A gas tank head

A gas storage cylinder and head technology, which is applied in gas/liquid distribution and storage, metal processing equipment, forming tools, etc., can solve the problems of reducing production cost and poor application effect, and achieves low production cost, convenient replacement, and convenient welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

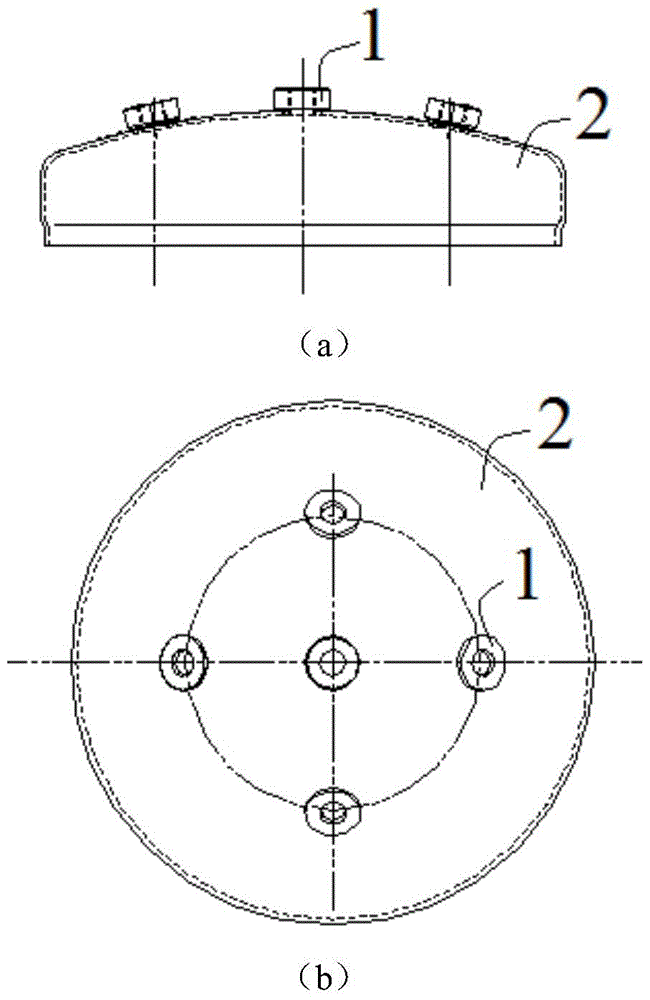

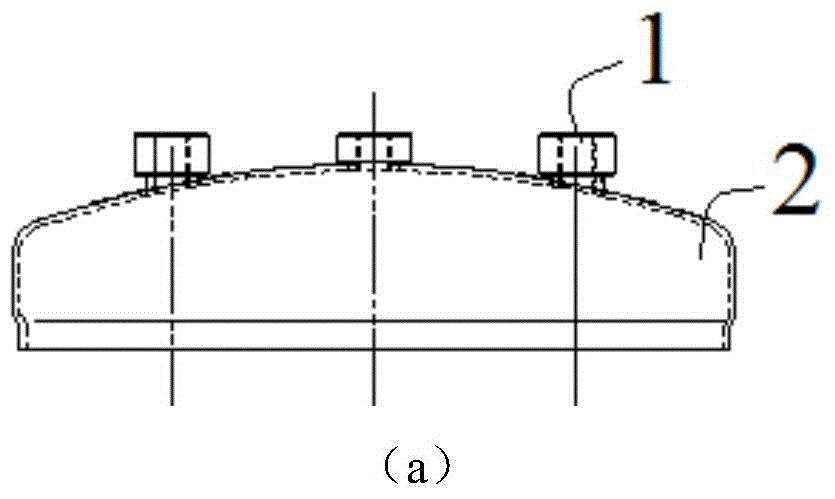

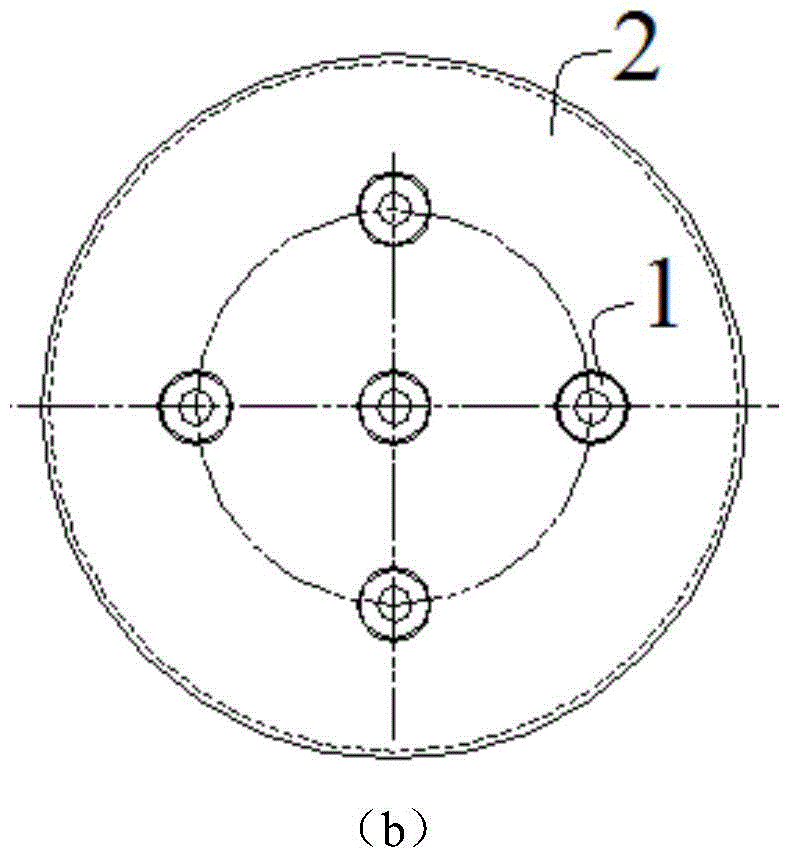

[0032] Combine figure 1 with figure 2 , And the introduction of background technology. In this embodiment, in order to solve the problem that the vent pipe of the air storage cylinder adopts a hard pipe connection, the pipe socket 1 welded on the head 2 of the air storage cylinder is required to be kept on the same horizontal plane. As a result, the welding quality of the pipe socket 1 cannot be guaranteed by the conventional circular automatic welding method. The problem that standard tube sockets can no longer be used. Designed as Figure 4 An air storage cylinder head is shown, the material thickness of the head 2 is 3mm, the head 2 is provided with a boss 3, and the boss 3 is distributed on the circle centered on the highest point of the arc surface of the head 2 Up, see image 3 In (b), in this embodiment, a total of 4 bosses 3 are provided, and the bosses 3 are equally spaced at 90°. The distribution of the bosses 3 can also be designed according to different situations ...

Embodiment 2

