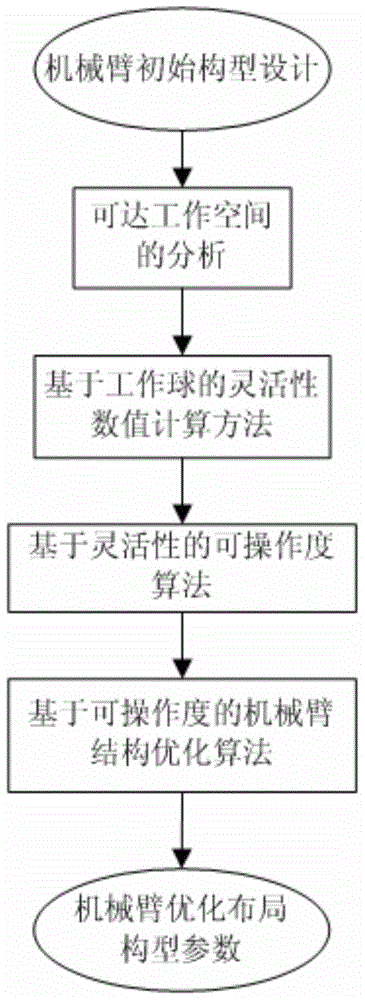

A method for optimizing structural parameters of space manipulator based on operability

A technology of space manipulator and optimization method, applied in the direction of electric digital data processing, special data processing application, instrument, etc., can solve the problem that the calculated value deviates from the actual value, it is difficult to obtain the expression, and the flexibility of the manipulator cannot be reflected, etc. problem, to achieve the effect of simple flexibility and simple solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

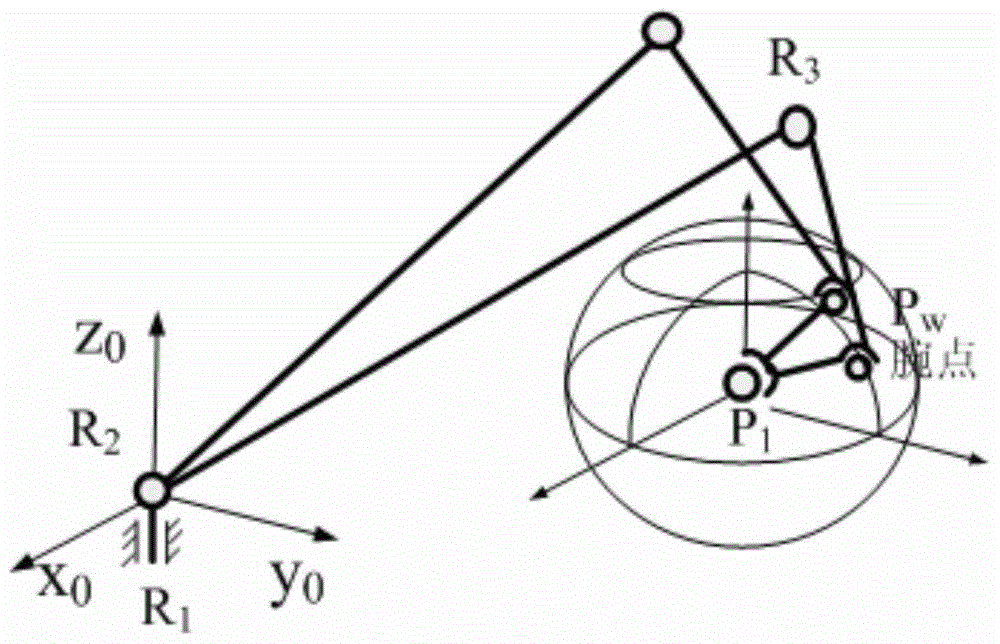

[0075] The first step is to design a space manipulator with seven degrees of freedom according to the task requirements. Every two adjacent degrees of freedom are connected by connecting rods, and the manipulator is divided into three parts: shoulder, elbow and wrist. Three degrees of freedom are assigned to the head and wrist, and one degree of freedom is assigned to the elbow. The schematic diagram of its structure is as follows Figure 4 As shown, determine the total length of the manipulator as l 0 +l 1 +l 2 +l 3 +l 4 +l 5 +l 6 +l 7 =1.87m, where l 0 rod and l 1 The rod is designed to facilitate the installation of the mechanical arm, so its length is set to l according to actual needs 0 =0.1, l 1 =0.12, so the two parameters are not optimized in the follow-up optimization, and the design value of the remaining rods is l according to the constant total length 2 =0.2,l 3 =0.4, l 4 =0.2,l 5 =0.4,l 6 =0.2, l 7 =0.25; use the forward kinematics of the manipulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com