Motion control method for later-cutting rounded glass

A laser cutting and motion control technology, used in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as general accuracy and increased processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

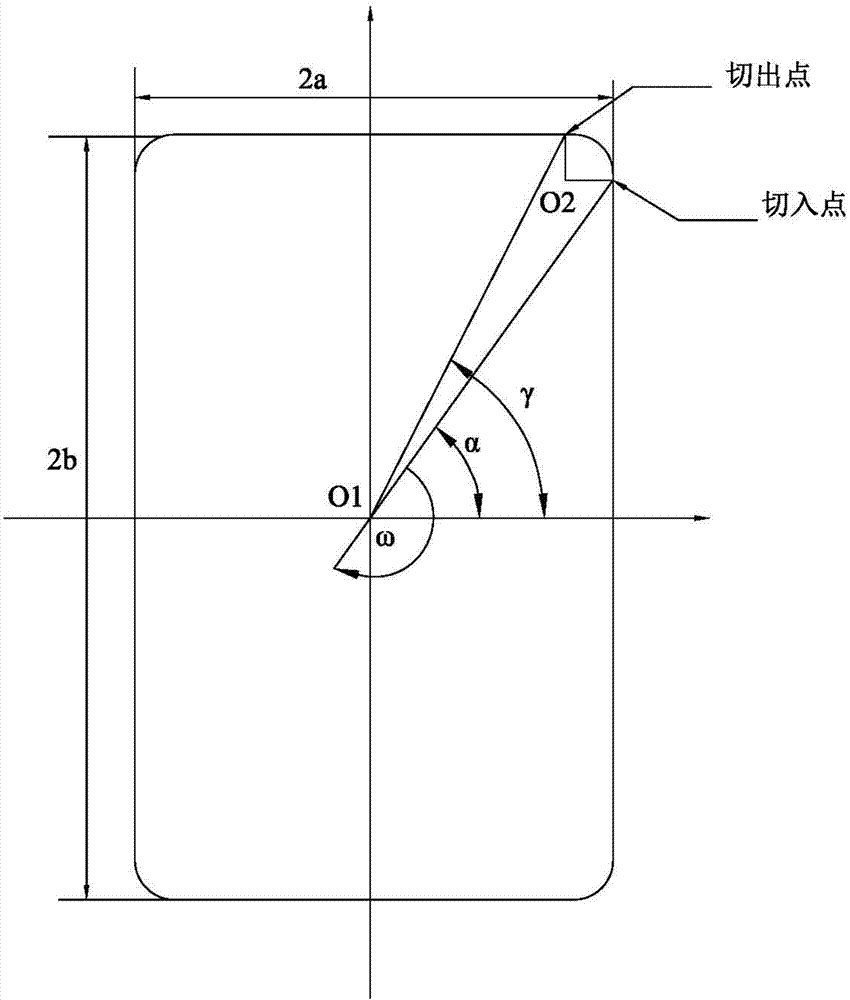

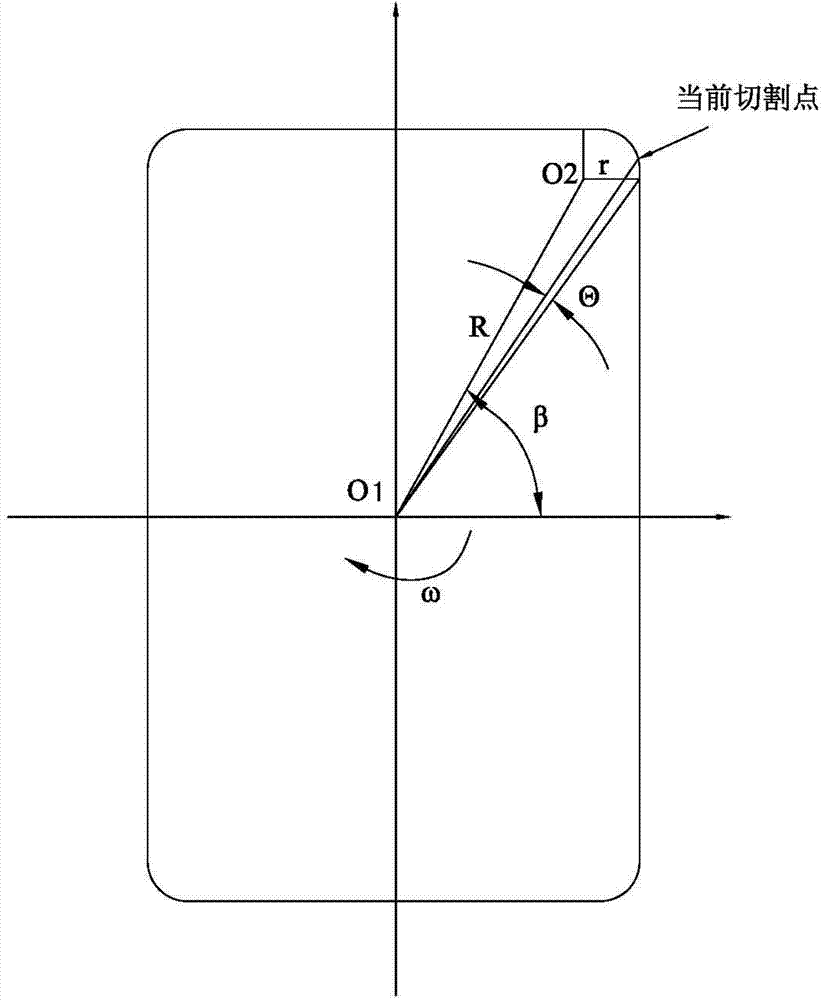

[0036] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 and 2 As shown, in the motion control method of laser cutting rounded glass of the present invention:

[0037] 1. In the initial linear cutting stage, the Y axis moves, and the speed is increased to the normal cutting speed by linear acceleration and deceleration.

[0038] In the initial stage of laser cutting, the Y-axis of the worktable moves, and the speed gradually increases from 0 to the normal cutting speed v set by the system using linear acceleration and deceleration planning.

[0039] v=A*n 1 *T,

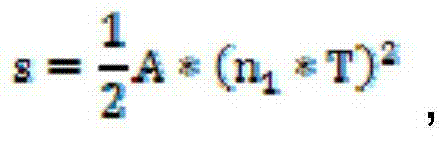

[0040] s = 1 2 A * ( n 1 * T ) 2 ,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com