Movable exhaust hood

An exhaust hood, mobile technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient equipment movement and high air leakage rate of local exhaust hoods, achieving a high degree of automation and easy operation. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

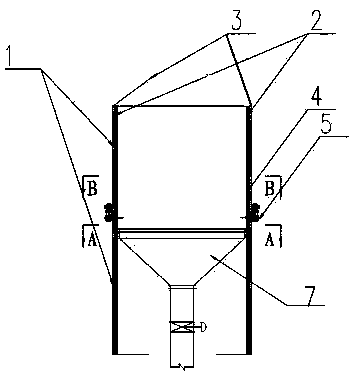

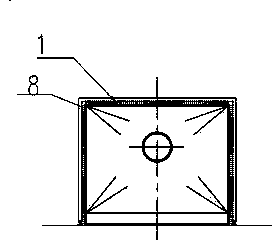

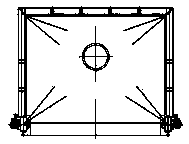

[0015] For better understanding and implementation, a mobile exhaust hood of the present invention will be described in detail below in conjunction with the accompanying drawings, including a movable exhaust hood 1 located above the source of harmful substances, and the front of the movable exhaust hood is provided with a side-by-side door 3. It is convenient for routine operation of the internal equipment. The lower part of the movable exhaust hood is equipped with a roller 2, which is located on the guide rail 4, driven by a motor 5, and a limiter 6 is set to limit the position to ensure safe use. The exhaust hood is fixed 7 A sealing brush 8 is set at the junction with the movable exhaust hood 1 to reduce air leakage, and the outlet of the fixed exhaust hood 7 is fixedly connected with one end of the exhaust circular pipe, and the exhaust circular pipe is equipped with a valve to control the exhaust volume.

[0016] The invention improves the disadvantage that the local exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com