Gapless assembly structure of embedded hinge

An assembly structure, no gap technology, used in hinges with pins, door/window fittings, building structures, etc. Improve the adjustment experience, prolong the service life, and eliminate the effect of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

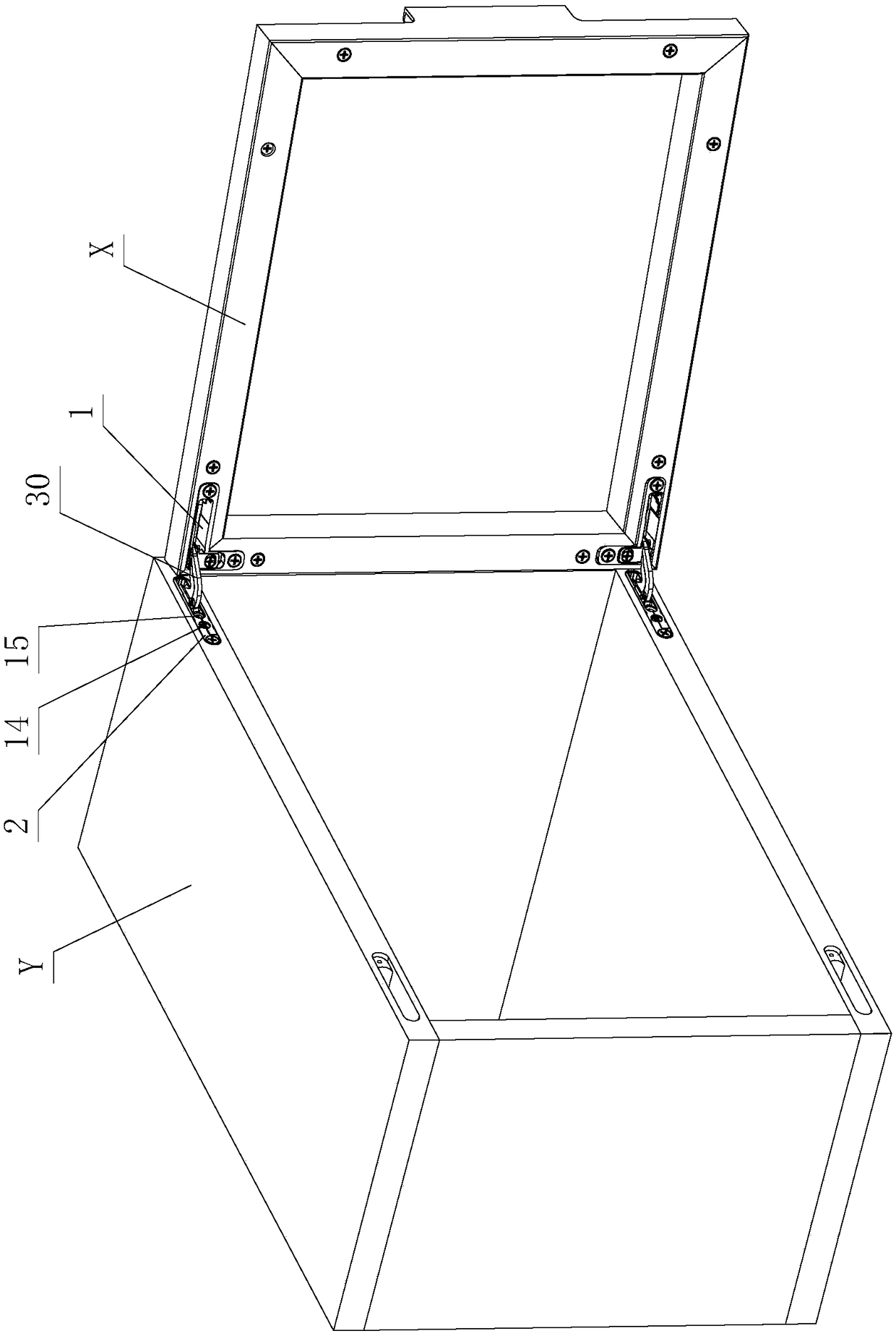

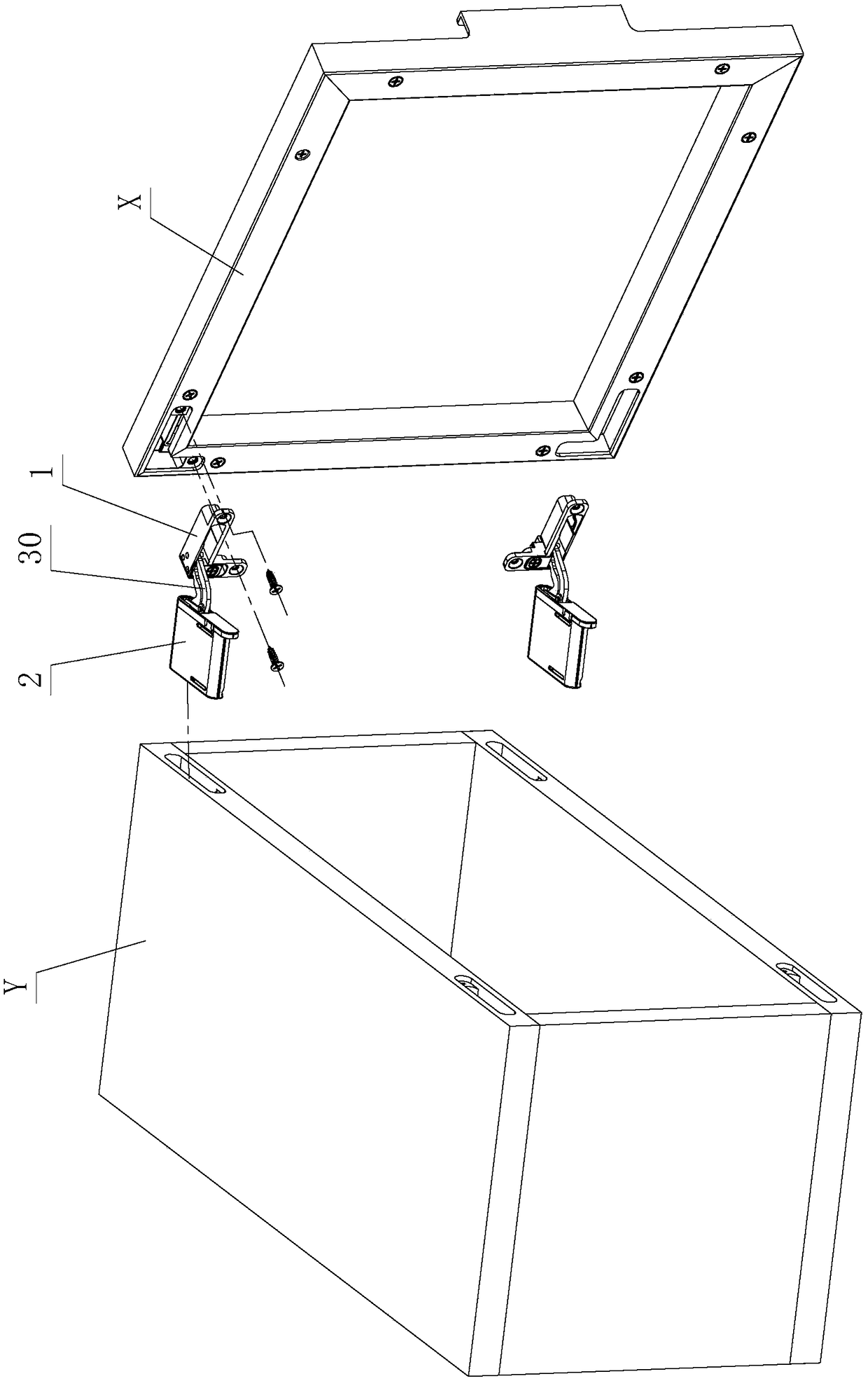

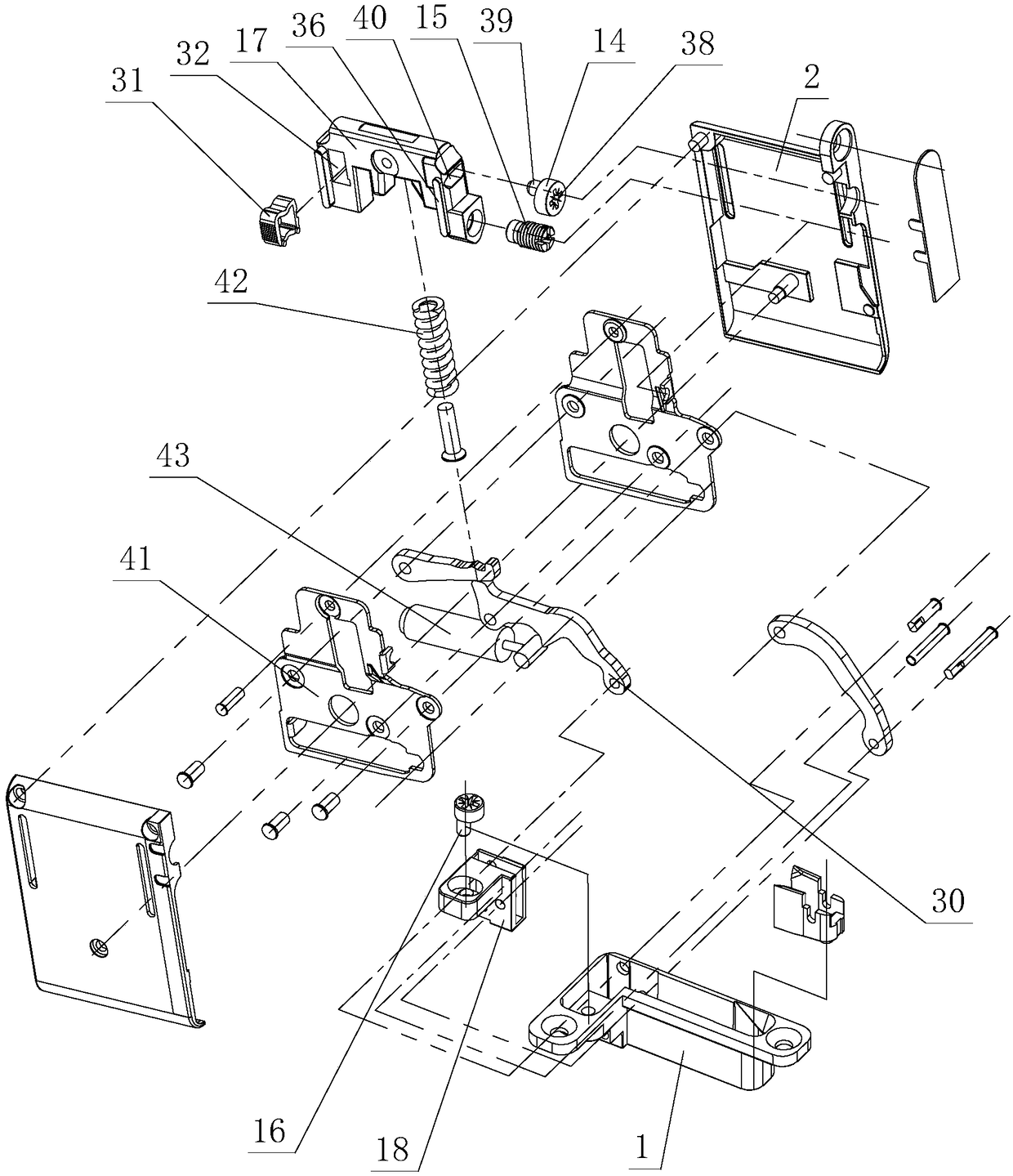

[0032] see Figure 1-Figure 10 , the non-gap assembly structure of the embedded hinge includes the hinge cup 1 and the fixed bracket 2 that are hinged and opened and closed through the connecting arm assembly 30. The fixed bracket 2 is provided with a cavity part, and at least a bracket movable 17, the movable part 17 of the bracket is provided with a gap eliminating part 31, and the gap eliminating part 31 can be adjusted and set in the cavity part without gap.

[0033] A notch 32 is provided on the bracket movable part 17 , and the gap eliminating part 31 is positioned on the bracket movable part 17 through the notch 32 .

[0034] Further, a certain distance A is formed in the cavity, a certain distance B is formed in the notch 32, and the gap eliminating member 31 has certain elasticity or plasticity, and its peripheral dimension is larger than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com