A kind of solar power generation battery alloy tile and solar module

A solar energy and battery technology, applied in photovoltaic power generation, electrical components, renewable energy integration, etc., can solve problems such as high temperature, single function, and insufficient structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

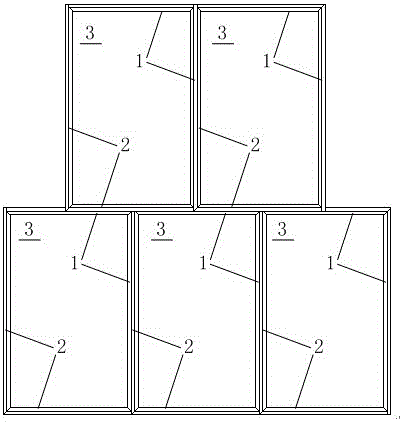

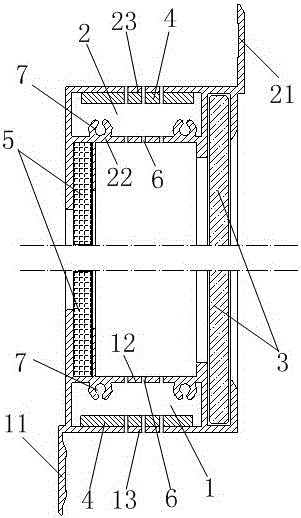

[0039] Such as figure 1 and 2 As shown, the solar module of the present invention includes: five solar power generation cell alloy tiles that are interlocked with each other (the combination of solar power generation cell alloy tiles is not limited to this, and is combined according to the number of arrangements actually required), and the solar power generation cell alloy tiles The bottom plate 11 of the first aluminum-steel composite material 1 of the tile supports the bottom surface of the second aluminum-steel composite material 2 of the adjacent solar power generation battery alloy tile, and the cover plate 21 of the second aluminum-steel composite material 2 of the solar power generation battery alloy tile presses Cover the top surface of the first aluminum-steel composite material 1 of the adjacent solar power generation battery alloy tile.

[0040] The solar power generation battery alloy tile of the present invention includes: a frame composed of a pair of rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com