A cycloidal hydraulic motor oil hole

A technology of cycloidal hydraulic motor and oil hole, which is applied in the field of spacer holes and oil hole of cycloidal hydraulic motor spacer, which can solve the problems of small distribution hole gap and small distribution hole gap, and increase the oil flow area , Reduce leakage and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

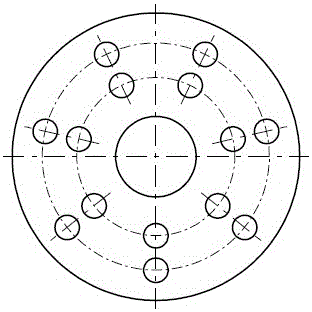

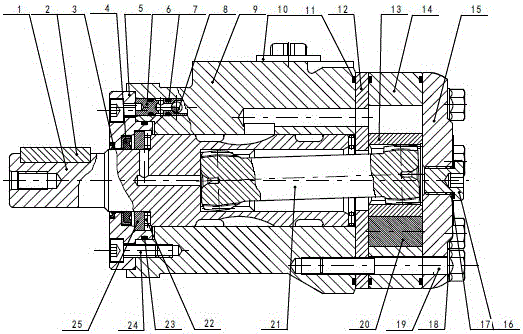

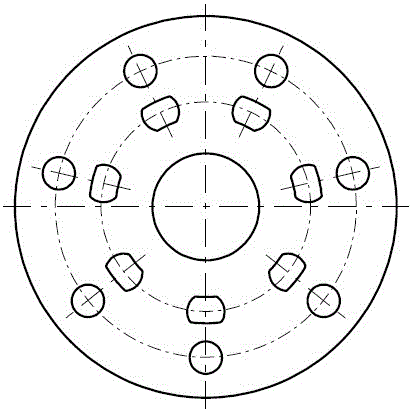

[0021] The basic structure of the shaft distribution cycloid hydraulic motor of this embodiment is as follows: figure 2 As shown, it mainly includes the output shaft 1, the front cover 5, the body shell 9, the linkage shaft 21, the spacer 12, the rotating stator pin wheel pair 13, 14 and 20, the rear cover 15, etc., wherein the cycloid pin wheel meshing pair is composed of the rotor , stator and needle teeth or rotor and integral stator, the stator 14, the partition plate 12 and the rear cover 15 are fixed together on the body shell 9 by bolts 19, thus forming seven distribution channels only in the same body shell 9, A cavity in which the high and low pressure oil passage holes of the partition plate 12 are communicated one by one.

[0022] The structural schematic diagram of the spacer 12 is image 3 As shown, there are two annular distribution channels with different distribution circles on the circular surface, the outer ring channel is a bolt connection channel, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com