Charged replacement method for whole string of insulators of ultra-high-voltage transmission line, and hardware fitting thereof

A transmission line and live replacement technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of uneasy replacement of UHV tension insulator strings, unstable operation of tension insulator strings, safety accidents, etc., to achieve convenient live single The effect of changing side by side, reducing work difficulty and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

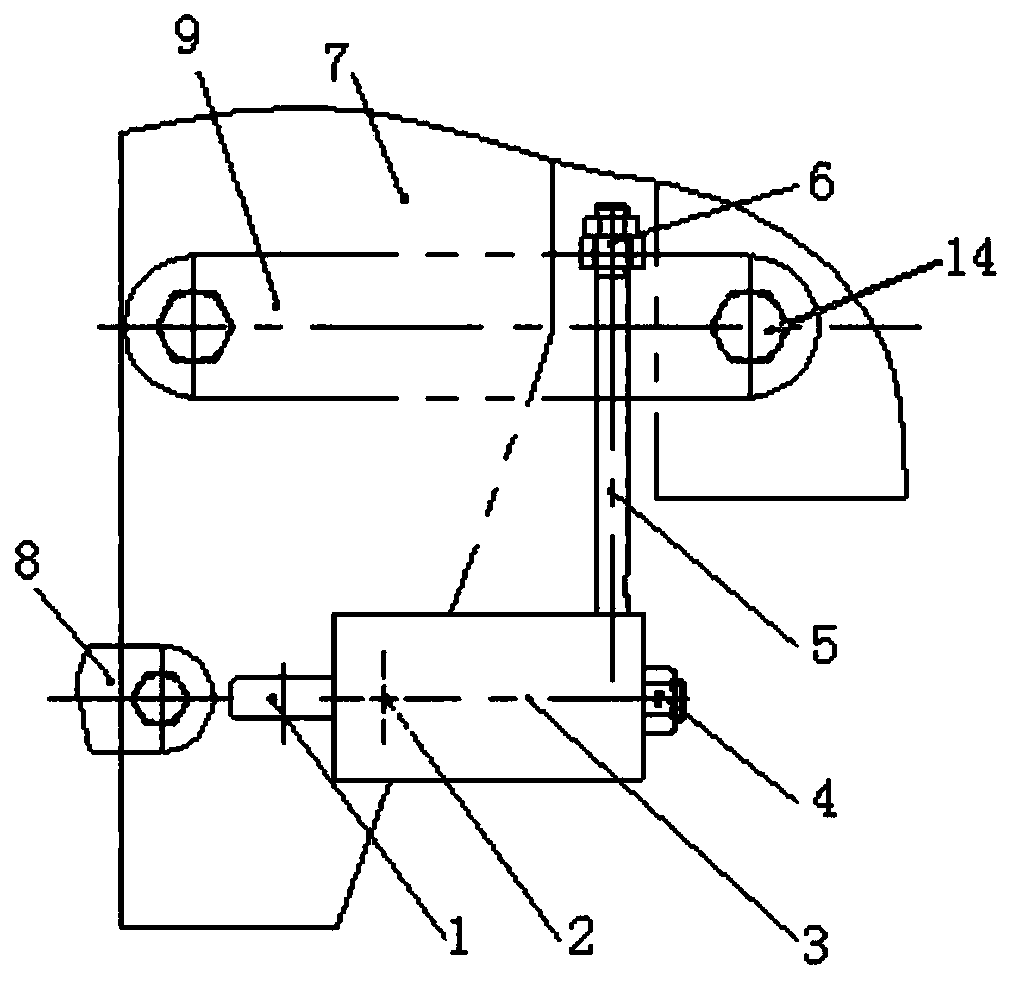

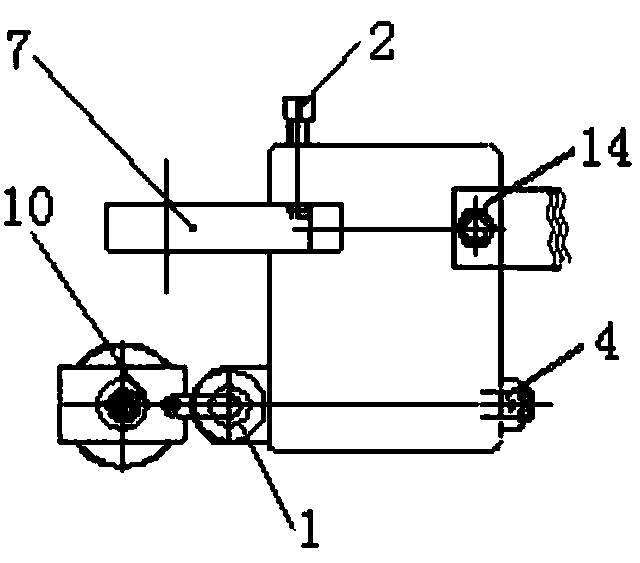

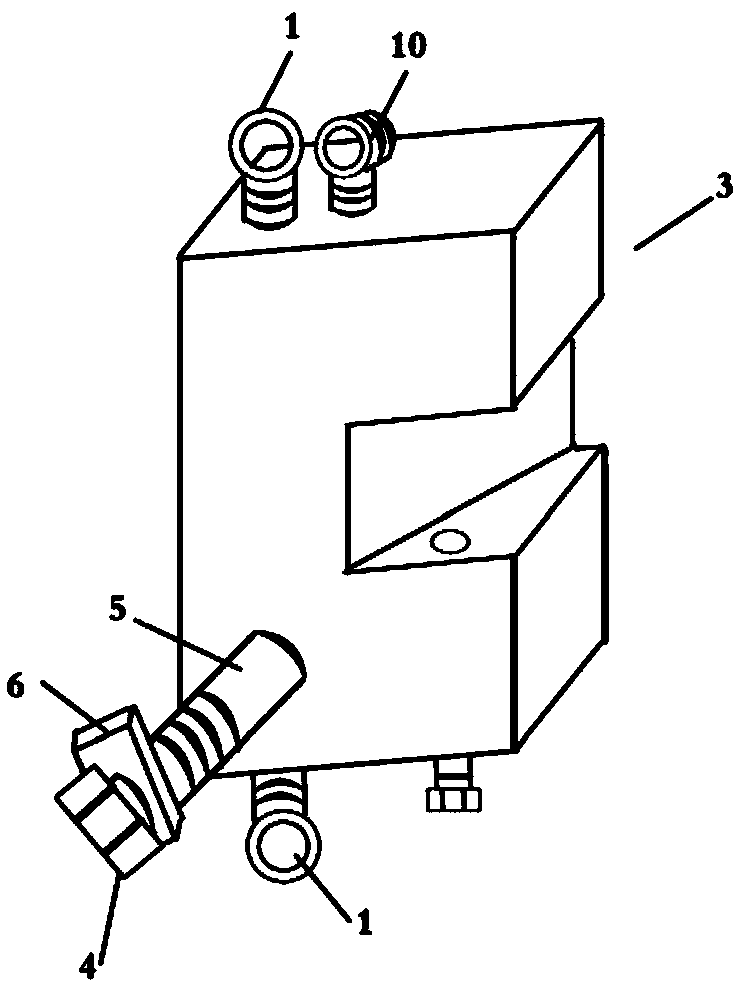

[0044] The live-line replacement method and fittings of the tensile insulator string for UHV transmission lines of the present invention will be further described below in conjunction with the accompanying drawings.

[0045] A tensile insulator string for UHV transmission lines is used for live replacement of the tensile insulator string. The tensile insulator string detachment includes a first connecting plate 7 in the shape of an isosceles triangle or an isosceles trapezoid. The first connecting plate 7 is horizontal The load side is connected with multiple strings of insulator strings with a total weight of several tons, and the second connecting plate 14 on the other side is used to connect the six-split conductors in parallel and uniformly, and one second connecting plate is provided, Is rectangular. The first connecting plate is provided with two pieces. The first connecting plate 7 is an isosceles trapezoid or an isosceles triangle, and the second connecting plate 14 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com