Train test platform

A test platform and train technology, applied in vehicle testing, testing/monitoring control systems, testing of machine/structural components, etc., can solve problems such as lack of simulation, cumbersome components, and complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

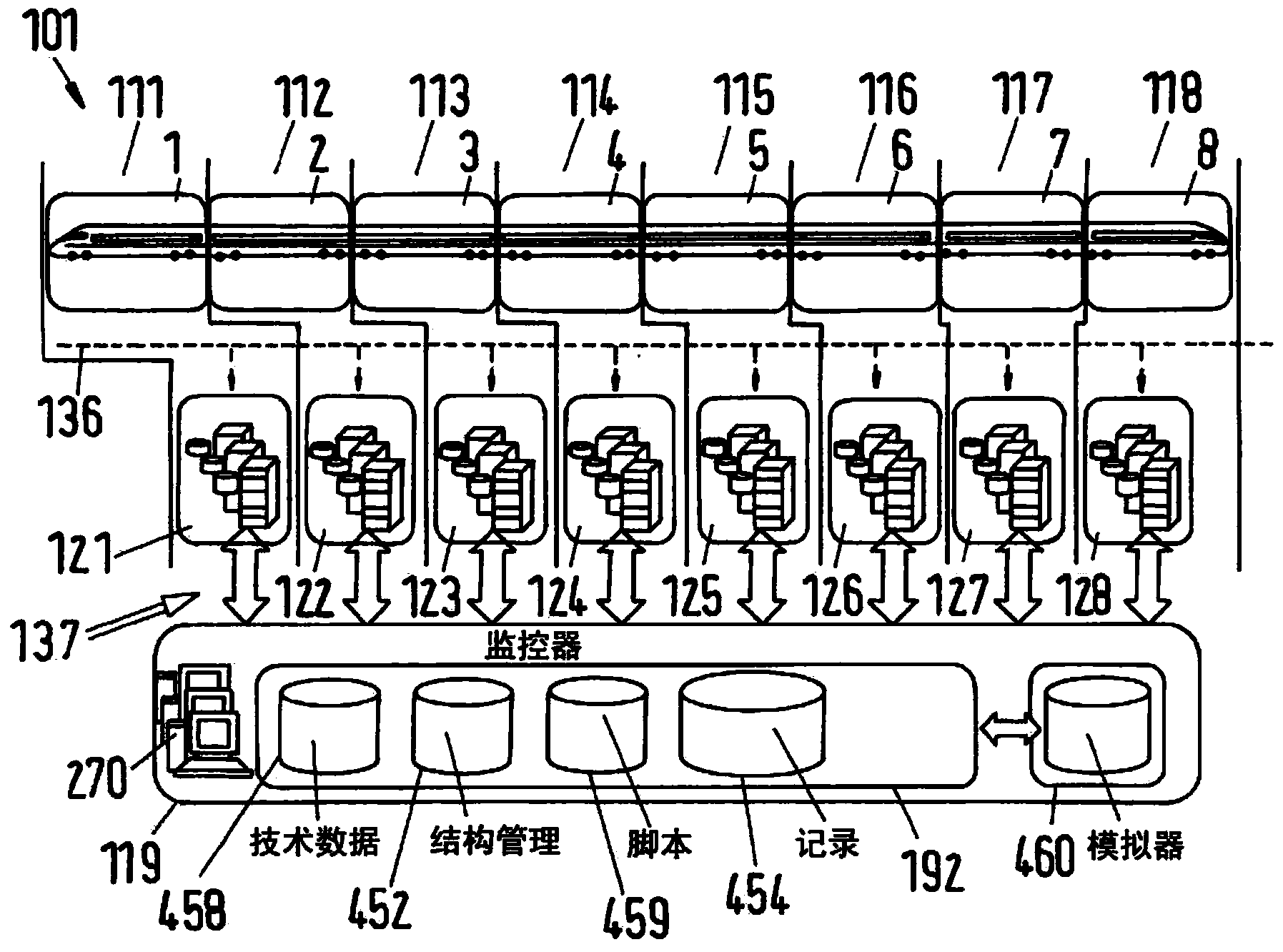

[0072] figure 1 An overview of a multi-car railway train test platform 101 is shown. The test platform 101 is suitable for a train comprising eight cars. The test platform 101 thus consists of eight car units 111 to 118 . Reference numerals 1 to 8 represent each respective car train system comprised by a production train car represented by a respective car unit 111 to 118 . For example, the symbol 1 of the car unit 111 represents all or at least a majority of the most important operational train components and safety-related functional train components associated with the first car of the production train. For example, in other car train systems, this first car also includes the driver's station, braking system, door system, heating ventilation air conditioning system (HVAC), train control and management system (TCMS) components, just to name a few example. Those components included in the integration tests to be performed by the test platform 101 are denoted by the symbol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com