[0046] The head of an air storage cylinder of this embodiment is basically the same as that of embodiment 1, except that the radius of the arc surface of the first transition surface 31 close to the arc surface of the head 2 of this embodiment is 17mm, and the punch 63 is assembled Eccentric distance L 1 4.5mm, the distance L between the side wall of the inclined drawing groove 621 and the outer side wall of the convex and concave mold 71 2 12mm; the arc surface radius R of the arc surface at the bottom of the side wall of the inclined drawing groove 621 1 It is 17mm.

Embodiment 3

[0048] The head of an air storage cylinder of this embodiment is basically the same as that of Embodiment 1. The difference is that the radius of the arc surface of the first transition surface 31 near the arc surface of the head 2 of this embodiment is 20 mm, and the punch 63 is assembled Eccentric distance L 1 Is 5.0mm, the distance L between the side wall of the inclined drawing groove 621 and the outer side wall of the convex and concave mold 71 2 13mm; the arc surface radius R of the arc surface at the bottom of the side wall of the inclined drawing groove 621 1 It is 20mm.

[0049] The head of a gas storage cylinder described in Examples 1 to 3, the design of the head of the gas storage cylinder not only meets the requirements of the direction of the tube seat, but also unifies the standard of the tube seat, which facilitates welding; the design structure of the upsetting and punching die is simple , The two processes of upsetting and punching are reduced into one process, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com