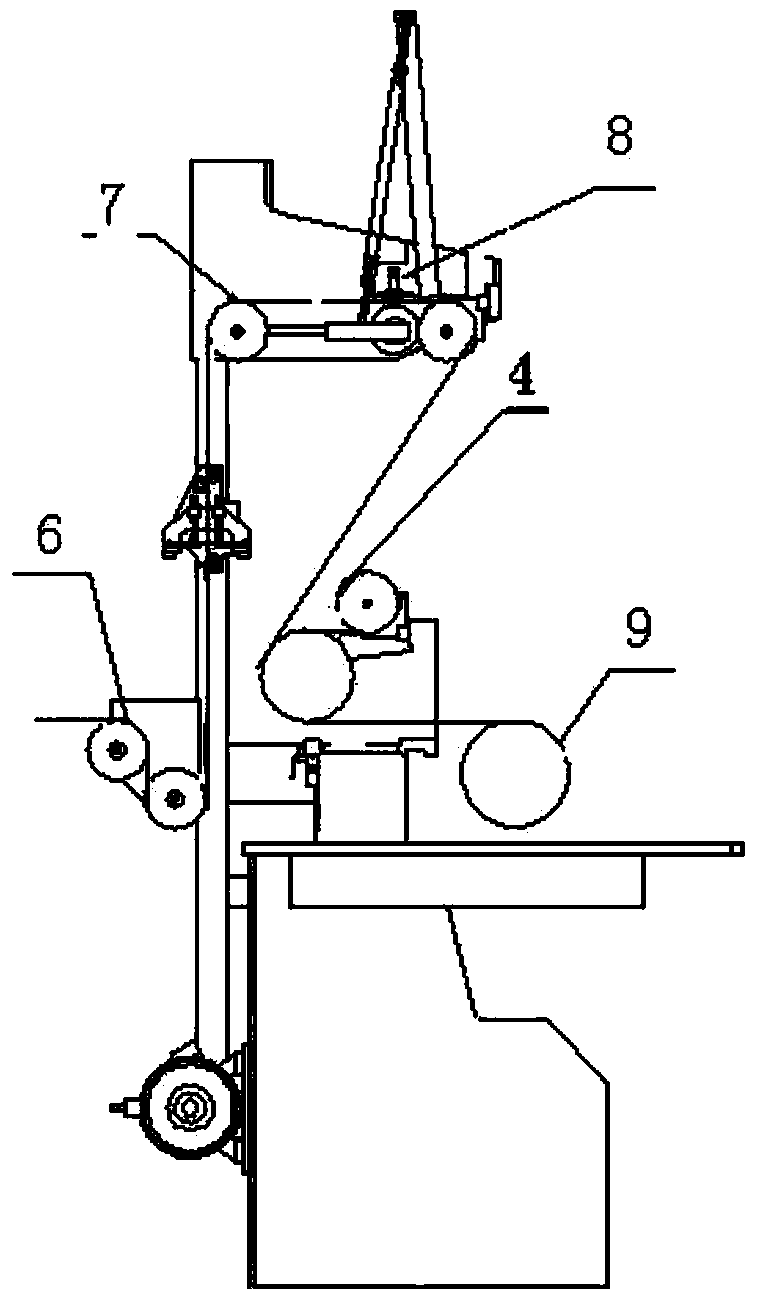

[0019] Such as figure 1 As shown, respectively determine the fixed position of the left proximity switch 1 and the right proximity switch 2 when the cable wheel 4 moves to the two inner sides of the I-shaped wheel 9, and the two inner sides of the I-shaped wheel 9 respectively leave an arc R angle 3. Such as image 3 As shown, the steel wire enters the take-up I-shaped wheel 9 after passing through the wire-passing wheel set 6, the tension arm swing bar 7, and the wire arranging wheel 4 of the take-up mechanism, and a displacement sensor 8 is installed at the fulcrum of the tension arm swing bar 7. When the steel wire If the tension is too large or too small, the tension arm swing rod 7 will fluctuate up and down, and the distance between the displacement sensor 8 and the fulcrum of the tension arm swing rod 7 will also change. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com