Reed type vacuum contact mechanism

A contact mechanism and reed type technology, applied in the direction of detailed information of electromagnetic relays, relays, electrical components, etc., can solve problems such as inconvenient opening and closing conduction operations, achieve safe and reliable layout and planning, reduce processing costs, Ease of maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

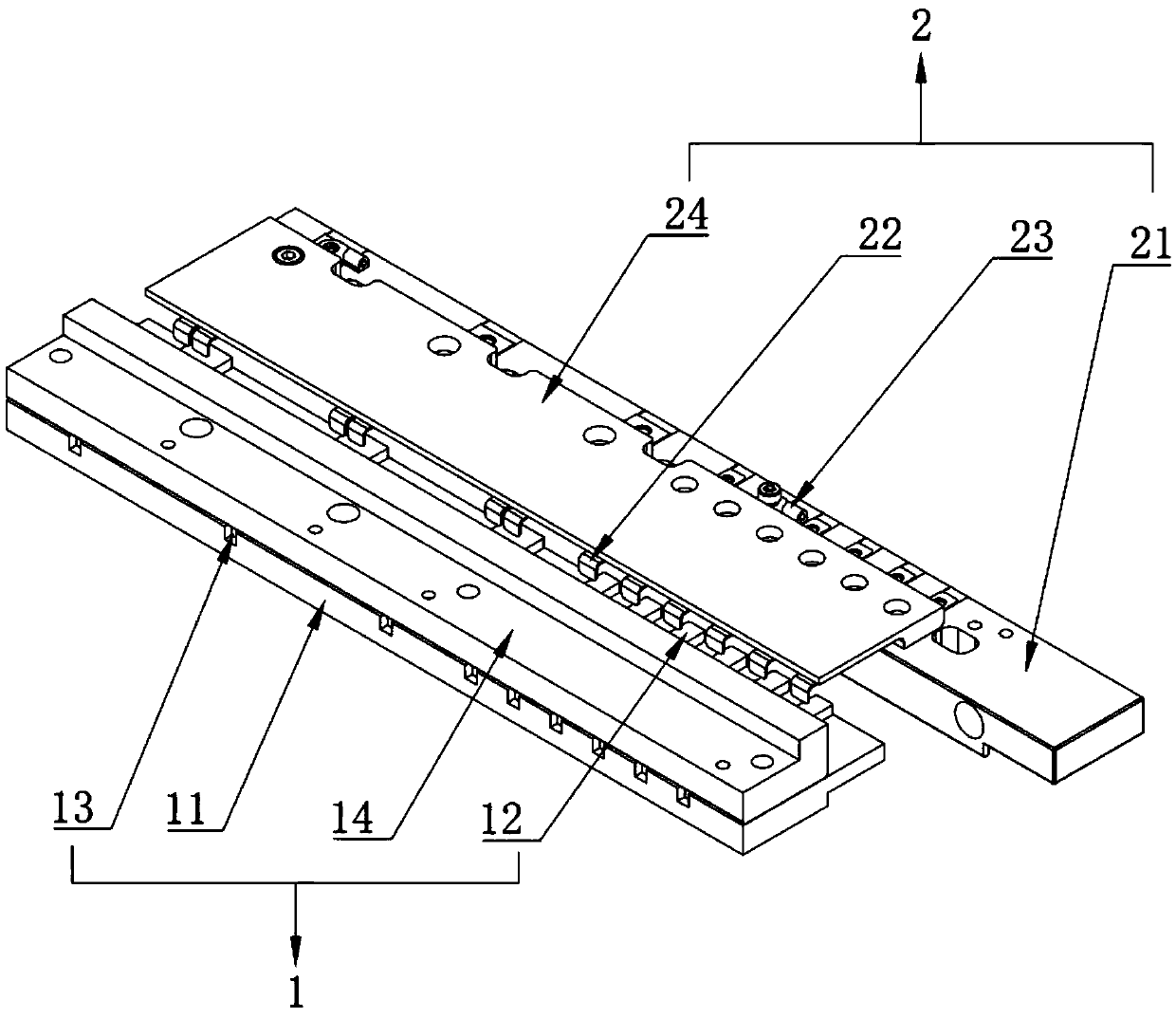

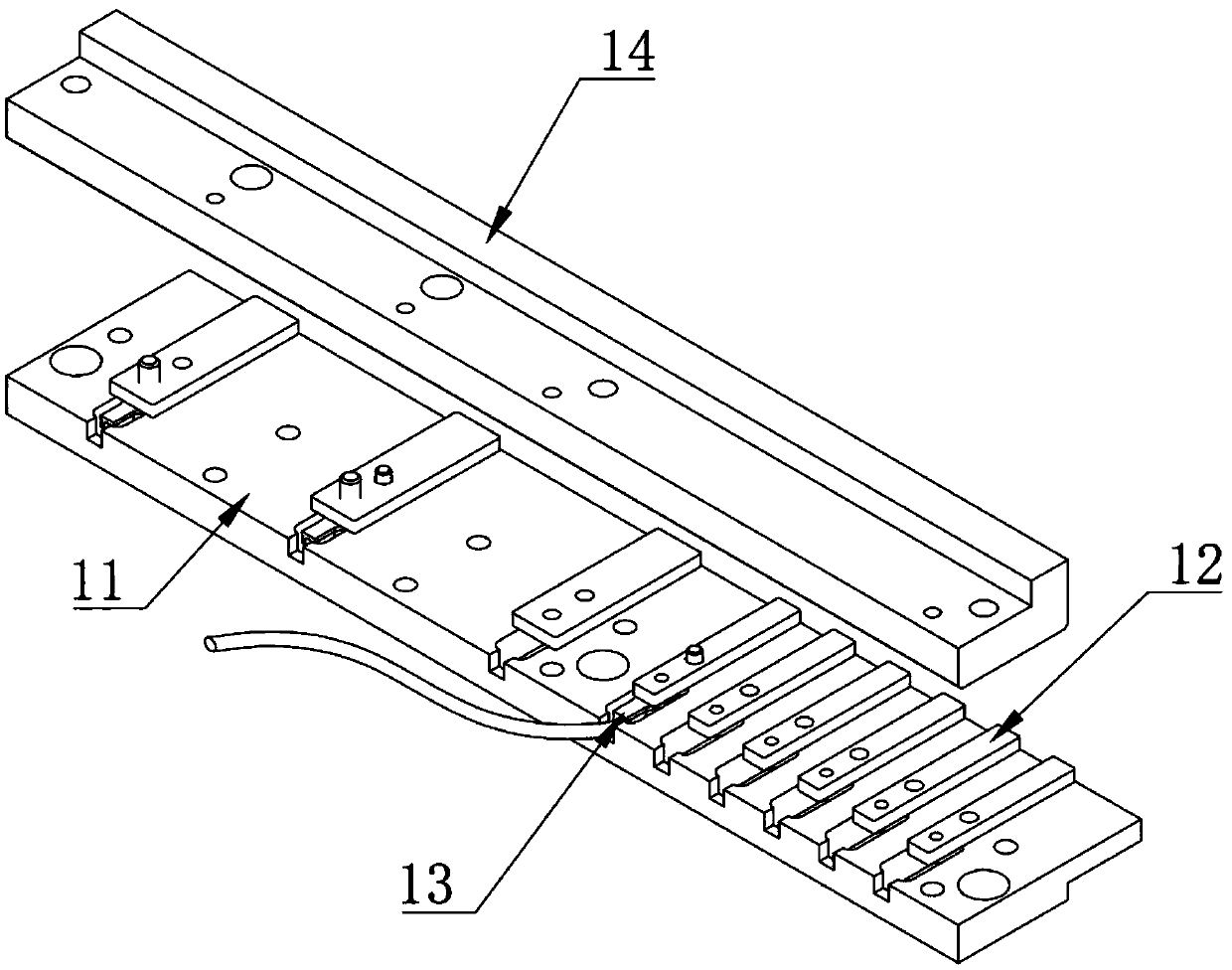

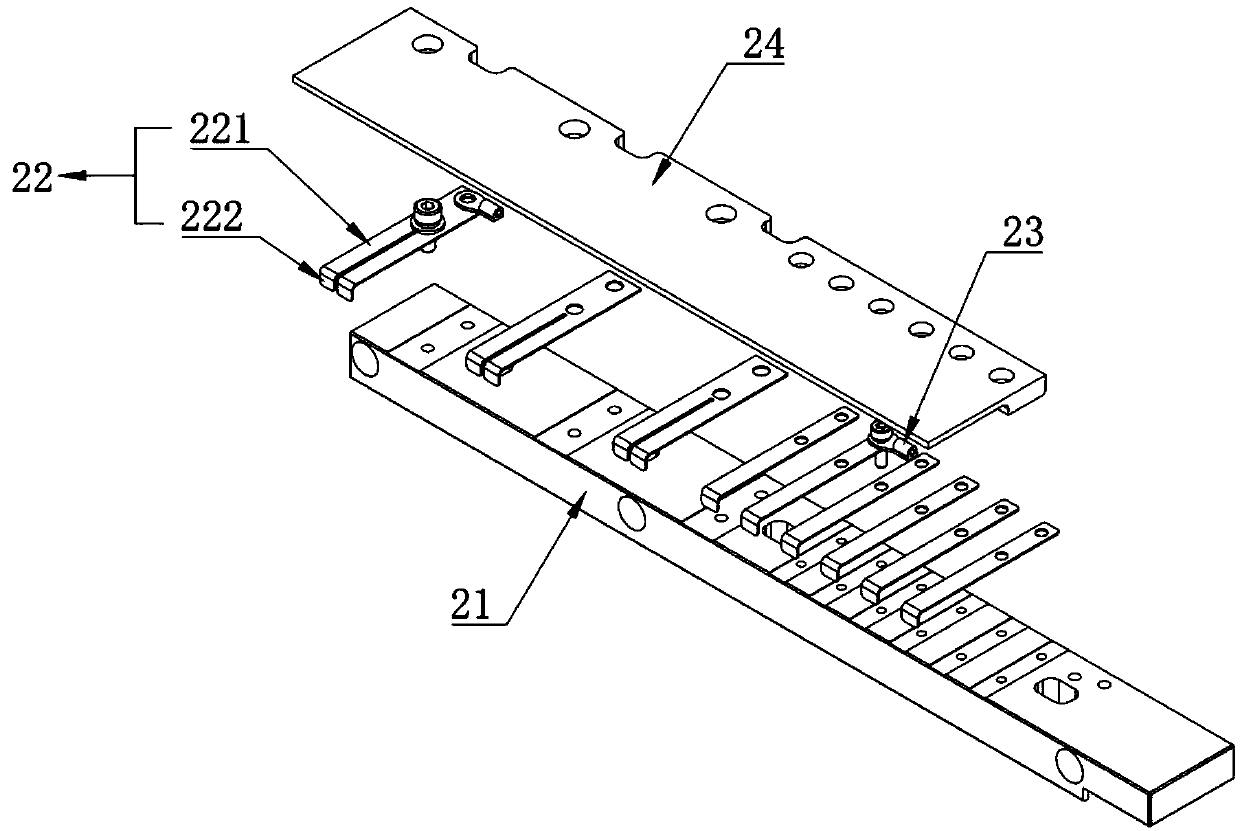

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a reed type vacuum contact mechanism, which includes a static contact group 1 and a movable contact group 2 which are oppositely arranged. Static contact group 1 comprises the static contact mounting plate 11 that is installed on the horizontal moving equipment and is installed on the multiple static contact 12 on the static contact mounting plate 11 upper surface, and multiple static contact 12 along the static contact The mounting plate 11 is distributed along the length direction, and a plurality of static contacts 12 are all bolted to the static contact mounting plate 11 . The first copper lug 13 (referring to figure 2 ), and the first copper nose 13 is bolted to the static contact 12, and a static contact cover 14 for covering the non-contact end of the static contact 12 is provided above the first copper nose 13, thereby preventing the static contact 12 from contacting the wire The join...

Embodiment 2

[0035] The difference from Example 1 is that the combination figure 1 and Figure 4 shown. On the bottom surface of the movable contact mounting plate 21 are etched a plurality of wire grooves 3 for fixing wires, and one end of the wire grooves 3 is provided with a threaded hole that runs through the moving contact mounting plate 21 and is used for wires to pass through 4. Make the wires connected to the movable contact 22 pass through the threaded hole 4 and insert them into the wire groove 3 from the bottom surface of the movable contact mounting plate 21, so that the arrangement and planning of the circuit are safe, reliable, clean and beautiful, and convenient for maintenance and overhaul.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com