Process method of laser cutting thin plate sector of generator with full-scale high-precision positioning

A technology of laser cutting and process method, which is applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, manufacturing tools, etc., can solve the problems of poor cross-section surface quality, defocus change, and out-of-tolerance dimensions, and achieve good consistency, Guaranteed surface quality and short preparation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

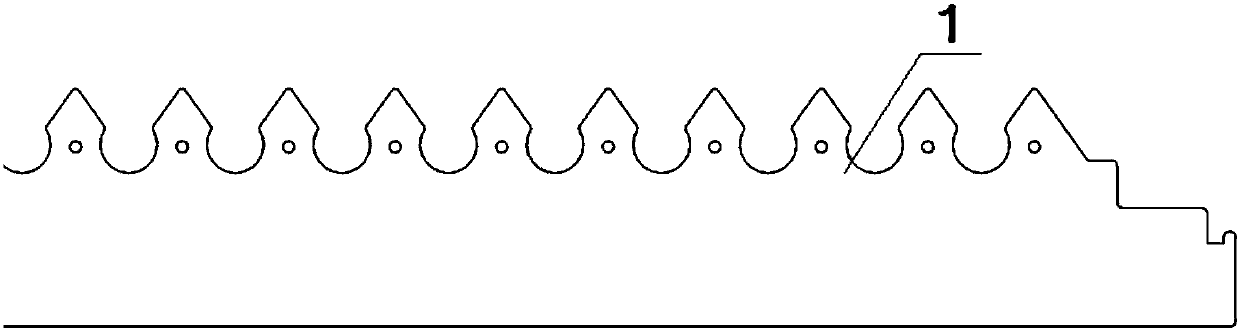

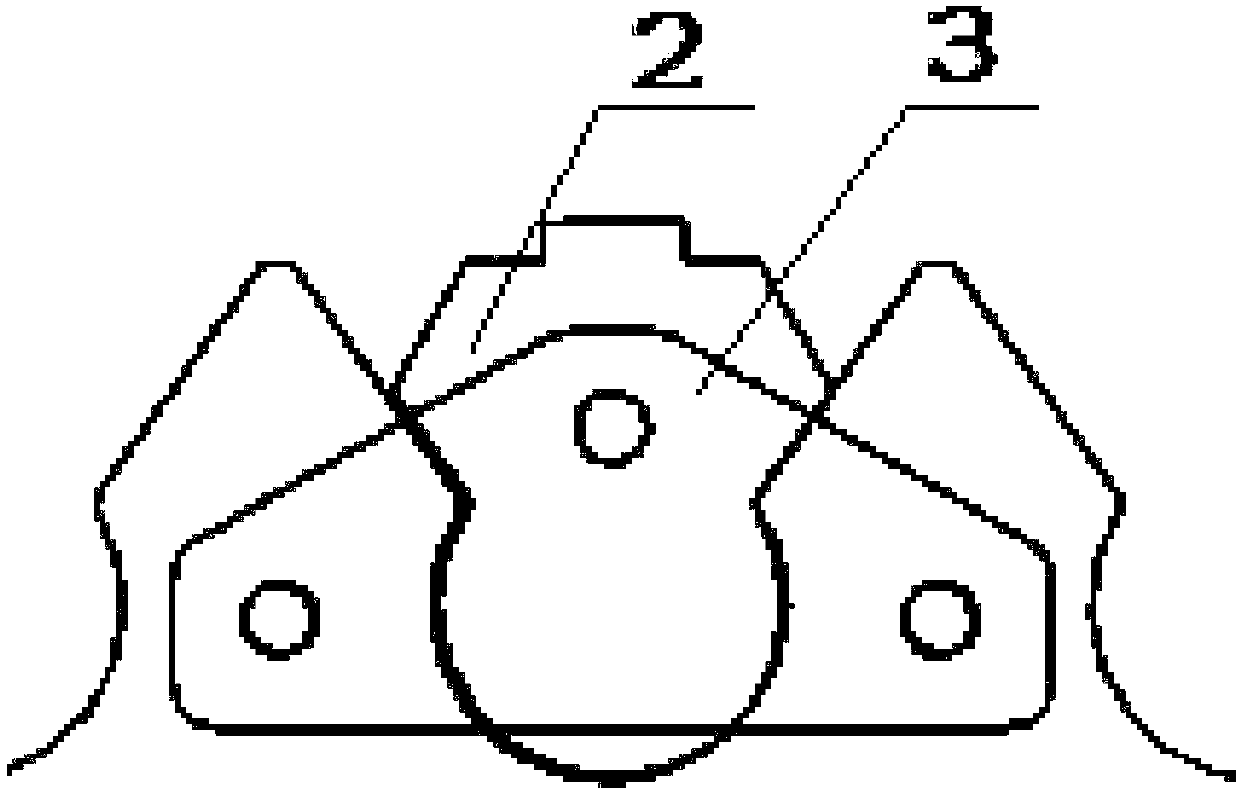

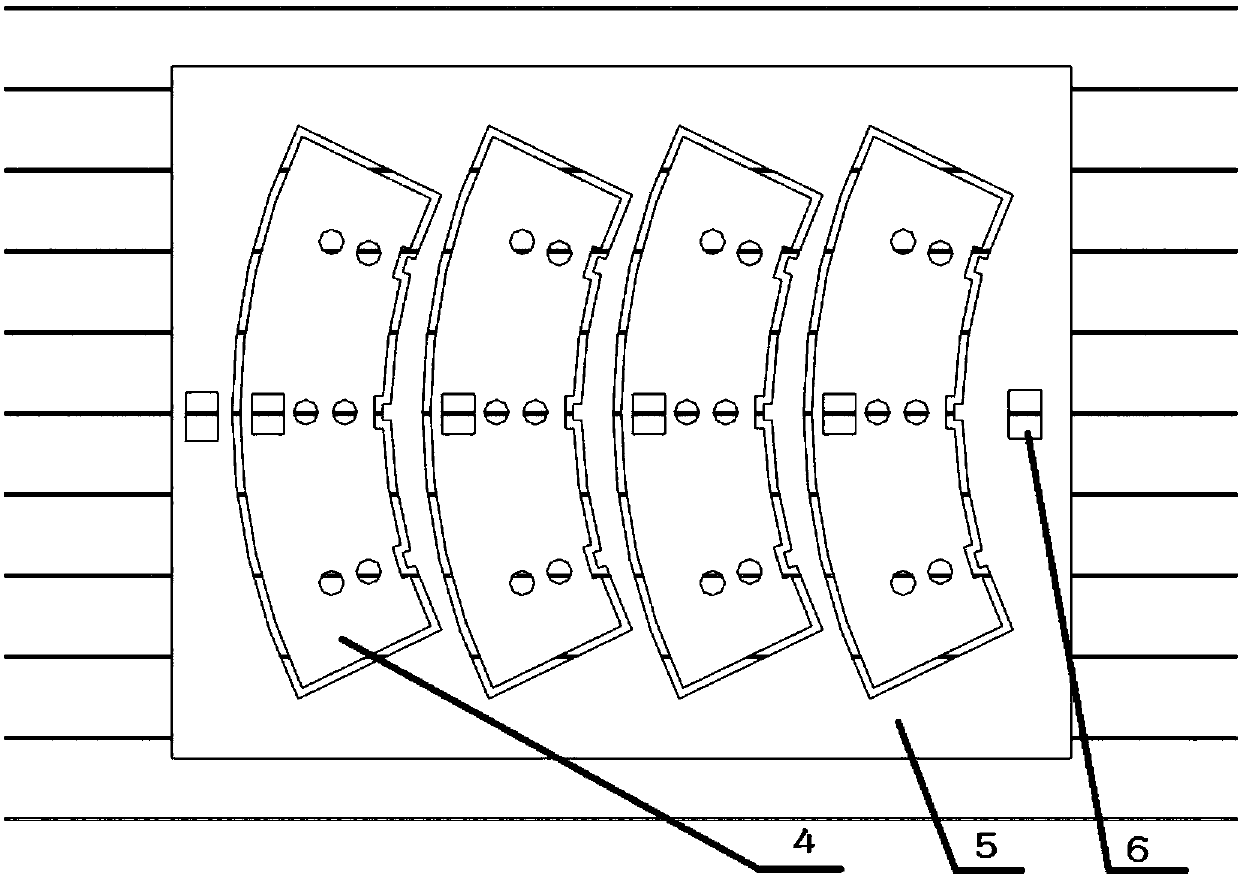

[0015] 1) Firstly, according to the edge contour of the generator stator and rotor punching sheet drawing and the holes are offset 4mm toward the inner direction of the punching sheet to form an internal supporting plate laser cutting program, then offset 4mm toward the outer direction of the punching sheet, and form an external supporting plate with the appropriate outer contour Plate laser cutting procedure. According to the prepared program, the positions of the fixed keys close to, on the outer edge of the inner pallet and the outer edge of the outer pallet are randomly selected, and the coordinate positions are recorded for use in making the inner pallet and the outer pallet, such as image 3 shown;

[0016] 2) Design the connection quantity and position of positioning tools: according to the pre-prepared drawings, select the positions of the fixed keys close to the outer edges of the inner pallet 4 and the outer pallet 5, and the number of fixed keys is required to be no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com