A live replacement method for insulators that can prevent traction ropes from slipping

A live replacement and pulling rope technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient operation, heavy tension insulator strings, and slipping of pulling ropes, so as to reduce the difficulty of work, facilitate live replacement, and reduce the weight of detachment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The method for live replacement of tension insulator strings for UHV transmission lines of the present invention and its fittings will be further described below in conjunction with the accompanying drawings.

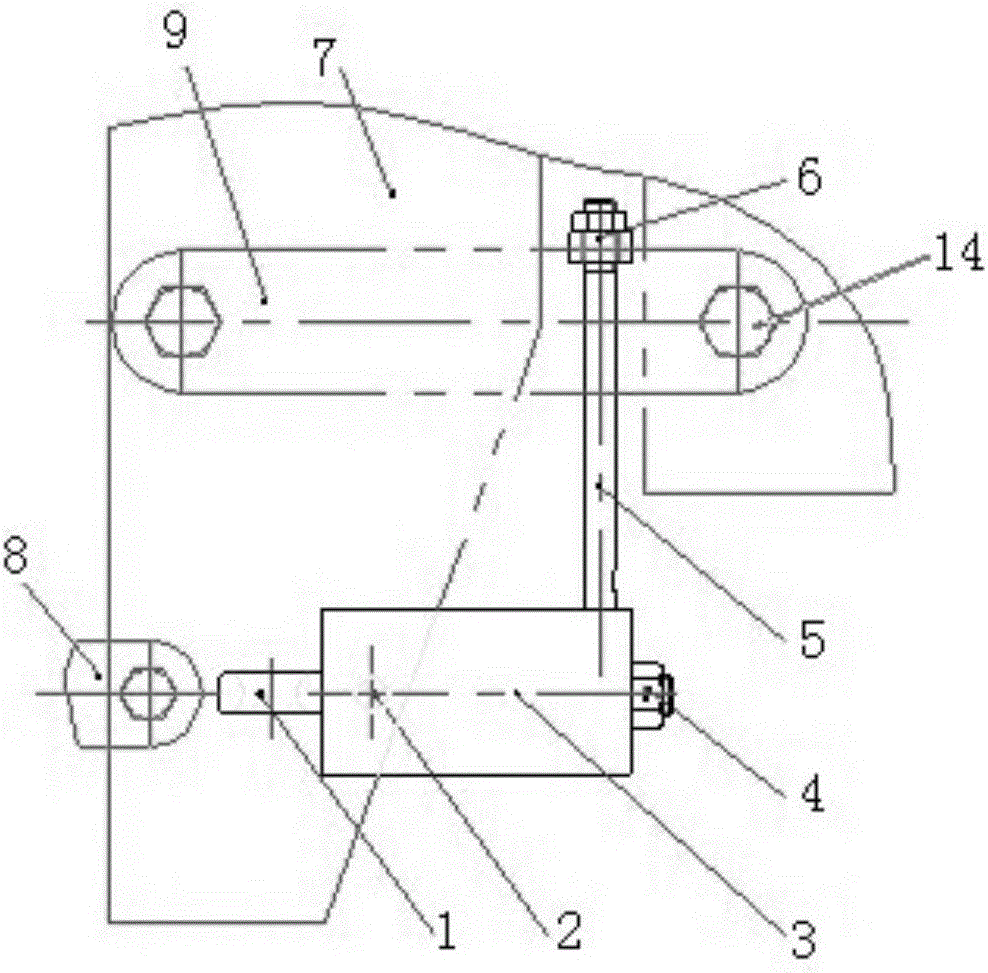

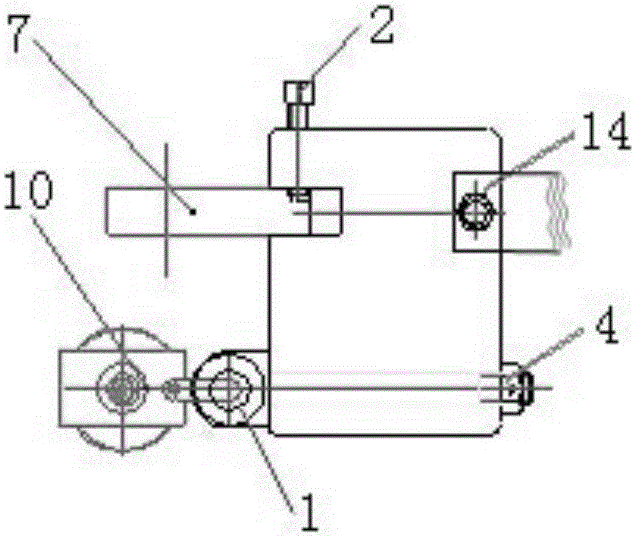

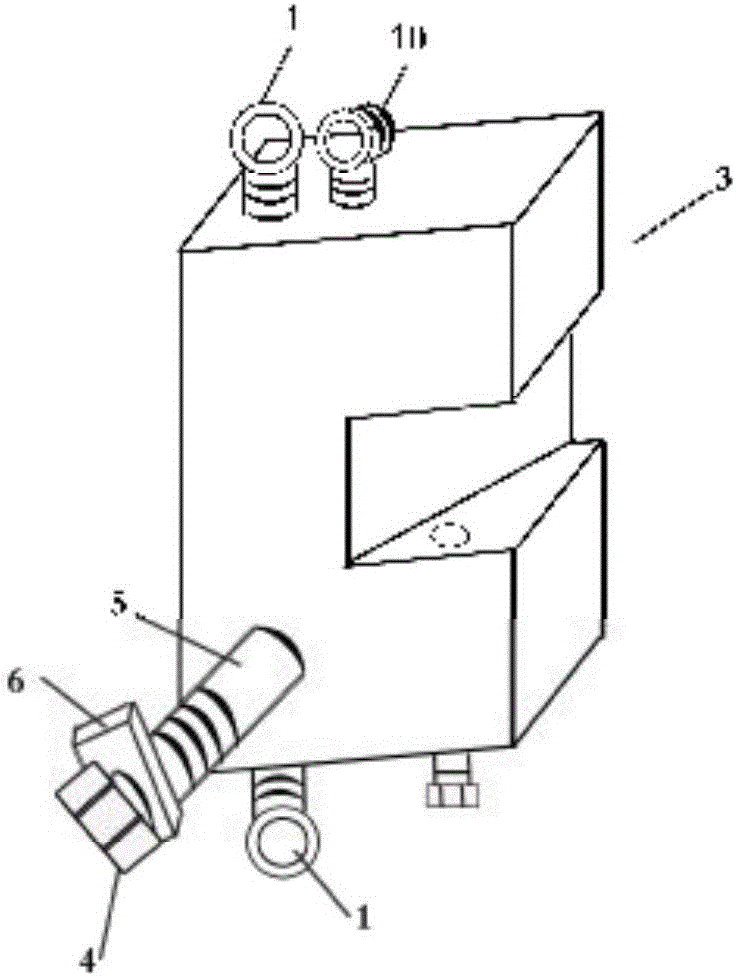

[0045] A metal tool for live replacement of tension insulator strings for UHV transmission lines, the metal tool for detaching tension insulator strings includes a first connecting plate 7 in the shape of an isosceles triangle or an isosceles trapezoid, and the first connecting plate 7 is transversely The side of the load is connected with multiple strings of insulator strings with a total weight of several tons, and the second connecting plate 14 on the other side is used to connect six split conductors in parallel and uniformly. The second connecting plate is provided with one piece. is a rectangle. There are two first connecting plates. The first connecting plate 7 is an isosceles trapezoid or an isosceles triangle, and is connected to the second connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com