A carbon grinding device

A carbon sanding and sanding technology, which is applied to textiles and papermaking, roughening, and trimming of the fabric surface, etc., can solve the problems of easy generation of wrinkles, unguaranteed sanding quality, and increased fabric damage. To achieve the effect of expanding the tension adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

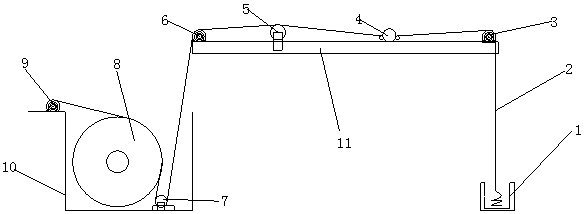

[0011] Example. A carbon sanding device, such as figure 1 Shown: comprise conveying frame 11, conveying frame 11 two ends are provided with first roller 3 and second roller 6 respectively, first roller 3 is provided with ingot trolley 1, and second roller 6 is provided with sanding groove 10; The middle section of the transmission frame 11 is provided with a traction roller 4, and a tension detection roller 5 is provided between the traction roller 4 and the second roller 6; a carbon sanding roller 8 and a moving pressure roller 7 are arranged in the sanding groove 10, Described mobile pressure roller 7 is positioned at the groove bottom of sanding groove 10; The third roller 9 is also established above described sanding groove 10; side, and the moving pressure roller 7 is on the side close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com