Ultrahigh power transmission line cross-arm side whole-string dead end insulator disengagement and recovery method

A technology for tensile insulators and tensile insulator strings, which is applied in the field of detachment and recovery of the entire string of tensile insulators on the cross arm side of UHV transmission lines, can solve problems such as inconvenience in operation, reduce work difficulty, improve work efficiency, and easily electrify The effect of one-sided swap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

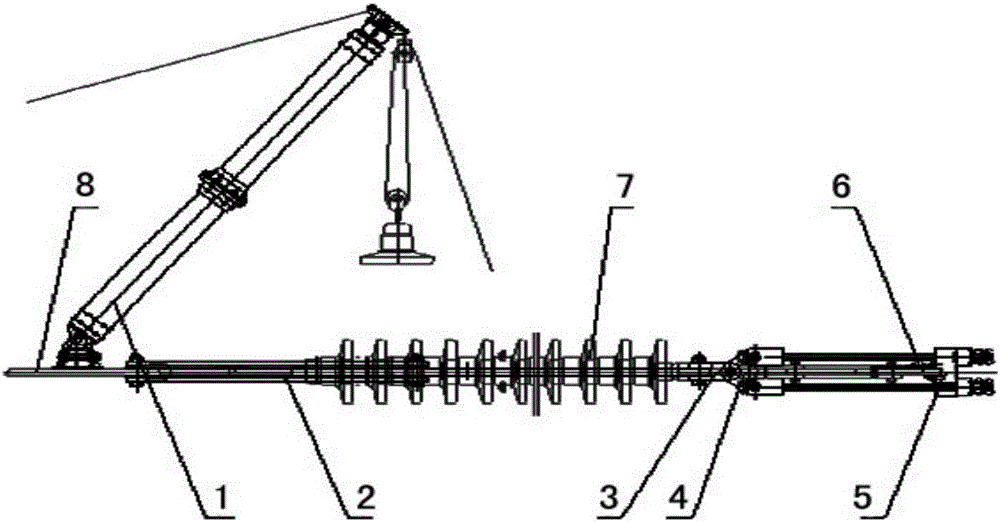

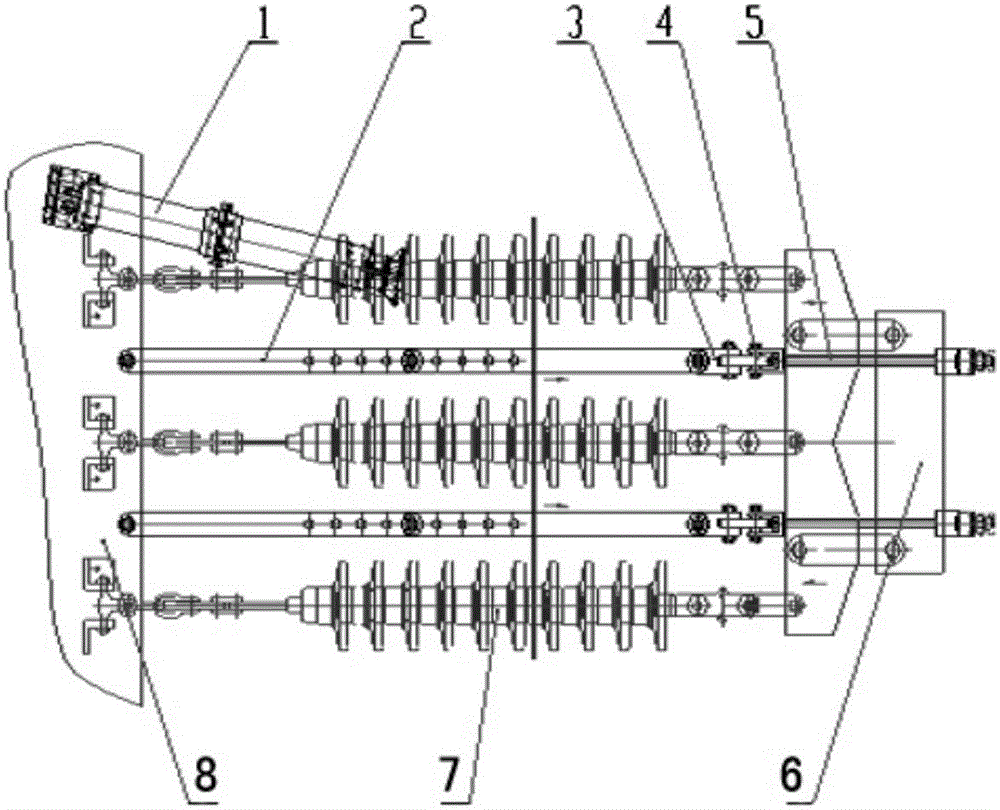

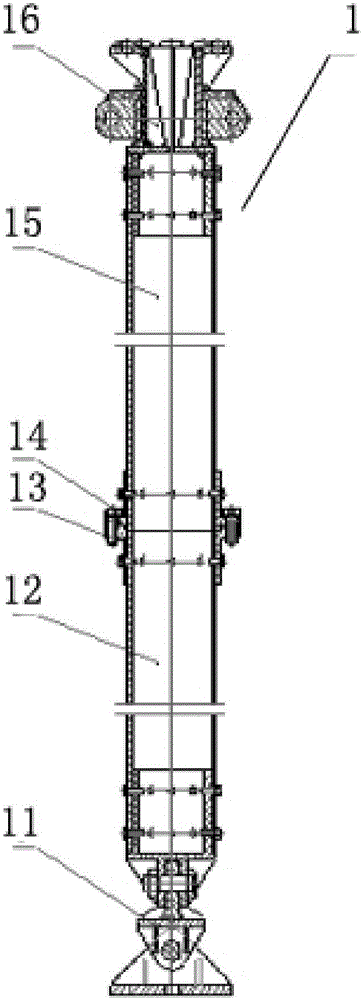

[0056] Such as figure 1 , 2 As shown, a 1000KV transmission line replacement tension-resistant whole string insulator device, including the cross-arm side whole string insulator detachment and recovery device 1, adjustable length pull rod 2, steering connecting plate 3, connecting clamping plate 4, mechanical tightening device 5 composition. On the side 8 of the iron tower cross arm, a set of insulator detachment and recovery device 1 is installed. The main body of the insulator detachment and recovery device is a cylindrical member. Universal rotation.

[0057] The whole series of insulators are separated and restored on the side of the cross arm,

[0058] Length-adjustable pull bar 2 is made up of three adjustable pull plates, and there are many holes on the adjustable pull plates, which can be adjusted with bolts according to different length requirements. One end is connected to the steering joint plate, and the other end is connected to the iron tower cross arm with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com