Garment steamer

A garment steamer and steam technology, applied in washing devices, wrinkle-removing and flattening equipment, hand irons, etc., can solve problems such as limited operation methods and inability to support ironing boards, and achieve the effect of humanized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

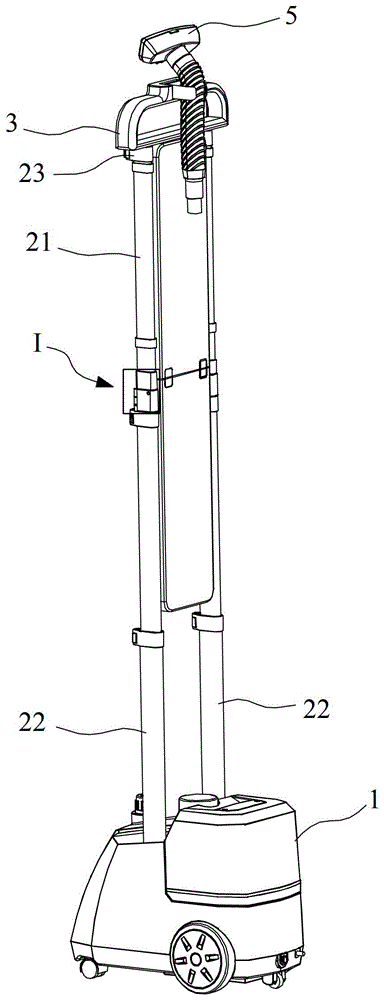

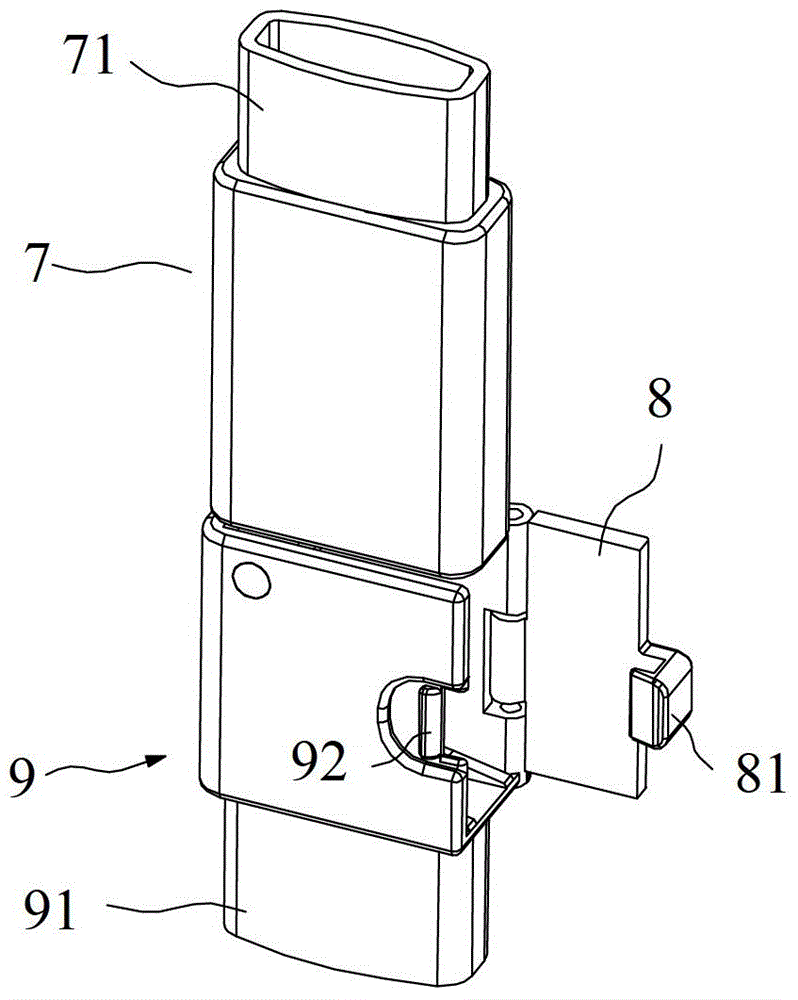

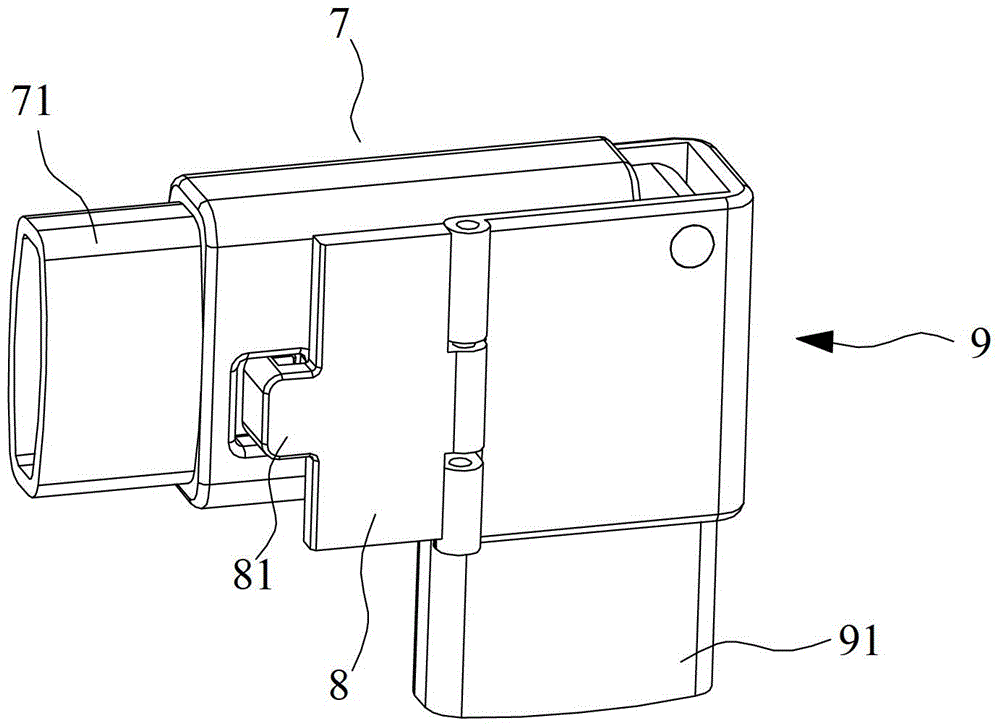

[0035] Figure 1 to Figure 11The garment steamer of this embodiment includes a body 1, a heating nozzle 5 connected to the body 1, a support rod and a clothes hanger 3, one end of the support rod is connected to the body 1, and the two can be fixedly connected or detachably connected. The other end of the support rod is detachably connected to the bottom of the hanger 3 through the hanger lock 23. The hanger lock 23 is integrated with the support rod. The hanger 3 is provided with a nozzle hanger 4, and the heating nozzle 5 is provided with PTC heating. element. The support rods of the garment steamer in this embodiment are two spaced apart. An ironing board extending in the same direction as the support rods is arranged between the two support rods. Each support rod includes an upper support rod 21 and a lower support rod. Support rod 22, the lower support rod 22 specifically adopts telescopic rods to adjust the support rod to different heights according to specific needs; t...

Embodiment 2

[0047] Figure 12 to Figure 15 For the garment steamer of this embodiment, the difference from Embodiment 1 is that the positioning mechanism between the upper ironing board 61 and the lower ironing board 62 includes an upper slot 210, a lower slot 211 and a fixing rod 212, and the upper insertion The groove 210 is located at the bottom of the upper ironing board 61, the lower slot 211 is located at the upper part of the lower ironing board 62, and the top of the fixing rod 212 extends outwards to a limit portion, when the fixing rod 212 is inserted into the upper slot 210 and the lower slot 211, the limit part cooperates with the upper end surface of the upper slot 210 to fix the lower ironing board 62 in the open state. If the lower ironing board 62 in the open state is to be folded upwards, it only needs to be pulled out and fixed The rod 212 is used to separate the upper slot 210 from the lower slot 211.

[0048] In this embodiment, when the upper support rod 21 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com