Leg robot large-gradient walking leg oriented to hard mountain environment

A robot and high-slope technology, which is applied in motor vehicles, transportation and packaging, etc., can solve the problems of poor foot movement performance, insufficient foot-to-ground equivalent adhesion coefficient, and insufficient use of high-slope terrain, so as to improve the ability to adapt to sports. , the effect of improving the equivalent adhesion coefficient and improving the ability to adapt to sports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

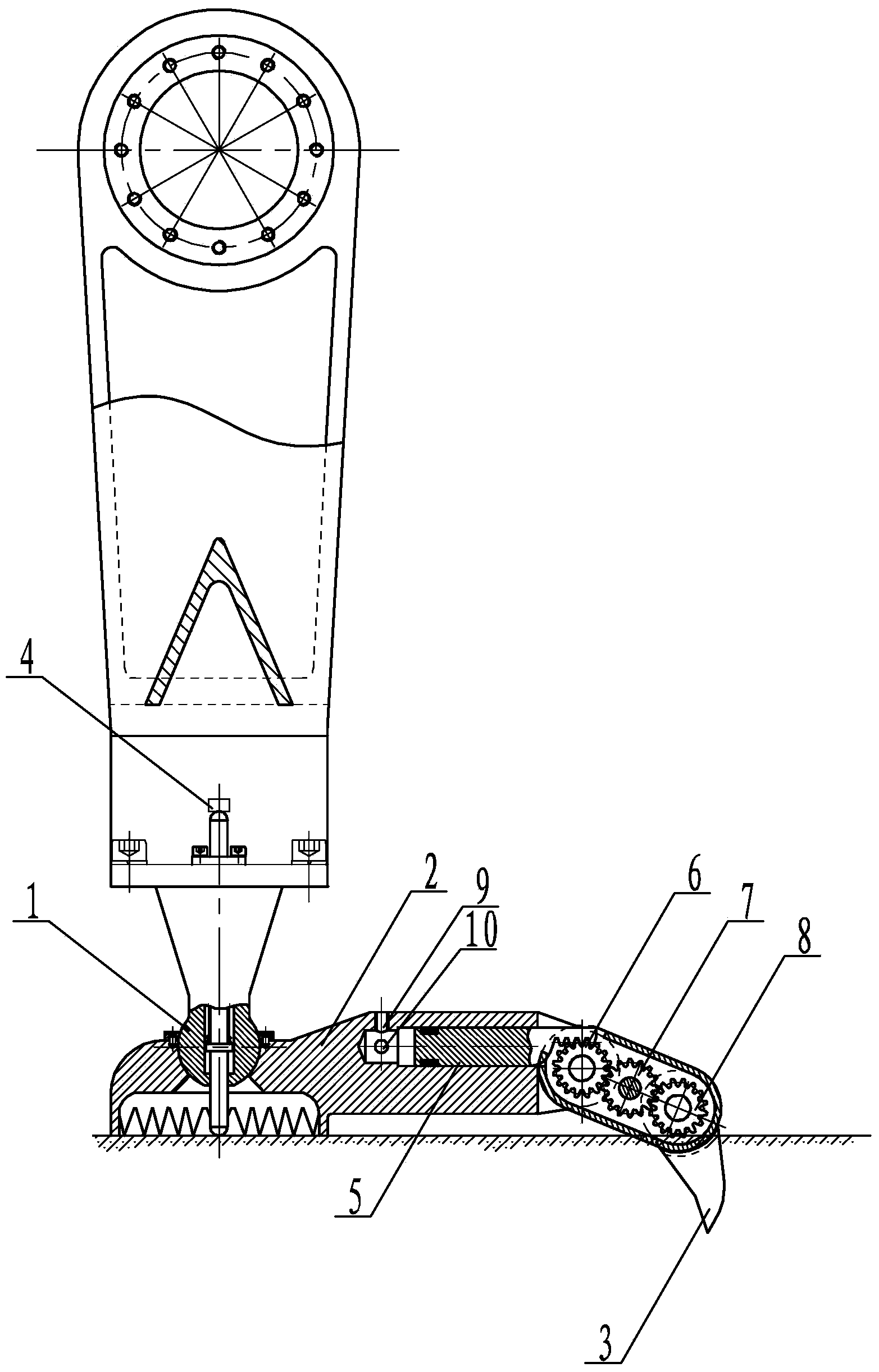

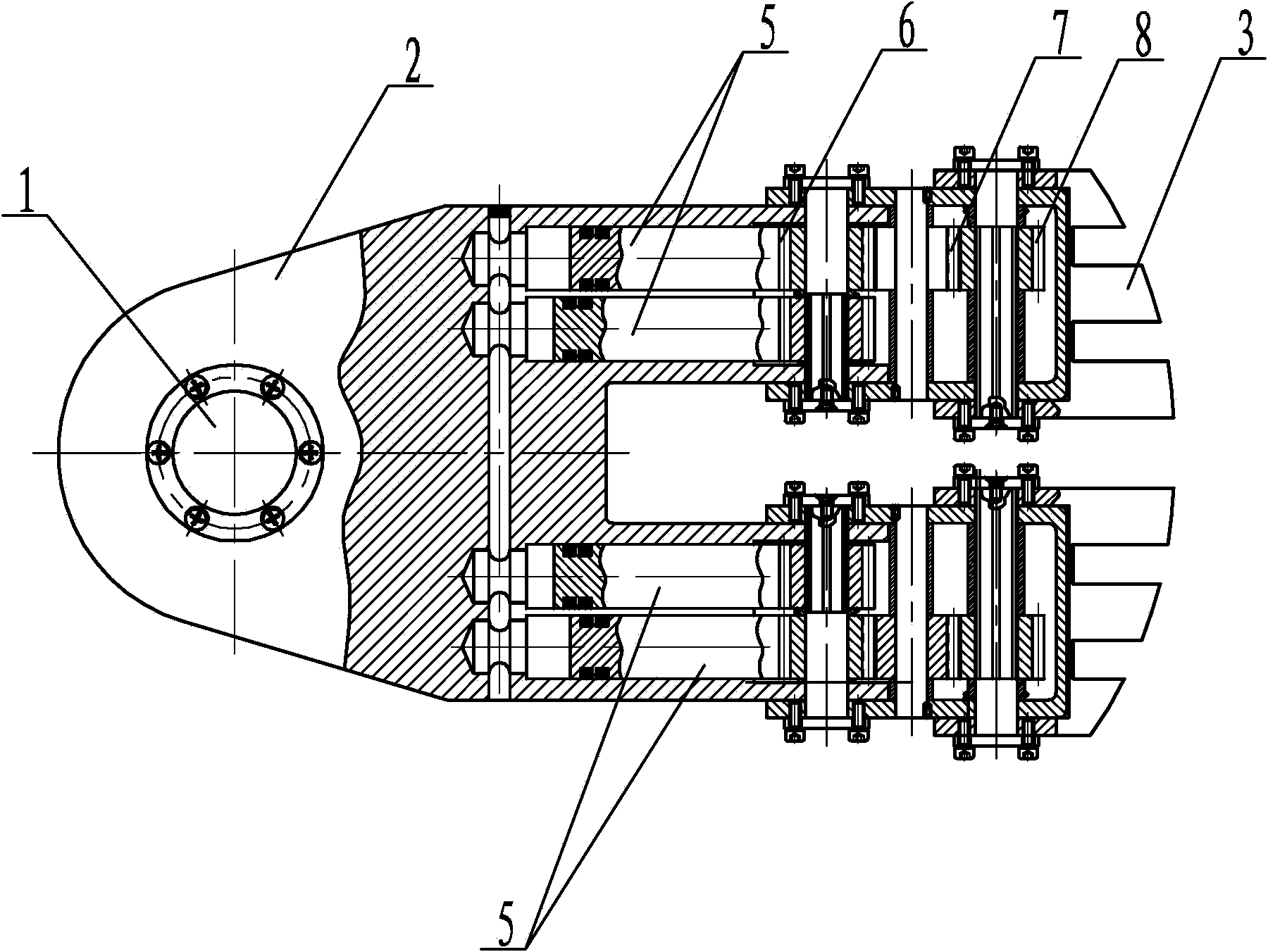

[0010] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment mode, a kind of leg type robot walking foot of this embodiment facing the hard mountainous environment with large slope includes ball hinge foot ankle joint 1, sole 2, toe 3, limit switch 4, rack group 5, The first transmission gear set 6, the second transmission gear set 7 and the third transmission gear set 8, the limit switch 4 is installed on the ball hinge foot ankle joint 1, the ball hinge foot ankle joint 1 is installed on the root of the sole 2, and the tooth The bar group 5 is slidably installed on the sole of the foot 2, and the first transmission gear group 6, the second transmission gear group 7 and the third transmission gear group 8 are sequentially engaged and installed on the right side of the rack group 5 from left to right, and the second A transmission gear set 6 meshes with the rack set 5, and the toe 3 is fixedly connected through a third transmission gear set...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the bottom of the base of the sole 2 of this embodiment is a tooth-shaped sole. In this way, on the basis of having active joints, the tooth-shaped sole is set at the bottom of the sole of the foot 2, so that the adaptability of the robot foot to the ground can be improved again. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 and figure 2 The present embodiment will be described. The toe 3 of the present embodiment is a hook toe. Such arrangement facilitates the improvement of the ability of the walking foot of the robot to adhere to the ground. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com